Must-Know Skills for Marine Electrical Engineers on Ships

Discover essential skills for marine electrical engineers, from power systems to automation, ensuring ship safety and efficiency.

Marine electrical engineering is a specialized field that ensures the seamless operation of electrical systems aboard ships, from small vessels to massive container ships and naval fleets. These professionals are responsible for designing, installing, maintaining, and troubleshooting complex electrical systems that power critical ship functions. With the maritime industry evolving rapidly, marine electrical engineers must possess a diverse skill set to handle power generation, automation, safety systems, and compliance with stringent regulations. This article explores the critical skills required, the challenges faced, and guidance for aspiring engineers choosing between specializations like Industrial Automation and Control or Power Systems Operation.

The Role of a Marine Electrical Engineer

Marine electrical engineers are the backbone of a ship’s electrical infrastructure. Their work ensures that vessels remain operational, safe, and compliant with international maritime standards. Unlike other engineering disciplines, marine electrical engineering demands adaptability to unique challenges, such as operating in harsh marine environments, troubleshooting issues at sea, and ensuring uninterrupted power for navigation, communication, and propulsion systems.

Key responsibilities include:

- Power Generation and Distribution: Managing AC and DC systems, including generators, switchboards, and distribution panels.

- Electrical Propulsion: Designing and maintaining electric propulsion systems for modern vessels.

- Instrumentation and Control: Overseeing monitoring, alarm, and control systems for shipboard equipment.

- Lighting, Communication, and Navigation: Ensuring reliable electrical systems for lighting, communication devices, and navigation tools.

- Safety and Security: Maintaining emergency lighting, fire detection, and security systems.

- Compliance: Adhering to standards set by classification societies like the American Bureau of Shipping (ABS), Det Norske Veritas (DNV), and the U.S. Coast Guard.

- Troubleshooting and Maintenance: Diagnosing electrical faults and performing preventive maintenance to ensure system reliability.

Marine electrical engineers work in diverse settings, including shipyards, cruise ships, offshore platforms, naval vessels, and research and development for innovative marine technologies. Companies like Mareleng provide specialized services, deploying expert engineers to resolve complex electrical issues at sea when onboard crew lack the expertise.

Essential Skills for Marine Electrical Engineers

To excel in this field, marine electrical engineers must master technical, analytical, and interpersonal skills. Below are the must-have skills, along with practical applications and challenges.

1. Insulation Resistance Management

Insulation resistance is critical for the safety and reliability of shipboard electrical systems. Wiring and cabling are encased in sheath insulation, which can degrade due to environmental factors like saltwater exposure, vibrations, or heavy operational use. Low insulation resistance can lead to short circuits, equipment damage, or earth faults, posing significant risks at sea.

Key Skills:

- Measurement and Interpretation: Engineers must use tools like meggers to measure insulation resistance and interpret readings relative to the ship’s electrical demands.

- Maintenance and Repair: Performing regular inspections and repairs, such as replacing worn insulation, is essential to prevent failures.

- Problem Resolution: Diagnosing and resolving issues like short circuits or earth faults, often under time constraints in remote locations.

Challenges:

- Harsh marine environments accelerate insulation wear.

- Repairs at sea require improvisation with limited resources.

- Misinterpreting resistance readings can lead to catastrophic failures.

Example: A marine electrical engineer on a container ship detects low insulation resistance in a generator’s cabling. Using a megger, they confirm the issue, replace the damaged section, and restore system stability, preventing a potential blackout.

2. Motor Overhauling and Maintenance

Ships rely on numerous electrical motors to drive machinery like pumps, fans, purifiers, and winches. These motors are subject to heavy wear and require regular maintenance to ensure operational efficiency.

Key Skills:

- Routine Maintenance: Conducting preventive maintenance, such as cleaning, lubricating, and inspecting motor components.

- Troubleshooting: Diagnosing motor failures, such as bearing issues or winding faults, and implementing repairs.

- Overhauling: Disassembling, inspecting, and reassembling motors to extend their lifespan.

Challenges:

- Limited access to spare parts during long voyages.

- Balancing maintenance schedules with operational demands.

- Diagnosing complex motor issues under time pressure.

Example: A pump motor on an oil tanker fails, disrupting fuel transfer. The engineer overhauls the motor, replaces worn bearings, and recalibrates the system, restoring functionality without delaying the vessel’s schedule.

3. Electrical Instrument Operations

Marine electrical engineers must be proficient in operating and interpreting shipboard electrical instruments, such as clamp meters, multimeters, and meggers. These tools are essential for monitoring system performance and diagnosing issues.

Key Skills:

- Operation: Using instruments to measure voltage, current, and resistance accurately.

- Interpretation: Analyzing readings to identify anomalies, such as voltage drops or irregular currents.

- Maintenance: Calibrating and repairing instruments to ensure accuracy.

Challenges:

- Instruments must function reliably in humid, salty environments.

- Misinterpretation of readings can lead to incorrect diagnoses.

- Limited training on specialized marine instruments.

Example: An engineer uses a clamp meter to detect an abnormal current in a navigation system’s wiring, identifying a faulty connection and preventing a potential navigation failure.

4. Starter Panel Maintenance

Starter panels control the activation of electrical equipment, such as motors and pumps. These panels contain contacts that are prone to wear, burnouts, or deposit accumulation, which can disrupt operations.

Key Skills:

- Routine Maintenance: Cleaning and inspecting contacts to prevent failures.

- Troubleshooting: Diagnosing issues like contact burnouts or arcing.

- Repair Procedures: Replacing faulty components and ensuring proper panel functionality.

Challenges:

- High-voltage panels pose safety risks during maintenance.

- Limited downtime for repairs on operational vessels.

- Complex panel designs vary across ships, requiring adaptability.

Example: A starter panel for a ship’s ventilation system fails due to burnt contacts. The engineer replaces the contacts and tests the panel, restoring ventilation and ensuring crew safety.

5. Software Proficiency

Marine electrical engineers use specialized software for designing, monitoring, and troubleshooting electrical systems. Familiarity with these tools enhances efficiency and accuracy.

Key Skills:

- CAD Software: Using tools like AutoCAD or EPLAN for designing electrical schematics and layouts.

- PLC Programming: Programming and troubleshooting Programmable Logic Controllers (PLCs) for automation systems.

- Monitoring Software: Using software to track system performance and predict failures.

Challenges:

- Keeping up with evolving software technologies.

- Limited access to software updates at sea.

- Integrating software with legacy ship systems.

Example: An engineer uses CAD software to redesign a ship’s power distribution layout, optimizing load balancing and improving energy efficiency.

6. Problem-Solving and Troubleshooting

Electrical issues at sea can range from minor glitches to system-wide failures, requiring quick and effective problem-solving.

Key Skills:

- Diagnostics: Identifying the root cause of issues using systematic approaches.

- Decision-Making: Choosing the best course of action under pressure.

- Adaptability: Improvising solutions with limited resources.

Challenges:

- Time-sensitive repairs in critical systems.

- Lack of immediate support or spare parts.

- Complex interdependencies between electrical systems.

Example: A power outage affects a cruise ship’s lighting system. The engineer traces the issue to a faulty switchboard, reroutes power, and restores lighting within hours.

7. Compliance with Maritime Standards

Marine electrical systems must comply with standards set by organizations like ABS, DNV, and the International Maritime Organization (IMO). Engineers must ensure systems meet these requirements to avoid penalties or safety risks.

Key Skills:

- Knowledge of Standards: Understanding regulations for electrical installations, safety, and emissions.

- Documentation: Maintaining accurate records for inspections.

- Audits: Preparing systems for classification society audits.

Challenges:

- Evolving regulations require continuous learning.

- Balancing compliance with operational efficiency.

- Variations in standards across regions.

Example: An engineer ensures a naval vessel’s electrical system complies with ABS standards, passing a rigorous inspection and avoiding costly delays.

8. Teamwork and Communication

Marine electrical engineers work closely with other engineers, crew members, and shore-based teams. Effective communication ensures smooth operations and safety.

Key Skills:

- Collaboration: Working with mechanical engineers, deck officers, and technicians.

- Reporting: Communicating technical issues clearly to non-technical crew.

- Training: Educating crew on basic electrical safety procedures.

Challenges:

- Language barriers on multinational crews.

- Coordinating with remote teams during emergencies.

- Explaining complex issues to non-technical stakeholders.

Example: An engineer collaborates with the chief engineer to troubleshoot a generator issue, providing clear updates to the captain and ensuring a swift resolution.

Specialization: Industrial Automation and Control vs. Power Systems Operation

Aspiring marine electrical engineers often face a critical decision: choosing a specialization. The two most relevant tracks for this field are Industrial Automation and Control and Power Systems Operation. Each offers unique advantages and aligns with different aspects of marine electrical engineering.

Industrial Automation and Control

Overview:

This specialization focuses on automating ship systems using PLCs, Human-Machine Interfaces (HMIs), and control systems. It is prevalent in modern ships, where automation streamlines operations like generator control, engine monitoring, and cargo handling.

Key Skills:

- Programming PLCs for automation tasks.

- Designing and maintaining HMIs for system monitoring.

- Troubleshooting control systems for cranes, pumps, and valves.

- Integrating automation with electrical and mechanical systems.

Applications:

- Controlling generator synchronization on dual-fuel ships.

- Managing automated cargo systems on container ships.

- Monitoring alarms and safety systems.

Pros:

- High demand due to increasing automation in maritime systems.

- Applicable to specialized vessels like dredgers and tankers.

- Opportunities in research and development for smart ships.

Cons:

- Steep learning curve for PLC programming and software.

- Limited application on older vessels with minimal automation.

- Requires continuous updates on evolving technologies.

Example: An engineer programs a PLC to automate a tanker’s pump system, reducing manual intervention and improving efficiency.

Power Systems Operation

Overview:

This specialization focuses on designing, operating, and maintaining power generation and distribution systems, including generators, switchboards, and circuit breakers.

Key Skills:

- Sizing circuit breakers and calculating fault currents.

- Managing power quality and load distribution.

- Maintaining generators and switchboards.

- Troubleshooting power system failures.

Applications:

- Ensuring reliable power for propulsion and navigation.

- Designing power distribution for newbuild ships.

- Managing high-voltage systems on naval vessels.

Pros:

- Broad applicability across all vessel types.

- Critical for ship safety and operational continuity.

- Strong foundation for career advancement in ship design.

Cons:

- Less focus on emerging automation technologies.

- High responsibility for preventing power outages.

- Requires deep knowledge of electrical theory.

Example: An engineer recalibrates a ship’s switchboard to balance load distribution, preventing blackouts during heavy operations.

Choosing the Right Specialization

The choice between Industrial Automation and Control and Power Systems Operation depends on your career goals and interests:

- Choose Industrial Automation and Control if you enjoy programming, working with cutting-edge technologies, and specializing in automated systems. This track is ideal for container ships, tankers, and vessels with complex automation needs.

- Choose Power Systems Operation if you prefer a broad, foundational role focused on power management and electrical design. This track is critical for all ships and offers versatility across shipyards, naval vessels, and offshore platforms.

Recommendation: Discuss your goals with your academic advisor to align your specialization with your school’s curriculum and the maritime industry’s needs. If possible, take electives in both areas to gain a balanced skill set, as many marine electrical engineering roles require knowledge of both automation and power systems.

Career Preparation Tips

To succeed as a marine electrical engineer, consider the following steps:

- Pursue Relevant Education: A bachelor’s degree in electrical or marine engineering is essential. Courses in power systems, control systems, and marine technology are highly beneficial.

- Gain Practical Experience: Seek internships or co-op programs at shipyards, maritime companies, or engineering firms like Mareleng.

- Learn Industry Software: Master CAD software, PLC programming tools, and monitoring systems used in marine applications.

- Obtain Certifications: Pursue certifications like STCW (Standards of Training, Certification and Watchkeeping) or specific maritime electrical training.

- Develop Soft Skills: Hone teamwork, communication, and problem-solving skills to thrive in collaborative maritime environments.

- Stay Updated: Keep abreast of evolving technologies, such as electric propulsion and renewable energy integration in ships.

Challenges in Marine Electrical Engineering

Marine electrical engineers face unique challenges due to the maritime environment and operational demands:

- Isolation at Sea: Engineers must resolve issues without immediate access to spare parts or external support.

- Harsh Conditions: Saltwater, humidity, and vibrations accelerate equipment wear.

- Regulatory Compliance: Adhering to strict maritime standards requires meticulous documentation and expertise.

- Time Pressure: Electrical failures can halt ship operations, demanding rapid solutions.

Companies like Mareleng address these challenges by deploying specialized engineers to vessels worldwide, ensuring quick and reliable solutions. For example, Mareleng offers 24/7 support and can fly experts to any location, as detailed on their website (mareleng.com) or by contacting them at (954) 491-3050.

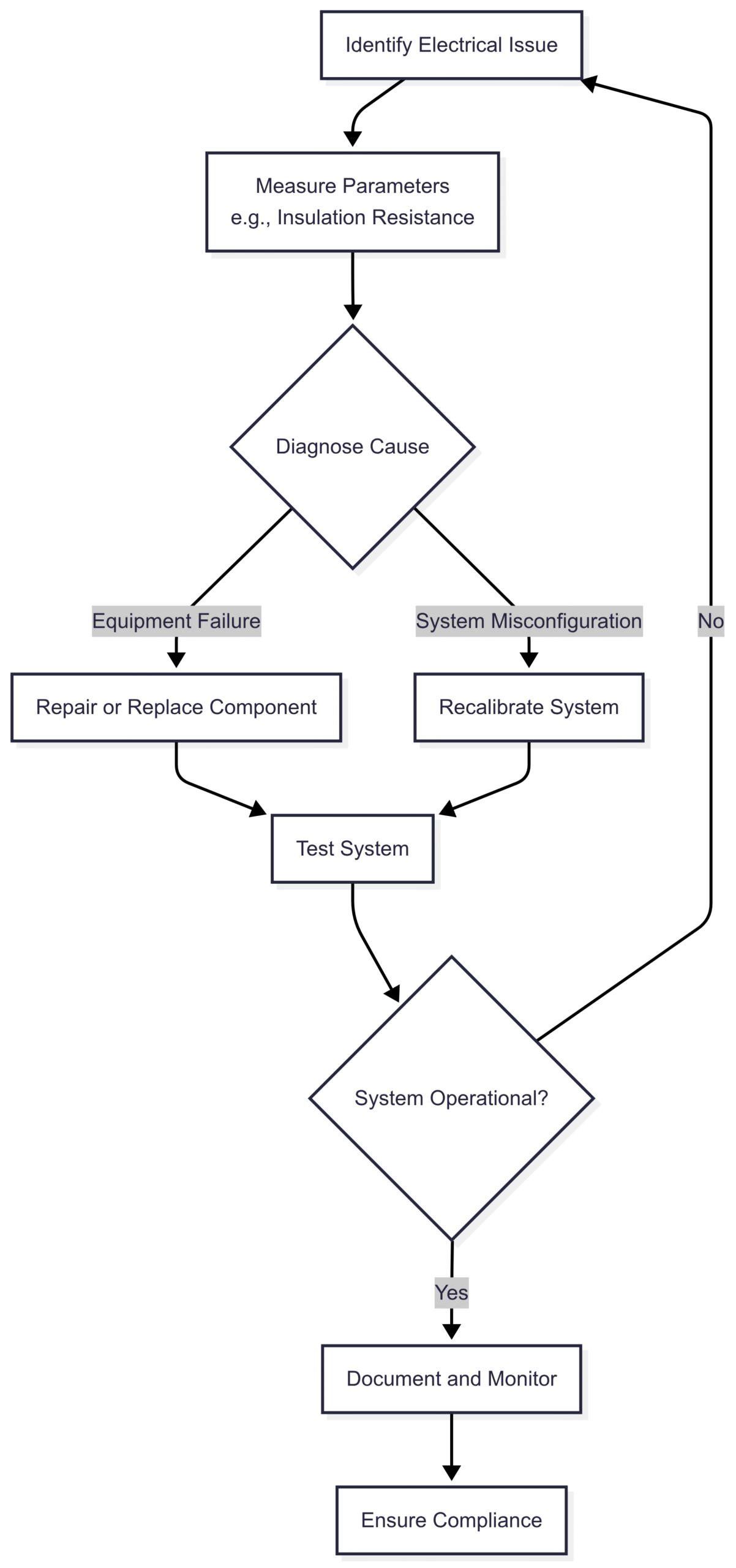

Chart: Marine Electrical Engineering Workflow

Below is a flowchart illustrating the typical workflow of a marine electrical engineer addressing an electrical issue at sea.

This chart outlines the systematic approach marine electrical engineers use to troubleshoot and resolve issues, ensuring compliance and reliability.

Table: Comparison of Specialization Tracks

| Aspect | Industrial Automation and Control | Power Systems Operation |

|---|---|---|

| Focus | PLCs, HMIs, control systems | Generators, switchboards, power distribution |

| Applications | Automation of cargo, pumps, alarms | Power management, propulsion systems |

| Key Skills | PLC programming, system integration | Fault current analysis, load balancing |

| Demand | High on modern, automated vessels | Universal across all ships |

| Challenges | Steep learning curve, software updates | High responsibility, complex diagnostics |

| Career Path | R&D, specialized vessels | Ship design, broad maritime roles |

Conclusion

Marine electrical engineering is a dynamic and rewarding career that demands a robust skill set, from managing insulation resistance to mastering automation and power systems. Whether working on container ships, cruise liners, or naval vessels, engineers play a critical role in ensuring safety, efficiency, and compliance. Aspiring engineers should focus on building technical expertise, gaining practical experience, and choosing a specialization that aligns with their interests. Both Industrial Automation and Control and Power Systems Operation offer promising paths, with automation catering to modern, tech-driven ships and power systems providing a versatile foundation. By mastering the skills outlined in this article and leveraging resources like Mareleng’s expertise, you can navigate the challenges of this field and build a successful career at sea.

Happy Boating!

Share Must-Know Skills for Marine Electrical Engineers on Ships with your friends and leave a comment below with your thoughts.

Read MARPOL Annex I – Prevention of Pollution by Oil until we meet in the next article.