Marine Fire Pumps: The Ultimate Guide

Comprehensive guide to marine fire pumps: types, regulations, installation, maintenance, and top models for ship fire safety.

Fire safety is paramount in the maritime industry, where the confined environment of a ship amplifies the dangers of fire. Surrounded by water, it may seem counterintuitive that fire is a significant hazard, yet the presence of heavy machinery, flammable fuels, and limited escape routes makes robust firefighting systems critical. At the heart of these systems are marine fire pumps, which deliver high-pressure water or foam to extinguish fires. This comprehensive guide explores marine fire pumps in detail, covering their types, regulatory requirements, installation, maintenance, and top models to ensure ship safety.

What Are Marine Fire Pumps?

Marine fire pumps are specialized pumps designed to supply water or firefighting foam to a ship’s fire suppression systems, including sprinklers, water mist systems, and fire hoses. These pumps are engineered to operate reliably under harsh marine conditions, such as exposure to seawater corrosion and extreme temperatures. They are a cornerstone of a ship’s fire control plan, ensuring that sufficient water or foam is available at the right pressure to combat fires effectively.

Fire pumps on ships serve multiple purposes beyond firefighting. When not in use for emergencies, main fire pumps can assist with general services like ballasting or bilge pumping, though they must never be used to pump oil or flammable liquids due to safety concerns. Emergency fire pumps, however, are reserved exclusively for fire emergencies and are designed to function independently of the ship’s main power supply.

Types of Marine Fire Pumps

Marine fire pumps are categorized into two primary types: centrifugal and positive displacement. Each type has distinct characteristics, advantages, and applications, making them suitable for different firefighting needs on ships.

Centrifugal Fire Pumps

Centrifugal fire pumps are the most common type used on ships due to their high flow rates and reliability. These pumps use a rotating impeller within a volute casing to generate centrifugal force, pushing water outward and through the discharge. The design allows for rapid water delivery, which is critical during fire emergencies.

How Centrifugal Pumps Work

The impeller’s vanes spin at high speeds, flinging water to the sides of the pump. The volute casing, shaped like a snail shell, narrows at the inlet and widens toward the discharge, forcing water out rather than allowing it to circulate within the pump. This creates a low-pressure zone at the inlet, drawing in more water. However, centrifugal pumps require priming—filling the pump with water before operation—to function effectively, as air in the system can prevent proper operation.

Advantages

- High Flow Rates: Capable of delivering large volumes of water, ideal for firefighting.

- Simple Design: Easy to manufacture and maintain.

- Cost-Effective: More affordable than other pump types.

- Reliable: Proven performance in marine environments.

Disadvantages

- Priming Required: Must be filled with water before operation, which can delay response if not pre-primed.

- Limited Pressure: Less effective for high-pressure applications compared to positive displacement pumps.

Positive Displacement Fire Pumps

Positive displacement pumps are less common but valuable for specific applications, particularly where high-pressure delivery or foam injection is required. These pumps operate by trapping a fixed volume of fluid in a cavity and forcing it out through one-way valves.

How Positive Displacement Pumps Work

These pumps use mechanisms like gears, pistons, or plungers to expand and contract a cavity. As the cavity expands, it creates a vacuum that draws water or foam through an inlet valve. When the cavity contracts, the fluid is forced out through a discharge valve. This design allows positive displacement pumps to handle air, high-viscosity fluids, and foam effectively, making them suitable for oil fire suppression.

Advantages

- High Pressure: Capable of delivering water or foam at higher pressures than centrifugal pumps.

- Foam Compatibility: Effective for injecting foam into fire lines, crucial for oil fires.

- No Priming Needed: Can operate without pre-filling, simplifying startup.

Disadvantages

- Lower Flow Rates: Cannot match the water volume of centrifugal pumps.

- Higher Cost: More expensive to purchase and maintain.

- Complex Maintenance: Requires more technical expertise for repairs.

Comparison Table: Centrifugal vs. Positive Displacement Fire Pumps

| Feature | Centrifugal Pumps | Positive Displacement Pumps |

|---|---|---|

| Flow Rate | High (up to 180 m³/hr) | Moderate (lower than centrifugal) |

| Pressure | Moderate (36–58 psi, depending on ship) | High (suitable for mist/foam systems) |

| Priming | Required | Not required |

| Cost | Affordable | Expensive |

| Maintenance | Simple | Complex |

| Best Use | General firefighting, high water volume | Foam injection, high-pressure delivery |

Regulatory Requirements for Marine Fire Pumps

Marine fire pumps are subject to stringent regulations to ensure they meet the safety needs of ships. The International Convention for the Safety of Life at Sea (SOLAS) and the International Maritime Organization (IMO) set the primary standards, dictating pump capacity, pressure, and installation requirements based on ship type and size.

SOLAS Requirements

SOLAS Chapter II-2 outlines fire safety standards, including specific requirements for fire pumps:

- Passenger Ships:

- Ships under 4,000 gross tonnage (GT) require at least two independent main fire pumps.

- Ships over 4,000 GT require at least three independent main fire pumps.

- Pump capacity must be at least two-thirds of the bilge pumps’ capacity.

- Cargo Ships:

- Ships over 1,000 GT require at least two independent main fire pumps.

- Ships under 1,000 GT have pump requirements determined by the administration.

- Pump capacity must be at least four-thirds of the bilge pumps’ capacity for a passenger ship of equivalent size, with a maximum total capacity of 180 m³/hr.

- Each pump must deliver at least 80% of the total required capacity divided by the number of pumps, with a minimum of 25 m³/hr and the ability to produce two water jets.

- Emergency Fire Pumps:

- Required for passenger ships over 1,000 GT and cargo ships over 2,000 GT.

- Must be located outside the engine room, in a separate compartment.

- Must have an independent power source (diesel engine or emergency generator).

- Minimum capacity of 25 m³/hr, delivering two ½-inch bore jets with a horizontal throw of at least 40 feet.

- Total suction head must not exceed 4.5 meters under all conditions of list or trim.

IMO Guidelines

The IMO provides additional guidance on fire safety equipment, emphasizing reliability and redundancy. Emergency fire pumps must have independent suction arrangements, and their pipelines must be made of corrosion-resistant materials like galvanized steel. The IMO also recommends regular testing to ensure operational readiness.

Pressure Requirements by Ship Type

| Ship Type | Gross Tonnage | Minimum Pressure (N/mm²) | Minimum Pressure (psi) |

|---|---|---|---|

| Passenger Ships | <4,000 GT | 0.30 | 44 |

| Passenger Ships | >4,000 GT | 0.40 | 58 |

| Cargo Ships | <6,000 GT | 0.25 | 36 |

| Cargo Ships | >6,000 GT | 0.27 | 39 |

Installation of Marine Fire Pumps

Proper installation of marine fire pumps is critical to ensure compliance with regulations and effective operation during emergencies. The following considerations guide the installation process.

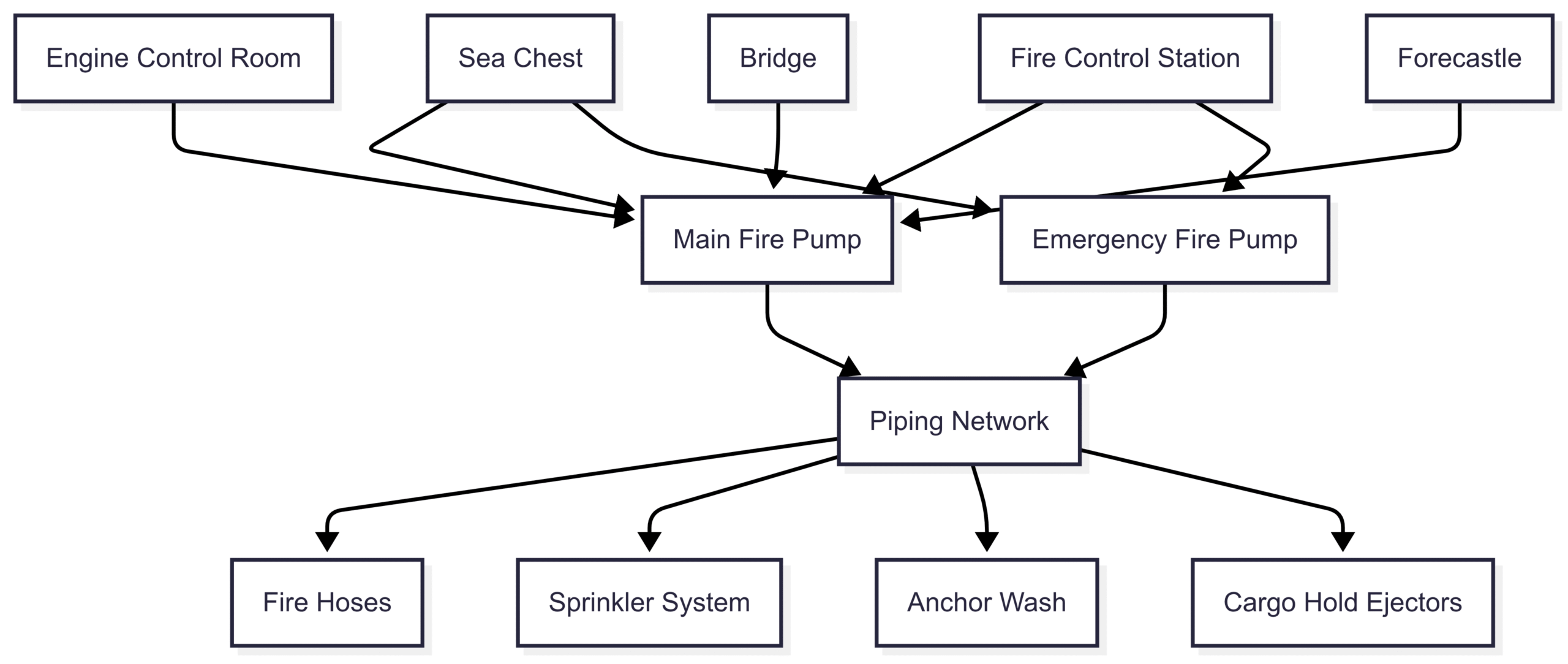

System Overview

A ship’s fire pump system is integrated into a network of pipes that distribute water or foam to critical areas, including the engine room, main deck, accommodation, shaft tunnel, and steering gear room. The system typically includes:

- Sea Chest: Filters seawater to prevent debris from entering the pump.

- Main Fire Pumps: Located in the engine room, powered by the ship’s main electrical supply.

- Emergency Fire Pump: Located outside the engine room, powered by a diesel engine or emergency generator.

- Piping Network: Galvanized pipes (50–180 mm in diameter) resistant to seawater corrosion, equipped with non-return valves for centrifugal pumps or relief valves for positive displacement pumps.

- Control Points: Fire pumps can be operated from the fire control station, engine control room, bridge, or forecastle.

Installation Guidelines

- Location:

- Main fire pumps are typically installed at the bottom platform of the engine room, near general service and ballast pumps.

- Emergency fire pumps must be in a separate compartment, such as the steering flat, shaft tunnel, or bow thruster room, to ensure redundancy.

- Suction for emergency pumps should ideally come from a different sea chest than the main pumps to avoid shared vulnerabilities, though SOLAS allows exceptions with A-60 fire-rated piping.

- Power Supply:

- Main fire pumps are electrically driven by the ship’s main power supply.

- Emergency fire pumps require an independent power source, either a diesel engine with a 3-hour fuel supply or an electric motor powered by the emergency generator.

- Priming:

- Centrifugal pumps must be primed before operation. Self-priming pumps or vacuum pumps can automate this process.

- Pumps above the waterline require priming arrangements to fill the casing with water.

- Piping:

- Use galvanized pipes to resist corrosion.

- Avoid cutting or welding fire lines to preserve the galvanized coating. Replace damaged sections with spare galvanized pipes.

Chart: Marine Fire Pump System Layout

This chart illustrates the flow of water from the sea chest through the main and emergency fire pumps to various ship systems, with control points for operation.

Operating Marine Fire Pumps

Operating a marine fire pump involves specific procedures to ensure rapid and effective response during emergencies.

Starting a Centrifugal Fire Pump

- Ensure the suction valve is fully open.

- For self-priming pumps, verify the priming water tank is full.

- Close the discharge valve and open the air vent on the volute casing.

- Allow water to fill the pump until it exits the vent, then close the vent.

- Start the pump and gradually open the discharge valve.

- For self-priming centrifugal pumps, close the check valve on the vacuum pump line after priming.

Starting an Emergency Fire Pump

- Verify the independent power source (diesel engine or emergency generator) is operational.

- Ensure the suction valve is open or remotely operated.

- Start the pump manually or via remote controls from the fire control station, bridge, or engine control room.

- In freezing conditions, ensure the pump and lines are drained to prevent ice buildup.

General Checks

- Bearings: Lubricate and check for overheating.

- Gland Packing/Mechanical Seals: Ensure minimal leakage for gland packing; no leakage for mechanical seals.

- Non-Return Valves: Verify functionality to prevent backflow in centrifugal pumps.

- Noise and Vibration: Investigate any abnormalities immediately.

- Priming System: Ensure readiness for centrifugal pumps.

Maintenance of Marine Fire Pumps

Regular maintenance is essential to ensure fire pumps are ready for emergencies. Maintenance schedules include daily, weekly, monthly, and semi-annual checks.

Daily Checks

- Visual Inspection: Look for leaks, corrosion, or damage.

- Temperature Check: Monitor motor and bearing temperatures.

- Sound Check: Listen for unusual noises indicating loose parts.

Weekly Checks

- Vibration Check: Investigate vibrations to identify misalignments or bearing issues.

- Discharge Pressure: Ensure pressure meets regulatory requirements; address drops immediately.

- Power Reading: Monitor motor amperage to detect potential issues.

Monthly Checks

- Coupling Alignment: Verify and grease couplings and bearings.

- Foundation Bolts: Tighten bolts to ensure stability.

Semi-Annual Checks

- Run Standby Pumps: Operate emergency pumps to ensure functionality.

- Running Hours: Replace parts nearing the end of their lifespan, even if functional, to maintain reliability.

Precautions

- In freezing conditions, drain fire lines to prevent freezing.

- Never throttle the suction valve while the pump is running.

- During blackouts, ensure ventilation in the emergency pump room (e.g., bow thruster room) by keeping doors open.

Choosing the Right Marine Fire Pump

Selecting a marine fire pump involves balancing ship size, regulatory requirements, and operational needs. Key considerations include:

- Ship Type and Size: Passenger and cargo ships have different pump and capacity requirements based on gross tonnage.

- Pump Type: Centrifugal pumps are ideal for high flow rates; positive displacement pumps are better for foam or high-pressure needs.

- Certifications: Ensure pumps are ABS-certified for compliance with international standards.

- Material: Choose pumps made of corrosion-resistant materials like stainless steel or nickel-aluminum bronze.

- Priming Needs: Consider self-priming centrifugal pumps for faster response times.

Top Marine Fire Pump: Carver Pump GH Series

Carver Pump’s GH end-suction centrifugal pump is a leading choice for marine firefighting. Key specifications include:

- Material: Available in stainless steel or nickel-aluminum bronze for seawater resistance.

- Capacity: Up to 180 m³/hr, meeting SOLAS requirements for most ships.

- Pressure: Capable of delivering 44–58 psi, suitable for passenger and cargo ships.

- Certification: ABS-certified, ensuring compliance with maritime standards.

- Price: Approximately $5,000–$15,000, depending on configuration and capacity (prices vary by supplier and customization).

Carver Pump, based in Muscatine, Iowa, has over 80 years of experience manufacturing pumps to military and engineering standards. Their ISO 9001:2015 certification ensures quality and reliability, making the GH series a trusted choice for marine fire safety.

Conclusion

Marine fire pumps are critical to ship safety, providing the water or foam needed to combat fires in high-risk environments. By understanding the types of pumps, regulatory requirements, installation guidelines, and maintenance practices, ship operators can ensure compliance and readiness. Centrifugal pumps dominate due to their high flow rates and affordability, while positive displacement pumps offer advantages for specific applications like foam injection. Adhering to SOLAS and IMO standards, combined with regular maintenance and choosing high-quality pumps like Carver Pump’s GH series, ensures that ships are well-equipped to handle fire emergencies, protecting lives and property at sea.

Happy Boating!

Share Marine Fire Pumps: The Ultimate Guide with your friends and leave a comment below with your thoughts.

Read Types of Propulsion System in Ship until we meet in the next article.