How Emergency Bilge Suction Valves Work

Learn how emergency bilge suction valves work on ships, their role in flood control, and maintenance tips for safety.

In the maritime world, safety is paramount. Among the critical systems ensuring a vessel’s stability and operational integrity during emergencies is the emergency bilge suction valve. This vital component is designed to manage severe flooding in critical areas like the engine room, preventing catastrophic damage to machinery and maintaining the ship’s buoyancy. Unlike regular bilge pumps, which handle routine water accumulation, the emergency bilge suction valve is a high-capacity, rapid-response mechanism that connects to the ship’s most powerful pumps to remove large volumes of water quickly during crises such as hull breaches, collisions, or grounding. This article provides an in-depth exploration of how emergency bilge suction valves function, their integration with ship systems, operational considerations, maintenance requirements, and their application across various vessel types.

What is an Emergency Bilge Suction Valve?

The emergency bilge suction valve is a specialized component within a ship’s bilge system, designed to address severe flooding in critical compartments, particularly the engine room. Unlike the standard bilge system, which collects and removes water from the hull’s lowest points under normal conditions, the emergency bilge suction valve is reserved for dire situations where rapid water removal is essential. Typically marked with a red handle or painted red for easy identification, this valve is manually operated and connects directly to the ship’s largest capacity pumps, such as seawater cooling pumps, fire pumps, or ballast pumps, to discharge water overboard.

Key Features of Emergency Bilge Suction Valves

- High Capacity: Designed to handle significantly larger water volumes than standard bilge pumps, ensuring rapid dewatering during emergencies.

- Direct Connection to Main Pumps: Integrated with the ship’s main seawater system, allowing high-capacity pumps to draw water from flooded compartments.

- Manual Operation: Typically operated manually to prevent accidental activation, ensuring deliberate use during emergencies.

- Accessibility: Located in easily accessible areas, often at the lowest point of the engine room, with clear markings for quick identification.

- Overboard Discharge: Facilitates rapid water removal by discharging it directly overboard, bypassing smaller bilge systems.

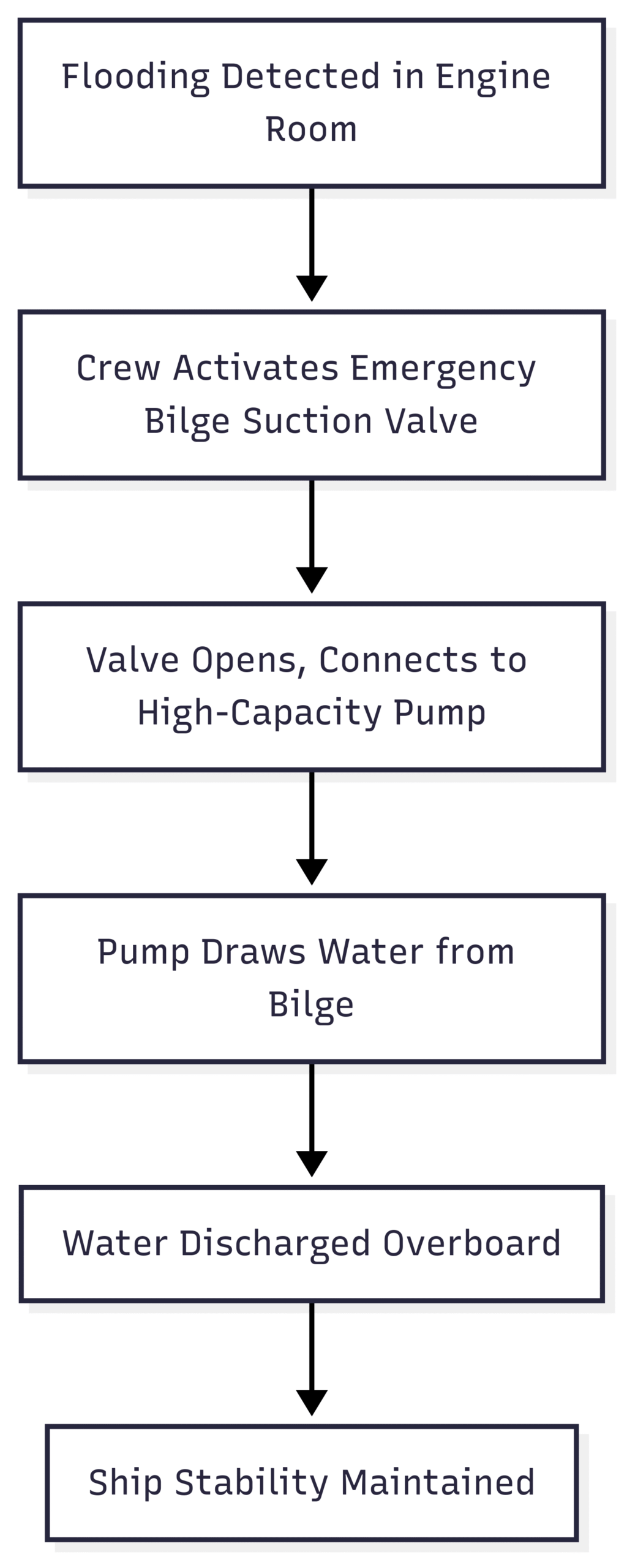

How Emergency Bilge Suction Valves Work

The emergency bilge suction valve operates by providing a direct suction line from the flooded compartment to a high-capacity pump, bypassing the standard bilge system. Here’s a step-by-step breakdown of its functionality:

- Activation in Emergency: When flooding is detected (e.g., via bilge alarms or visual inspection), the crew identifies the need to activate the emergency bilge suction valve. This is typically done when regular bilge pumps are overwhelmed or disabled.

- Manual Operation: The duty engineer manually opens the valve, which is often located at the lowest point of the engine room to maximize water intake.

- Pump Engagement: The valve connects to a high-capacity pump, such as the main seawater cooling pump, fire pump, or ballast pump. These pumps are designed for high flow rates, making them ideal for rapid dewatering.

- Water Discharge: The pump draws water from the flooded compartment through the valve and discharges it overboard, preventing accumulation that could destabilize the vessel or damage critical machinery.

- Coordination with Other Systems: Activating the emergency bilge suction valve may require rerouting suction from other systems (e.g., engine cooling). Crews must ensure these systems are not compromised during operation.

Diagram: Emergency Bilge Suction Valve Operation

This diagram illustrates the straightforward yet critical process of using the emergency bilge suction valve to manage flooding, highlighting its role in maintaining vessel safety.

Integration with Ship Systems

Unlike the standard bilge system, which operates independently to manage routine water accumulation, the emergency bilge suction valve is integrated with the ship’s main seawater system. This integration allows it to leverage high-capacity pumps typically used for other purposes, such as:

- Seawater Cooling Pumps: Used to cool the ship’s engines, these pumps can be redirected to draw water from the bilge during emergencies.

- Fire Pumps: Designed for high-pressure water delivery, fire pumps can also serve as emergency bilge pumps.

- Ballast Pumps: On vessels with ballast systems, these pumps can be used to remove water from flooded compartments.

This integration requires careful coordination to avoid disrupting other critical systems. For example, redirecting a seawater cooling pump to bilge duties may temporarily affect engine cooling, necessitating crew awareness and preparedness.

Types of Ships and Their Emergency Bilge Suction Systems

The design and application of emergency bilge suction valves vary depending on the vessel type, each tailored to specific operational and safety requirements. Below is an overview of how different ship types utilize these systems:

1. Cargo Ships

Cargo vessels, such as bulk carriers and container ships, face risks of water accumulation in holds due to cargo seepage or hull breaches. Their emergency bilge suction valves are connected to high-capacity pumps capable of handling water mixed with debris or cargo residue. These systems often include robust strainers to prevent clogging.

2. Passenger Ships (Cruise Ships and Ferries)

Passenger ships prioritize safety due to the large number of people on board. Their emergency bilge suction valves are part of complex systems that may include remote operation capabilities and auxiliary pumps to protect accommodations, public areas, and the engine room. Rapid dewatering is critical to maintain passenger safety and vessel stability.

3. Tanker Ships (Oil, Chemical, and LNG Carriers)

Tankers must comply with strict environmental regulations to prevent pollution from bilge water mixed with cargo residues. Their emergency bilge suction valves are often connected to segregated ballast systems or dedicated pumps to ensure controlled, environmentally compliant discharge.

4. Naval Vessels

Naval ships require robust, redundant systems due to potential combat-related damage. Emergency bilge suction valves are integrated into damage control systems with multiple valves across compartments, often featuring sensors and remote operation for rapid response.

5. Fishing Vessels

Operating in harsh marine environments, fishing vessels are prone to water ingress from waves or hull breaches. Their emergency bilge suction valves are typically connected to simple, high-capacity manual pump systems, ensuring functionality even during power loss.

Table: Emergency Bilge Suction Valve Characteristics by Ship Type

| Ship Type | Pump Type Used | Key Features | Environmental Considerations |

|---|---|---|---|

| Cargo Ships | Ballast/Seawater Pumps | Robust strainers, high-capacity flow | Debris management |

| Passenger Ships | Auxiliary/Emergency Pumps | Remote operation, complex systems | Passenger safety priority |

| Tanker Ships | Segregated Ballast Pumps | Environmentally compliant discharge | Pollution prevention |

| Naval Vessels | Damage Control Pumps | Redundant valves, remote sensors | Combat resilience |

| Fishing Vessels | Manual/High-Capacity Pumps | Simple, reliable design | Rough sea operation |

Operational Considerations

Operating an emergency bilge suction valve requires careful planning and execution to ensure effectiveness without compromising other ship systems. Key considerations include:

- Crew Training: Crew members must be trained in valve operation as part of emergency response drills. Understanding when and how to use the valve prevents errors that could exacerbate a crisis.

- System Coordination: Activating the valve may affect other systems, such as engine cooling or firefighting. Crews must balance these priorities during operation.

- Environmental Compliance: In non-emergency situations, pumping bilge water overboard must comply with international regulations (e.g., MARPOL Annex I). Emergency situations may allow direct discharge, but crews must ensure no oil or contaminants are released.

- Accessibility: The valve must be clearly marked and located in an easily accessible area, typically at the engine room’s lowest point, to enable rapid response.

Maintenance and Testing

The reliability of the emergency bilge suction valve depends on regular maintenance and testing. Neglecting these can lead to issues like stuck valves, corrosion, or leaks, which could render the system ineffective during an emergency. Key maintenance practices include:

- Regular Inspections: Check for corrosion, blockages, or wear in the valve and associated piping. Ensure the valve operates smoothly and is free of debris.

- Greasing and Lubrication: Apply marine-grade grease to prevent the valve from seizing due to corrosion or prolonged inactivity.

- Testing: Periodically operate the valve and associated pumps to verify functionality. This should be part of routine safety drills.

- Strainer Cleaning: Ensure strainers are clear to prevent clogging during operation, especially on cargo ships where debris is common.

- Record Keeping: Maintain detailed logs of maintenance and testing activities to track the system’s condition and ensure compliance with regulatory standards.

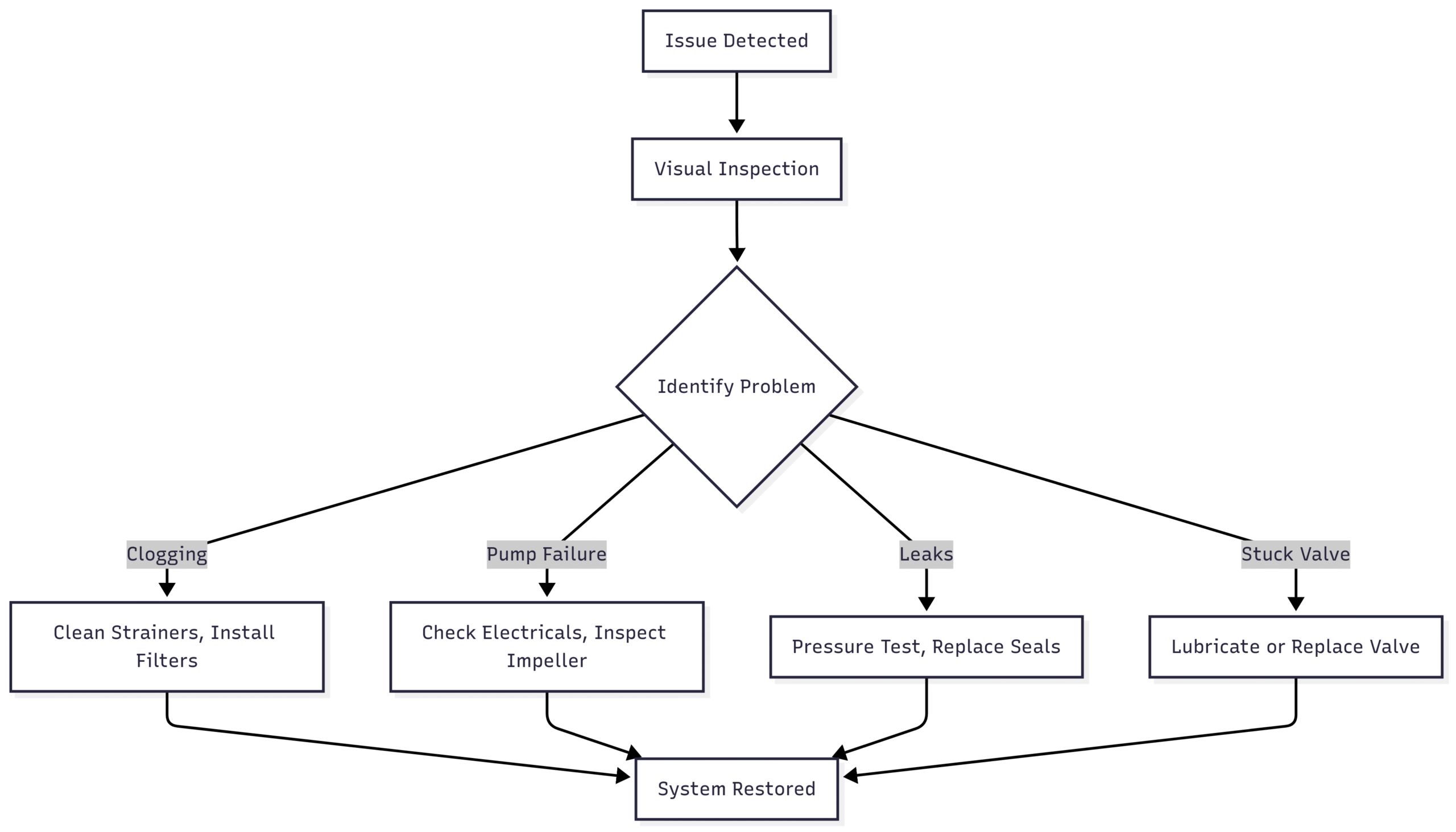

Common Issues and Troubleshooting

Despite regular maintenance, issues can arise with emergency bilge suction valves. Below are common problems and troubleshooting steps:

- Stuck Valves:

- Cause: Corrosion or lack of lubrication.

- Solution: Apply penetrating oil, lubricate, and manually test the valve. Replace if damaged.

- Leaks:

- Cause: Worn seals, corrosion, or cracks in the valve or piping.

- Solution: Conduct a pressure test to identify leaks, then replace seals or damaged components.

- Pump Failure:

- Cause: Electrical issues, impeller damage, or blockages.

- Solution: Inspect electrical connections, test with a multimeter, and check the impeller for wear or debris.

- Clogging:

- Cause: Debris or marine growth in the valve or piping.

- Solution: Clean strainers and pipes, and install additional filters if needed.

Diagram: Troubleshooting Process

This diagram outlines a systematic approach to diagnosing and resolving issues with the emergency bilge suction valve, ensuring rapid restoration of functionality.

Regulatory Requirements

The emergency bilge suction valve is subject to strict international regulations to ensure vessel safety and environmental protection. Key standards include:

- SOLAS (Safety of Life at Sea): Requires ships to have effective bilge systems, including emergency suction capabilities, that are accessible, high-capacity, and corrosion-resistant.

- Classification Societies: Organizations like Lloyd’s Register and DNV-GL provide guidelines for valve design, operation, and maintenance, ensuring compliance with safety standards.

- MARPOL Annex I: Regulates the discharge of bilge water to prevent pollution. Emergency discharges are permitted in life-threatening situations, but crews must ensure compliance under normal conditions.

Importance in Vessel Safety

The emergency bilge suction valve is a cornerstone of a ship’s flood control strategy. By enabling rapid water removal, it prevents:

- Loss of Stability: Excessive water accumulation can compromise a vessel’s buoyancy, leading to capsizing or sinking.

- Machinery Damage: Flooding in the engine room can disable critical systems, halting propulsion and power generation.

- Environmental Harm: Proper operation and maintenance prevent accidental discharge of contaminated bilge water, protecting marine ecosystems.

Case Study: Engine Room Flooding

Consider a scenario where a bulk carrier experiences a hull breach due to grounding. Water floods the engine room, overwhelming the standard bilge pumps. The duty engineer activates the emergency bilge suction valve, connecting it to the main seawater cooling pump. Within minutes, the pump removes thousands of gallons of water, stabilizing the vessel and preventing engine failure. This rapid response highlights the valve’s critical role in averting disaster.

Specifications and Costs

While specific designs vary by ship type and manufacturer, typical specifications for emergency bilge suction valves include:

- Material: Bronze or stainless steel to resist corrosion.

- Size: 4–12 inches in diameter, depending on pump capacity and ship size.

- Pressure Rating: Up to 10 bar, suitable for high-capacity pumps.

- Operation: Manual (handwheel or lever) or automated with sensors in advanced systems.

Table: Typical Specifications and Estimated Costs

| Component | Specification | Estimated Cost (USD) |

|---|---|---|

| Emergency Bilge Suction Valve | Bronze, 6-inch, 10 bar | $500–$1,500 |

| Associated Piping | Stainless steel, 6-inch diameter | $200–$600 per meter |

| High-Capacity Pump | 500–2,000 m³/h flow rate | $10,000–$50,000 |

| Strainer/Filter | Stainless steel, 6-inch | $300–$800 |

Note: Costs vary based on ship size, valve material, and manufacturer. For precise pricing, consult marine equipment suppliers or refer to https://x.ai/grok for general guidance on maritime equipment.

Conclusion

The emergency bilge suction valve is a critical safety feature that ensures a ship’s survival during flooding emergencies. By providing a high-capacity, rapid-response mechanism to remove water from critical compartments, it protects the vessel’s stability, machinery, and crew. Its integration with high-capacity pumps, adherence to regulatory standards, and regular maintenance are essential for reliable operation. Whether on cargo ships, passenger vessels, tankers, naval ships, or fishing boats, the emergency bilge suction valve is a universal safeguard against the perils of flooding. By understanding its functionality, maintaining it diligently, and training crews in its operation, ship operators can ensure safety and compliance, keeping their vessels afloat even in the most challenging conditions.

For further inquiries, engage with maritime communities like Seafarer’s World or contact marine safety experts for vessel-specific guidance.

Happy Boating!

Share How Emergency Bilge Suction Valves Work with your friends and leave a comment below with your thoughts.

Read Understanding SOLAS: A Comprehensive Overview until we meet in the next article.