Marine Diesel Engines on Ships: A Comprehensive Overview

Marine diesel engines are the pulsating heart of the global shipping industry, powering vessels that transport over 95% of the world’s trade by volume. From colossal container ships to sleek yachts, these engines deliver the mechanical energy needed to drive propellers or generate electricity, ensuring the seamless flow of maritime commerce. Known for their reliability, fuel efficiency, and durability, marine diesel engines are engineered to withstand the harsh marine environment while meeting stringent operational demands.

This article provides an in-depth exploration of marine diesel engines, covering their history, operational principles, types, maintenance strategies, technological advancements, and future challenges. With a focus on their critical role in maritime operations, we aim to deliver a comprehensive resource for professionals, enthusiasts, and students alike.

History and Evolution of Marine Diesel Engines

Early Developments

The journey of marine diesel engines began in the late 19th century with Rudolf Diesel’s invention of the diesel engine in 1893. His compression-ignition design, which ignited fuel through the heat of compressed air, laid the foundation for a revolution in marine propulsion.

The first significant marine application came in 1903 with the diesel-electric river tanker Vandal, followed by the landmark launch of the MS Selandia in 1912, the first fully diesel-powered ocean-going ship. The Selandia marked a turning point, offering greater efficiency and reliability compared to steam engines, which dominated maritime propulsion at the time.

Advancements and Milestones

Over the decades, marine diesel engines evolved significantly, driven by the demands of global trade and technological innovation. Key milestones include:

- 1905: Sulzer introduced the first reversing two-stroke marine engine, enabling better maneuverability.

- 1930: Airless fuel injection systems became standard, improving combustion efficiency and reducing maintenance.

- 1946: Sulzer’s 6TAD48 engine became the first turbocharged two-stroke diesel engine in regular operation, boosting power output.

- 1950s: The rise of container shipping necessitated larger, more powerful engines, leading to designs capable of producing tens of thousands of horsepower.

- 1960s: Electronically controlled fuel injection systems enhanced precision and efficiency.

- 1990s: Exhaust gas recirculation (EGR) systems were introduced to curb nitrogen oxide (NOx) emissions.

- 2000s: Stricter environmental regulations spurred the development of selective catalytic reduction (SCR) systems.

- 2010s: Dual-fuel engines, capable of running on diesel or liquefied natural gas (LNG), gained traction for their lower emissions.

These advancements have transformed marine diesel engines into highly efficient, eco-conscious powerhouses, capable of meeting the rigorous demands of modern shipping while addressing environmental concerns.

Operation and Working Principles

Marine diesel engines operate on the principle of internal combustion, converting the chemical energy in fuel into mechanical energy to drive ship propellers or generate electricity. Their robust design and precise engineering make them ideal for the challenging marine environment. Below, we explore the operational principles and key components in detail.

Basic Principles

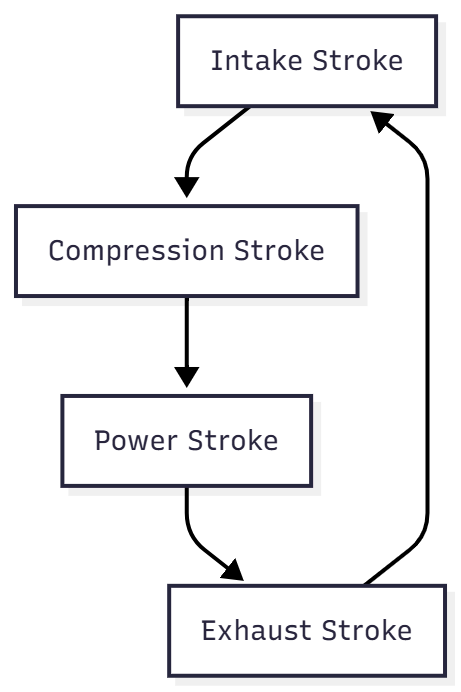

Marine diesel engines typically operate on a four-stroke cycle, though two-stroke engines are common in large vessels. The four-stroke cycle consists of:

- Intake Stroke: The piston moves downward, creating a vacuum that draws air into the cylinder through an intake valve.

- Compression Stroke: The piston moves upward, compressing the air to a high pressure and temperature (typically 30–40 bar and 500–600°C).

- Power Stroke: Fuel is injected as a fine mist into the compressed air, where it ignites spontaneously due to the high temperature. The resulting combustion produces high-pressure gases (up to 150 bar) that drive the piston downward, generating mechanical energy.

- Exhaust Stroke: The piston moves upward again, expelling combustion gases through an exhaust valve.

In two-stroke engines, the cycle is condensed into two strokes, combining intake and exhaust processes in one piston movement and power and compression in another. This results in a higher power-to-weight ratio, making two-stroke engines ideal for large ships.

The following diagram illustrates the four-stroke cycle:

Key Components and Systems

Marine diesel engines are complex assemblies of components working in harmony. Below are the primary components and their functions:

Bedplate

The bedplate is the foundation of the engine, supporting its weight and dynamic loads. Made of cast steel, it consists of longitudinal and transverse girders that hold the crankshaft in alignment. The bedplate is bolted to the ship’s hull via chocks and must be flexible enough to withstand hull bending during rough seas.

Function:

- Supports the engine’s weight (up to 2,300 tons for large two-stroke engines).

- Absorbs dynamic loads from running parts.

- Collects lubricating oil and drains it to the sump.

A-Frame

The A-frame, named for its shape, connects the bedplate to the cylinder block (entablature). It houses the crosshead and guides, forming the crankcase. Made of cast iron or steel, it is bolted to the bedplate and entablature for alignment.

Function:

- Supports the cylinder block.

- Houses the crosshead and guides.

- Forms the crankcase to isolate engine units.

Entablature (Cylinder Block)

The entablature houses the cylinder liners, scavenge spaces, cooling water jackets, and other components. It is designed to withstand combustion forces and is typically made of cast iron.

Function:

- Houses cylinder liners and cooling systems.

- Supports the cylinder head and valves.

Crankshaft

The crankshaft converts the linear motion of pistons into rotational motion to drive the propeller. Made of alloyed steel (with elements like nickel and chromium), it withstands cyclic loads from combustion and propeller forces.

Function:

- Transmits power to the propeller.

- Converts linear motion to rotational motion.

- Distributes forces to the ship’s hull via bearings.

Connecting Rod

The connecting rod links the crosshead (or piston in four-stroke engines) to the crankshaft, converting reciprocating motion into rotational motion. It endures tensile, compressive, and bending forces.

Function:

- Transfers motion from the crosshead to the crankshaft.

- Supplies lubricating oil to the crankpin and piston.

Crosshead

In two-stroke engines, the crosshead connects the piston to the connecting rod, eliminating side loads on the cylinder liner. It includes guide shoes that slide along rails for smooth operation.

Function:

- Transmits piston motion to the connecting rod.

- Prevents side loads on the cylinder liner.

- Supplies lubricating oil.

Piston

The piston converts combustion forces into mechanical energy. Comprising a crown and skirt, it is heat-treated to withstand thermal and shock loads.

Function:

- Transfers combustion energy to the crankshaft.

- Compresses the air-fuel mixture.

- Seals the combustion chamber.

Cylinder Liner

The cylinder liner forms the combustion chamber, enduring high temperatures and pressures. It is a wearable part, typically replaced when wear exceeds 0.6–0.8% of the bore volume.

Function:

- Facilitates heat dissipation.

- Provides a sliding surface for the piston.

- Seals the combustion chamber.

Cylinder Head

The cylinder head seals the top of the combustion chamber and houses valves (fuel, exhaust, starting air) and cooling passages. It is made of cast iron or steel.

Function:

- Seals the combustion chamber.

- Transfers combustion forces to the engine structure.

- Provides cooling water passages.

Exhaust Valve

The exhaust valve, mounted on the cylinder head, releases combustion gases to the exhaust manifold. It is operated by a hydraulic pump and cooled by jacket water to manage temperatures of 350–400°C.

Function:

- Extracts exhaust gases.

- Maintains combustion chamber sealing.

- Transfers gases to the manifold.

Camshaft

The camshaft, driven by the crankshaft, operates the exhaust valve (and fuel injection in some engines). Its speed matches the crankshaft in two-stroke engines and is half in four-stroke engines.

Function:

- Operates exhaust and fuel valves.

- Converts crankshaft rotation into valve motion.

Turbocharger

The turbocharger uses exhaust gases to drive a turbine, which powers a compressor to force air into the combustion chamber, increasing power output. A charge air cooler reduces the air temperature for efficiency.

Function:

- Increases air mass for combustion.

- Improves engine efficiency using exhaust energy.

Types of Marine Diesel Engines

Marine diesel engines are classified based on various criteria, including their use, stroke cycle, ignition type, cylinder arrangement, speed, charging method, operating cycle, and fuel type. Below, we explore the primary classifications.

Type of Use

- Marine Propulsion Engines: These “main engines” drive the ship’s propeller, operating at variable speeds. They are typically slow-speed, two-stroke engines in large vessels.

- Diesel Generators: Auxiliary engines coupled to alternators generate electricity for onboard systems. Multiple generators ensure redundancy during critical operations.

Number of Strokes

- Two-Stroke Engines: Complete a power cycle in one crankshaft revolution, offering a high power-to-weight ratio. They are used in large ships due to their simplicity and ability to couple directly to propellers.

- Four-Stroke Engines: Require two crankshaft revolutions per power cycle, providing better fuel efficiency and durability. They are common in smaller vessels and auxiliary applications.

Single-Acting vs. Double-Acting

- Single-Acting Engines: Combustion occurs on one side of the piston, common in most marine applications.

- Double-Acting Engines: Combustion occurs on both sides, doubling power strokes per cycle. They are less common due to sealing challenges in the lower combustion chamber.

Type of Ignition

- Compression-Ignition: Fuel ignites due to the heat of compressed air, standard in diesel engines.

- Spark-Ignition: Used in non-diesel fuels (e.g., petrol, CNG), requiring spark plugs. Rarely used in marine diesel engines.

Single vs. Multi-Cylinder

- Single-Cylinder Engines: Used in small boats (<50 HP), easier to cool but limited in power.

- Multi-Cylinder Engines: Common in larger vessels, offering higher power and smoother operation due to balanced crankshaft loads.

Piston Type

- Crosshead Engines: Feature a crosshead between the piston and connecting rod, ideal for slow-speed, two-stroke engines. They reduce cylinder liner wear and allow higher power output.

- Trunk Piston Engines: The piston connects directly to the crankshaft, common in four-stroke and auxiliary engines.

Cylinder Arrangement

- In-Line: Cylinders are arranged in a straight line, common in main and auxiliary engines.

- V-Type, W-Type, X-Type: Used in high-power applications for compact design.

- Radial, Opposed-Piston, Delta: Less common but used in specialized applications.

Speed

- Slow-Speed Engines (<350 rpm): Used in large ships, directly coupled to propellers, and run on heavy fuel oil (HFO).

- Medium-Speed Engines (350–750 rpm): Versatile for propulsion or auxiliary roles, often requiring gearboxes.

- High-Speed Engines (>750 rpm): Used in smaller, high-speed vessels, offering cost and emission benefits.

Charging Method

- Naturally Aspirated: Air enters at atmospheric pressure, less efficient but simpler.

- Supercharged/Turbocharged: Uses exhaust gases to compress intake air, increasing power output. Most modern marine engines are turbocharged.

Operating Cycle

- Diesel Cycle: Fuel ignites in compressed air, standard in marine diesel engines.

- Dual Cycle: Combines diesel and Otto cycles for more complete combustion, used in some modern engines.

Fuel Type

- Heavy Fuel Oil (HFO): Affordable but high in sulfur, used in 65,000 vessels until stricter regulations.

- Low Sulphur Fuel Oil (LSFO): Complies with MARPOL Annex VI for emission control areas (ECAs).

- Marine Diesel Oil (MDO)/Marine Gas Oil (MGO): Cleaner, more expensive distillates, reducing the need for exhaust treatment.

- Liquefied Natural Gas (LNG): Used in dual-fuel engines for lower emissions.

The following table summarizes key engine types and their applications:

| Engine Type | Stroke | Speed (rpm) | Primary Use | Fuel Type |

|---|---|---|---|---|

| Slow-Speed Two-Stroke | 2 | <350 | Large cargo ships (propulsion) | HFO, LSFO, LNG |

| Medium-Speed Four-Stroke | 4 | 350–750 | Smaller ships, auxiliary | MDO, MGO, LNG |

| High-Speed Four-Stroke | 4 | >750 | High-speed craft, small boats | MDO, MGO |

| Dual-Fuel | 2 or 4 | Varies | Eco-sensitive areas | Diesel, LNG |

Maintenance and Troubleshooting

Preventive Maintenance

Regular maintenance is critical for ensuring the longevity and efficiency of marine diesel engines. Key tasks include:

- Oil and Filter Changes: Replace engine oil and filters to reduce friction and wear.

- Cooling System Maintenance: Inspect and clean heat exchangers to prevent overheating.

- Fuel System Maintenance: Clean fuel injectors and filters to ensure proper combustion.

- Component Inspections: Monitor wear on pistons, cylinder liners, and bearings, replacing them as needed.

Troubleshooting

Common issues include:

- Excessive Fuel Consumption: Caused by clogged injectors or improper air-fuel ratios.

- Loss of Power: Due to turbocharger issues, worn components, or fuel quality problems.

- Abnormal Noises: Indicate bearing wear or misalignment.

- Overheating: Resulting from cooling system blockages or pump failures.

Timely troubleshooting minimizes downtime and prevents costly repairs.

Future Developments and Challenges

Green Technologies

Stringent regulations, such as MARPOL Annex VI, are driving the adoption of greener technologies:

- Exhaust Gas Cleaning Systems (Scrubbers): Remove sulfur oxides and particulate matter from exhaust gases.

- Selective Catalytic Reduction (SCR): Reduces NOx emissions by converting them into nitrogen and water.

- Waste Heat Recovery Systems: Capture exhaust heat to improve fuel efficiency.

- Dual-Fuel and LNG Engines: Offer lower emissions and compliance with ECAs.

Challenges

- Regulatory Compliance: Meeting evolving emission standards requires significant investment.

- Fuel Transition: Shifting to alternative fuels like LNG or hydrogen involves infrastructure challenges.

- Cost vs. Sustainability: Balancing operational costs with eco-friendly technologies remains a hurdle.

Specifications and Pricing (Approximate)

Marine diesel engines vary widely in specifications and cost based on size, type, and application. Below is a sample table of common engines:

| Engine Model | Type | Power (kW) | Speed (rpm) | Price (USD) |

|---|---|---|---|---|

| MAN B&W 6G95ME-C10.5 | 2-Stroke, Slow | 34,000 | 80–100 | $15–20M |

| Wärtsilä 12V46F | 4-Stroke, Medium | 14,400 | 600 | $5–7M |

| Caterpillar 3516C | 4-Stroke, High | 2,350 | 1,800 | $500K–$1M |

| MAN Energy Solutions DFE | Dual-Fuel | 12,000 | 500–600 | $6–10M |

Note: Prices are approximate and vary based on configuration and market conditions.

Conclusion

Marine diesel engines are the backbone of global maritime trade, powering vessels with unmatched reliability and efficiency. From their historical roots in the early 20th century to modern advancements in fuel efficiency and emission reduction, these engines have evolved to meet the demands of a dynamic industry. Understanding their operation, types, maintenance needs, and future trends is essential for maritime professionals. As environmental pressures mount, innovations like dual-fuel engines and scrubbers will shape the future of marine propulsion, ensuring sustainability without compromising performance. By mastering these engines, the shipping industry can continue to drive global commerce across the seas.

Happy Boating!

Share Marine Diesel Engines on Ships: A Comprehensive Overview with your friends and leave a comment below with your thoughts.

Read Ship Safety Equipment – Lifejacket until we meet in the next article.