How to Choose the Right Bilge Pump for Your Boat

Learn how to choose the right bilge pump for your boat with our comprehensive guide. Explore types, sizing, and key factors for optimal safety and performance.

A bilge pump is a critical piece of equipment for any boat, ensuring it remains dry and safe by removing excess water from the bilge—the lowest part of the vessel where water naturally collects. Whether you’re a novice boater or a seasoned captain, selecting the right bilge pump can prevent water damage, enhance safety, and provide peace of mind on the water. This comprehensive guide explores the key factors in choosing a bilge pump, including boat size, pump types, capacity, and maintenance, while offering practical insights to help you make an informed decision.

Understanding the Role of a Bilge Pump

A bilge pump’s primary function is to remove water that accumulates in the bilge from sources like rainwater, wave spray, wash-down water, or minor leaks. While not designed to prevent sinking in catastrophic scenarios like a hull breach, a reliable bilge pump buys critical time to address emergencies, call for help, or evacuate safely. For smaller boats, where water accumulation can quickly affect stability, a high-capacity pump is particularly vital. For larger vessels, multiple pumps may be necessary to manage water across various compartments.

Why You Need a Bilge Pump

Water accumulation in the bilge is inevitable. Rain, spray, condensation, or leaks from fittings can pool in the lowest part of the boat. Without a bilge pump, this water can compromise the boat’s stability, damage equipment, or lead to costly repairs. In extreme cases, unchecked water buildup can cause a vessel to become too heavy, increasing the risk of capsizing or sinking. A properly sized and maintained bilge pump mitigates these risks, keeping your boat operational and safe.

Key Factors to Consider When Choosing a Bilge Pump

Selecting the right bilge pump involves evaluating several factors tailored to your boat’s size, design, and operating conditions. Below are the critical considerations to guide your decision.

1. Boat Size and Type

The size and type of your boat significantly influence the pump’s required capacity and configuration. Larger boats with multiple compartments often require multiple pumps, while smaller boats may suffice with a single high-capacity unit. For example:

- Small Boats (16-20 feet): These vessels, such as small fishing boats or center consoles, typically need a total capacity of 700-1000 GPH. A single pump may suffice, but a backup is recommended.

- Medium Boats (21-35 feet): Boats in this range, like cabin cruisers, require 1000-1800 GPH, often achieved with two pumps—a smaller one for routine water and a larger one for emergencies.

- Large Boats (36-45 feet): Larger vessels, such as yachts, need 1600-4000 GPH, typically using two or three pumps across different compartments.

Boats used in rough waters or for activities like fishing, where water ingress is more likely, may require higher-capacity pumps to handle increased water flow.

2. Actual Pumping Capacity

Bilge pumps are rated in gallons per hour (GPH), but real-world performance is typically 60% of the listed rating due to factors like:

- Head (Vertical Discharge Height): The distance water must be pumped vertically reduces efficiency. For example, a 3-foot head can decrease performance by about 30%.

- Hose Type and Length: Corrugated hoses increase friction, reducing flow by up to 30% compared to smooth-bore hoses. Shorter hoses improve efficiency.

- Power Supply: Pumps may not receive full power when running on a boat’s battery, especially if the engine is off.

To account for this, select a pump with a higher GPH rating than your minimum requirement. For instance, a 1000 GPH pump may only deliver 600 GPH in real-world conditions.

3. Number of Bilge Compartments

Boats with multiple compartments, such as engine rooms, midship bilges, or stern areas, may require separate pumps for each. Larger vessels often have isolated bilge areas to prevent water from flowing freely, necessitating a pump in each compartment. Ensure each pump is appropriately sized for the compartment it serves.

4. Wiring and Battery Capacity

Bilge pumps rely on the boat’s electrical system, so ensure your wiring and battery can handle the pump’s power requirements. Use marine-grade wiring routed upward to avoid water exposure, and seal all connections to prevent corrosion. Verify that your battery can support the pump’s amperage draw, especially for high-capacity models.

5. Discharge Hose Specifications

The diameter and type of discharge hose impact pump performance. A larger diameter hose (e.g., 1.5 inches vs. 1 inch) reduces resistance and improves flow. Smooth-bore hoses are preferred over corrugated ones to minimize friction. Keep hose runs as short and straight as possible to maximize efficiency.

6. Automatic vs. Manual Operation

- Automatic Bilge Pumps: Equipped with float switches or sensors, these pumps activate when water reaches a preset level, making them ideal for unattended boats. They’re especially useful for boats kept in the water long-term.

- Manual Bilge Pumps: These require manual activation, either by hand (for small boats like kayaks) or via a helm switch. They’re practical as backups but less convenient for routine water removal.

For most boaters, an automatic pump with a manual override switch offers the best balance of convenience and control.

7. Emergency Backup Systems

A secondary pump or manual backup is critical for safety. A two-pump system is common:

- Primary Pump: A smaller pump (400-500 GPH) handles routine water accumulation.

- Secondary Pump: A high-capacity pump (2000-4000 GPH) activates in emergencies, mounted slightly higher in the bilge.

Manual pumps, such as hand-operated diaphragm pumps, serve as a last resort in case of electrical failure.

Types of Bilge Pumps

Bilge pumps come in three main types, each with unique characteristics suited to different boats and conditions.

1. Centrifugal Bilge Pumps

Centrifugal pumps are the most common due to their affordability, high flow rates, and ability to handle small debris. They use an impeller to create suction, moving large volumes of water quickly.

- Pros:

- High GPH ratings (up to 4000 GPH or more).

- Cost-effective and reliable.

- Ideal for large vessels with significant water ingress.

- Cons:

- Not self-priming, requiring submersion to function.

- Poor performance pumping water uphill.

- Can overheat if run dry, damaging the impeller.

- Best For: Large boats or as primary pumps in a multi-pump system.

Example: Rule 2000 GPH Automatic Bilge Pump ($150-$200).

2. Diaphragm Bilge Pumps

Diaphragm pumps use a flexible membrane to move water, making them positive displacement pumps. They excel at pumping water uphill and can be mounted above the bilge for easier maintenance.

- Pros:

- Self-priming and can run dry without damage.

- Suitable for small to medium boats.

- Manual versions available for small vessels like dinghies.

- Cons:

- Lower flow rates than centrifugal pumps.

- Struggle with debris, requiring a filter.

- Best For: Small to medium boats or as secondary pumps.

Example: Jabsco Par-Max 4.0 Diaphragm Pump ($200-$250).

3. Reciprocating (Piston) Bilge Pumps

Reciprocating pumps use a piston to displace water, similar to diaphragm pumps. They’re self-priming and can handle viscous liquids like sludge, making them ideal for boats with dirty bilge water.

- Pros:

- Self-priming and can be mounted remotely.

- Effective for viscous liquids.

- Durable in harsh conditions.

- Cons:

- Lower flow rates than centrifugal pumps.

- Require filters to handle debris.

- Best For: Small to medium boats or in combination with centrifugal pumps.

Example: Whale Gulper 220 ($180-$220).

Comparison Table: Bilge Pump Types

| Type | Flow Rate | Self-Priming | Debris Handling | Best For | Price Range |

|---|---|---|---|---|---|

| Centrifugal | High (1000-4000 GPH) | No | Moderate | Large boats, high water volume | $50-$200 |

| Diaphragm | Low-Medium (500-1500 GPH) | Yes | Poor | Small to medium boats | $100-$250 |

| Reciprocating | Low-Medium (500-1200 GPH) | Yes | Poor | Small to medium boats, sludge | $150-$300 |

Sizing a Bilge Pump

Choosing the right pump size depends on your boat’s length and the potential water ingress. Below are general guidelines for pump capacity based on boat size:

| Boat Length | Recommended GPH | Number of Pumps |

|---|---|---|

| <20 feet | 700-1000 GPH | 1-2 |

| 20-25 feet | 1000-1400 GPH | 2 |

| 26-30 feet | 1200-1600 GPH | 2-3 |

| 31-35 feet | 1400-1800 GPH | 2-3 |

| 36-40 feet | 1600-2200 GPH | 3 |

| 41-45 feet | 2000-4000 GPH | 3-4 |

Note: These are minimum recommendations. Opt for higher-capacity pumps to account for reduced real-world performance (60% of rated GPH).

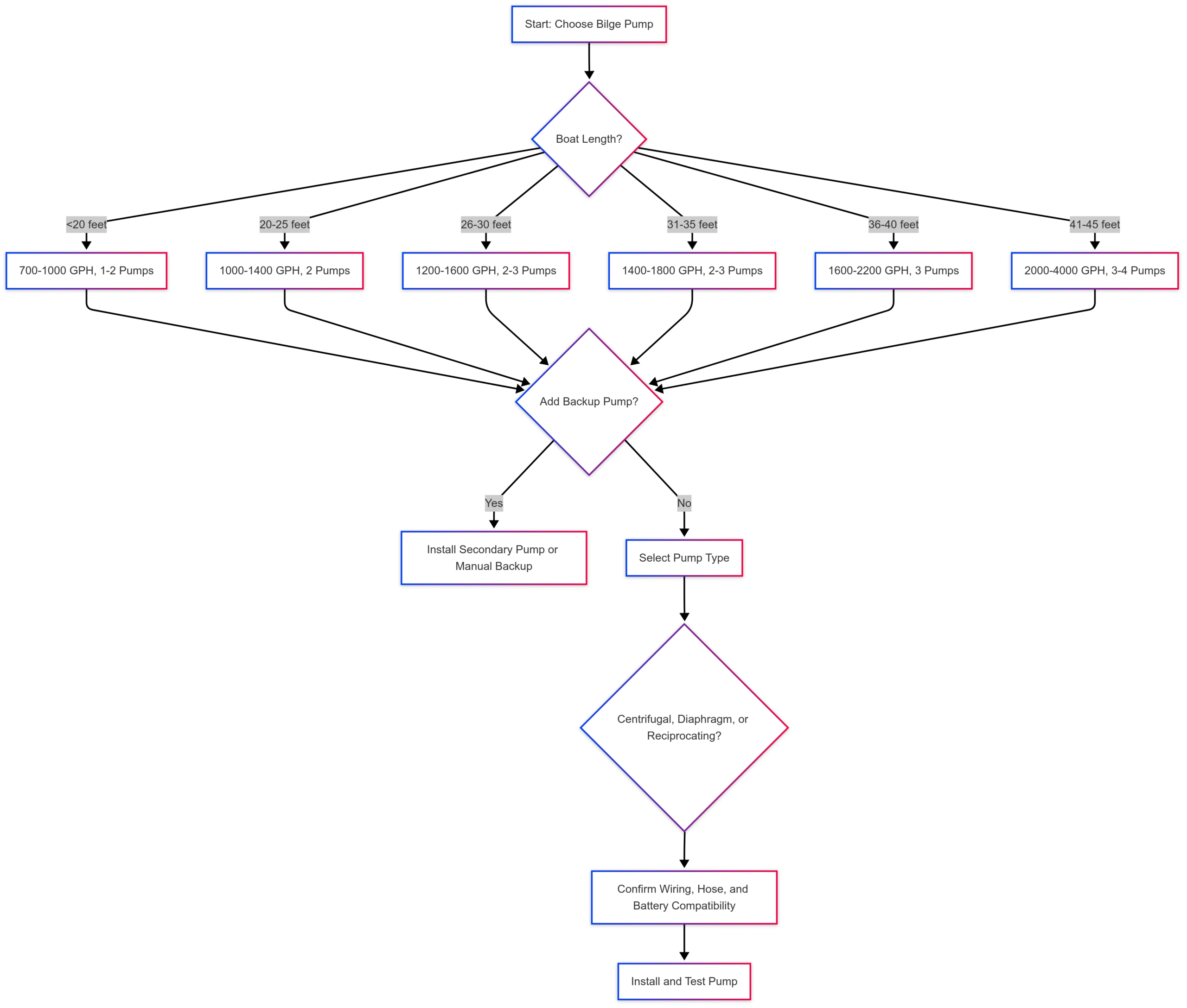

Chart: Bilge Pump Sizing Workflow

Where Are Bilge Pumps Located?

Bilge pumps are installed in the lowest areas of the boat where water collects, such as:

- Engine Compartment: Common for inboard boats, where leaks or condensation accumulate.

- Midship Bilge: Found in boats with central compartments to manage water pooling.

- Stern Area: Near transom drains or stern compartments.

- Bow (Larger Boats): For forward compartments on larger vessels.

The number and placement depend on the boat’s design. Larger boats may require pumps in multiple locations to ensure comprehensive water management.

How to Use and Maintain a Bilge Pump

Operating a Bilge Pump

- Automatic Pumps: Activate via float switches when water reaches a preset level. Check the switch regularly for corrosion or debris buildup.

- Manual Pumps: Require activation via a helm switch or hand operation. Use them when standing water is visible or after heavy rain.

- Testing: Test the pump before and after outings by adding water to the bilge to confirm operation.

Maintenance Tips

- Clear Debris: Inspect the bilge for materials like sawdust, fiberglass, or screws that can clog the pump, especially in new boats.

- Check Float Switches: Ensure switches are free of buildup and function correctly.

- Inspect Wiring: Verify that wiring is dry, sealed, and corrosion-free.

- Test Regularly: Run the pump periodically to ensure it operates efficiently.

- Replace Worn Parts: Replace impellers, seals, or hoses showing signs of wear.

Top Bilge Pump Brands and Models

1. Rule

- Model: Rule 2000 GPH Automatic Bilge Pump

- Specs: 2000 GPH, 12V, 1.5-inch discharge, automatic float switch

- Price: $150-$200

- Pros: High capacity, reliable, easy to install

- Cons: Not self-priming, requires submersion

2. Johnson Pumps

- Model: Johnson Ultima 1250 GPH

- Specs: 1250 GPH, 12V, 1.1-inch discharge, electronic sensor

- Price: $120-$180

- Pros: Compact, durable, debris-resistant

- Cons: Moderate capacity for larger boats

3. Attwood

- Model: Attwood Sahara S1100

- Specs: 1100 GPH, 12V, 1-inch discharge, automatic

- Price: $80-$120

- Pros: Affordable, reliable for small boats

- Cons: Limited capacity for larger vessels

Why a Two-Pump System is Recommended

A two-pump system enhances safety by addressing both routine and emergency needs:

- Primary Pump: A smaller pump (400-500 GPH) handles daily water accumulation, such as rainwater or spray.

- Secondary Pump: A high-capacity pump (2000-4000 GPH) activates during emergencies, mounted higher to avoid frequent use.

This setup ensures redundancy, critical for preventing flooding if one pump fails. For small boats, a single high-capacity pump with a manual backup may suffice, but larger vessels benefit from multiple pumps.

Conclusion

Choosing the right bilge pump is a critical decision that impacts your boat’s safety and longevity. By considering your boat’s size, real-world pumping capacity, compartment layout, and operational needs, you can select a pump—or combination of pumps—that keeps your vessel dry and secure. Opt for high-quality materials, ensure proper installation, and maintain your pump regularly to maximize performance. Whether you choose a centrifugal, diaphragm, or reciprocating pump, investing in a reliable bilge pump system is essential for safe and enjoyable boating.

Happy Boating!

Share How to Choose the Right Bilge Pump for Your Boat with your friends and leave a comment below with your thoughts.

Read Furuno DRS6AX Radar Review: ‘X-Class’ until we meet in the next article.