How to Choose the Right Boat Fuel Tank

Learn how to choose the right boat fuel tank with our comprehensive guide. Explore types, materials, installation, and maintenance tips for optimal boating performance.

Boating is an exhilarating experience, whether you’re cruising along a serene river or tackling the open sea. However, the performance, safety, and efficiency of your vessel heavily depend on a critical component: the boat fuel tank. Selecting the right fuel tank involves more than just picking a container to hold fuel—it requires careful consideration of your boat’s specifications, fuel consumption, desired range, and safety requirements. This guide dives deep into the factors to consider when choosing a boat fuel tank, the types and materials available, installation best practices, and maintenance tips to ensure your boating adventures are safe and enjoyable.

Why Choosing the Right Boat Fuel Tank Matters

A boat fuel tank is more than a storage unit; it’s a cornerstone of your vessel’s performance and safety. A well-chosen fuel tank ensures a steady fuel supply to the engine, maintains the boat’s balance, and minimizes risks like fuel leaks or instability in rough waters. Poorly selected or maintained tanks can lead to fuel starvation, environmental hazards, or even dangerous situations like fires. By investing time in selecting the right fuel tank, you enhance your boat’s efficiency, extend its lifespan, and prioritize the safety of everyone on board.

For example, consider a scenario where you’re navigating the Neuse River in North Carolina with an 18-foot Shoal Kat powered by a 2004 Johnson 2-stroke 90hp engine. You aim for a 60-mile range while adhering to the “rule of thirds” (one-third of fuel for the trip out, one-third for the return, and one-third as a safety reserve). Choosing a fuel tank that meets these needs requires understanding your boat’s fuel consumption, available space, and the type of fuel your engine requires.

Key Factors to Consider When Choosing a Boat Fuel Tank

Selecting the right fuel tank involves evaluating several critical factors to ensure compatibility with your boat and boating habits. Below are the primary considerations:

1. Fuel Consumption

Your boat’s fuel consumption depends on the engine type, size, and operating conditions. For instance, a 2-stroke 90hp outboard engine, like the one on the Shoal Kat, is known to be fuel-thirsty, often consuming 6–10 gallons per hour (gph) at cruising speeds of 20–25 knots. To estimate fuel needs, calculate consumption based on your typical cruising speed and trip duration. Consult your engine’s owner manual for precise fuel consumption data, as this varies by model and conditions like load, waves, or currents.

Example Calculation:

- Cruising speed: 25 knots

- Fuel consumption: 8 gph (based on user estimates for a 90hp 2-stroke)

- Desired range: 60 miles

- Trip duration: 60 miles ÷ 25 knots = 2.4 hours

- Fuel needed: 2.4 hours × 8 gph = 19.2 gallons

- Rule of thirds: 19.2 gallons × 3 = 57.6 gallons total capacity

This suggests a tank capacity of at least 58 gallons to safely cover the trip, though practical space constraints may require compromises, such as supplementing with portable tanks.

2. Desired Range

Your desired range dictates the tank size. For the Shoal Kat, a 60-mile range in inland waters like Beaufort or Adams Creek requires a tank that supports this distance while adhering to safety margins. Longer trips or areas without easy access to refueling stations demand larger tanks, while shorter trips may allow for smaller, space-saving options.

3. Available Space

Space is often limited on smaller boats like an 18-foot vessel. Measure the available storage area, considering the tank’s shape and placement to avoid disrupting the boat’s balance. Flexible bladder systems, as recommended by Flixtank, can maximize space utilization by conforming to irregular areas. For the Shoal Kat, which lacks an internal tank, above-deck or under-deck portable tanks (e.g., a 20-gallon tank supplemented by a 6-gallon jug) are practical solutions.

4. Fuel Type

Ensure the tank is compatible with your engine’s fuel requirements, particularly ethanol content. Most modern marine engines, including the 2004 Johnson 2-stroke, are designed for E10 (10% ethanol) fuel. Higher ethanol blends like E15 or E85 can corrode fuel system components and void warranties. Aluminum tanks, common in marine applications, require proper treatment to resist ethanol-related corrosion, while polyethylene tanks are naturally resistant.

5. Material

The material of the fuel tank affects durability, weight, and cost. The three primary materials are:

- Aluminum: Lightweight, corrosion-resistant (with proper treatment), and ideal for custom tanks. However, it can react with ethanol if not coated or maintained. Suitable for the Shoal Kat due to its durability and weight advantages.

- Polyethylene: Lightweight, corrosion-resistant, and cost-effective but less durable than aluminum. Ideal for portable tanks but prone to cracking if mishandled.

- Stainless Steel: Highly durable and corrosion-resistant, best for larger permanent tanks in saltwater environments. Its weight and cost make it less practical for smaller boats like the Shoal Kat.

6. Installation Requirements

Portable tanks are easier to install and remove, making them suitable for smaller boats or those kept in slips to avoid high marina fuel costs. Permanent tanks require professional installation to ensure secure mounting, proper venting, and compliance with safety standards like those set by the American Boat and Yacht Council (ABYC). For the Shoal Kat, a portable 20-gallon tank under the rear deck, as chosen by the user, is a practical solution given space constraints.

7. Budget

Consider long-term costs over a 10-year period. While polyethylene tanks are cheaper upfront, aluminum or flexible bladder systems may offer better durability and value. For example, a used 20-gallon tank for $100, as found by the Shoal Kat owner, is a cost-effective option, though supplementing with a 6-gallon jug increases flexibility.

8. Safety and Compliance

Ensure the tank meets EPA and ABYC standards, including proper venting and EPA-compliant fuel lines to prevent leaks and emissions. Regularly inspect fittings, hoses, and connections for wear to maintain system integrity.

Types of Boat Fuel Tanks

Boat fuel tanks come in two main types: portable and permanent. Each has distinct advantages depending on your boat’s size, usage, and storage needs.

Portable Fuel Tanks

Portable tanks, typically made of polyethylene, range from 1 to 50 gallons and are designed for easy removal and refilling at fuel stations. They’re ideal for smaller boats like the Shoal Kat, where space is limited, and for owners who trailer their boats or avoid marina fuel prices. For example, user Corndog38 used four 6-gallon tanks on an 18-foot Privateer, swapping them out as needed for flexibility.

Pros:

- Easy to install and remove

- Cost-effective

- Flexible for short or long trips

- Avoid high marina fuel costs

Cons:

- Limited capacity (e.g., 6 gallons per tank)

- Can be cumbersome to transport

- Require secure storage to prevent tipping

Permanent Fuel Tanks

Permanent tanks, often made of aluminum or stainless steel, are integrated into the boat’s hull and range from 10 to several hundred gallons. They’re common on larger vessels but less practical for smaller boats due to space and installation complexity.

Pros:

- Higher capacity for long-range trips

- Integrated design for better weight distribution

- Reduced risk of tipping or spilling

Cons:

- Requires professional installation

- Higher cost

- Less flexible for refueling

For the Shoal Kat, a portable 20-gallon tank supplemented by a 6-gallon jug balances capacity and practicality, as noted by the user’s final choice.

Materials Used in Boat Fuel Tanks

The choice of material impacts the tank’s durability, weight, and compatibility with your boat’s fuel system. Below is a comparison of the three main materials:

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Aluminum | Lightweight, corrosion-resistant (with treatment), durable, customizable | Susceptible to ethanol corrosion if untreated, higher cost than plastic | Custom tanks, saltwater use |

| Polyethylene | Lightweight, corrosion-resistant, affordable, easy to install | Less durable, prone to cracking if mishandled | Portable tanks, budget-conscious |

| Stainless Steel | Highly durable, corrosion-resistant, ideal for saltwater | Heavy, expensive, difficult to customize | Large permanent tanks, saltwater |

For the Shoal Kat, an aluminum or polyethylene portable tank is likely the best fit due to its lightweight nature and the boat’s limited space.

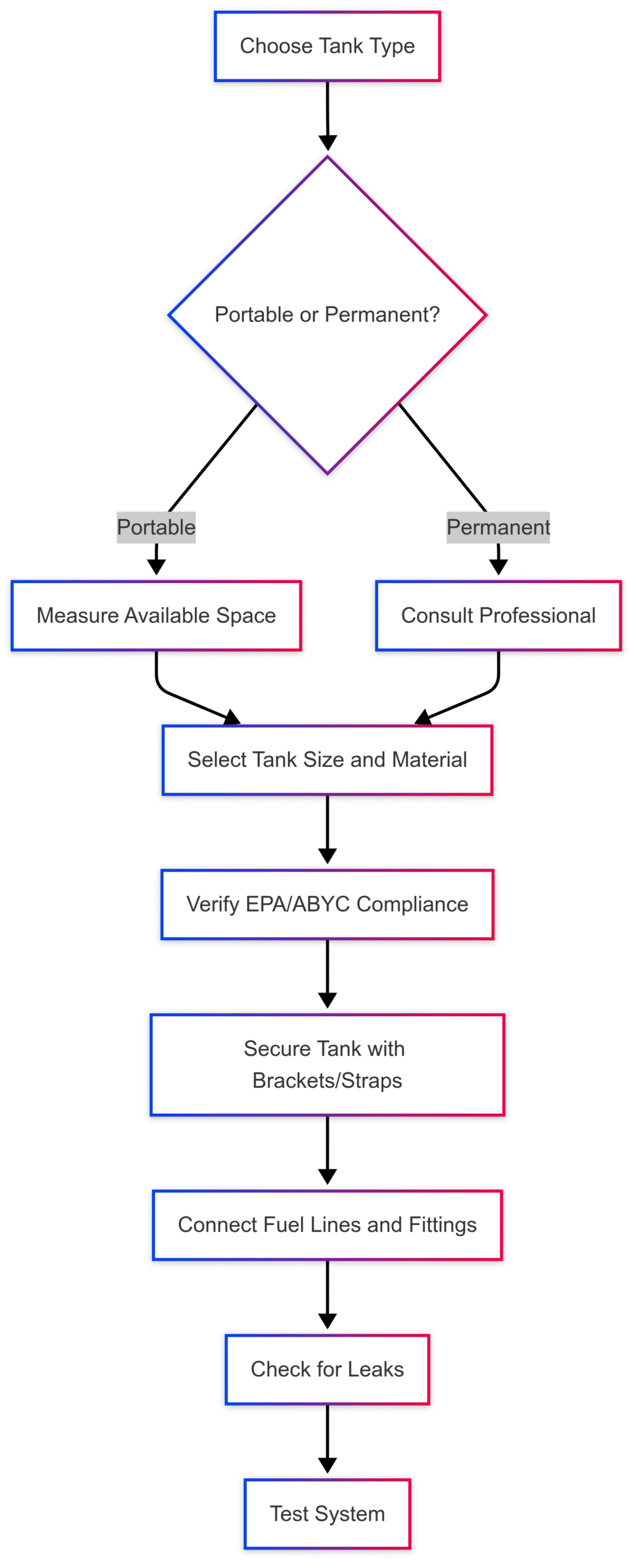

Installation Best Practices

Proper installation ensures safety and performance. Follow these steps:

- Choose the Right Location: Place the tank where it won’t disrupt the boat’s balance. For the Shoal Kat, the user placed a 20-gallon tank under the rear deck to optimize space.

- Ensure Compliance: Verify the tank meets ABYC and EPA standards, including proper venting and EPA-compliant fuel lines.

- Secure Mounting: Use appropriate brackets or straps to prevent movement, especially for portable tanks.

- Check Connections: Ensure fuel lines, fittings, and vents are secure and leak-free. Use threaded, barbed, or quick-connect fittings as specified by the engine manual.

- Professional Installation for Permanent Tanks: Hire a certified marine technician to ensure safety and compliance.

Chart: Fuel Tank Installation Process

Maintaining Your Boat Fuel Tank

Regular maintenance extends the life of your fuel tank and ensures safe operation. Follow these tips:

- Inspect Regularly: Check for leaks, corrosion, or debris in the tank, fittings, and hoses.

- Clean the Tank: Remove contaminants to prevent clogs or engine damage.

- Use Fuel Stabilizers: Add marine-specific stabilizers to prevent oxidation, especially for E10 fuel, which can deteriorate in 15 days.

- Replace Worn Components: Swap out damaged hoses, fittings, or filters promptly.

- Monitor Ethanol Effects: For aluminum tanks, use stabilizers to mitigate ethanol corrosion and drain the tank when not in use.

- Carry Spare Filters: A 10-micron water-separating filter is essential for keeping water and contaminants out of the engine.

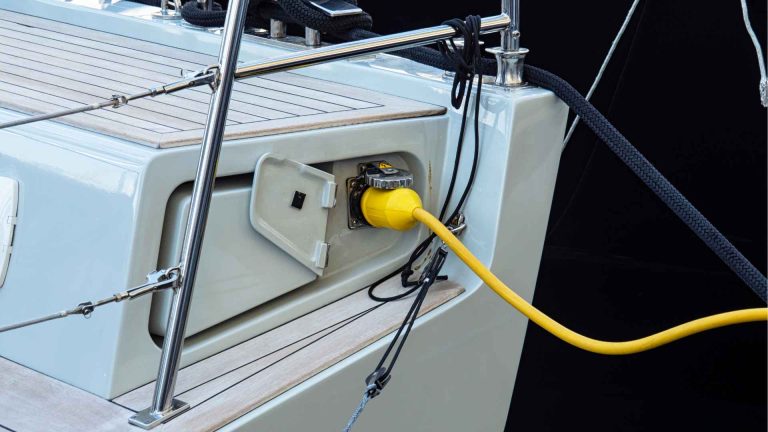

Fuel System Components: Connectors and Hoses

The fuel tank is part of a broader fuel system that includes connectors and hoses. Choosing the right components is critical for safety and performance.

Fuel Connectors

- Threaded Fittings: Used in permanent tanks, requiring a secure threaded connection.

- Barbed Fittings: Common in portable tanks, secured with hose clamps.

- Quick-Connect Fittings: Easy to use for fast, secure connections.

Regularly inspect connectors for wear and ensure compatibility with your engine, as specified in the owner’s manual.

EPA-Compliant Fuel Hoses

EPA-compliant hoses are designed to resist ethanol corrosion and reduce emissions. They’re critical for preventing leaks and maintaining engine performance. Non-compliant hoses can degrade, causing clogs or hazards.

Case Study: Fuel Tank Selection for the Shoal Kat

To illustrate the selection process, let’s revisit the Shoal Kat example:

- Boat Specs: 18-foot Shoal Kat, 7-foot beam, 2004 Johnson 2-stroke 90hp engine (saltwater edition).

- Desired Range: 60 miles in Beaufort/Adams Creek/Neuse River areas.

- Fuel Consumption: Estimated 8 gph at 25 knots, requiring ~58 gallons for the rule of thirds.

- Space Constraints: No internal tank, limited deck space.

- Solution: The owner chose a used 20-gallon portable tank ($100) under the rear deck, supplemented by a 6-gallon jug for a total of 26 gallons. While slightly below the ideal capacity, this setup balances cost, space, and practicality, with the option to carry additional jugs for longer trips.

Fuel and Oil Recommendations

Fuel

Use E10 fuel (10% ethanol) as specified for the 2004 Johnson 2-stroke. Avoid E15 or E85, which can damage the engine and void warranties. Check fuel pump labels to ensure compliance and use a marine-specific fuel stabilizer to prevent oxidation.

Oil

For 2-stroke engines like the Johnson 90hp, use TC-W3 certified oil, as specified in the owner’s manual. This ensures proper lubrication and performance in marine environments.

Conclusion

Choosing the right boat fuel tank is a critical decision that impacts your vessel’s safety, efficiency, and performance. By considering factors like fuel consumption, range, space, and material, you can select a tank that meets your needs. For the Shoal Kat, a 20-gallon portable tank supplemented by a 6-gallon jug offers a practical solution for a 60-mile range, balancing cost and space constraints. Proper installation and regular maintenance, including EPA-compliant hoses and fuel stabilizers, ensure long-term reliability. Whether you’re a weekend cruiser or a long-distance adventurer, a well-chosen fuel tank will keep your boating experiences safe and enjoyable.

Happy Boating!

Share How to Choose the Right Boat Fuel Tank with your friends and leave a comment below with your thoughts.

Read How to Choose the Right Bilge Pump for Your Boat until we meet in the next article.