Is this a normal price for replacing a starter?

Discover the cost to replace a boat starter, ranging from $200-$800. Learn factors, DIY tips, and how to save on labor and parts.

The starter motor is a critical component of a boat’s engine, responsible for initiating the combustion process that brings the engine to life. When it fails, replacing it becomes a priority, but the costs can vary significantly, leaving many boat owners wondering, “Is this a normal price for replacing a starter?” Based on a detailed analysis of boat starter replacement costs, the price typically ranges between $200 and $800, influenced by factors such as boat type, engine complexity, part quality, labor charges, and whether you opt for a professional mechanic or a DIY approach. This article provides an in-depth exploration of these costs, offering insights into what drives them, how to save money, and whether the price you’re quoted is reasonable. We’ll also include real-world examples, practical tips, and technical details to guide you through the process.

Understanding the Boat Starter and Its Role

The starter motor is an electric device that engages the engine’s flywheel to turn the crankshaft, initiating the engine’s operation. In marine applications, starters are designed to withstand harsh conditions, such as moisture and saltwater exposure, but they can still fail due to wear, corrosion, or electrical issues. A failing starter typically manifests as a clicking sound when the ignition is turned, a whirring noise without engine turnover, or complete silence, indicating a need for replacement.

The replacement process involves disconnecting the battery, removing the faulty starter, installing a new one, and ensuring proper electrical connections. While the task sounds straightforward, the complexity depends on the boat’s design, engine type, and accessibility of the starter.

Factors Influencing Boat Starter Replacement Costs

Several variables determine the cost of replacing a boat starter. Understanding these factors can help you assess whether a quoted price is reasonable and identify opportunities to save.

1. Boat Type and Engine Complexity

The type of boat and its engine significantly impact replacement costs. Smaller outboard motors, common on fishing boats or small recreational vessels, typically have simpler starters that are easier to access and replace. For example, a starter for a small outboard motor might cost $100-$200, with minimal labor due to straightforward access.

Conversely, larger boats with inboard engines, such as a 1986 Cobalt with a 260hp GM 8-cylinder engine, often have more complex systems. These starters are pricier, ranging from $150-$600, and their location may require disassembling parts of the engine bay, increasing labor time. In some cases, rusted bolts or design flaws (e.g., starters sitting on stringers) may necessitate lifting the engine, further escalating costs.

2. Part Quality and Source

The cost of the starter itself varies based on whether you choose a new, remanufactured, or used part. Here’s a breakdown:

- New Starters: These typically cost $100-$600, depending on the brand and engine compatibility. Original Equipment Manufacturer (OEM) starters, designed specifically for your boat’s engine, are at the higher end but offer reliability and warranties (e.g., a 5-year warranty for $170, as noted in a user’s experience).

- Remanufactured Starters: These are refurbished units, often costing 20-40% less than new starters ($80-$400). They provide a balance of affordability and reliability, though quality varies by supplier.

- Used Starters: Found on platforms like eBay, used starters can cost as little as $50-$100 but carry risks of limited lifespan or compatibility issues.

Sourcing parts from reputable suppliers, such as marine-specific retailers like eBasicPower or local shops, can ensure compatibility. However, some boat owners report high markups at repair shops, with parts priced 100-200% above retail (e.g., a $240 starter at NAPA marked up to $500 at a shop).

3. Labor Costs

Labor charges are a significant component of the total cost, typically ranging from $100-$200 for professional installation. Labor rates vary by region and shop, with hourly rates of $80-$225 reported. The time required depends on the starter’s accessibility:

- Easy Access: For outboard motors or easily reachable starters, labor may take 1-2 hours, costing $80-$200.

- Complex Access: Inboard engines or starters requiring disassembly (e.g., removing seats or engine supports) can take 3-5 hours, pushing labor costs to $200-$500. Issues like rusted bolts or design flaws can further increase time and expense.

DIY replacement eliminates labor costs but requires mechanical skills, tools (e.g., wrenches, socket sets), and time. For instance, a user replacing a starter on a 1986 Cobalt described removing seats and supports, a labor-intensive process that could cost as much as the part if done professionally.

4. Additional Repairs

During starter replacement, mechanics may uncover related issues, such as faulty wiring, a defective solenoid, or corrosion, adding to the cost. For example, a solenoid replacement might add $50-$150, while addressing rusted bolts could require additional labor or parts. These discoveries can push the total cost beyond initial estimates, especially for older boats like the 1986 Cobalt, where corrosion is common.

5. Regional and Shop Variations

Labor rates and part markups vary by location and shop type. Dealerships and chain shops (e.g., Firestone for automotive, or marine equivalents) often charge higher rates ($150-$225/hour) and mark up parts significantly. Independent marine mechanics may offer lower rates ($80-$120/hour) but vary in expertise. Comparing quotes from multiple shops can help identify fair pricing.

Cost Breakdown: What to Expect

Based on the data, here’s a detailed cost range for boat starter replacement:

| Scenario | Parts Cost | Labor Cost | Total Cost |

|---|---|---|---|

| DIY, Small Outboard Motor | $100-$200 | $0 | $100-$200 |

| DIY, Inboard Engine | $150-$400 | $0 | $150-$400 |

| Professional, Small Outboard | $100-$200 | $80-$150 | $180-$350 |

| Professional, Mid-Range Boat | $150-$400 | $100-$200 | $250-$600 |

| Professional, Large Inboard | $300-$600 | $200-$500 | $500-$1,100 |

Real-World Example: 1986 Cobalt 260hp GM 8-Cylinder

A boat owner with a 1986 Cobalt reported a starter cost of $170 with a 5-year warranty. Labor estimates varied, with some suggesting $100-$200 for installation, depending on accessibility. If rusted bolts or engine lifting were required, costs could rise significantly, potentially reaching $400-$600 total. Another user cited a $50 eBay starter but noted labor-intensive access, suggesting professional labor could match or exceed the part cost.

Comparison to Automotive Starter Replacement

To provide context, automotive starter replacement costs offer a useful comparison. For a Mercury Mariner (a compact SUV), the average cost is $353-$581, with parts at $235-$409 and labor at $117-$172. Boat starters, particularly for inboard engines, tend to be pricier due to marine-grade materials and complex access. However, the principles of part markups and labor charges apply similarly, with shops often doubling part costs (e.g., a $240 starter marked up to $500).

Tips for Saving Money on Starter Replacement

To ensure you’re not overpaying, consider these strategies:

- Get Multiple Quotes: Contact several marine repair shops or mechanics for estimates. Prices can vary widely, as seen with labor rates ranging from $80-$225/hour.

- Source Your Own Parts: Purchase starters from reputable suppliers like eBasicPower, NAPA, or even eBay for used options. For example, a user found a starter for $100 online versus $170 locally.

- Consider Remanufactured Parts: These can save 20-40% compared to new starters while maintaining reliability. Ensure they come with a warranty.

- DIY if Skilled: If you have mechanical experience, tools, and time, replacing the starter yourself can save $100-$500 in labor. YouTube tutorials and marine repair manuals can guide you.

- Negotiate Diagnostic Fees: Some shops waive diagnostic fees (e.g., $90) if you proceed with the repair. Clarify this upfront.

- Return the Core: Many suppliers offer a core charge refund (e.g., $20-$50) when you return the old starter, reducing costs.

DIY vs. Professional Replacement: Pros and Cons

DIY Replacement

- Pros:

- Saves $100-$500 in labor costs.

- Empowers owners to learn about their boat’s mechanics.

- Flexible timing, avoiding shop schedules.

- Cons:

- Requires tools (e.g., socket set, wrenches) and mechanical knowledge.

- Risk of errors, such as incorrect electrical connections or misalignment, potentially damaging the flywheel.

- Time-consuming, especially for complex engines (e.g., 3-5 hours for inboard starters).

Professional Replacement

- Pros:

- Expertise ensures proper installation and diagnosis of related issues.

- Warranties on labor and parts provide peace of mind.

- Faster turnaround for those needing immediate repairs.

- Cons:

- Higher costs due to labor and potential part markups.

- Risk of overcharging or unnecessary repairs at less reputable shops.

Common Challenges in Boat Starter Replacement

Replacing a boat starter can encounter several hurdles, particularly with older vessels:

- Rusted Bolts: As noted with a 1986 Cobalt, rusted or corroded bolts can complicate removal, potentially requiring engine lifting or specialized tools.

- Accessibility: Starters in inboard engines may be tucked under seats, supports, or other components, increasing labor time. A user described removing seats and supports to access a starter, a process that could take hours.

- Design Flaws: Some boats have starters positioned in ways that complicate replacement, such as sitting on stringers, necessitating extensive disassembly.

- Electrical Issues: Faulty wiring or solenoids can mimic starter failure, requiring thorough diagnosis to avoid unnecessary replacements.

Diagnostic Process for Starter Issues

Before replacing a starter, proper diagnosis is crucial to avoid wasting money on the wrong repair. Here’s how professionals typically diagnose starter issues:

- Initial Testing: A mechanic uses a starting and charging system tester to check battery voltage, starter draw, and solenoid function.

- Visual Inspection: The starter, wiring, and connections are examined for corrosion, loose connections, or physical damage.

- Bench Testing: If the starter is suspected, it’s removed and tested off the vehicle to confirm failure.

- Related Components: The ignition switch, fuses, and solenoid are checked to rule out alternative causes.

DIYers can perform basic checks, such as listening for a click when turning the key or testing battery voltage with a multimeter, but complex diagnostics may require professional tools.

Starter Replacement Process

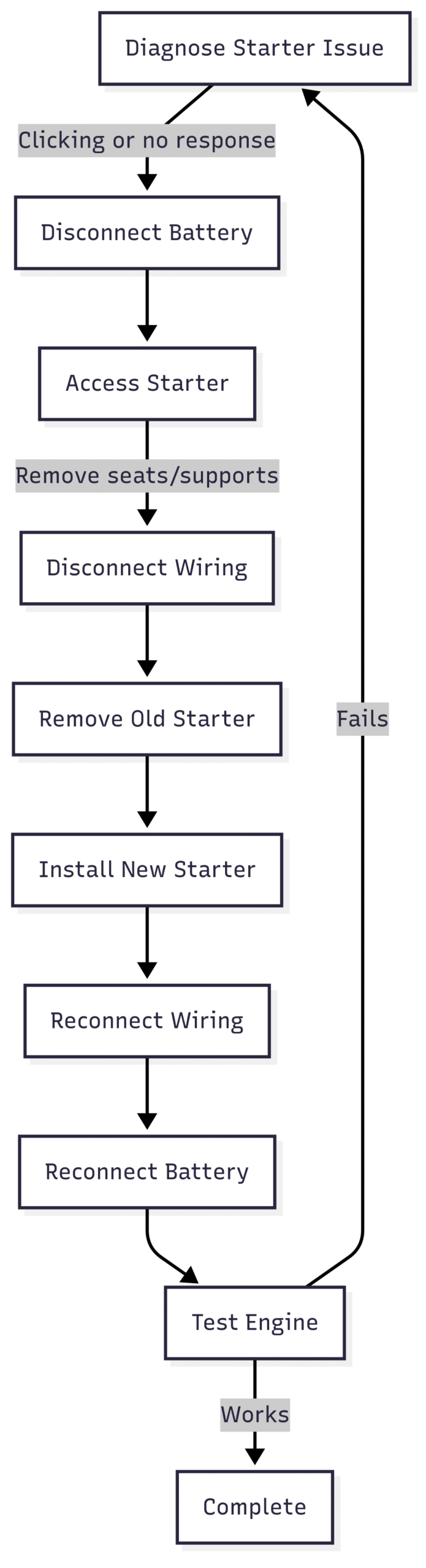

The replacement process involves several steps, which vary slightly by boat type:

- Disconnect the Battery: Prevents electrical shock or damage to components.

- Access the Starter: Remove seats, panels, or supports as needed to reach the starter.

- Disconnect Wiring: Detach electrical connectors from the starter and solenoid.

- Remove the Starter: Unbolt the starter (typically 2-3 bolts) and remove it, noting any shims for alignment.

- Install New Starter: Secure the new starter, ensuring proper alignment and tight connections.

- Reconnect and Test: Reattach wiring, reconnect the battery, and test the engine.

For older boats, shims may be required to align the starter with the flywheel, a task best left to professionals if you’re unfamiliar with the process.

Chart: Starter Replacement Process

Below is a simplified flowchart of the starter replacement process, created using syntax for clarity:

When to Replace a Starter

Starters typically last 75,000-125,000 miles or several years in marine applications, but frequent starts (e.g., in boats with start-stop systems) can accelerate wear. Symptoms of a failing starter include:

- Clicking when turning the key.

- Whirring or grinding noises without engine turnover.

- Intermittent starting issues.

If these symptoms appear, prompt replacement prevents being stranded, as seen in a case where a boat owner was stuck 2.5 hours from home, incurring over $300 in repairs plus travel costs.

Choosing a Reliable Shop

Selecting a trustworthy repair shop is critical to avoid overcharging or poor service. Here are tips based on user experiences:

- Avoid Chain Shops: Some users reported negative experiences with chain shops like Firestone, citing high markups and subpar work. For boats, seek marine-specific mechanics.

- Check Reviews: Look for shops with strong reputations for marine repairs, ideally with certifications from organizations like the American Boat and Yacht Council (ABYC).

- Ask About Markups: Clarify part costs and compare them to retail prices from suppliers like NAPA or eBasicPower.

- Request Detailed Invoices: Ensure the shop provides a breakdown of parts, labor, and diagnostic fees to avoid surprises.

Case Study: Mercury Mariner vs. Boat Starter Costs

To contextualize boat starter costs, consider the Mercury Mariner (automotive) data:

| Year | Parts Cost | Labor Cost | Total Cost |

|---|---|---|---|

| 2005-2007 | $235-$409 | $117-$172 | $380-$627 |

| 2008-2010 | $235-$409 | $117-$172 | $331-$555 |

| 2011 | $235-$409 | $117-$172 | $362-$503 |

Boat starters, especially for inboard engines, often exceed these costs due to marine-grade parts and complex labor. For example, a high-end inboard starter replacement could reach $800-$1,100, compared to $581 for a Mercury Mariner.

Conclusion

Replacing a boat starter typically costs $200-$800, with DIY options as low as $100-$400 and professional repairs reaching $1,100 for complex systems. Factors like boat type, engine complexity, part quality, and labor rates drive these costs. For a 1986 Cobalt with a $170 starter, expect $250-$400 total with professional labor, though issues like rusted bolts could push it higher. To save money, get multiple quotes, consider remanufactured parts, or tackle the job yourself if skilled. Always verify part prices and shop reputations to ensure a fair deal. By understanding these factors, you can confidently assess whether a quoted price is normal and make informed decisions to keep your boat running smoothly.

Happy Boating!

Share Is this a normal price for replacing a starter? with your friends and leave a comment below with your thoughts.

Read How Much Does It Cost to Get a Captain’s License? until we meet in the next article.

Helpful breakdown! This post gave me a clear idea of what to expect cost-wise when replacing a boat starter. Straightforward, easy to understand, and saved me some stress.