The Importance of Machinery Space on Ships: Types of Equipment and Systems

The machinery space, commonly known as the engine room, serves as the operational core of any ship. Located typically in the lower sections of the vessel, this area houses an intricate network of equipment and systems essential for propulsion, power distribution, and auxiliary functions. It centralizes the ship’s mechanical and electrical operations, ensuring seamless navigation, stability, and compliance with environmental standards. Without a well-maintained machinery space, ships risk failures that could lead to operational downtime, safety hazards, or environmental violations.

This space is designed with safety and efficiency in mind, often segmented into multiple levels to organize equipment by function. For instance, the bottom level might accommodate the main engine and heavy machinery, while upper levels house boilers, fans, and control systems. Isolation from living quarters is achieved through watertight doors that provide fireproofing, waterproofing, and noise reduction. Temperatures in the machinery space can range from 40-50°C due to continuous equipment operation, and noise levels often average 85-100 decibels, necessitating protective gear for personnel.

Engineers and technicians man this area, requiring specialized training and certifications to handle maintenance, repairs, and monitoring. The layout varies by ship type—cargo vessels, tankers, or passenger ships—but core principles remain consistent, focusing on reliability under diverse sea conditions.

The Critical Importance of Machinery Space

The machinery space is indispensable for several reasons. Primarily, it ensures safety by containing systems that prevent incidents like power loss, fires, or flooding. For example, fire suppression equipment and emergency controls are integrated to mitigate risks. Functionality is another key aspect; it powers propulsion for movement, generates electricity for navigation and accommodations, and supports systems like HVAC for crew comfort.

Environmental compliance is increasingly vital, with equipment such as oily water separators, sewage treatment plants, and ballast water systems designed to minimize pollution. These prevent the discharge of untreated waste or invasive species, adhering to international regulations like those from the International Maritime Organization (IMO).

Efficiency stems from proper design and maintenance. Segmented layouts optimize space, reduce hazards, and facilitate quick access for repairs. Regular servicing prevents breakdowns that could cause collisions, groundings, or costly delays. In essence, the machinery space underpins the ship’s overall performance, making it a focal point for maritime engineering.

Key Equipment and Systems in Machinery Space

The machinery space encompasses a wide array of interconnected equipment and systems. Below, we detail the primary categories, their functions, and interdependencies.

Propulsion System

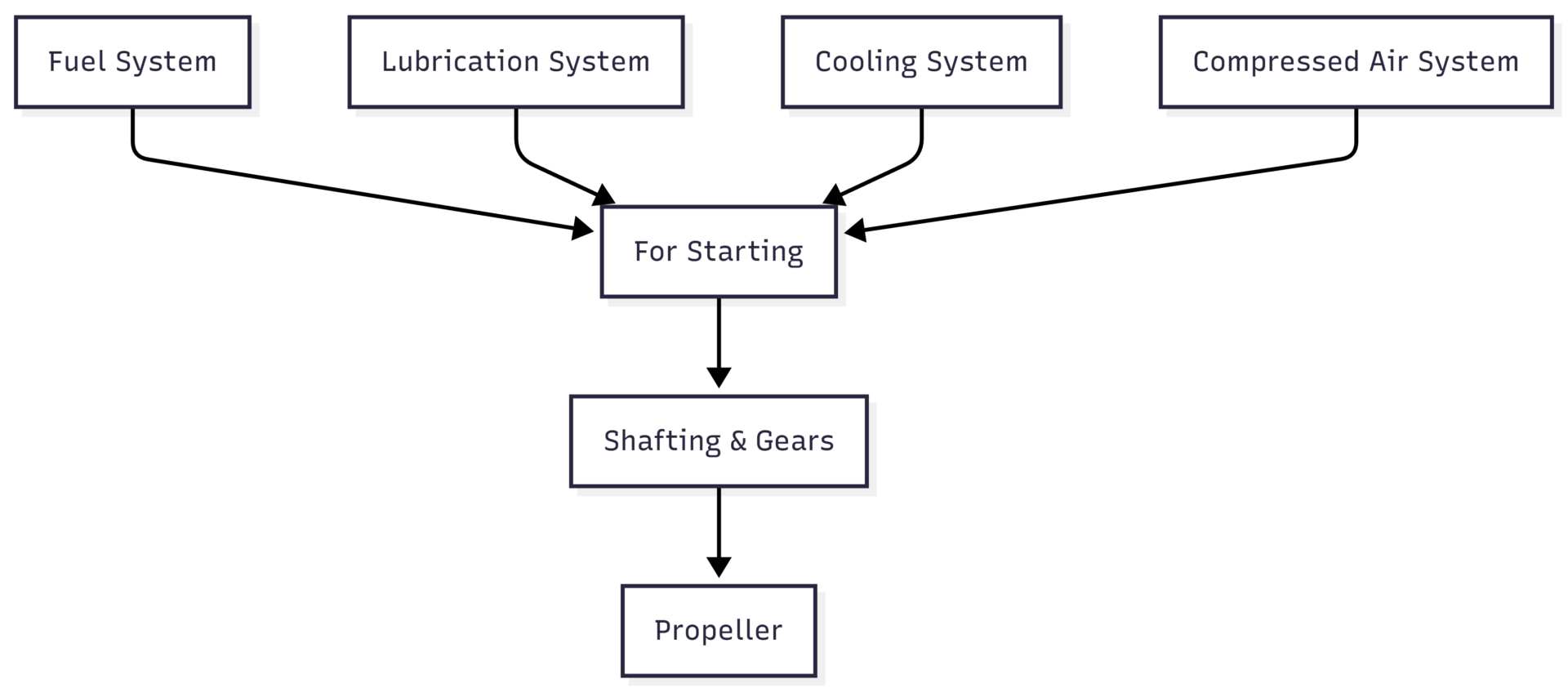

At the heart of the machinery space is the propulsion system, responsible for converting fuel energy into thrust. The main engine—often a large low-speed two-stroke or medium-speed four-stroke diesel engine—drives the propeller via shafting and gears. For example, engines can feature cylinders with diameters up to 90 cm, standing over 10 meters tall, with exhaust manifolds handling gases at around 400°C.

This system includes fuel injectors operating under high pressure, exhaust valves, and lubricating pipes to ensure smooth operation. Auxiliary components like turbochargers enhance efficiency by compressing intake air. Propulsion is supported by other systems, such as cooling to prevent overheating and lubrication to reduce wear.

In modern ships, alternatives like steam turbines or electric motors may be used, especially in specialized vessels. The system’s performance directly impacts speed, maneuverability, and fuel consumption, making it critical for mission success.

This Mermaid diagram illustrates the flow of the propulsion system, showing how supporting systems feed into the main engine.

Power Generation System

Power generation relies on diesel generators or alternators, providing electricity for the entire ship. These auxiliary engines, smaller than the main propulsion unit, supply power for lighting, navigation, communications, and pumps. Ships often have multiple generators for redundancy, ensuring continuous operation even if one fails.

Generators are fueled by diesel or natural gas and integrate with control systems for automated load sharing. Their output is vital for all electrical-dependent functions, from engine starting to HVAC.

| Component | Function | Typical Specifications |

|---|---|---|

| Diesel Generator | Generates electrical power | Output: 500-2000 kW; Fuel: Diesel; RPM: 900-1800 |

| Alternator | Converts mechanical energy to electricity | Voltage: 440V; Frequency: 60Hz |

| Auxiliary Engine | Powers generators | Cylinders: 4-8; Power: 300-1000 hp |

This table outlines key power generation components with example specifications (variations depend on ship size).

Fuel and Lubrication Systems

Fuel systems manage storage, purification, and delivery to engines. They include tanks (often holding thousands of gallons), pumps, filters, heaters, and purifiers to remove impurities and ensure clean, pressurized fuel. Systems are redundant to prevent interruptions, complying with environmental rules to avoid spills.

Lubrication systems supply oil to engine components, reducing friction and acting as a coolant. They feature tanks, pumps, filters, and piping, with oil selected for properties like detergency and alkalinity to neutralize acids. Proper lubrication extends component life and prevents failures.

These systems interconnect; for instance, boilers may heat fuel for viscosity control, and cooling systems manage heat from lubrication oil.

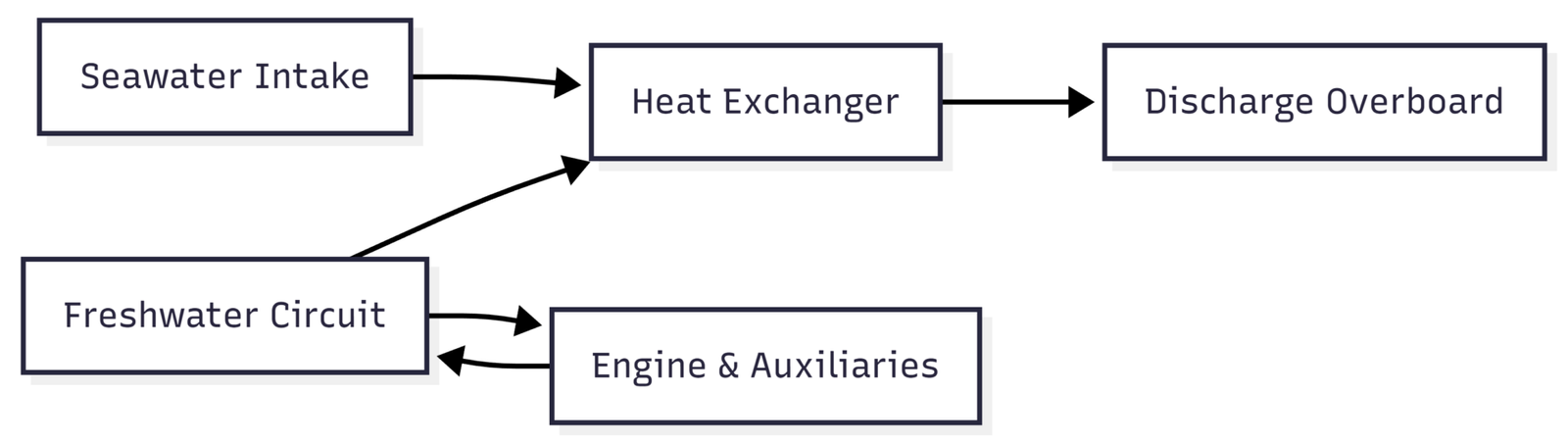

Cooling Systems

Cooling prevents overheating in engines and auxiliaries. Seawater systems draw ocean water through heat exchangers to absorb heat, then discharge it. Freshwater systems, used for internal circuits, include expansion tanks, coolers, pumps, and anti-corrosive treatments to avoid fouling.

High-temperature and low-temperature circuits are often linked, with seawater cooling the freshwater loop. Air conditioning ties into this for cabin temperature control.

This diagram shows the seawater and freshwater cooling loops.

Compressed Air System

Compressed air powers starting engines, pneumatic tools, and control valves. Categories include starting air (for large diesels), control air (for valves and pistons), and service air (for tools like drills). Compressors and tanks store air, ensuring dryness and cleanliness.

This system supports safety features, such as quick-closing valves, and integrates with hydraulics for machinery operation.

Steam Generation System

Boilers generate steam from fuel combustion or waste heat, powering turbines, heating fuel/cargo, or desalination. They are crucial for vessels requiring heat, like tankers. Steam drives pumps, winches, and HVAC elements.

Maintenance is key to avoid malfunctions, with materials resistant to high pressures and temperatures.

Waste Management Systems

These ensure environmental compliance. Sewage treatment plants process wastewater to meet discharge standards. Oily water separators remove oil from bilge water, collecting contaminants for disposal. Incinerators burn solid waste, reducing volume.

Bilge pumps remove accumulated water from the hull’s lowest points, equipped with sensors for automatic operation. Ballast water systems stabilize the ship by managing water intake/discharge, incorporating treatment to prevent invasive species spread via physical, chemical, or biological methods.

| System | Function | Key Components |

|---|---|---|

| Sewage Treatment | Processes wastewater | Aeration tanks, filters, disinfection units |

| Oily Water Separator | Separates oil from water | Coalescers, monitors; Capacity: 0.5-5 m³/h |

| Incinerator | Burns solid waste | Burners, ash collectors; Temperature: 850-1200°C |

| Bilge Pump | Removes hull water | Electric/hydraulic pumps; Flow rate: 50-200 m³/h |

Refrigeration and HVAC Systems

Refrigeration maintains low temperatures for food, cargo (e.g., perishables or LNG), using compressors, condensers, and evaporants. HVAC provides ventilation, heating, and air conditioning, crucial for machinery spaces (ventilation) and accommodations (comfort).

These tie into cooling and power systems, complying with MARPOL for refrigerant handling.

Control and Monitoring Systems

The Engine Control Room (ECR) is a soundproofed, air-conditioned hub with computer systems for monitoring. Electronic and hydraulic controls manage machinery, providing real-time data on performance. Sensors detect issues, enabling predictive maintenance.

Workshop areas include lathes, drills, and welding equipment for on-site repairs, with spare parts storage.

Fire Suppression and Safety Systems

Firefighting equipment includes extinguishers, hoses, CO2 systems, foam generators, and alarms. These are strategically placed for rapid response in high-risk areas like the engine room.

Hydraulic systems power valves, cranes, and steering, offering precision over steam alternatives.

Potable Water and Desalination Systems

Water makers convert seawater to fresh water via reverse osmosis or distillation, sterilized for safety. They support cooling, drinking, and operations on long voyages.

Interconnections and Maintenance

Systems in the machinery space are highly interdependent. For example, the propulsion system relies on fuel, lubrication, cooling, and compressed air. Power generation supports controls and pumps, while waste management integrates with bilge and ballast for stability.

Maintenance is paramount, involving regular inspections, cleaning, and part replacements. Personnel use protective gear and follow protocols to handle high-heat, noisy environments. Advanced designs incorporate automation for efficiency, reducing human error.

Conclusion

The machinery space embodies the engineering prowess of modern ships, integrating propulsion, power, and auxiliary systems for safe, efficient operations. Its design prioritizes segmentation, safety, and environmental stewardship, ensuring vessels meet global demands. Understanding these elements highlights their role in maritime success, from cargo transport to passenger travel. Proper investment in maintenance and technology sustains this vital area, driving the industry’s future.

Happy Boating!

Share Fish of the Ocean 4K HD Wallpapers with your friends and leave a comment below with your thoughts.

Read What are the duties of watchkeeping in the engine room? until we meet in the next article.