How to Synchronize Generators on a Ship?

Learn how to synchronize generators on a ship for stable power supply. Detailed guide on methods, parameters, and load sharing.

Synchronizing generators on a ship is a critical process to ensure a stable and reliable power supply for maritime operations. Ships rely heavily on electrical systems to power navigation, propulsion, communication, and other essential functions. Synchronization involves matching the voltage, frequency, phase angle, and phase sequence of an incoming generator with the running generator(s) or the ship’s electrical busbars to connect them in parallel. This process enables load sharing, enhances system reliability, and prevents damage to equipment. Improper synchronization can lead to power surges, equipment damage, or system instability, making it a vital skill for marine engineers.

This article provides an in-depth exploration of generator synchronization on ships, covering its importance, key parameters, methods, and step-by-step procedures. It also delves into load sharing, the structure of synchronous generators, and practical considerations for achieving seamless operation. By the end, you’ll have a thorough understanding of how to synchronize generators effectively and maintain a robust power system on board.

Importance of Generator Synchronization

Generator synchronization is essential for several reasons, each contributing to the safe and efficient operation of a ship’s electrical system:

- System Stability: Synchronization ensures that the incoming generator integrates seamlessly with the running system, preventing voltage or frequency fluctuations that could disrupt power supply. A stable power system is critical for maintaining the operation of critical systems like navigation and propulsion.

- Load Sharing: By connecting multiple generators in parallel, synchronization allows them to share the electrical load. This prevents any single generator from being overloaded, improving efficiency and extending equipment lifespan.

- Equipment Protection: Proper synchronization minimizes current surges and mechanical stresses that could damage generators, switchgear, or other electrical components. This is particularly important in the harsh marine environment, where equipment reliability is paramount.

- Operational Continuity: Ships often operate far from shore, where power interruptions can be catastrophic. Synchronization ensures a continuous power supply, even when switching between generators for maintenance or load management.

- Fuel Efficiency: When generators share loads optimally, they operate closer to their rated capacity, improving fuel efficiency and reducing operational costs.

Key Parameters for Synchronization

To synchronize generators successfully, four critical parameters must be matched between the incoming generator and the running system (busbars or other generators):

- Frequency: The frequency of the incoming generator must match that of the running system. On ships, the standard frequency is typically 50 Hz or 60 Hz, depending on the region or design. Mismatched frequencies can cause rapid acceleration or deceleration of the generator’s prime mover, leading to mechanical stress.

- Voltage: The voltage output of the incoming generator must equal the busbar voltage. Significant differences can result in reactive power flow, which may overload the system or cause instability.

- Phase Sequence: The phase sequence (the order in which the three phases alternate) of the incoming generator must match that of the running system. Incorrect phase sequences can cause short circuits or equipment damage, especially during initial installation or maintenance.

- Phase Angle: The phase angle between the incoming generator and the running system should be as close to zero as possible at the moment of connection. A large phase angle difference can cause a sudden surge in current, damaging the generator or other equipment.

The table below summarizes these parameters and their significance:

| Parameter | Description | Impact of Mismatch |

|---|---|---|

| Frequency | Must match the busbar frequency (e.g., 50 Hz or 60 Hz). | Mechanical stress, transient torque. |

| Voltage | Must equal the busbar voltage (e.g., 440 V). | Reactive power flow, system instability. |

| Phase Sequence | Must align with the busbar’s phase order (e.g., R-Y-B). | Short circuits, equipment damage. |

| Phase Angle | Should be near zero at connection. | Current surges, mechanical damage. |

Structure of a Synchronous Generator

A synchronous generator, commonly used on ships, consists of two main components: the rotor and the stator.

- Rotor: The rotor is an electromagnet that rotates within the stator, driven by a prime mover (typically a diesel engine on ships). The rotor’s magnetic field is created by an exciter current, which induces voltage in the stator windings.

- Stator: The stator contains three stationary coils (phase coils) that produce a three-phase alternating voltage as the rotor’s magnetic field rotates. The stator windings require magnetization to generate current, as no voltage is induced without a magnetic field.

The synchronous speed of the generator, which determines its frequency, is calculated using the formula:

Ns = (120 * f) / P

Where:

- Ns: Synchronous speed (in RPM)

- f: Frequency (in Hz)

- P: Number of poles

- 120: Constant to convert frequency and pole pairs to RPM

For example, a generator with 4 poles operating at 60 Hz has a synchronous speed of:

Ns = (120 * 60) / 4 = 1800 RPM

This formula is critical for setting the correct speed of the prime mover during synchronization.

Synchronization Methods

Two primary methods are used to synchronize generators on a ship: the synchroscope method (normal) and the three-bulb method (emergency). Each method has its advantages and limitations, as outlined below.

1. Synchroscope Method

The synchroscope is a specialized instrument that visually indicates the phase difference between the incoming generator and the busbars. It consists of a small motor with coils connected across two phases of the incoming generator and the busbars. The synchroscope’s rotor rotates clockwise if the incoming generator’s frequency is higher than the busbars and anticlockwise if it’s lower. The goal is to align the phase angle so the synchroscope pointer is near the 12 o’clock position, indicating minimal phase difference.

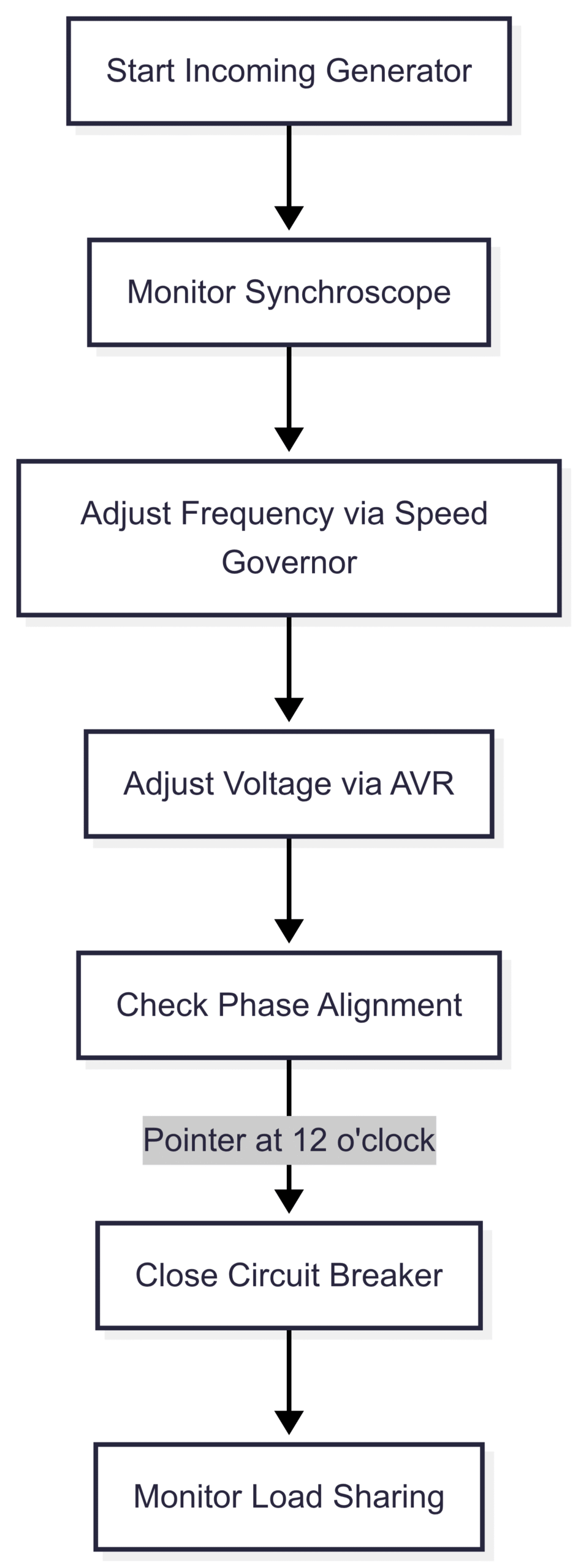

Steps for Synchroscope Synchronization:

- Start the incoming generator and bring it to a speed close to the busbar frequency.

- Use the synchroscope to monitor the phase difference.

- Adjust the generator’s speed using the prime mover’s speed governor to align the frequency.

- Adjust the voltage using the Automatic Voltage Regulator (AVR) to match the busbar voltage.

- When the synchroscope pointer approaches 12 o’clock (indicating phase alignment), close the circuit breaker to connect the generator to the busbars.

Pros:

- High accuracy in phase alignment.

- Reduces operator judgment errors.

- Faster and more reliable than manual methods.

Cons:

- More expensive than lamps.

- Does not indicate phase sequence, requiring separate verification.

- Requires maintenance and calibration.

Diagram: Synchroscope Method Workflow

2. Three-Bulb Method (Emergency)

The three-bulb method is used when a synchroscope is unavailable or malfunctioning. It involves connecting three lamps between the three phases of the incoming generator and the busbars. The brightness of the lamps indicates the phase difference:

- When the phases are aligned, two lamps are bright, and one is dark.

- The sequence of bright and dark lamps indicates whether the incoming generator is running faster (clockwise sequence) or slower (anticlockwise sequence).

Steps for Three-Bulb Synchronization:

- Connect three lamps between the incoming generator’s phases and the busbars.

- Start the incoming generator and adjust its speed to approach the busbar frequency.

- Observe the lamps’ brightness pattern to determine frequency alignment.

- Adjust the prime mover’s speed to minimize the flickering rate, indicating frequency matching.

- When two lamps are bright and one is dark, close the circuit breaker to synchronize.

Pros:

- Simple and cost-effective.

- Can be used in emergencies when a synchroscope fails.

Cons:

- Less accurate than the synchroscope method.

- Relies on operator judgment, increasing the risk of error.

- Does not provide precise frequency information.

3. Two Bright, One Dark Lamp Method

A variation of the three-bulb method, this approach connects the lamps differently to better indicate whether the incoming generator’s frequency is higher or lower than the busbars. The lamps (L1, L2, L3) are wired such that L2 is connected across the middle line, and L1 and L3 are transposed. The sequence of bright and dark lamps (e.g., L1-L2-L3 or L1-L3-L2) indicates whether the generator’s frequency needs to be increased or decreased.

Steps:

- Connect the lamps as described.

- Start the generator and monitor the lamp sequence.

- Adjust the prime mover’s speed to reduce flickering until L1 and L3 are equally bright and L2 is dark.

- Close the circuit breaker to synchronize.

Pros:

- Provides clearer indication of frequency mismatch direction.

- Simple to implement in emergencies.

Cons:

- Cannot verify phase sequence.

- Less precise than the synchroscope method.

Step-by-Step Synchronization Process

The synchronization process involves precise adjustments to ensure all parameters are aligned. Below is a detailed step-by-step guide applicable to both methods:

- Start the Incoming Generator:

- Start the generator and bring it to a speed close to the synchronous speed, corresponding to the busbar frequency (e.g., 1800 RPM for a 4-pole, 60 Hz system).

- Monitor Parameters:

- Use a synchroscope or three-bulb setup to monitor frequency and phase alignment.

- Check voltage using a voltmeter and phase sequence using a phase sequence indicator.

- Adjust Frequency and Voltage:

- Use the speed governor to adjust the prime mover’s speed, matching the frequency to the busbars.

- Adjust the AVR to align the generator’s voltage with the busbar voltage.

- Align Phase Angle:

- For the synchroscope method, wait for the pointer to approach 12 o’clock.

- For the three-bulb method, wait for two lamps to be bright and one dark, indicating phase alignment.

- Close the Circuit Breaker:

- Close the breaker when the phase angle is near zero to connect the generator to the busbars.

- For the synchroscope, close slightly before 12 o’clock to account for breaker closing time.

- Monitor and Adjust Load Sharing:

- After synchronization, monitor the load distribution using load sensors or a Load Sharing Controller.

- Adjust the generator’s output to ensure even load sharing among all running generators.

Load Sharing in Ship Generators

Once synchronized, generators must share the electrical load to operate efficiently and reliably. Load sharing involves distributing the electrical demand evenly among all connected generators, preventing overloading and optimizing performance.

Functions of Load Sharing

- Optimal Utilization: Load sharing ensures each generator operates at a high percentage of its rated capacity, improving fuel efficiency and reducing wear.

- Redundancy: If one generator fails, the remaining units can take on the load, ensuring continuous power supply.

- Efficiency: Even load distribution reduces fuel consumption and operational costs by avoiding underloading or overloading.

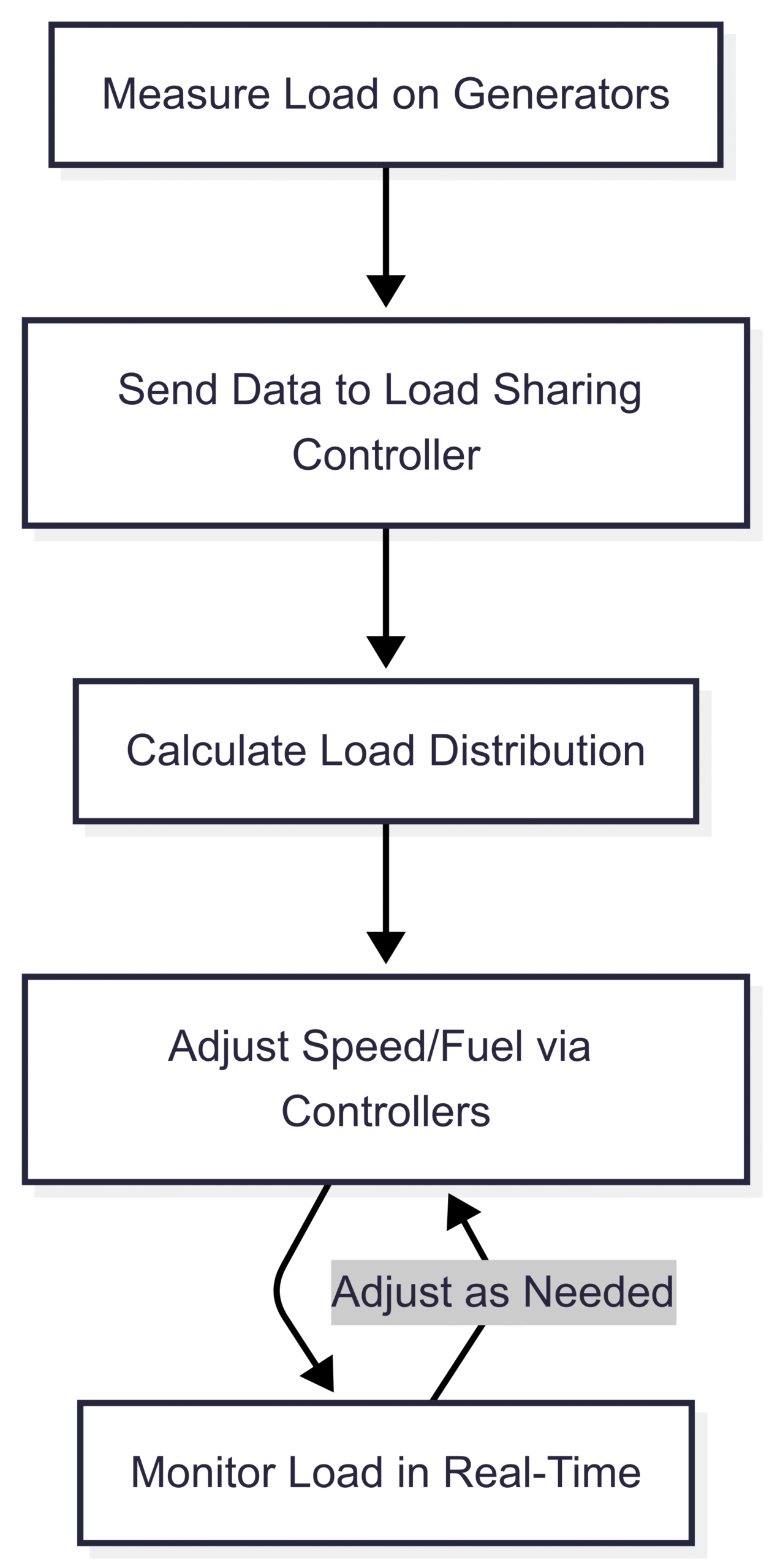

Operation of Load Sharing

- Load Measurement: Load sensors or current transformers measure the electrical load on each generator in real-time.

- Load Sharing Calculation: A Load Sharing Controller compares the measured load to the desired distribution and calculates necessary adjustments.

- Load Adjustment: The controller sends commands to the speed governors or fuel control systems to adjust each generator’s output, balancing the load.

- Continuous Monitoring: The system continuously monitors and adjusts load sharing to account for changes in demand or operating conditions.

Diagram: Load Sharing Process

Importance of Synchronization and Load Sharing

Synchronization and load sharing are critical for the following reasons:

- System Reliability: Synchronized generators with effective load sharing provide redundancy, ensuring power availability even during generator failures or maintenance.

- Operational Efficiency: Load sharing optimizes generator performance, reducing fuel consumption and operating costs.

- System Stability: Proper synchronization prevents voltage and frequency imbalances, maintaining a stable power supply.

- Maintenance Flexibility: Load sharing allows one generator to be taken offline for maintenance without disrupting the power supply, as the remaining generators compensate.

Practical Considerations

- Equipment Specifications: Marine generators typically operate at 440 V and 50/60 Hz, with power ratings ranging from 100 kW to several MW, depending on the ship’s size. For example, a typical container ship may use 4-pole synchronous generators with a rated output of 1–2 MW.

- Cost Considerations: Synchroscopes cost approximately $500–$2,000, depending on the model and features. Lamps for the three-bulb method are significantly cheaper, costing $10–$50. However, the synchroscope’s accuracy justifies its cost for regular use.

- Safety Protocols: Always verify phase sequence during initial setup or after maintenance to prevent short circuits. Operators should wear insulated gloves and follow lockout-tagout procedures when working on electrical systems.

- Training: Marine engineers must be trained in both synchronization methods, as emergencies may require the three-bulb method despite its limitations.

Conclusion

Synchronizing generators on a ship is a complex but essential process to ensure a stable, reliable, and efficient power supply. By matching frequency, voltage, phase sequence, and phase angle, marine engineers can connect generators in parallel, enabling load sharing and system redundancy. The synchroscope method offers precision and reliability, while the three-bulb method serves as a cost-effective backup in emergencies. Load sharing complements synchronization by optimizing generator performance and enhancing system reliability.

By following the detailed steps and understanding the underlying principles outlined in this guide, marine engineers can master generator synchronization, ensuring safe and efficient operation of a ship’s electrical system. Whether navigating open seas or docked at port, a well-synchronized power system is the backbone of modern maritime operations.

Happy Boating!

Share How to Synchronize Generators on a Ship? with your friends and leave a comment below with your thoughts.

Read Essential Curriculum for Ship Engineering Officers until we meet in the next article.