MAN 175D Engines Selected for Carbon Capture Storage Application

MAN 175D engines power Easymax 5, a CO2 carrier for offshore carbon storage, advancing decarbonization with high efficiency and sustainability.

The maritime industry is undergoing a transformative shift toward sustainability, driven by global mandates to reduce carbon emissions. At the forefront of this transition is the innovative application of carbon capture and storage (CCS) technologies, which aim to sequester CO2 from industrial sources and store it safely underground or beneath the seabed. A pivotal development in this arena is the deployment of the MAN 175D engines in the Easymax 5, a Multi-Purpose Vessel (MPV) designed specifically as a CO2 carrier for offshore storage operations. Built by the Royal Niestern Sander shipyard in the Netherlands for Wagenborg Operator, this vessel represents a significant step toward decarbonizing hard-to-abate industries. This article explores the role of the MAN 175D engines in powering Easymax 5, the vessel’s mission in the Danish North Sea, and the broader implications for maritime and industrial decarbonization.

The Easymax 5: A Purpose-Built CO2 Carrier

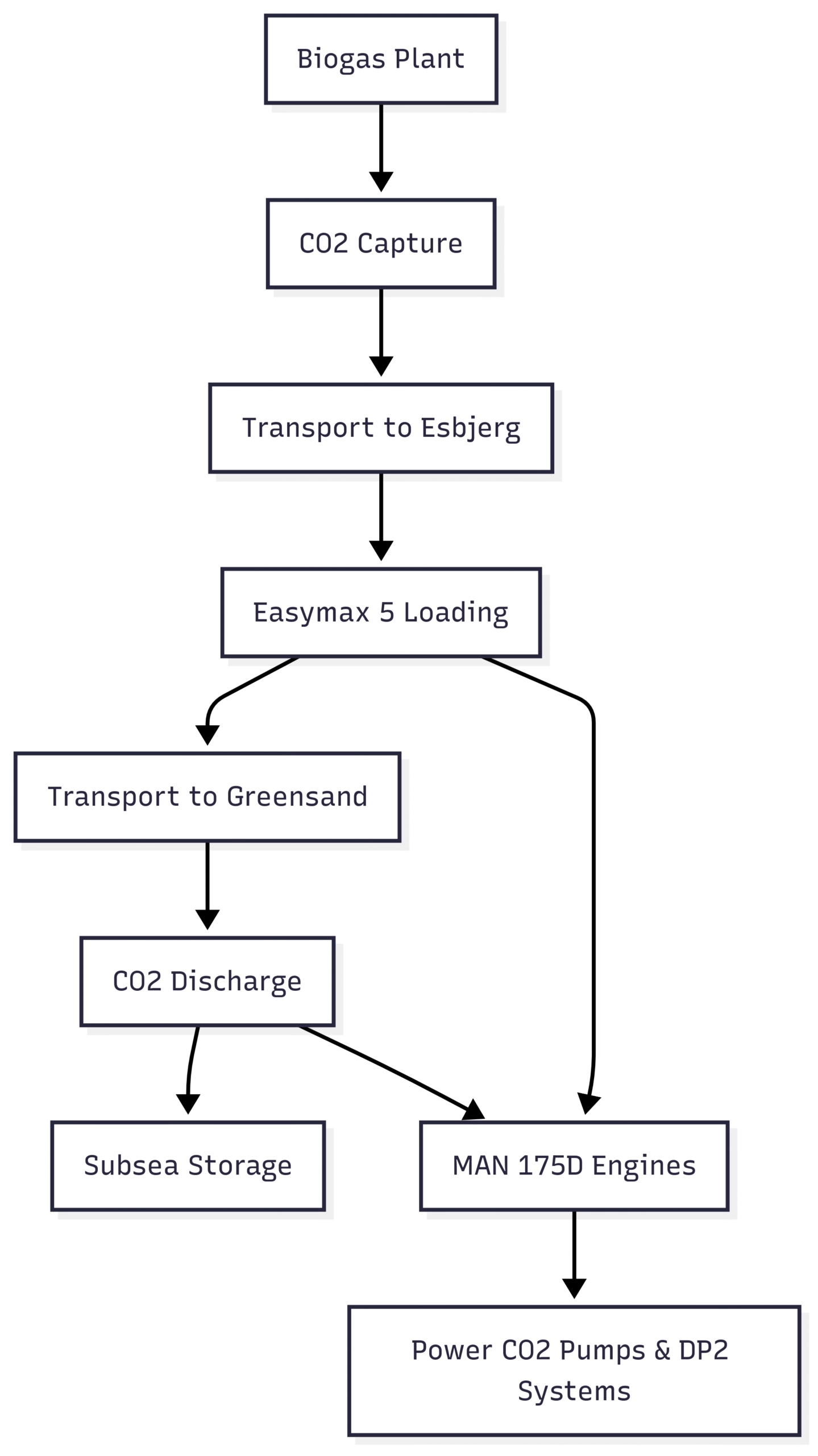

The Easymax 5 is the fifth vessel in a series developed through a collaboration between Wagenborg Operator and Royal Niestern Sander. With a cargo capacity of 14,000 tons, this MPV is engineered to transport liquefied CO2 from a biogas plant in Denmark to the port of Esbjerg on the country’s west coast. From there, the CO2 is loaded onto the vessel and transported to the Greensand storage site in the Danish North Sea, where it is injected into subsea reservoirs for permanent storage. The vessel, chartered by Ineos Denmark, exemplifies how maritime logistics can integrate with CCS to address emissions from industries with high carbon outputs, such as biogas production.

The Easymax 5’s design emphasizes efficiency and reliability, critical for its specialized role. The vessel is equipped with advanced systems, including CO2 pumps and a Dynamic Positioning (DP2) system, which ensure precise operations during offshore unloading. These systems demand significant power, particularly during CO2 discharge, which is where the MAN 175D engines come into play. By serving as generator sets (GenSets), these engines provide the necessary energy to support the vessel’s auxiliary systems, ensuring seamless and environmentally responsible operations.

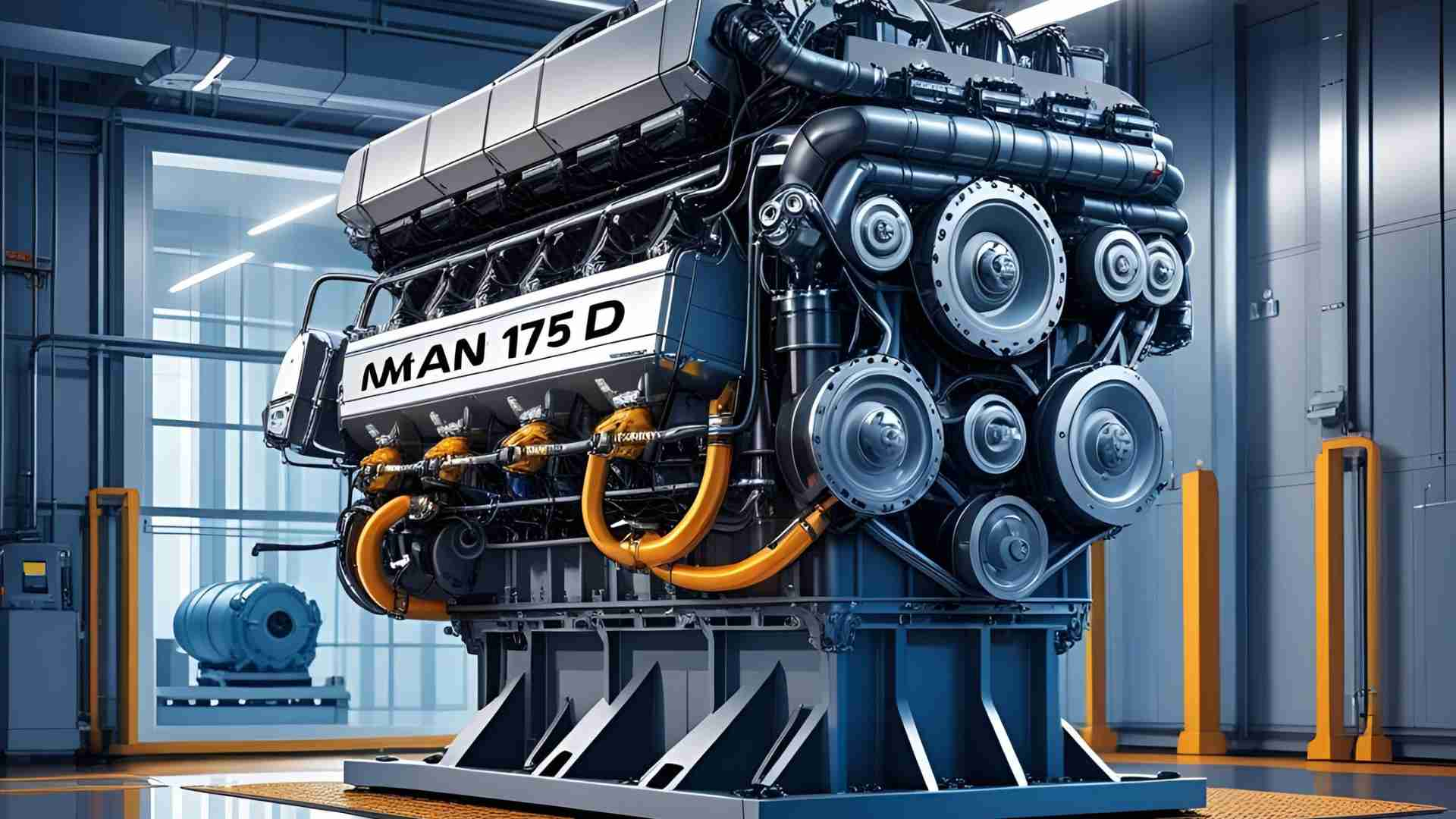

MAN 175D Engines: Engineering for Sustainability

The MAN 175D engine, developed by MAN Energy Solutions, is a cornerstone of the Easymax 5’s operational capabilities. Specifically, the vessel is powered by two MAN 16V175D MEM engines, each delivering 2,400 kWm at 1,800 rpm. These engines are designed to meet the rigorous demands of maritime applications while prioritizing fuel efficiency, low emissions, and compatibility with sustainable fuels.

Key Specifications of the MAN 175D Engine

| Feature | Specification |

|---|---|

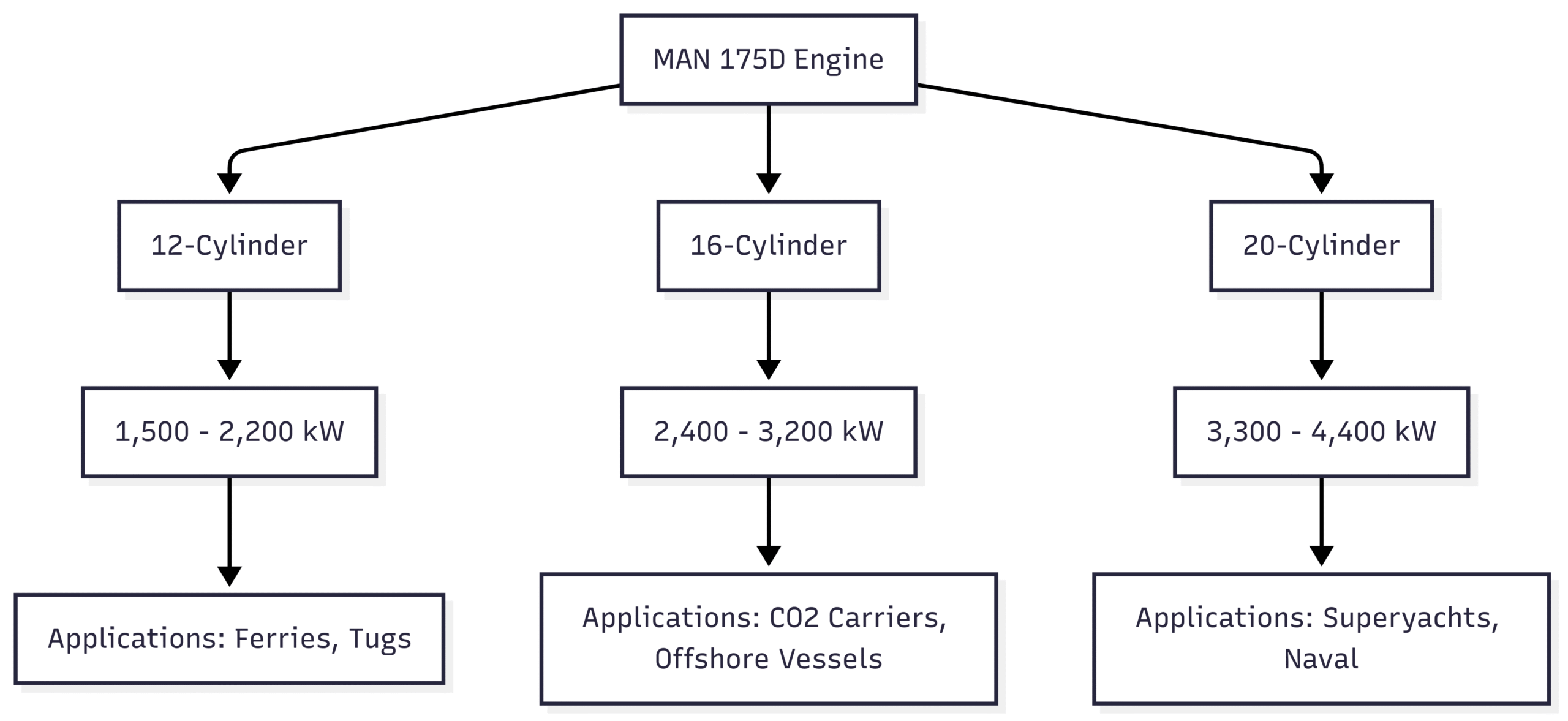

| Engine Variants | 12-, 16-, and 20-cylinder configurations |

| Power Output | 1,500 to 4,400 kW |

| RPM | 1,800 rpm (for 16V175D MEM) |

| Fuel Compatibility | Diesel, FAME, HVO (biofuels) |

| Emission Standards | Compliant with latest exhaust-gas-emission standards |

| Applications | Ferries, offshore vessels, tugs, superyachts, naval |

| Service Intervals | Long intervals for reduced maintenance costs |

The MAN 175D is engineered for versatility, serving a wide range of maritime vessels, including ferries, offshore support ships, tugs, and superyachts. Its high fuel efficiency and long service intervals contribute to the lowest operating costs in its class, making it an economically viable choice for operators. Additionally, the engine’s compliance with stringent exhaust-emission standards and its ability to run on biofuels like Fatty Acid Methyl Esters (FAME) and Hydrotreated Vegetable Oil (HVO) align it with future fuel requirements, ensuring longevity in a rapidly evolving regulatory landscape.

Bart Speckens, Regional Sales Manager at MAN Energy Solutions, emphasized the significance of this project: “This order represents a new type of reference for the 175D. In general, 175D is a versatile engine with the lowest environmental footprint and operating costs in its class due to its high fuel-efficiency and long service-intervals. We’re proud to be involved in such a crucial project that ultimately will sequester millions of tonnes of carbon dioxide from hard-to-abate industries.”

Chart: MAN 175D Engine Variants

This chart illustrates the range of MAN 175D engine variants and their respective power outputs, highlighting their suitability for diverse maritime applications, including the Easymax 5’s role as a CO2 carrier.

The Role of MAN 175D in Offshore CO2 Storage

The Easymax 5’s mission is to transport CO2 from a Danish biogas plant to the Greensand storage site, a pioneering CCS project in the Danish North Sea. Biogas plants produce CO2 as a byproduct of organic waste processing, and capturing this CO2 prevents its release into the atmosphere. The MAN 175D engines are integral to this process, providing the power needed to operate the vessel’s CO2 pumps and DP2 systems during offshore discharge. The DP2 system ensures the vessel maintains its position without anchoring, minimizing environmental impact on the seabed while enabling precise injection of CO2 into subsea reservoirs.

The Greensand project is a flagship initiative in Europe’s CCS efforts, aiming to store millions of tonnes of CO2 from hard-to-abate industries. By facilitating the transport and storage of biogenic CO2, the Easymax 5 contributes to the EU’s climate targets, including achieving net-zero emissions by 2050. The MAN 175D engines’ eco-friendly design enhances the project’s sustainability, as their low fuel consumption and biofuel compatibility reduce the vessel’s operational carbon footprint.

MAN Energy Solutions: A Leader in Decarbonization

MAN Energy Solutions is a global leader in sustainable maritime and industrial technologies, with a mission encapsulated in its slogan, “Moving Big Things to Zero.” Beyond the MAN 175D engines, the company provides CO2 compression technologies used in eight of the world’s 18 large-scale commercial CCS facilities. These systems are critical for capturing, transporting, and storing CO2, forming the backbone of a circular carbon economy where CO2 is reused or permanently sequestered.

MAN’s Contributions to CCS

| Aspect | Details |

|---|---|

| CO2 Compression Technology | Used in 8 of 18 global large-scale CCS facilities |

| Applications | Industrial CO2 capture, transport, and storage |

| Impact | Supports circular carbon economy, reduces emissions from heavy industries |

| Sustainability Focus | Engines compatible with climate-neutral fuels (e.g., FAME, HVO) |

MAN’s expertise in both engine manufacturing and CCS technologies positions it as a key player in the global push for decarbonization. The company’s involvement in the Easymax 5 project underscores its commitment to integrating maritime logistics with industrial sustainability, creating a synergy that addresses climate change on multiple fronts.

The Broader Context: CCS and Maritime Decarbonization

Carbon capture and storage is emerging as a critical strategy for mitigating climate change, particularly for industries where electrification or renewable energy adoption is challenging. The International Energy Agency (IEA) estimates that CCS could account for 15% of global emissions reductions by 2050, highlighting its importance in achieving net-zero targets. In the maritime sector, vessels like the Easymax 5 are becoming essential components of the CCS supply chain, transporting captured CO2 to storage sites safely and efficiently.

The Easymax 5 project also reflects the Netherlands and Denmark’s leadership in sustainable energy practices. The Netherlands has a strong maritime industry, with shipyards like Royal Niestern Sander driving innovation in vessel design. Denmark, meanwhile, is a hub for renewable energy and CCS, with projects like Greensand setting a precedent for offshore carbon storage. The collaboration between these nations, facilitated by companies like Wagenborg, Ineos, and MAN Energy Solutions, demonstrates how international partnerships can accelerate the transition to a low-carbon economy.

Challenges and Opportunities in CCS

While CCS holds immense promise, it faces challenges such as high upfront costs, regulatory uncertainties, and public acceptance. However, advancements in technology, such as the MAN 175D engines and CO2 compression systems, are reducing costs and improving efficiency. The Easymax 5 project serves as a proof of concept, showcasing how purpose-built vessels can overcome logistical hurdles in CCS operations.

Opportunities abound as well. The global CCS market is projected to grow significantly, driven by policy incentives and corporate sustainability goals. Vessels like the Easymax 5, powered by eco-friendly engines, are well-positioned to meet this demand, creating economic benefits for shipbuilders, operators, and technology providers.

Economic and Environmental Impact of Easymax 5

The Easymax 5 project is a milestone in maritime decarbonization, with far-reaching economic and environmental implications. Economically, it supports jobs in the Netherlands’ shipbuilding industry and strengthens Wagenborg’s position as a leader in specialized maritime logistics. The charter agreement with Ineos Denmark further underscores the project’s commercial viability, as demand for CCS services grows.

Environmentally, the Easymax 5 contributes to reducing emissions from Denmark’s biogas sector, a critical step in addressing emissions from hard-to-abate industries. By storing CO2 in the Greensand site, the project helps prevent millions of tonnes of CO2 from entering the atmosphere, aligning with global climate goals. The MAN 175D engines’ low fuel consumption and biofuel compatibility further enhance the vessel’s environmental credentials, minimizing its operational impact.

Future Prospects: Scaling Up CCS with Maritime Support

The success of the Easymax 5 could pave the way for more CO2 carriers, expanding the maritime sector’s role in CCS. As more countries invest in offshore storage sites, the demand for specialized vessels will increase, creating opportunities for shipyards and engine manufacturers. MAN Energy Solutions is well-positioned to capitalize on this trend, with its proven track record in both engine design and CCS technologies.

Future developments may include larger CO2 carriers, integration of alternative fuels like ammonia or hydrogen, and enhanced automation for offshore operations. The MAN 175D engine’s flexibility ensures it can adapt to these innovations, supporting the maritime industry’s transition to a zero-carbon future.

Chart: CO2 Transport and Storage Process

This chart outlines the CO2 transport and storage process, highlighting the MAN 175D engines’ role in powering critical systems aboard the Easymax 5.

Conclusion

The MAN 175D engines’ selection for the Easymax 5 marks a significant advancement in the integration of maritime logistics with carbon capture and storage. By powering a purpose-built CO2 carrier, these engines enable efficient and sustainable operations, supporting the sequestration of millions of tonnes of CO2 from Denmark’s biogas sector. The project, driven by collaboration between Royal Niestern Sander, Wagenborg, Ineos, and MAN Energy Solutions, underscores the potential of innovative technologies to address climate change.

As the global demand for CCS grows, vessels like the Easymax 5 and engines like the MAN 175D will play a pivotal role in scaling up carbon storage efforts. With their high efficiency, low emissions, and biofuel compatibility, the MAN 175D engines are not just powering ships—they are powering the future of a decarbonized world.

Happy Boating!

Share MAN 175D Engines Selected for Carbon Capture Storage Application with your friends and leave a comment below with your thoughts.

Read What is an Inert Gas or IG System on Ships? until we meet in the next article.