Hybrid/dual fuel propulsion systems towards decarbonization

Explore dual-fuel propulsion systems for sustainable shipping, reducing emissions and ensuring compliance with IMO regulations.

The maritime industry, a cornerstone of global trade, faces mounting pressure to reduce its environmental footprint. Responsible for approximately 3% of global greenhouse gas (GHG) emissions, the sector is under scrutiny to align with international regulations like the International Maritime Organization’s (IMO) MARPOL Annex VI and the upcoming Carbon Intensity Indicator (CII). Dual-fuel propulsion systems, which combine conventional fuels like diesel or heavy fuel oil (HFO) with cleaner alternatives such as liquefied natural gas (LNG), methanol, or hydrogen, have emerged as a pragmatic solution. These systems offer flexibility, reduced emissions, and compliance with stringent environmental standards, positioning them as a critical technology in the journey toward decarbonization. This article delves into the mechanics, benefits, challenges, and future prospects of dual-fuel propulsion systems, with a focus on their role in sustainable shipping.

Understanding Dual-Fuel Propulsion Systems

Dual-fuel propulsion systems are engineered to operate on two distinct fuel types, typically a primary fuel like diesel or HFO and a secondary fuel such as LNG, methanol, or hydrogen. This dual capability allows vessels to switch between fuels or operate in a blended mode, optimizing performance based on operational needs, fuel availability, and regulatory requirements.

How Dual-Fuel Systems Work

Dual-fuel engines are designed with advanced fuel injection and control systems that manage the combustion of two fuel types. The primary components include:

- Dual-Fuel Engines: These engines can combust diesel or HFO alongside an alternative fuel. For instance, in LNG-diesel dual-fuel engines, LNG is injected into the combustion chamber alongside a small amount of diesel as a pilot fuel to initiate combustion.

- Fuel Storage Tanks: Specialized tanks, such as cryogenic tanks for LNG or reinforced tanks for hydrogen, ensure safe storage of alternative fuels. These tanks are equipped with insulation to maintain fuel stability.

- Fuel Supply Systems: Complex piping and delivery systems transport fuels from storage to the engine, maintaining safety and efficiency.

- Control and Automation Systems: Sophisticated digital platforms monitor and adjust fuel mixtures, engine performance, and emissions in real-time to optimize efficiency and ensure compliance with environmental standards.

The system can operate in three modes:

- Diesel Mode: The engine runs solely on diesel or HFO, using the Diesel process where fuel is injected at the end of the compression stroke.

- Gas Mode: The engine operates on a lean air-fuel mixture (e.g., LNG) using the Otto process, with diesel serving as a backup fuel.

- Dual-Fuel Mode: Both fuels are used simultaneously, with the ratio adjusted based on operational conditions.

This flexibility allows vessels to adapt to varying fuel availability, cost fluctuations, and regional regulations, making dual-fuel systems highly versatile.

Key Applications in Maritime and Beyond

Dual-fuel propulsion systems are not limited to maritime applications. They are increasingly utilized across industries due to their adaptability and environmental benefits:

- Maritime Propulsion: LNG carriers, container ships, and cruise vessels use dual-fuel engines to run on boil-off gas from LNG cargo or other liquid fuels. For example, the LNG-powered cruise ship AIDAnova has set a benchmark for sustainable maritime tourism.

- Combined Heat and Power (CHP): In industrial settings, dual-fuel systems generate electricity and heat using natural gas and diesel, improving energy efficiency.

- Heat Pumps: Dual-fuel heat pumps combine electric heat pumps with gas furnaces, offering energy savings in residential and commercial buildings.

Environmental and Economic Benefits

Dual-fuel propulsion systems offer significant advantages, making them a compelling choice for the maritime industry’s decarbonization efforts.

1. Reduced Emissions

By incorporating cleaner fuels like LNG, dual-fuel systems significantly lower emissions of sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter (PM). For example, LNG-powered engines can reduce CO2 emissions by up to 25% compared to HFO. A case study of the CMA CGM Jacques Saadé, an LNG-powered container ship, demonstrates a 25% reduction in CO2 emissions since its commissioning. Additionally, a hybrid propulsion system combining dual-fuel engines with solid oxide fuel cells (SOFC) can reduce NOx by 52%, SOx by 63.7%, and CO2 by 30.4% compared to conventional HFO-based systems, as evidenced by a study on a class A19 container ship.

2. Regulatory Compliance

The IMO’s MARPOL Annex VI and the forthcoming CII regulations set stringent emission limits, particularly in Emission Control Areas (ECAs). Dual-fuel systems enable vessels to meet these standards by switching to cleaner fuels like LNG or methanol, avoiding costly penalties and ensuring operational continuity.

3. Fuel Flexibility and Cost Savings

Dual-fuel systems mitigate risks associated with fuel price volatility and supply disruptions. Operators can switch to the most cost-effective or regionally available fuel, reducing operating expenses (OpEx). For instance, using on-site natural gas in oil and gas applications eliminates the need for diesel transportation and refining, lowering costs. A study on the M/V Al Dahna, a 19,870 TEU container ship, found that a dual-fuel system using diesel and natural gas was the most cost-effective option, with a levelized cost of energy (LCOE) competitive with traditional systems.

4. Enhanced Efficiency

Modern dual-fuel engines achieve thermal efficiencies exceeding 47%, surpassing single-fuel engines. Advanced control systems optimize fuel combustion, reducing fuel consumption and extending engine life. In oil and gas applications, dual-fuel engines maintain diesel-like power density and transient response, ensuring reliable performance under varying loads.

5. Future-Proofing

Dual-fuel systems are adaptable to emerging fuels like hydrogen, ammonia, and bio-LNG, positioning them as a bridge to a zero-emission future. This flexibility ensures long-term compliance with evolving regulations, such as the IMO’s 2050 goal to reduce GHG emissions by 50%.

Case Study: M/V Al Dahna

To illustrate the impact of dual-fuel propulsion, consider the M/V Al Dahna, a class A19 container ship with a capacity of 19,870 TEU. A comparative study evaluated three propulsion systems: a conventional HFO-based mechanical system, a dual-fuel diesel-LNG system, and a hybrid system integrating SOFC and dual-fuel engines.

| Propulsion System | CO2 Emissions (ton/TEU) | NOx Reduction (%) | SOx Reduction (%) | LCOE ($/kWh) | Cost-Effectiveness ($/ton) |

|---|---|---|---|---|---|

| Conventional (HFO) | 8.512 | 0 | 0 | 0.09 | 25.0 |

| Dual-Fuel (Diesel-LNG) | 7.021 | 30 | 40 | 0.08 | 22.5 |

| Hybrid (SOFC + Dual) | 5.926 | 52 | 63.7 | 0.07 | 21.9 |

The hybrid system emerged as the most environmentally effective, reducing CO2 emissions to 5.926 ton/TEU. The dual-fuel system, however, was the most cost-effective, balancing lower emissions with competitive costs. These findings highlight the trade-offs between environmental performance and economic viability, with hybrid systems offering superior long-term benefits for regulatory compliance.

Challenges and Limitations

Despite their advantages, dual-fuel propulsion systems face several hurdles that must be addressed for widespread adoption.

1. Methane Slip

LNG-powered engines can release unburned methane, a potent GHG with a global warming potential 25 times higher than CO2. Mitigating methane slip requires advanced combustion technologies, such as high-pressure direct injection (HPDI), which achieves near-complete combustion.

2. High Capital Costs

The installation of dual-fuel systems involves significant upfront costs due to complex engine designs, specialized fuel storage, and retrofitting requirements. For example, retrofitting an existing vessel with LNG infrastructure can cost millions, posing a barrier for smaller operators.

3. Fuel Infrastructure

The global availability of alternative fuels like LNG, methanol, and hydrogen is limited. Expanding bunkering infrastructure requires substantial investment and international coordination, particularly for long-haul routes.

4. Operational Complexity

Dual-fuel systems demand advanced crew training and maintenance expertise due to their sophisticated control systems and fuel management requirements. This increases operational costs and necessitates investment in workforce development.

Technological Innovations

Ongoing advancements are addressing these challenges, enhancing the feasibility of dual-fuel systems:

- High-Pressure Direct Injection (HPDI): HPDI technology minimizes methane slip by optimizing LNG combustion, improving environmental performance.

- Hybrid Propulsion: Combining dual-fuel engines with battery-electric systems enables zero-emission port operations and reduces fuel consumption during low-load conditions.

- Digital Twin Platforms: These platforms simulate engine performance in real-time, enabling predictive maintenance and optimizing fuel efficiency. For instance, digital twins can reduce downtime by 20% through early detection of maintenance needs.

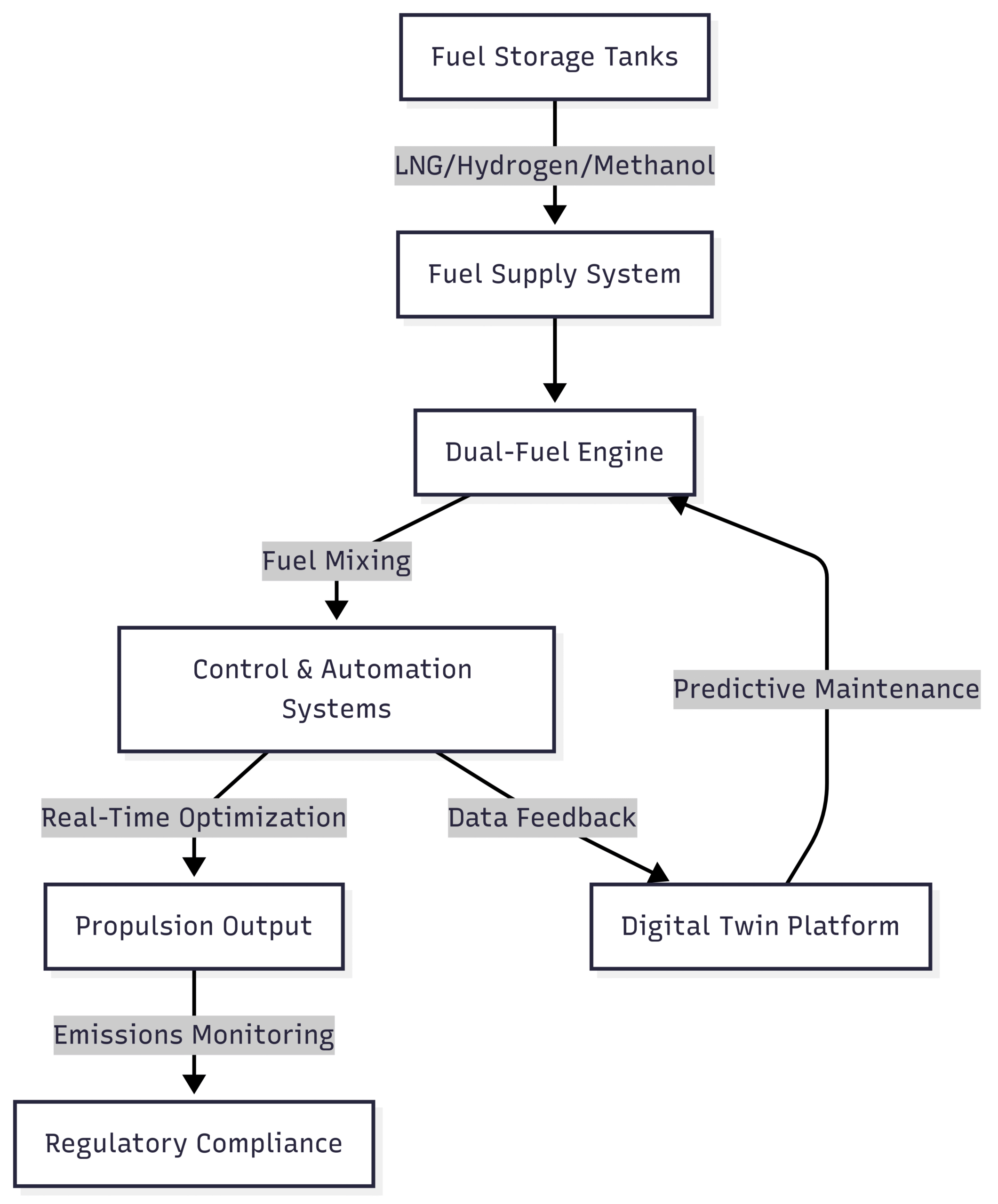

Chart: Dual-Fuel System Workflow

This chart illustrates the workflow of a dual-fuel propulsion system, highlighting the integration of fuel storage, supply, engine operation, and digital monitoring for optimal performance and compliance.

Industry Applications

Dual-fuel propulsion systems are transforming various maritime sectors:

- Cruise Ships: Carnival Corporation’s AIDAnova, the first LNG-powered cruise ship, reduces SOx emissions to near zero, enhancing sustainability in tourism.

- Container Ships: Maersk’s methanol-powered vessels aim for net-zero emissions by 2050, aligning with corporate sustainability goals.

- Tankers: LNG-powered tankers reduce carbon footprints while ensuring reliable energy transport for oil and gas companies.

Future Prospects and Policy Implications

The maritime industry’s transition to a zero-emission future hinges on scalable solutions like dual-fuel propulsion. Key trends shaping their adoption include:

- IMO 2050 Goals: The IMO’s target to halve GHG emissions by 2050 will drive investment in dual-fuel technologies, particularly for fuels like hydrogen and ammonia.

- Fuel Innovation: Emerging fuels such as bio-LNG and green ammonia offer carbon-neutral alternatives, supported by advancements in production and storage.

- Global Collaboration: Partnerships between governments, shipping companies, and fuel suppliers are critical to expanding bunkering infrastructure and standardizing safety regulations.

Economic Considerations

While dual-fuel systems require high initial investments, their long-term cost-effectiveness is evident. For instance, the hybrid propulsion system’s LCOE of 0.07 $/kWh is lower than conventional systems, and fuel savings from using on-site natural gas can offset capital costs over time. Retrofitting existing engines with dual-fuel kits further reduces costs, making the technology accessible to a broader range of operators.

Conclusion

Dual-fuel propulsion systems represent a pivotal step toward decarbonizing the maritime industry. By offering fuel flexibility, reduced emissions, and compliance with stringent regulations, these systems balance environmental and economic priorities. While challenges like methane slip, high costs, and limited infrastructure persist, technological innovations such as HPDI, hybrid systems, and digital twins are paving the way for broader adoption. As the industry navigates toward the IMO’s 2050 goals, dual-fuel propulsion systems will serve as a critical bridge, ensuring sustainable and efficient global trade.

Happy Boating!

Share Hybrid/dual fuel propulsion systems towards decarbonization with your friends and leave a comment below with your thoughts.

Read PSC focus on nox technical files and machinery components until we meet in the next article.