Heat Exchangers on Ship Explained

Discover how heat exchangers on ships ensure efficient engine cooling, refrigeration, and desalination for optimal maritime performance.

Heat exchangers are indispensable to the maritime industry, serving as the backbone for temperature regulation in critical ship systems. These devices facilitate the transfer of heat between fluids, ensuring engines, lubrication systems, refrigeration units, and even desalination plants operate efficiently. By maintaining optimal temperatures, heat exchangers enhance reliability, reduce energy consumption, and contribute to the sustainability of maritime operations. This article explores the types, functions, applications, and maintenance of heat exchangers on ships, providing a comprehensive guide for maritime professionals and enthusiasts.

What Are Heat Exchangers?

A heat exchanger is a device designed to transfer thermal energy between two or more fluids without allowing them to mix. The fundamental principle is straightforward: heat flows from a hotter medium to a cooler one until thermal equilibrium is achieved. In marine environments, this process is critical for cooling engines, lubricating oil, and other systems, as well as supporting auxiliary functions like refrigeration and freshwater production.

Heat exchangers operate using three primary modes of heat transfer:

- Conduction: Heat moves through direct molecular contact, typically in solids or stationary fluids.

- Convection: Heat is transferred via fluid movement, either naturally due to temperature differences or forced by pumps or fans.

- Radiation: Heat is transferred through electromagnetic waves, though this is less common in marine heat exchangers.

The design of a heat exchanger maximizes the surface area of the separating wall to enhance heat transfer while minimizing flow resistance. This ensures efficient operation across various ship systems.

Key Functions of Heat Exchangers on Ships

Heat exchangers serve multiple purposes onboard, each tied to the efficient operation of critical systems. Below are their primary applications:

1. Engine Cooling

Marine engines generate significant heat during operation, which, if not managed, can lead to overheating and mechanical failure. Heat exchangers transfer heat from the engine coolant (typically freshwater or a coolant mixture) to seawater or another cooling medium. This process maintains the engine at optimal operating temperatures, ensuring performance and longevity.

2. Lubrication System Cooling

Lubricating oil reduces friction in engines and machinery but heats up during operation. Overheated oil can degrade, losing its lubricating properties. Heat exchangers cool the oil by transferring heat to seawater, preserving its viscosity and effectiveness.

3. Refrigeration Systems

Refrigeration units on ships, used for preserving perishable cargo or provisions, rely on heat exchangers to manage heat. Evaporators and condensers, both types of heat exchangers, facilitate phase changes in refrigerants to maintain low temperatures in storage areas like meat, fish, or vegetable rooms.

4. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems ensure comfortable conditions for crew and passengers. Heat exchangers, often in the form of evaporators or condensers, regulate temperatures in these systems, maintaining a habitable environment onboard.

5. Desalination

Modern ships often include desalination plants to convert seawater into freshwater for drinking, cooking, and other needs. Heat exchangers, such as seawater condensers and jacket water evaporators, use waste heat to drive this process, improving energy efficiency.

6. Combined Heat and Power (CHP) Systems

Some vessels employ CHP systems to recover waste heat from power generation. Heat exchangers capture this heat, redirecting it to other systems, such as heating or desalination, enhancing overall energy efficiency.

7. Fuel Systems

In fuel injection systems, heat exchangers heat fuel oil to reduce viscosity, ensuring proper atomization for combustion. Additionally, direct-contact heat exchangers may mix fuel with water sprays to reduce sulfur oxide (SOx) emissions, supporting environmental compliance.

8. Starting Air Systems

High-pressure air compressors used in starting air systems generate heat. Intercoolers, a type of heat exchanger, cool this air to improve compressor efficiency and safety.

Types of Heat Exchangers Used on Ships

Marine heat exchangers are broadly categorized into direct and indirect types, with indirect heat exchangers being the most common due to their efficiency and ability to keep fluids separated. Below are the main types used onboard:

1. Plate Heat Exchangers

Plate heat exchangers consist of thin, corrugated plates stacked between a fixed and a movable pressure plate. The primary and secondary fluids flow through alternating channels in a counter-current arrangement, maximizing heat transfer efficiency. The corrugated design creates turbulence, reducing fouling and enhancing heat transfer.

Advantages:

- Compact Design: Occupies less space than shell-and-tube exchangers, ideal for confined ship environments.

- High Efficiency: Thin plates and turbulent flow improve heat transfer rates.

- Flexibility: Easy to expand or clean (for gasketed types).

- Self-Cleaning Effect: Turbulence reduces fouling, extending maintenance intervals.

Materials: Titanium plates offer superior corrosion resistance, though stainless steel and aluminum brass are also used. Nitrile rubber seals are common for temperatures up to 110°C.

Applications: Engine cooling, lubrication oil cooling, and HVAC systems.

2. Shell-and-Tube Heat Exchangers

Shell-and-tube heat exchangers feature a bundle of tubes inside a cylindrical shell. One fluid (typically seawater) flows through the tubes, while the other (e.g., engine coolant or oil) flows through the shell. Baffles direct the shell-side fluid across the tubes, enhancing heat transfer.

Advantages:

- Robust Design: Suitable for high-pressure and high-temperature applications.

- Versatility: Used in various systems, including engine cooling and fuel heating.

- Durability: Materials like aluminum brass (76% copper, 22% zinc, 2% aluminum) form protective films, extending tube life.

Materials: Tubes are often made of aluminum brass, with tube plates constructed from naval brass, gunmetal, or aluminum bronze. Cathodic protection, such as mild steel anodes, is used to combat corrosion.

Applications: Engine jacket water cooling, lubrication oil cooling, and condensers in refrigeration systems.

3. Spiral Heat Exchangers

Spiral heat exchangers consist of two concentric spiral channels, one for each fluid. They are compact and efficient, often used in steam turbine units or turbine generators onboard.

Advantages:

- Compact and Efficient: Ideal for applications requiring high heat transfer in limited spaces.

- Low Fouling: Continuous flow paths reduce clogging.

Applications: Steam turbine systems and specialized cooling needs.

4. Double Pipe Heat Exchangers

Double pipe heat exchangers feature one pipe inside another, with one fluid flowing through the inner pipe and the other through the annular space. They are simple but less common in marine applications due to their lower efficiency compared to plate or shell-and-tube designs.

Applications: Niche uses where simplicity is prioritized.

Flow Patterns

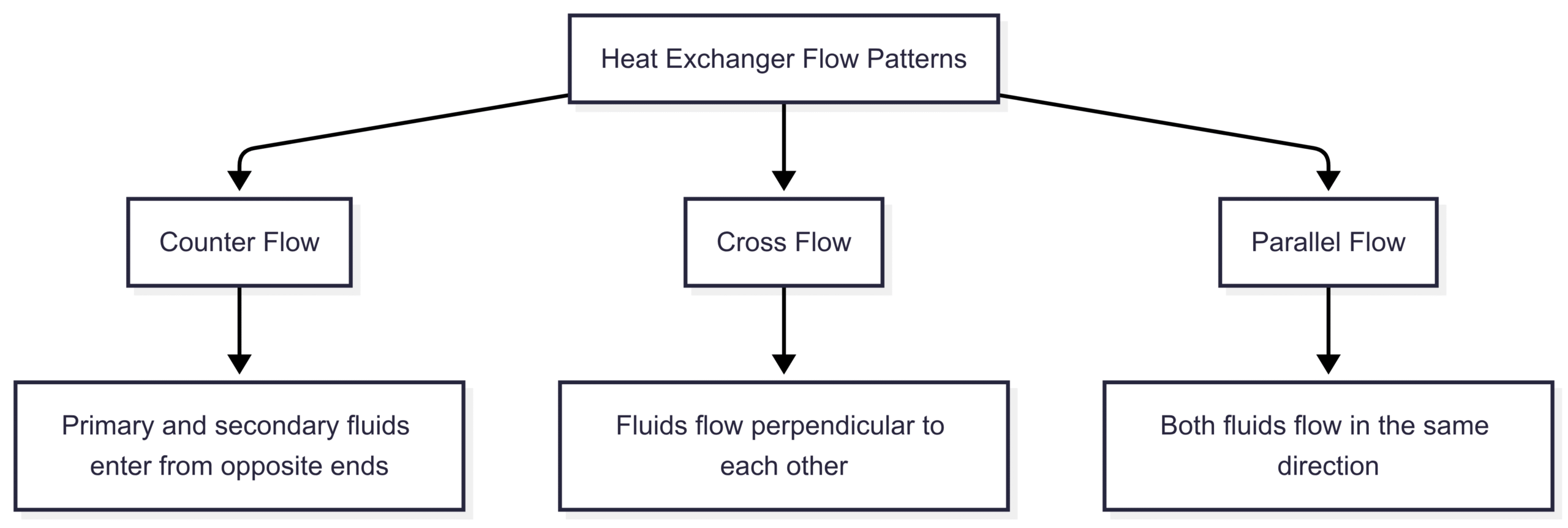

Heat exchangers use three flow patterns to optimize heat transfer:

- Counter Flow: Primary and secondary fluids enter from opposite ends, maximizing temperature difference and efficiency.

- Cross Flow: Fluids flow perpendicular to each other, balancing efficiency and design simplicity.

- Parallel Flow: Both fluids flow in the same direction, less efficient but used in specific applications.

Marine Cooling Systems

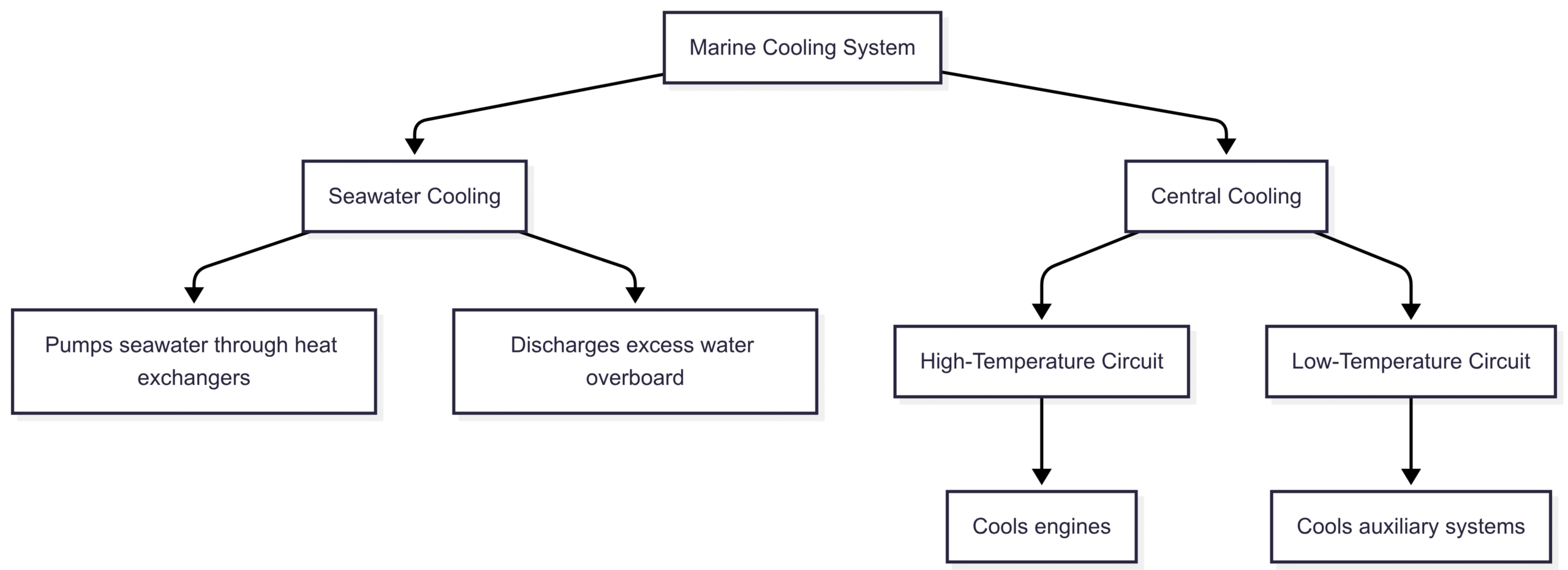

Marine cooling systems are designed to manage heat across various ship components. They typically consist of:

- Seawater Cooling System: Seawater is pumped through heat exchangers to cool engine jacket water, lubricating oil, or piston water. Excess water is discharged overboard.

- Central Cooling System: This system separates high- and low-temperature circuits. High-temperature circuits cool engines, while low-temperature circuits handle auxiliary systems. Regulating valves and temperature sensors control water mixing to maintain optimal temperatures.

- Adjustable Seawater Flow: Seawater flow is adjusted to optimize cooler efficiency, often by bypassing hot fluid or recirculating discharge water.

Maintenance and Cleaning

Marine heat exchangers operate in harsh environments, exposed to seawater and marine organisms, making regular maintenance critical. Key considerations include:

- Corrosion Prevention: Materials like titanium, aluminum brass, and naval brass resist corrosion. Cathodic protection, using soft iron or mild steel anodes, further protects components.

- Fouling Prevention: Marine organisms and debris can clog heat exchangers, reducing efficiency. Strainers and minimal saltwater circulation help prevent blockages.

- Cleaning Methods:

- Mechanical Cleaning: Soft brushes remove deposits without damaging surfaces.

- Chemical Cleaning: Approved chemicals, such as hydrochloric acid, dissolve scale and fouling. Proper handling is essential due to chemical hazards.

- Regular Inspections: Routine checks ensure optimal performance and identify issues early, preventing costly downtime.

Specifications and Pricing

| Type | Material | Applications | Price Range (USD) |

|---|---|---|---|

| Plate Heat Exchanger | Titanium, Stainless Steel, Aluminum Brass | Engine Cooling, HVAC, Lubrication | $5,000 – $50,000 |

| Shell-and-Tube | Aluminum Brass, Naval Brass | Engine Cooling, Refrigeration, Fuel Heating | $10,000 – $100,000 |

| Spiral Heat Exchanger | Stainless Steel | Steam Turbine Systems | $15,000 – $80,000 |

| Double Pipe Exchanger | Stainless Steel, Copper | Niche Applications | $2,000 – $20,000 |

Note: Prices vary based on size, material, and manufacturer. For precise pricing, consult suppliers like Alfa Laval or Kelvion.

Benefits of Heat Exchangers in Maritime Operations

- Energy Efficiency: By recovering waste heat, heat exchangers reduce fuel consumption and operational costs.

- Space Optimization: Compact designs, especially plate heat exchangers, maximize space in confined ship environments.

- Environmental Impact: Efficient heat transfer lowers energy wastage, reducing the vessel’s carbon footprint.

- Reliability: Properly maintained heat exchangers ensure consistent system performance, minimizing downtime.

- Versatility: Applicable across propulsion, refrigeration, HVAC, and desalination systems.

Challenges and Considerations

- Corrosion: Seawater exposure accelerates corrosion, necessitating robust materials and cathodic protection.

- Fouling: Marine organisms and debris can reduce efficiency, requiring regular cleaning.

- Maintenance Costs: While essential, maintenance can be costly, especially for chemical cleaning or part replacements.

- Material Selection: Choosing the right materials (e.g., titanium vs. stainless steel) balances cost and durability.

FAQs About Marine Heat Exchangers

- Why are heat exchangers critical on ships?

They regulate temperatures for engines, machinery, and auxiliary systems, preventing overheating and ensuring operational efficiency. - What are the main types of marine heat exchangers?

Direct (media contact without mixing) and indirect (media separated by a wall). Indirect types, like plate and shell-and-tube, are most common. - How do plate and shell-and-tube heat exchangers differ?

Plate heat exchangers use thin, corrugated plates for compact, efficient heat transfer. Shell-and-tube exchangers use tubes within a shell, ideal for high-pressure applications. - How is temperature controlled in marine heat exchangers?

By bypassing hot fluid, limiting seawater flow, or recirculating discharge water to adjust seawater temperature. - What maintenance do marine heat exchangers require?

Regular cleaning with soft brushes or chemicals like hydrochloric acid to prevent fouling and corrosion.

Conclusion

Heat exchangers are vital for the efficient and sustainable operation of ships. From cooling engines to supporting refrigeration and desalination, these devices ensure that critical systems function reliably in the demanding marine environment. By selecting the right type—whether plate, shell-and-tube, spiral, or double pipe—and maintaining them properly, ship operators can optimize performance, reduce energy consumption, and minimize environmental impact. As maritime technology advances, heat exchangers will continue to play a pivotal role in powering the vessels that drive global trade.

Happy Boating!

Share Heat Exchangers on Ship Explained with your friends and leave a comment below with your thoughts.

Read Types of Governors for Engines Used On Ships until we meet in the next article.