MAN’s dual-fuel methanol engine passes class test in China

Discover MAN Energy Solutions’ groundbreaking dual-fuel methanol engines, passing rigorous class tests in China, advancing decarbonization in maritime transport.

The maritime industry stands at a pivotal moment in its journey toward sustainability, with alternative fuels like methanol emerging as key players in reducing carbon emissions. MAN Energy Solutions, a global leader in marine engine technology, has achieved a significant milestone with its dual-fuel methanol engines, notably the MAN 7L21/31DF-M and the MAN B&W 12G95ME-C10.5-LGIM. These engines, tested and approved in China, represent a technological leap in supporting the industry’s decarbonization goals. This article delves into the development, specifications, applications, and broader implications of these engines, highlighting their role in shaping a sustainable maritime future.

Introduction: The Push for Decarbonization in Maritime Transport

The maritime sector, responsible for approximately 2.5% of global greenhouse gas emissions, faces increasing pressure to adopt cleaner fuels and technologies to meet international regulations, such as the International Maritime Organization’s (IMO) targets for reducing emissions by 50% by 2050 compared to 2008 levels. Methanol, particularly green methanol produced from renewable sources, has gained traction as a low-carbon or carbon-neutral fuel option due to its scalability, availability, and compatibility with existing infrastructure.

MAN Energy Solutions has positioned itself at the forefront of this transition with its dual-fuel methanol engines, designed to operate on both methanol and conventional fuels. The successful type-approval test (TAT) of the MAN 7L21/31DF-M genset and the development of the world’s most powerful two-stroke methanol engine, the MAN B&W 12G95ME-C10.5-LGIM, mark significant steps toward a multi-fuel future. These advancements not only address environmental challenges but also cater to the industry’s demand for fuel flexibility amid evolving fuel strategies.

The MAN 7L21/31DF-M: A Versatile Dual-Fuel Genset

Development and Testing

The MAN 7L21/31DF-M, a dual-fuel methanol genset, successfully passed its type-approval test at CSSC Marine Power’s (CMP) production facility in Zhenjiang, China. The test, conducted in collaboration with CMP, MAN Energy Solutions’ licensee, received approval from all major classification societies, validating the engine’s reliability and compliance with stringent maritime standards.

The development of the 7L21/31DF-M took approximately two years, with 18 months dedicated to intensive testing at MAN Energy Solutions’ facilities. Michael Køel Andersen, Head of Testing at MAN Energy Solutions, emphasized the significance of this achievement: “Integrating a methanol system into our well-proven L21/31 engine, despite the tight timeline and intense R&D, is an important milestone. It demonstrates that our gensets are agile and ready for the future market.”

Technical Specifications

The 7L21/31DF-M is based on the MAN 21/31 Mk II platform, a part-load optimized engine known for its world-leading specific fuel-oil consumption in the 1–2 MW power range. Key specifications include:

- Power Output: 1–2 MW, ideal for genset and diesel-electric propulsion applications.

- Fuel Compatibility: Operates on methanol, heavy fuel oil (HFO), and distillate fuels per ISO8217:2024 standards, as well as other biofuels.

- Injection System: Utilizes a cost-effective port fuel injection methanol system.

- Applications: Designed for genset use and diesel-electric propulsion, complementing MAN’s methanol-fueled two-stroke engines.

The engine’s design prioritizes fuel efficiency and flexibility, making it suitable for a wide range of vessels, from ferries to offshore support vessels. Its ability to switch seamlessly between methanol and conventional fuels addresses the uncertainty in fuel availability and pricing, a critical concern for shipowners navigating the transition to low-carbon fuels.

Market Impact and Sales

Since its market launch in 2024, the 7L21/31DF-M has seen double-digit sales, reflecting strong market demand for fuel-flexible solutions. Hakon Juel Hansen, Manager of Global Promotion and Business Development at MAN Energy Solutions, noted, “Sales of the 21/31DF-M show that we are capable of providing solutions to power the merchant fleet in a period of uncertainty in terms of customer fuel strategy.” With nearly 3,000 units of the L21/31 engine sold historically, the dual-fuel variant builds on a proven platform, enhancing its appeal to shipowners seeking reliable, future-proof technology.

The MAN B&W 12G95ME-C10.5-LGIM: The World’s Most Powerful Methanol Engine

Development and Production

MAN Energy Solutions is set to deliver the MAN B&W 12G95ME-C10.5-LGIM, touted as the world’s most powerful two-stroke methanol engine, to Chinese shipyards. This engine, rated at 82,440 kW at 80 rpm, is being constructed by CSSC-MES Diesel Co., Ltd. (CMD) for a series of 12 × 24,000 TEU container vessels. Seven vessels are under construction at Nantong COSCO KHI Ship Engineering (NACKS) for Orient Overseas Container Line (OOCL), and five at Dalian COSCO KHI Ship Engineering (DACKS) for COSCO Shipping Lines.

The engine incorporates MAN’s proprietary Exhaust Gas Recirculation Turbocharger Cut-out (EGRTC) system, the largest two-string EGR system for two-stroke engines to date. This system enhances emissions performance, reducing nitrogen oxides (NOx) and aligning with IMO Tier III requirements.

Technical Specifications

The 12G95ME-C10.5-LGIM is a dual-fuel engine based on MAN’s proven ME-series, with approximately 8,500 engines in service globally. Key specifications include:

- Power Output: 82,440 kW at 80 rpm, making it the most powerful methanol engine in its class.

- Fuel Compatibility: Operates on methanol and conventional fuels, with green methanol enabling carbon-neutral propulsion.

- Operating Principle: Functions on the Diesel cycle, ensuring high fuel efficiency and reliability.

- Emissions Control: Features the EGRTC system for NOx reduction, compliant with IMO Tier III standards.

- Applications: Designed for large merchant vessels, particularly ultra-large container ships.

The engine’s ability to operate on green methanol offers a pathway to carbon-neutral propulsion, a critical feature for large vessels aiming to meet decarbonization targets. Its track record, with over 230 ME-LGIM engines accumulating more than 600,000 methanol running hours, underscores its reliability and maturity.

Strategic Importance

Bjarne Foldager, Head of Two-Stroke Business at MAN Energy Solutions, highlighted the engine’s role in the company’s decarbonization strategy: “Our vision of ‘Moving Big Things to Zero’ motivates everything we do. This latest milestone—the world’s most powerful methanol engine—is a testament to our commitment to zero-emission solutions.” The engine’s development aligns with growing interest in methanol as a marine fuel, driven by its low carbon intensity and potential for carbon neutrality when produced from renewable sources.

Complementary Technologies and Collaborations

Methanol Fuel Supply Systems

The successful testing of the 6G50ME-C9.6-LGIM+EGRBP engine, another methanol dual-fuel low-speed engine, at Dalian Marine Diesel Engine (DMD) marked a milestone for China’s marine power sector. Headway Technology Group (Qingdao) provided the methanol fuel supply system (FSS) for this test, incorporating modules such as the fuel supply unit, auxiliary heat exchange system, nitrogen system, and control and security system. This was the first successful application of a domestically made methanol FSS in China, highlighting the country’s growing expertise in low-carbon marine technologies.

Strategic Partnerships

Headway Technology Group’s collaboration with CEEC Hydrogen Energy aims to advance hydrogen, ammonia, and methanol solutions for shipping. This partnership focuses on developing integrated green fuel projects, further supporting the adoption of alternative fuels in the maritime industry. Additionally, the China Classification Society (CCS) awarded a type approval certificate to CSSC Shanghai Marine Diesel Research Institute for the CHG234V8MMPI, China’s first marine pure methanol engine, underscoring the region’s commitment to sustainable marine propulsion.

The Role of Methanol in Maritime Decarbonization

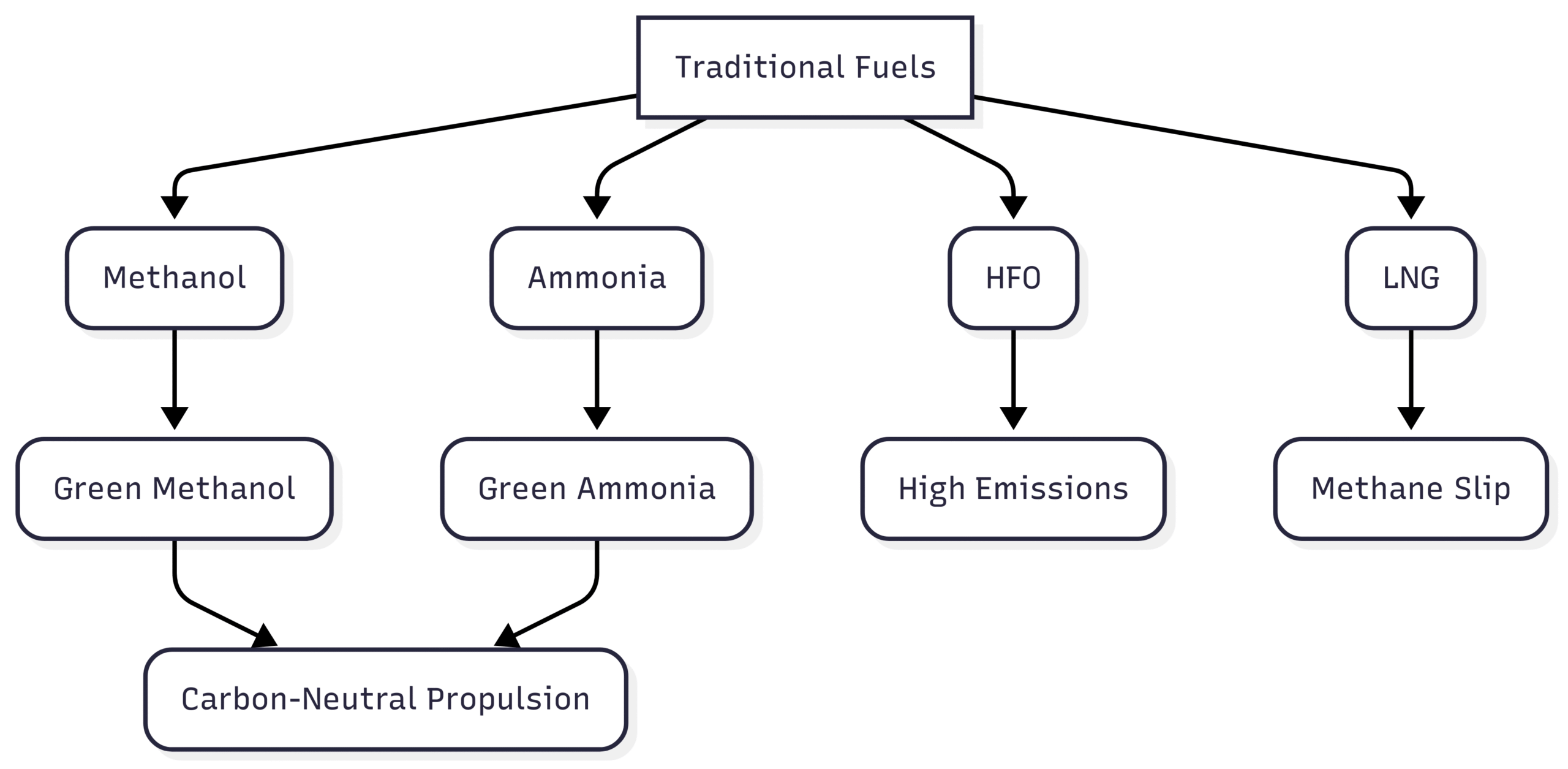

Methanol’s appeal as a marine fuel lies in its versatility, availability, and potential for carbon neutrality. Green methanol, produced from renewable sources such as biomass or carbon capture, can reduce lifecycle emissions to near zero. The following table compares methanol with other marine fuels:

| Fuel Type | Carbon Intensity | Availability | Infrastructure Compatibility | Challenges |

|---|---|---|---|---|

| Methanol (Green) | Low to Neutral | Growing | High | Production scalability |

| Heavy Fuel Oil (HFO) | High | Widespread | High | High emissions |

| Liquefied Natural Gas (LNG) | Moderate | Widespread | Moderate | Methane slip |

| Ammonia (Green) | Low to Neutral | Limited | Developing | Toxicity, handling challenges |

Chart: Maritime Fuel Transition

This chart illustrates the transition from traditional fuels to low-carbon alternatives, with green methanol and ammonia leading to carbon-neutral propulsion.

Applications and Market Outlook

The MAN 7L21/31DF-M and 12G95ME-C10.5-LGIM engines cater to different segments of the maritime industry. The 7L21/31DF-M is ideal for smaller vessels requiring genset or diesel-electric propulsion, while the 12G95ME-C10.5-LGIM targets ultra-large container ships. The dual-fuel capability of both engines allows shipowners to hedge against fuel price volatility and regulatory changes, making them attractive investments.

The retrofit market also presents significant opportunities. For instance, MAN PrimeServ’s successful conversion of the Maersk Halifax’s main engine to a dual-fuel ME-LGIM unit demonstrates the feasibility of upgrading existing vessels to methanol operation. With over 230 ME-LGIM engines in service or on order, the technology has a proven track record, supported by a decade of operational experience.

Pricing and Cost Considerations

While exact pricing for the 7L21/31DF-M and 12G95ME-C10.5-LGIM engines is not publicly disclosed, interested parties can contact MAN Energy Solutions for detailed inquiries. The cost-effectiveness of these engines stems from their fuel flexibility and efficiency. Green methanol, while currently more expensive than HFO, offers long-term savings through compliance with emissions regulations and potential carbon credit incentives. Retrofit costs vary depending on vessel size and engine type but are generally lower than newbuild installations due to the reuse of existing infrastructure.

Challenges and Future Directions

Despite methanol’s promise, challenges remain, including:

- Production Scalability: Green methanol production must expand to meet growing demand, requiring significant investment in renewable energy and carbon capture technologies.

- Infrastructure Development: While methanol is compatible with existing bunkering infrastructure, global supply chains need further development to ensure availability at major ports.

- Regulatory Alignment: Harmonized international standards for methanol as a marine fuel are essential to encourage widespread adoption.

MAN Energy Solutions is addressing these challenges through continuous innovation and partnerships. The company’s focus on developing engines for other alternative fuels, such as ammonia, and its collaboration with industry stakeholders like Headway Technology Group and CSSC demonstrate a holistic approach to decarbonization.

Conclusion

MAN Energy Solutions’ dual-fuel methanol engines, the 7L21/31DF-M and 12G95ME-C10.5-LGIM, represent a transformative step in the maritime industry’s decarbonization journey. By combining fuel flexibility, high efficiency, and proven reliability, these engines offer shipowners a practical solution to meet stringent emissions targets while navigating fuel market uncertainties. The successful type-approval tests in China and the delivery of the world’s most powerful methanol engine underscore MAN’s leadership in sustainable marine propulsion.

As the industry moves toward a multi-fuel future, methanol’s role as a scalable, low-carbon fuel will only grow. With ongoing advancements in engine technology and fuel supply systems, MAN Energy Solutions is paving the way for a cleaner, more sustainable maritime sector, aligning with the global vision of “Moving Big Things to Zero.”

Happy Boating!

Share MAN’s dual-fuel methanol engine passes class test in China with your friends and leave a comment below with your thoughts.

Read Back-Fire (Blow-Back) in Marine Boilers until we meet in the next article.