How to keep your boiler and cooling systems in top condition

Learn how to maintain marine boiler and cooling systems for optimal performance, preventing corrosion and scaling with expert tips and testing methods.

Marine boiler and cooling systems are the backbone of a vessel’s propulsion and auxiliary operations, providing steam and heat exchange critical for power generation, heating, and other functions. However, their performance hinges on proper maintenance, particularly the quality of water used within these systems. Poor water quality can lead to corrosion, scaling, foaming, and carryover, causing inefficiencies, costly repairs, and even catastrophic failures. This comprehensive guide explores the essential practices for maintaining marine boiler and cooling systems, including water quality management, testing procedures, chemical treatments, and blowdown methods, ensuring efficiency, safety, and compliance with regulations like the Carbon Intensity Index (CII) and International Safety Management (ISM) Code.

The Critical Role of Water Quality in Marine Systems

Marine boilers and cooling systems operate in demanding environments, where water quality directly impacts performance, safety, and longevity. Impurities such as dissolved oxygen, chlorides, calcium, magnesium, and total dissolved solids (TDS) can cause significant issues:

- Corrosion: Dissolved oxygen and acidic conditions (pH below 7) can corrode boiler steel, leading to pitting and structural weakening. High chloride levels, often from seawater contamination, accelerate oxidation, posing safety risks, especially in high-pressure boilers.

- Scaling/Deposition: Calcium and magnesium salts form insulating scale on boiler surfaces, reducing heat transfer efficiency and causing overheating, which can lead to tube ruptures. In cooling systems, scaling in plate heat exchangers (PHEs) impairs engine performance and fuel efficiency.

- Foaming and Carryover: Excessive TDS or alkalinity causes foaming, allowing water droplets to carry over into steam lines, depositing solids in turbines and condensers, which reduces efficiency and damages equipment.

- Biofouling: In cooling systems, operating temperatures of 20–45°C foster microbial growth, leading to biofouling, reduced heat transfer, odors, and potential health risks.

Failure to address these issues can result in significant financial losses, with repair and downtime costs potentially exceeding USD 50,000 per day, alongside regulatory non-compliance and safety hazards. For instance, a class surveyor may declare a vessel unseaworthy during dry docking if boiler or cooling system issues are detected, delaying operations.

Key Water Quality Parameters

To maintain optimal performance, several water quality parameters must be monitored and controlled:

| Parameter | Ideal Range | Purpose |

|---|---|---|

| pH | 9.5–11.5 (boiler), 8.5–9.5 (feedwater) | Prevents acidic corrosion and caustic embrittlement. |

| Alkalinity | 100–250 ppm (as CaCO₃) | Maintains protective film, prevents scaling, and controls corrosion. |

| Total Dissolved Solids (TDS) | <1500 ppm | Prevents foaming and carryover. |

| Dissolved Oxygen | <0.1 ppm | Minimizes pitting corrosion using oxygen scavengers. |

| Hardness | <2 ppm | Prevents scale formation from calcium/magnesium. |

| Chlorides | <50 ppm (cooling), <200 ppm (boiler) | Indicates seawater contamination, prevents corrosion. |

| Phosphate | 20–50 ppm | Binds with hardness ions to prevent scaling. |

| Hydrazine | 0.1–0.2 ppm | Removes dissolved oxygen to prevent corrosion. |

| Nitrite (Cooling) | 700–2400 ppm (as NO₂) | Inhibits corrosion in cooling systems. |

| Silica | <150 ppm | Prevents hard deposits on turbine blades. |

These ranges ensure efficient heat transfer, prevent corrosion, and comply with manufacturer and regulatory guidelines.

Water Treatment Strategies

Effective water treatment involves external and internal methods to maintain these parameters:

External Treatment

- Feedwater Quality: Use distilled water to minimize impurities. Fresh water generators on vessels produce high-purity water, reducing hardness and chloride content.

- Softening: Zeolite softeners exchange calcium and magnesium ions for sodium, reducing hardness. Regeneration with sodium chloride maintains softener efficiency.

- Deaeration: Removes dissolved oxygen and gases like carbon dioxide to prevent corrosion. Deaerators heat feedwater to release gases, which are vented out.

Internal Treatment

- Chemical Dosing: Chemicals like oxygen scavengers (sodium sulfite, hydrazine), alkalinity builders (sodium hydroxide, sodium carbonate), and phosphates are dosed based on test results to control pH, oxygen, and scaling.

- Sludge Conditioners: Polymers disperse solids, preventing sludge buildup.

- Anti-Foaming Agents: Reduce foaming to prevent carryover, using agents like polymerized esters.

Blowdown Procedures

Blowdown removes impurities and controls TDS levels:

- Bottom Blowdown: Removes sludge and sediments from the boiler’s bottom, typically performed weekly in port.

- Surface Blowdown: Continuously or periodically removes dissolved solids near the water surface.

- Procedure:

- Test water parameters to determine blowdown necessity.

- Open blowdown valve slowly to avoid thermal shock.

- Maintain steady flow for a few minutes.

- Close valve and check water levels, refilling if needed.

- Re-test water to ensure parameters are balanced.

Incorrect blowdown can cause thermal shock, waste energy, or fail to remove impurities, leading to scaling and corrosion. Documentation in the Oil Record Book (ORB) is critical for compliance.

Testing Boiler and Cooling Water

Regular testing ensures water quality remains within safe limits. Onboard test kits, such as Unitor’s Spectrapak 309 (cooling) and 310 (boiler), provide reliable results. Periodic laboratory analysis complements onboard testing for detailed profiling.

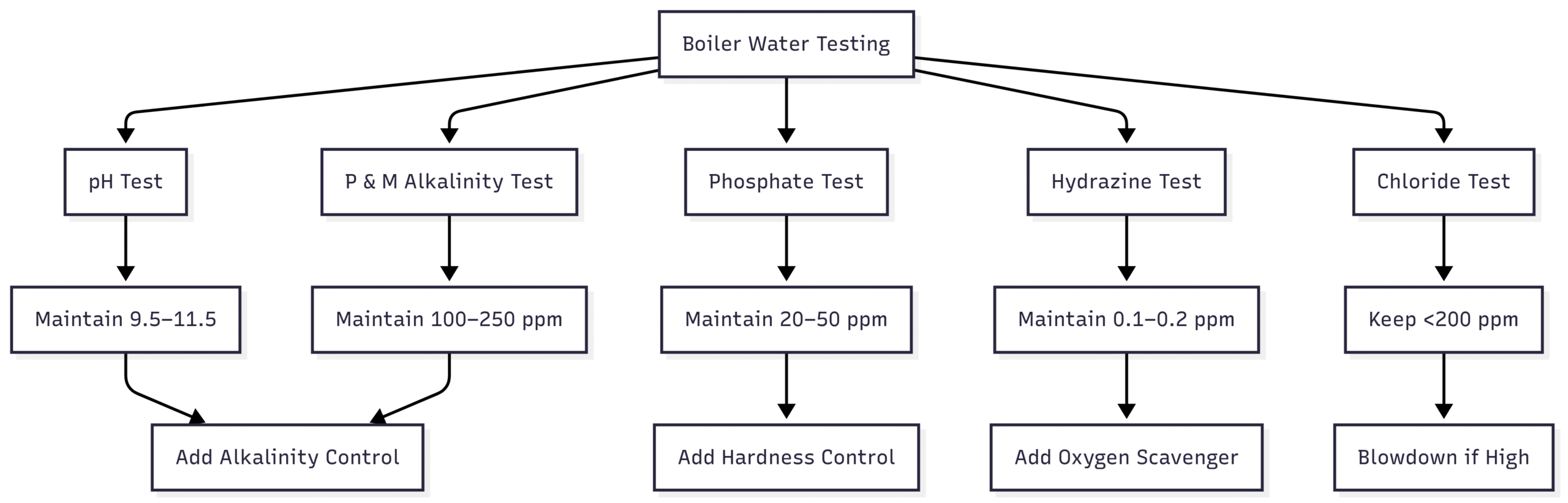

Boiler Water Tests

1. pH Test:

- Purpose: Ensures alkalinity (9.5–11.5) to prevent corrosion and scaling.

- Procedure:

- Fill a 50ml beaker with boiler water.

- Add 600mg pH reagent and mix.

- Dip pH indicator strip for 1 minute.

- Compare color to chart.

- Chemicals: Use Unitor’s Condensate Control (feedwater, pH 8.5–9.5) or Alkalinity Control (boiler, pH 9.5–11.5).

2. Phosphate Test:

- Purpose: Maintains 20–50 ppm to bind calcium and prevent scaling.

- Procedure:

- Fill two 10ml vials with boiler water.

- Add phosphate tablet to one vial, wait 10 minutes.

- Compare vials using a comparator and color disc.

- Chemicals: Unitor Hardness Control, 23g/ton for 20 ppm boost.

3. Hydrazine Test:

- Purpose: Maintains 0.1–0.2 ppm to remove dissolved oxygen.

- Procedure:

- Fill two 10ml vials with boiler water.

- Add 1g hydrazine reagent to one vial, wait 2 minutes.

- Compare using color disc.

- Chemicals: Unitor Oxygen Scavenger/Control.

4. Chloride Test:

- Purpose: Detects seawater contamination (<200 ppm).

- Procedure:

- Fill 100ml beaker with boiler water.

- Add chloride tablets until color shifts from yellow to brown.

- Count tablets to determine concentration.

- Action: Blowdown if levels are high, use distilled feedwater.

5. P & M Alkalinity Test:

- Purpose: Measures inorganic carbons (100–250 ppm as CaCO₃) to ensure corrosion protection.

- Procedure:

- Fill 200ml flask with boiler water.

- Add P-alkalinity tablets until color changes from blue to yellow (PAlk = pills × 20 – 10 ppm CaCO₃).

- Add M-alkalinity tablets until yellow turns purple (MAlk = (P + M pills) × 20 – 10 ppm CaCO₃).

- Chemicals: Unitor Alkalinity Control.

6. Conductivity Test:

- Purpose: Estimates TDS using a conductivity meter (micromhos × 0.55 ≈ ppm).

- Use: Monitors purity and carryover.

Cooling Water Tests

Using Spectrapak 309:

- Nitrite: Maintain 700–2400 ppm to inhibit corrosion.

- pH: Ensure 9.5–11.5 to prevent acidic corrosion.

- Chlorides: Keep below 50 ppm to avoid seawater contamination.

Testing Frequency

- Daily: pH, chloride, and TDS for high-pressure boilers.

- Weekly: Phosphate, hydrazine, and alkalinity.

- Monthly: Laboratory analysis for detailed profiling.

Common Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Corrosion | Low pH, dissolved oxygen, high chlorides | Maintain pH 9.5–11.5, use oxygen scavengers, blowdown for chloride control. |

| Scaling | High hardness, calcium/magnesium deposits | Use phosphates, softeners, and regular blowdown. |

| Foaming/Carryover | High TDS, alkalinity, or oil contamination | Control TDS (<1500 ppm), use anti-foaming agents, ensure proper water level. |

| Biofouling | Microbial growth in cooling systems | Maintain nitrite levels, use biocides, and monitor temperature. |

| Caustic Embrittlement | Excessive alkalinity (>11.5 pH) | Use disodium phosphate, control alkalinity below 250 ppm CaCO₃. |

Chemical Suppliers and Products

Reputable suppliers like Unitor (Wilhelmsen), Nalfleet (Ecolab), Veolia, and Kurita offer specialized chemicals:

| Supplier | Product | Purpose | Price (Approx.) |

|---|---|---|---|

| Unitor | Oxygen Scavenger Plus | Removes dissolved oxygen | $50–$100/25L |

| Unitor | Alkalinity Control | Maintains pH and alkalinity | $40–$80/25L |

| Unitor | Hardness Control | Prevents scaling | $45–$90/25L |

| Nalfleet | Nalfleet 2000 | Multi-purpose (oxygen, scale) | $60–$120/25L |

| Veolia | OptiClean | Sludge conditioner | $70–$150/25L |

| Kurita | Kurita NT | Corrosion inhibitor (nitrite) | $55–$110/25L |

Note: Prices vary based on region and order volume. Contact suppliers (e.g., https://x.ai/grok for Unitor) for exact pricing.

Best Practices for Maintenance

- Consistent Water Treatment:

- Dose chemicals based on test results and manufacturer guidelines.

- Use high-quality test kits (e.g., Spectrapak 309/310) for accurate readings.

- Avoid over-dosing, which wastes chemicals and fuel.

- Regular Testing:

- Conduct daily onboard tests and monthly lab analyses.

- Record results in a digital platform (e.g., WaterProof) for trend analysis.

- Performance Monitoring:

- Track water quality trends to identify issues early.

- Integrate with Ship Management Systems for regulatory compliance.

- Crew Training:

- Train engineers on water testing and chemical dosing.

- Use instructional videos (e.g., Unitor’s YouTube guides) for safety and accuracy.

- Avoid Common Pitfalls:

- Do not inject steam line treatments (e.g., ammonium hydroxide) into the boiler, as they increase alkalinity, requiring excessive blowdown.

- Inject steam line treatments into the steam line via a quill for proper atomization.

- Use phosphates tailored to water chemistry to avoid unnecessary blowdown.

Regulatory Compliance and Efficiency

The CII regulation emphasizes vessel efficiency, making boiler and cooling system maintenance critical for decarbonization. Regular inspections for corrosion, scaling, and sludge, conducted at least twice yearly, ensure compliance with ISM Code and classification society standards. Efficient systems reduce fuel consumption, aligning with environmental goals.

Conclusion

Maintaining marine boiler and cooling systems in top condition requires a disciplined approach to water quality management. By monitoring key parameters, conducting regular tests, implementing proper blowdown procedures, and using appropriate chemicals, marine engineers can prevent corrosion, scaling, and foaming. These practices enhance efficiency, ensure safety, extend equipment lifespan, and comply with stringent regulations. Investing in high-quality test kits and chemicals from trusted suppliers like Unitor and Nalfleet, combined with consistent crew training, safeguards vessels from costly downtime and repairs, ensuring smooth and sustainable operations.

Happy Boating!

Share How to keep your boiler and cooling systems in top condition with your friends and leave a comment below with your thoughts.

Read Emergency Exits on Commercial Ships until we meet in the next article.