How to Troubleshoot Marine Engineering Problems?

Learn expert techniques to troubleshoot marine engineering problems, ensuring ship safety and efficiency. Master engine room system diagnostics.

Marine engineering is the backbone of maritime operations, ensuring ships navigate the world’s oceans safely and efficiently. The engine room, often described as the heart of a vessel, houses complex systems that power propulsion, electrical supply, and onboard operations. However, these systems are prone to malfunctions, which can jeopardize safety, increase costs, and disrupt global trade. Effective troubleshooting is critical to diagnose and resolve issues swiftly, maintaining vessel performance and compliance with stringent maritime regulations.

This comprehensive guide explores systematic troubleshooting techniques for marine engine room systems, including cooling, lubrication, and electrical systems. Aimed at marine engineers, students, and maritime professionals, it provides actionable insights to enhance ship safety and operational efficiency.

Understanding Marine Engine Room Systems

The engine room is a hub of interconnected systems, each performing critical functions. A deep understanding of these systems is the foundation of effective troubleshooting. Key systems include:

- Main Engine Jacket Cooling Water System: Circulates coolant to regulate engine temperature, preventing overheating.

- Cylinder Lubrication System: Supplies lubricant to engine cylinders, reducing friction and wear.

- Lube Oil System: Lubricates moving parts, removes contaminants, and maintains system integrity.

- Sea Water Cooling System: Uses seawater to dissipate heat from various systems, ensuring optimal performance.

- Electrical Supply and Emergency Generator Systems: Provide primary and backup power for propulsion and onboard operations.

Familiarity with system design, operation, and interconnections is essential. Engineers must also have access to up-to-date documentation, such as manuals, schematics, and maintenance logs, to diagnose issues accurately.

The Importance of Systematic Troubleshooting

Troubleshooting marine engineering problems requires a structured approach to identify root causes and implement effective solutions. A systematic process minimizes downtime, reduces repair costs, and enhances safety. The following steps outline a proven methodology:

- Understand the System: Gain comprehensive knowledge of the affected system, including its components and operational parameters.

- Identify Symptoms: Observe and document symptoms, such as unusual noises, vibrations, or parameter deviations.

- Formulate Hypotheses: Develop potential causes based on observations and system knowledge.

- Test Solutions: Conduct experiments, simulations, or measurements to validate hypotheses.

- Analyze Results: Compare test outcomes with hypotheses, refining the approach if necessary.

- Document and Communicate: Record findings and share updates with relevant stakeholders.

This scientific method ensures logical progression from problem identification to resolution, avoiding hasty conclusions that could exacerbate issues.

Key Troubleshooting Techniques

Marine engineers employ various techniques to diagnose and resolve problems. These methods leverage observation, data analysis, and specialized tools to pinpoint issues.

1. Visual Inspection

Regular inspections identify visible signs of wear, leaks, corrosion, or misalignment. For example, checking for coolant leaks in the jacket cooling system or oil contamination in the lube oil system can prevent major failures.

2. Monitoring Operational Parameters

Tracking parameters like temperature, pressure, and flow rates is critical. Anomalies, such as elevated engine temperatures or fluctuating oil pressure, indicate potential problems. Regular comparison with baseline data helps detect deviations early.

3. Diagnostic Tools

Advanced tools enhance diagnostic accuracy:

- Multimeters: Measure electrical parameters to diagnose generator or motor faults.

- Vibration Analyzers: Detect mechanical imbalances in rotating equipment.

- Thermal Cameras: Identify overheating components or insulation failures.

- Pressure Gauges: Monitor system pressures to detect blockages or leaks.

4. Maintenance Records Review

Analyzing historical maintenance logs reveals recurring issues and effective solutions. For instance, frequent pump failures in the seawater cooling system may indicate inadequate strainer cleaning.

5. Root Cause Analysis (RCA)

RCA identifies underlying causes of problems to prevent recurrence. Techniques like the “5 Whys” or fishbone diagrams systematically explore contributing factors.

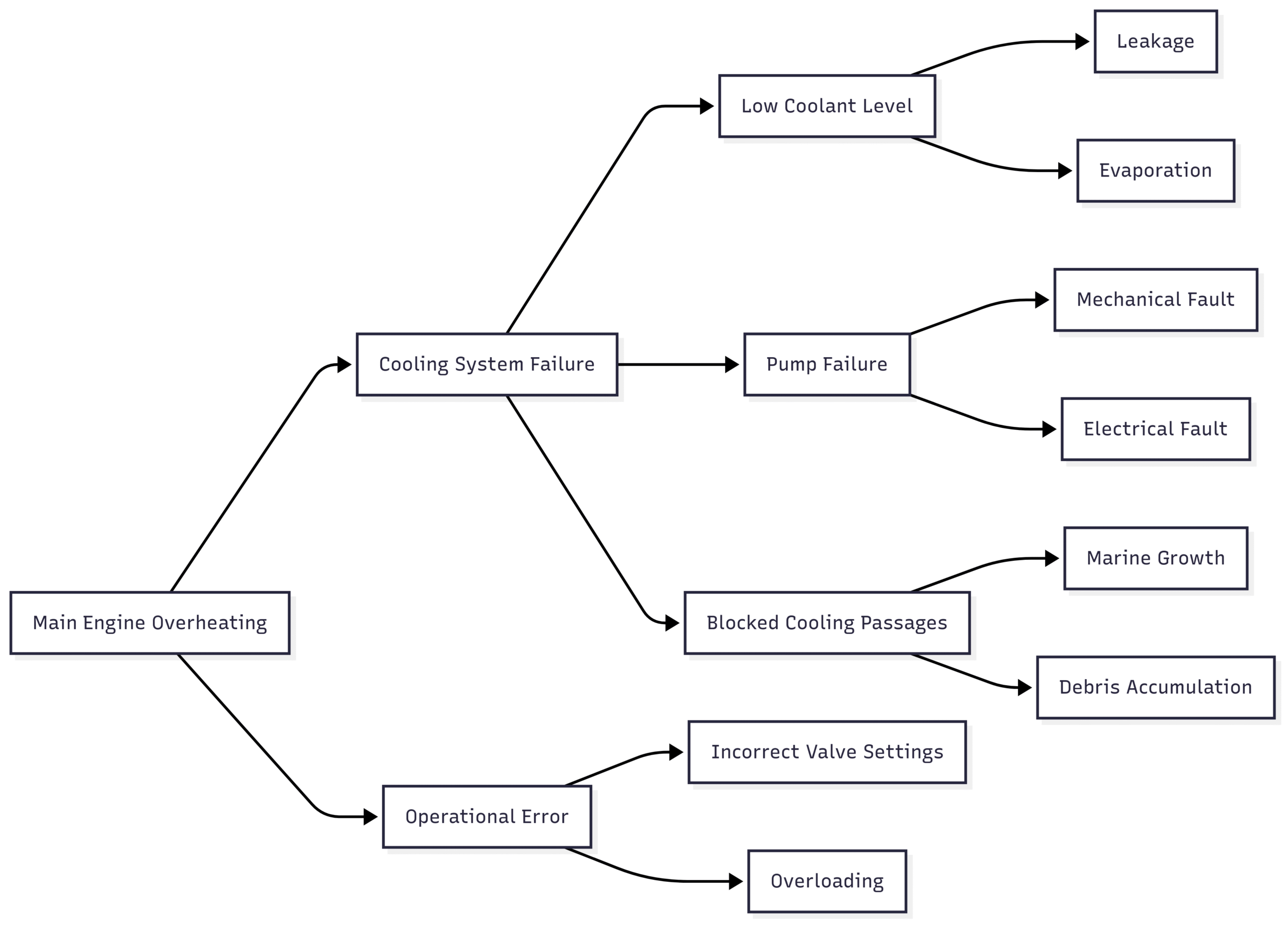

6. Fault Tree Analysis (FTA)

FTA maps potential causes of system failures, helping engineers prioritize hypotheses. Below is a simplified fault tree for a main engine overheating issue:

7. Failure Mode and Effects Analysis (FMEA)

FMEA evaluates potential failure modes and their impacts, prioritizing risks based on severity and likelihood. This proactive approach is particularly useful for critical systems like emergency generators.

Troubleshooting Specific Systems

Each engine room system presents unique challenges. Below, we explore common issues and troubleshooting steps for key systems, ensuring engineers can address problems effectively.

Main Engine Jacket Cooling Water System

The jacket cooling system prevents engine overheating by circulating coolant. Common issues include:

- Overheating: Caused by coolant leaks, pump failures, or blockages.

- Corrosion: Due to improper coolant chemistry.

- Low Coolant Levels: Resulting from leaks or evaporation.

Troubleshooting Steps:

- Inspect coolant levels and check for leaks in pipes or seals.

- Test pump functionality, ensuring no obstructions or mechanical faults.

- Clean cooling passages to remove blockages or scale buildup.

- Analyze coolant chemistry to prevent corrosion.

Table 1: Common Jacket Cooling System Issues and Solutions

| Issue | Symptoms | Solutions |

|---|---|---|

| Overheating | High engine temperature | Check coolant, inspect pumps |

| Corrosion | Rusty coolant, pitting | Adjust coolant pH, flush system |

| Low Coolant Levels | Low pressure, alarms | Repair leaks, replenish coolant |

Cylinder Lubrication System

This system reduces friction in engine cylinders, extending component life. Issues include:

- Inadequate Lubrication: Leading to increased wear and scoring.

- Contaminated Lubricant: Causing corrosion or sludge buildup.

- Pump Failures: Reducing lubricant delivery.

Troubleshooting Steps:

- Verify lubricant quality through oil analysis, replacing contaminated oil.

- Inspect lubrication lines for blockages or leaks.

- Test pump efficiency and repair or replace faulty units.

Lube Oil System

The lube oil system lubricates moving parts and removes contaminants. Common problems include:

- Oil Pressure Fluctuations: Indicating pump issues or blockages.

- Contamination: With water, fuel, or debris.

- Filter Clogging: Reducing oil flow.

Troubleshooting Steps:

- Monitor oil pressure and investigate anomalies.

- Conduct oil analysis to detect contaminants, replacing oil if necessary.

- Replace clogged filters and address contamination sources.

Sea Water Cooling System

This system uses seawater to cool engine components. Issues include:

- Reduced Efficiency: Due to marine growth or scale buildup.

- Pump Failures: Causing inadequate water flow.

- Corrosion: From saltwater exposure.

Troubleshooting Steps:

- Clean sea strainers and heat exchangers to remove marine growth.

- Inspect and maintain pumps, ensuring optimal performance.

- Apply anti-fouling coatings to prevent corrosion.

Electrical Supply and Emergency Generator Systems

Reliable power is critical for ship operations. Common issues include:

- Generator Failures: Due to mechanical or electrical faults.

- Faulty Wiring: Causing short circuits or outages.

- Battery Issues: Reducing emergency power reliability.

Troubleshooting Steps:

- Perform load testing on generators to ensure reliability.

- Inspect wiring for wear, corrosion, or loose connections.

- Test battery health and replace faulty units.

Table 2: Electrical System Troubleshooting Checklist

| Component | Check | Action |

|---|---|---|

| Generator | Load test performance | Repair or replace faulty units |

| Wiring | Visual inspection for damage | Repair or replace damaged wiring |

| Battery | Voltage and capacity test | Replace if below specifications |

Advanced Troubleshooting Strategies

For complex or recurring issues, advanced strategies enhance diagnostic precision:

Predictive Maintenance

Using data analytics and sensors, predictive maintenance anticipates failures before they occur. For example, vibration sensors on pumps can detect imbalances, prompting preemptive repairs.

Training and Simulation

Simulators train engineers to handle emergencies, such as generator failures or cooling system breakdowns, in a controlled environment. Regular training ensures readiness for real-world scenarios.

Collaboration and Knowledge Sharing

Encouraging open communication among crew members fosters collective problem-solving. Sharing troubleshooting experiences through documented case studies enhances team expertise.

Safety Considerations

Safety is paramount during troubleshooting, given the hazardous engine room environment. Key safety practices include:

- Personal Protective Equipment (PPE): Wear gloves, goggles, and helmets to protect against hazards.

- Lockout-Tagout Procedures: Isolate systems before maintenance to prevent accidental startups.

- Confined Space Protocols: Ensure proper ventilation and monitoring in enclosed areas.

- Compliance with IMO Guidelines: Adhere to International Maritime Organization standards for engine room safety.

Documentation and Compliance

Accurate documentation is critical for regulatory compliance and operational efficiency. Engineers should maintain detailed records of:

- Maintenance Activities: Including dates, actions, and outcomes.

- Troubleshooting Procedures: Documenting symptoms, hypotheses, and solutions.

- System Performance: Tracking parameters to identify trends.

Compliance with maritime regulations, such as those from the IMO and DNV, ensures vessels meet safety and environmental standards. Regular audits and inspections verify adherence.

Challenges in Marine Engineering Troubleshooting

Marine engineers face several challenges that complicate troubleshooting:

- Corrosion: Saltwater accelerates corrosion, damaging components like heat exchangers.

- Equipment Failure: High operational demands cause premature wear in engines and pumps.

- Environmental Regulations: Strict emissions and waste management standards require advanced solutions.

- Supply Chain Disruptions: Delays in spare parts delivery can extend downtime.

Addressing these challenges requires proactive maintenance, innovative technologies, and robust supply chain management.

Continuous Learning and Professional Development

Marine engineering is a dynamic field, with rapid advancements in automation, digitalization, and environmental technologies. Engineers must stay updated through:

- Training Programs: Covering new systems and troubleshooting techniques.

- Industry Publications: Such as Marine Insight and Wärtsilä’s technical guides.

- Professional Networks: Collaborating with peers to share knowledge.

Continuous learning enhances troubleshooting skills, ensuring engineers can tackle emerging challenges.

Conclusion

Troubleshooting marine engineering problems is a critical skill for ensuring ship safety, efficiency, and compliance. By understanding engine room systems, employing systematic techniques, and leveraging advanced tools, engineers can diagnose and resolve issues effectively. Prioritizing safety, documentation, and continuous learning further enhances troubleshooting success.

Whether addressing coolant leaks, generator failures, or lubrication issues, a structured approach minimizes downtime and optimizes performance. As global trade grows and environmental regulations tighten, mastering these techniques is essential for marine engineers navigating the complexities of modern maritime operations.

FAQs

What are common signs of engine room system failures?

How often should maintenance checks be performed?

What tools are essential for troubleshooting?

How does predictive maintenance benefit marine operations?

References and Further Reading

- Marine Engineering Troubleshooting Guide (Marine Insight)

- Electrical Systems for Marine Engineers (Routledge)

- IMO Engine Room Safety Guidelines (International Maritime Organization)

- Practical Marine Electrical Knowledge (Witherby Seamanship International)

- Marine Lubrication Systems Handbook (Technical Guide)

- Cooling System Maintenance for Marine Engines (Wärtsilä)

- Predictive Maintenance in Marine Engineering (SKF)

- Emergency Generator Testing Procedures (DNV)

Explore further resources like Troubleshooting For Marine Engineers (Amazon) and Marine Electrical Systems Textbook for in-depth knowledge.

Happy Boating!

Share How to Troubleshoot Marine Engineering Problems? with your friends and leave a comment below with your thoughts.

Read Complete Guide for Navigating Modern Shipboard Systems until we meet in the next article.