Marine Propulsion Systems | Types and Uses Explained

Explore marine propulsion systems: diesel, electric, nuclear, and more. Learn types, uses, and benefits for efficient, sustainable shipping.

Marine propulsion systems are the heart of any vessel, converting energy into thrust to navigate the seas. These systems have evolved from human-powered oars to sophisticated technologies like nuclear and fuel cell propulsion, driven by demands for efficiency, sustainability, and performance. This article explores the primary types of marine propulsion systems, their applications, advantages, and limitations, with a focus on their role in modern maritime operations. From diesel engines to emerging green technologies, we’ll cover how these systems power global trade and transportation while addressing environmental challenges.

What is a Marine Propulsion System?

A marine propulsion system generates the thrust needed to move a vessel through water, operating on Newton’s third law of motion: for every action, there is an equal and opposite reaction. The system typically comprises a power source, a transmission mechanism, and a thrust-generating device like a propeller or waterjet. The power source—whether a diesel engine, gas turbine, or nuclear reactor—produces energy. The transmission system, such as shafts, gears, or electric motors, transfers this energy to the thrust device, which propels the vessel by pushing against water or air.

Marine propulsion has advanced significantly, driven by the need for fuel efficiency, reduced emissions, and adaptability to diverse vessel types, from cargo ships to naval warships. Below, we explore the major types of propulsion systems, their mechanics, and their applications.

Types of Marine Propulsion Systems

Marine propulsion systems vary widely, each tailored to specific vessel types and operational needs. Here’s a detailed look at the most prominent systems, their components, and their use cases.

1. Diesel Propulsion

Overview: Diesel propulsion is the backbone of the maritime industry, powering vessels from small boats to massive container ships. These systems use internal combustion diesel engines to drive propellers, either directly or through reduction gears, converting thermal energy into mechanical work.

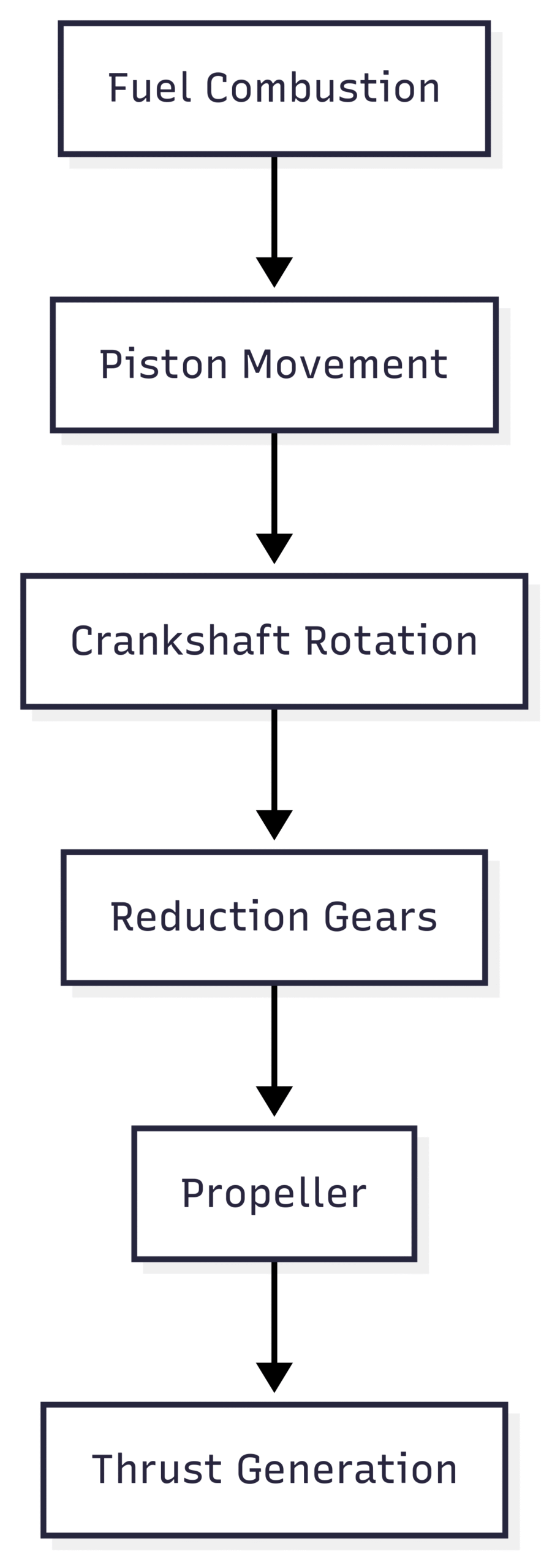

Mechanics: In a diesel propulsion system, fuel combustion in the engine’s cylinders moves pistons, rotating a crankshaft connected to the propeller. Two-stroke diesel engines, common in large ships, complete a power cycle in two piston strokes, offering a high power-to-weight ratio. Four-stroke engines, used in smaller vessels, provide smoother operation but lower power density.

Applications:

- Cargo Ships: Container vessels and bulk carriers rely on diesel for reliability and fuel efficiency.

- Tankers: Oil and gas tankers use diesel engines for long-haul voyages.

- Passenger Vessels: Ferries and cruise ships benefit from diesel’s proven technology.

Advantages:

- High thermal efficiency, reducing fuel costs.

- Reliable and widely available technology.

- Versatile, suitable for small and large vessels.

Disadvantages:

- Significant CO2 and NOx emissions.

- Dependency on fossil fuels, raising environmental concerns.

Specifications (Example: Wärtsilä 14RT-flex96C, one of the largest marine diesel engines):

- Power Output: Up to 108,920 HP.

- Fuel Consumption: ~171 g/kWh.

- Weight: ~2,300 tons.

- Price: ~$20–30 million (varies by configuration).

Chart: Diesel Propulsion System Flow

2. Diesel-Electric Propulsion

Overview: Diesel-electric systems combine diesel engines with electric generators to power electric motors that drive propellers. This setup offers flexibility and efficiency, particularly for vessels requiring precise control.

Mechanics: Diesel engines generate electricity via alternators, which power electric motors connected to the propeller. The system allows variable speed control and can integrate multiple engines for redundancy.

Applications:

- Cruise Ships: Quiet operation enhances passenger comfort.

- Submarines: Reduced noise improves stealth.

- Icebreakers: High torque aids navigation in tough conditions.

Advantages:

- Enhanced fuel efficiency through optimized engine operation.

- Reduced noise and vibration.

- Flexible power distribution for auxiliary systems.

Disadvantages:

- High initial costs due to complex components.

- Requires skilled maintenance.

Specifications (Example: ABB Diesel-Electric System):

- Power Output: 5–50 MW.

- Efficiency: ~90% (electric motor efficiency).

- Price: ~$10–50 million (system-dependent).

3. Gas Turbine Propulsion

Overview: Gas turbines, akin to jet engines, burn fuel to produce high-pressure exhaust, driving a turbine that powers the propeller. They are ideal for high-speed vessels due to their power-to-weight ratio.

Mechanics: Air is compressed, mixed with fuel, and ignited in a combustion chamber. The resulting high-pressure gas spins a turbine, which drives the propeller via a shaft or electric generator.

Applications:

- Naval Ships: Used in destroyers and frigates for speed.

- High-Speed Ferries: Enables rapid transit.

- Luxury Yachts: Offers compact, powerful propulsion.

Advantages:

- High power-to-weight ratio.

- Rapid startup and response.

- Low maintenance needs.

Disadvantages:

- Lower fuel efficiency than diesel engines.

- High operating costs due to fuel type (e.g., marine gas oil).

Specifications (Example: GE LM2500 Gas Turbine):

- Power Output: 25–35 MW.

- Fuel Consumption: ~250 g/kWh.

- Weight: ~20 tons.

- Price: ~$15–25 million.

4. Steam Turbine Propulsion

Overview: Steam turbines, once dominant, are now niche but still used in specialized vessels like LNG carriers. They convert steam energy into mechanical work to drive propellers.

Mechanics: A boiler generates steam, which expands through a turbine, rotating it. The turbine connects to the propeller via gears or directly. Turboelectric systems use turbines to generate electricity for propulsion motors.

Applications:

- LNG Carriers: Utilize boil-off gas for fuel.

- Naval Vessels: Provide high power for large ships.

Advantages:

- High power output for large vessels.

- Reliable for continuous operation.

Disadvantages:

- Inefficient at low speeds.

- High maintenance requirements.

Specifications (Example: Mitsubishi UE Steam Turbine):

- Power Output: 20–100 MW.

- Efficiency: ~35–40%.

- Price: ~$10–20 million.

5. Nuclear Propulsion

Overview: Nuclear propulsion uses a nuclear reactor to generate steam, driving turbines for propulsion. It’s primarily used in military vessels due to its high power and long range.

Mechanics: A nuclear reactor heats water to produce steam, which powers turbines connected to propellers or generators. The system requires no frequent refueling, unlike fossil fuel systems.

Applications:

- Submarines: Enables extended underwater operations.

- Aircraft Carriers: Supports high power demands.

- Icebreakers: Powers through thick ice.

Advantages:

- Long operational range without refueling.

- Zero CO2 emissions during operation.

- High power output.

Disadvantages:

- Extremely high initial and decommissioning costs.

- Complex safety and regulatory requirements.

Specifications (Example: A1B Reactor for U.S. Navy):

- Power Output: ~700 MW (thermal).

- Weight: Classified (estimated thousands of tons).

- Price: ~$1–2 billion (reactor and integration).

6. Fuel Cell Propulsion

Overview: Fuel cell propulsion generates electricity through a chemical reaction, typically using hydrogen, to power electric motors. It’s an emerging, eco-friendly technology.

Mechanics: Hydrogen and oxygen react at electrodes, producing electricity, water, and heat. The electricity powers motors driving the propeller, with no combustion involved.

Applications:

- Research Vessels: Ideal for low-emission trials.

- Small Ferries: Suitable for short routes.

- Push Boats: Used in inland waterways.

Advantages:

- Zero emissions (only water and heat as byproducts).

- High efficiency (~50–60%).

- Quiet operation.

Disadvantages:

- High costs for fuel cell systems.

- Challenges in hydrogen storage and supply.

Specifications (Example: Ballard Power FCwave):

- Power Output: 200 kW–1 MW.

- Efficiency: ~55%.

- Price: ~$500,000–$2 million (system size-dependent).

7. Dual-Fuel Propulsion

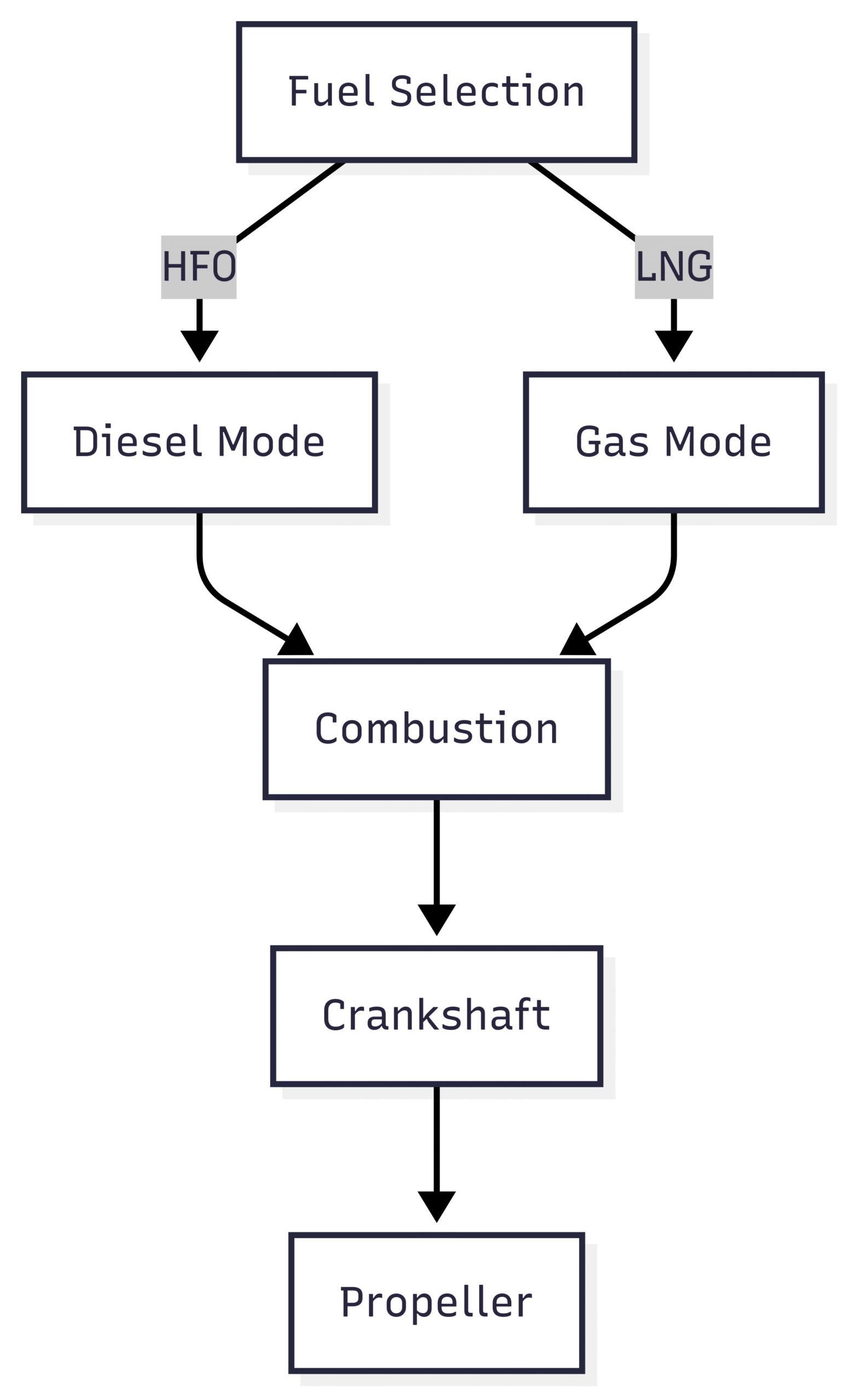

Overview: Dual-fuel engines can switch between fuels like heavy fuel oil (HFO) and natural gas, offering flexibility and environmental benefits. Two-stroke dual-fuel engines are particularly efficient for large vessels.

Mechanics: These engines operate in diesel mode (using HFO or marine diesel oil) or gas mode (using LNG or LPG). They use a pilot fuel for ignition in gas mode, reducing emissions.

Applications:

- LNG Carriers: Use boil-off gas as fuel.

- Container Ships: Benefit from fuel flexibility.

- Cruise Ships: Reduce emissions in sensitive areas.

Advantages:

- Reduced SOx, NOx, and particulate emissions in gas mode.

- Fuel flexibility optimizes costs.

- High thermal efficiency (~50%).

Disadvantages:

- Methane slip in gas mode (unburned methane emissions).

- Higher initial costs than diesel engines.

Specifications (Example: MAN B&W ME-GI Dual-Fuel Engine):

- Power Output: 5–82 MW.

- Fuel Consumption: ~150 g/kWh (gas mode).

- Price: ~$15–40 million.

Chart: Dual-Fuel Engine Operation

8. Waterjet Propulsion

Overview: Waterjet propulsion expels high-velocity water to generate thrust, ideal for high-speed, maneuverable vessels.

Mechanics: A pump, often powered by a diesel or electric motor, draws in seawater and expels it through a nozzle. The reaction force propels the vessel forward.

Applications:

- Naval Ships: High-speed patrol boats.

- Tugs and Trawlers: Require maneuverability.

- Recreational Vessels: Jetskis and small boats.

Advantages:

- Excellent maneuverability.

- No exposed propellers, reducing damage risk.

- High speeds for small vessels.

Disadvantages:

- Limited power for large vessels.

- Higher fuel consumption than propellers.

Specifications (Example: Rolls-Royce Kamewa Waterjet):

- Power Output: 1–20 MW.

- Speed: Up to 50 knots.

- Price: ~$1–5 million.

9. Wind Propulsion

Overview: Wind propulsion uses sails or modern wing sails to harness wind energy, primarily for recreational vessels but gaining traction in commercial shipping.

Mechanics: Sails capture wind, generating lift or drag to propel the vessel. Modern systems like wing sails or Flettner rotors use aerodynamic principles for efficiency.

Applications:

- Sailing Yachts: Primary propulsion for recreation.

- Cargo Ships: Emerging use in vessels like Oceanbird for auxiliary power.

Advantages:

- Zero fuel costs and emissions.

- Sustainable and renewable energy source.

Disadvantages:

- Weather-dependent performance.

- Limited applicability for large commercial vessels.

10. Solar and Biodiesel Propulsion

Overview: Solar and biodiesel propulsion systems are eco-friendly alternatives, often used as supplementary power sources.

Solar Mechanics: Solar panels generate electricity stored in batteries, powering electric motors. Often paired with diesel for hybrid systems.

Biodiesel Mechanics: Biodiesel fuels (e.g., FAME, HVO) replace or blend with diesel in standard engines, reducing emissions.

Applications:

- Solar: Recreational boats, ferries, and coastal vessels.

- Biodiesel: Tankers, bulk carriers, and dredgers.

Advantages:

- Solar: Zero emissions, low operating costs.

- Biodiesel: Nearly carbon-neutral, easy integration.

Disadvantages:

- Solar: Limited power output, weather-dependent.

- Biodiesel: NOx emissions challenges.

Specifications (Solar Example: Sunreef 80 Eco Solar System):

- Power Output: 180–360 kW (solar panels).

- Price: ~$500,000–$1 million (system integration).

11. Human-Powered Propulsion

Overview: The oldest propulsion method, using oars, paddles, or pedals, remains relevant for small recreational vessels.

Mechanics: Human muscle power drives oars or pedals, directly propelling the vessel or powering a small propeller.

Applications:

- Recreational Vessels: Kayaks, canoes, rowboats.

- Racing Shells: Competitive rowing.

Advantages:

- Zero emissions and fuel costs.

- Simple and low-cost.

Disadvantages:

- Limited speed and range.

- Impractical for commercial use.

Comparative Analysis of Propulsion Systems

| System | Power Output | Efficiency | Emissions | Cost ($M) | Applications |

|---|---|---|---|---|---|

| Diesel | 1–100 MW | 45–50% | High CO2, NOx | 5–30 | Cargo ships, tankers |

| Diesel-Electric | 5–50 MW | 45–90% | Moderate | 10–50 | Cruise ships, submarines |

| Gas Turbine | 25–35 MW | 30–35% | Moderate | 15–25 | Naval ships, ferries |

| Steam Turbine | 20–100 MW | 35–40% | High | 10–20 | LNG carriers, naval vessels |

| Nuclear | 100–700 MW | 40–50% | Zero (CO2) | 1000–2000 | Submarines, aircraft carriers |

| Fuel Cell | 0.2–1 MW | 50–60% | Zero | 0.5–2 | Research vessels, small ferries |

| Dual-Fuel | 5–82 MW | 45–50% | Low (gas mode) | 15–40 | LNG carriers, container ships |

| Waterjet | 1–20 MW | 30–40% | Moderate | 1–5 | Naval ships, recreational vessels |

| Wind | Variable | N/A | Zero | Low | Sailing yachts, auxiliary for cargo |

| Solar/Biodiesel | 0.1–1 MW | 40–50% | Low/Zero | 0.5–1 | Recreational, tankers |

Two-Stroke Dual-Fuel Engines: A Deep Dive

Two-stroke dual-fuel engines are a cornerstone of modern marine propulsion, combining the power density of two-stroke diesel engines with the flexibility of dual-fuel technology. These engines complete a power cycle in two piston strokes, delivering high power output per cycle. Their scavenging process—replacing exhaust gases with fresh air—enhances efficiency, using methods like port scavenging or piston porting.

Key Features:

- Fuel Flexibility: Operate on HFO, natural gas, MDO, biofuels, or LPG.

- Environmental Benefits: Gas mode reduces SOx, NOx, and particulate emissions by up to 80% compared to diesel.

- Efficiency: Thermal efficiency up to 50%, reducing fuel costs.

- Durability: Fewer moving parts increase lifespan.

Challenges:

- Methane slip in gas mode, where unburned methane (a potent greenhouse gas) escapes.

- Higher upfront costs than traditional diesel engines.

Applications: Widely used in LNG carriers, container ships, and cruise ships, where fuel flexibility and emissions compliance are critical.

Environmental and Economic Considerations

The maritime industry faces pressure to reduce emissions under regulations like the IMO’s MARPOL Annex VI. Propulsion systems are evolving to meet these standards:

- Diesel and Steam Turbines: High emissions drive the shift to alternatives.

- Dual-Fuel and Fuel Cells: Lower emissions make them attractive for compliance.

- Wind and Solar: Zero-emission options, though limited in scale.

- Nuclear: Offers zero CO2 but faces regulatory hurdles.

Economically, fuel costs dominate operating expenses. Dual-fuel engines and biodiesel reduce costs through flexibility and renewable fuels. Nuclear propulsion, while expensive, eliminates fuel costs for decades. The table below summarizes cost and emission profiles:

| System | Fuel Cost | Emission Profile | Maintenance Cost |

|---|---|---|---|

| Diesel | High | High CO2, NOx, SOx | Moderate |

| Dual-Fuel | Moderate | Low in gas mode | Moderate |

| Nuclear | Near-zero | Zero CO2 | High |

| Fuel Cell | High | Zero | Low |

Future Trends in Marine Propulsion

The push for sustainability is driving innovation:

- Hydrogen and Ammonia: Emerging as zero-carbon fuels, with pilot projects underway.

- Hybrid Systems: Combining diesel, electric, and renewable sources for efficiency.

- Automation: Advanced control systems optimize propulsion performance.

- Wind-Assisted Propulsion: Modern wing sails and rotors reduce fuel use in cargo ships.

The IMO’s goal of net-zero emissions by 2050 is accelerating research into fuel cells, nuclear, and alternative fuels. Companies like Wärtsilä and MAN are investing in dual-fuel and hydrogen technologies, while wind-assisted systems like Oceanbird signal a return to renewable energy.

Conclusion

Marine propulsion systems are critical to global trade, powering vessels that carry 90% of the world’s goods. From the reliability of diesel engines to the eco-friendly potential of fuel cells and wind propulsion, each system offers unique benefits and challenges. Two-stroke dual-fuel engines stand out for their efficiency and flexibility, while emerging technologies like hydrogen and solar promise a greener future. As environmental regulations tighten, the maritime industry must balance performance, cost, and sustainability to navigate the seas responsibly.

Happy Boating!

Share Marine Propulsion Systems | Types and Uses Explained with your friends and leave a comment below with your thoughts.

Read Ship Machinery and Systems: Guide for Maritime Learners until we meet in the next article.