A Guide to Ship Surveys and Inspections

Comprehensive guide to ship surveys and inspections, covering types, purposes, key areas, and compliance with IMO regulations.

Ship surveys and inspections are the backbone of maritime safety, ensuring vessels remain seaworthy, compliant with regulations, and environmentally responsible. These processes involve meticulous evaluations of a ship’s structure, machinery, equipment, and operational protocols by classification societies, flag state authorities, or independent marine surveyors. This guide provides an in-depth exploration of ship surveys and inspections, detailing their types, purposes, key areas of focus, and their critical role in the maritime industry.

Why Ship Surveys and Inspections Matter

The maritime industry operates in a high-stakes environment where safety, efficiency, and compliance are non-negotiable. Ship surveys and inspections serve multiple critical purposes:

- Safety: They verify that a vessel’s structure, machinery, and safety equipment function correctly to protect crew, cargo, and the environment.

- Regulatory Compliance: Ships must adhere to international standards set by the International Maritime Organization (IMO) and national regulations of the flag state.

- Insurance Requirements: Insurers often mandate surveys to assess a vessel’s risk profile before issuing or renewing policies.

- Operational Efficiency: Identifying potential issues early prevents costly downtime and enhances a ship’s performance.

- Loss Prevention: Surveys mitigate risks by addressing structural or operational weaknesses before they lead to accidents.

- Pre-Purchase Assessment: For buyers, surveys provide a detailed evaluation of a vessel’s condition and market value.

- Environmental Protection: Inspections ensure compliance with environmental regulations, reducing the maritime industry’s ecological footprint.

Understanding the distinction between surveys and inspections is key. An inspection is a surface-level check, noting visible issues like hull damage, mold, or wear that could affect seaworthiness. A survey, however, is a comprehensive assessment conducted by a qualified surveyor, diving deep into a vessel’s systems to ensure compliance with IMO conventions and other standards.

Types of Ship Surveys and Inspections

The maritime industry employs various types of surveys and inspections, each tailored to specific purposes and regulatory requirements. Below is a detailed breakdown of the most common types.

1. Initial Survey

The initial survey is a thorough inspection conducted before a ship enters service or when a new regulatory instrument applies to an existing vessel. It ensures all components related to a specific certificate—such as the Cargo Ship Safety Construction Certificate or Passenger Ship Safety Certificate—meet required standards. This survey is critical for issuing the vessel’s first certificate, verifying its fitness for its intended service.

2. Annual Survey

Annual surveys are mandatory inspections conducted within three months before or after the anniversary date of a vessel’s certificate. These surveys verify that the ship remains in satisfactory condition and complies with regulations. For different ship classes (e.g., oil tankers, cargo ships, or passenger vessels), specific components like cargo piping, ballast tanks, or fire control systems are scrutinized.

Example Requirements for Oil Tankers:

- Testing cargo piping and ballast tanks for integrity.

- Verifying corrosion protection in crude oil tanks.

- Checking for oil or water leakages.

- Testing remote controls for fuel pumps and ventilation systems.

3. Intermediate Survey

Intermediate surveys occur within three months before or after the second or third anniversary of a certificate. They focus on specific items relevant to the certificate, replacing one of the annual surveys. These surveys ensure ongoing compliance and address any emerging issues in critical systems.

4. Periodical Survey

Periodical surveys are similar to intermediate surveys but are conducted to ensure the vessel’s components remain fit for service. For cargo ship safety equipment certificates, they occur within three months of the second or third anniversary, while for safety radio certificates, they align with each anniversary date.

5. Renewal Survey

A renewal survey is a comprehensive inspection that mirrors a periodical survey but results in the issuance of a new certificate. For cargo ships, the safety construction renewal survey may begin during the fourth annual survey and must be completed by the fifth anniversary.

6. Additional Survey

Additional surveys are triggered by specific events, such as:

- Investigations following incidents or accidents.

- Major repairs or renewals to critical systems.

- Retrofitting of systems like ballast water management systems (BWMS).

7. Dry Dock Survey

Dry dock surveys involve removing the vessel from the water to inspect components typically submerged, such as the hull and propellers. These surveys use advanced techniques like ultrasonic thickness testing to assess structural integrity, particularly for corrosion caused by saltwater exposure.

8. Safety Construction Survey

This survey focuses on a vessel’s structural integrity, checking for:

- Excessive corrosion on the deck and hull.

- Functionality of watertight doors and draining systems.

- Condition of bilge pumping systems and fire protection equipment.

9. Load Line Survey

Load line surveys ensure the hull is watertight below the freeboard and weathertight above it. Surveyors inspect for cracks, verify locking bars, and test watertight hatch openings to confirm compliance with the International Load Line Convention.

10. Cargo Ship Safety Equipment Survey

This survey evaluates the management and effectiveness of safety systems, ensuring:

- Safety manuals (e.g., muster lists, lifejacket instructions) are accessible.

- Fire-fighting equipment, fire detection systems, and emergency alarms are operational.

- International shore connections are in place.

11. Terminal Safety Survey

Terminal safety surveys assess a vessel’s readiness for emergency response during cargo transfer operations. They verify the functionality of propulsion, steering, navigation, and safety systems. Failure can lead to severe consequences, including blacklisting.

12. Radio and AIS Surveys

Radio surveys, conducted by qualified radio surveyors, assess radio installations, including those in life-saving appliances, per SOLAS and International Telecommunication Union standards. Similarly, automatic identification system (AIS) surveys ensure compliance with performance standards, using specialized test equipment.

13. Polar Code Surveys

For ships operating in polar waters, surveys under the Polar Code supplement SOLAS and MARPOL requirements. These ensure vessels are equipped to handle extreme environmental conditions and comply with additional safety and environmental standards.

14. Remote Surveys

Advancements in technology have introduced remote surveys, where crew members or technicians perform inspections under a surveyor’s remote supervision using audio-visual communication. These surveys maintain compliance without requiring physical surveyor presence, improving efficiency for certain inspections.

15. Inspections of the Ship’s Bottom

Cargo ships require at least two inspections of the hull’s exterior bottom within a five-year period, with one typically coinciding with the renewal of the Cargo Ship Safety Construction Certificate. The interval between inspections must not exceed 36 months.

Key Areas Inspected During Surveys

Ship surveys cover critical areas to ensure safety and compliance:

| Area | Components Inspected |

|---|---|

| Hull | Plates, frames, welds, and structural components for corrosion, cracks, or deformation. |

| Machinery | Engines, propulsion systems, steering gear, and auxiliary machinery for functionality. |

| Equipment | Life-saving appliances (lifeboats, lifejackets), fire-fighting systems, and navigation equipment. |

| Operational Procedures | Crew adherence to safety protocols, emergency response plans, and operational manuals. |

| Cargo Handling | Cargo holds, hatches, and equipment for secure and efficient cargo operations. |

Role of Marine Surveyors

Marine surveyors are highly skilled professionals who provide independent, expert assessments of a vessel’s condition. Their responsibilities include:

- Independent Inspection: Offering unbiased evaluations free from conflicts of interest.

- Technical Expertise: Leveraging deep knowledge of ship design, machinery, and regulations to identify issues.

- Detailed Reporting: Producing comprehensive reports with findings, recommendations, and compliance status.

- Damage Assessment: Evaluating the extent of damage post-incident to guide repairs and insurance claims.

- Consultation: Advising ship owners, operators, and insurers on maintenance, upgrades, and regulatory compliance.

Surveyors often specialize in specific areas, such as hull inspections or radio systems, ensuring thorough evaluations tailored to the vessel’s needs.

IMO Conventions and Certificates

The IMO sets global standards through conventions, codes, and instruments that ships must comply with. Key conventions include:

- SOLAS (Safety of Life at Sea): Governs safety standards for ship construction, equipment, and operations.

- MARPOL: Addresses pollution prevention, covering oil, sewage, garbage, and air emissions.

- Load Lines: Ensures ship stability and watertight integrity.

- BWM (Ballast Water Management): Regulates ballast water to prevent invasive species spread.

- AFS (Anti-Fouling Systems): Controls harmful anti-fouling coatings.

Ships must carry certificates verifying compliance, such as:

| Certificate | Purpose |

|---|---|

| International Tonnage Certificate | Confirms the ship’s tonnage for regulatory and port fee purposes. |

| International Load Line Certificate | Verifies compliance with load line regulations for stability and safety. |

| Cargo Ship Safety Construction Certificate | Ensures structural integrity and safety of cargo ships. |

| Cargo Ship Safety Equipment Certificate | Confirms operational safety equipment, such as lifeboats and fire systems. |

| International Oil Pollution Prevention Certificate | Verifies measures to prevent oil pollution. |

| Safety Management Certificate | Confirms adherence to the International Safety Management (ISM) Code. |

These certificates are issued by flag state administrations or recognized organizations (ROs) and are subject to inspection by port state control officers (PSCOs).

Frequency of Surveys

The frequency of surveys depends on the type and certificate:

- Annual Surveys: Conducted yearly within a three-month window of the certificate’s anniversary.

- Intermediate/Periodical Surveys: Occur within three months of the second or third anniversary of specific certificates.

- Renewal Surveys: Required before certificate renewal, typically every five years.

- Additional Surveys: Triggered by incidents, repairs, or retrofitting.

- Bottom Inspections: At least two within a five-year period, with a maximum 36-month interval.

If major repairs or incidents occur (e.g., hull breaches or propulsion failures), additional surveys may be required to verify seaworthiness post-repair.

Maintaining Inspection Readiness

Continuous maintenance is critical to passing surveys and avoiding operational disruptions. Companies like VLS Environmental Solutions offer services such as:

- Corrective and Preventive Maintenance: Addressing issues before they escalate.

- Gas-Free Services: Ensuring safe conditions for inspections or repairs.

- Environmental Remediation: Supporting compliance with MARPOL and other regulations.

Regular upkeep minimizes the risk of failing inspections, which can lead to costly delays or blacklisting.

Challenges and Innovations

Ship surveys face challenges like scheduling disruptions, high costs, and the complexity of inspecting large vessels. However, innovations are transforming the process:

- Remote Surveys: Using drones and real-time video to reduce surveyor travel.

- AI and Data Analytics: Tools like Bureau Veritas’ AI-based remote inspection systems enhance efficiency and accuracy.

- Ultrasonic Testing: Non-invasive methods to assess hull integrity.

These advancements streamline inspections while maintaining rigorous standards.

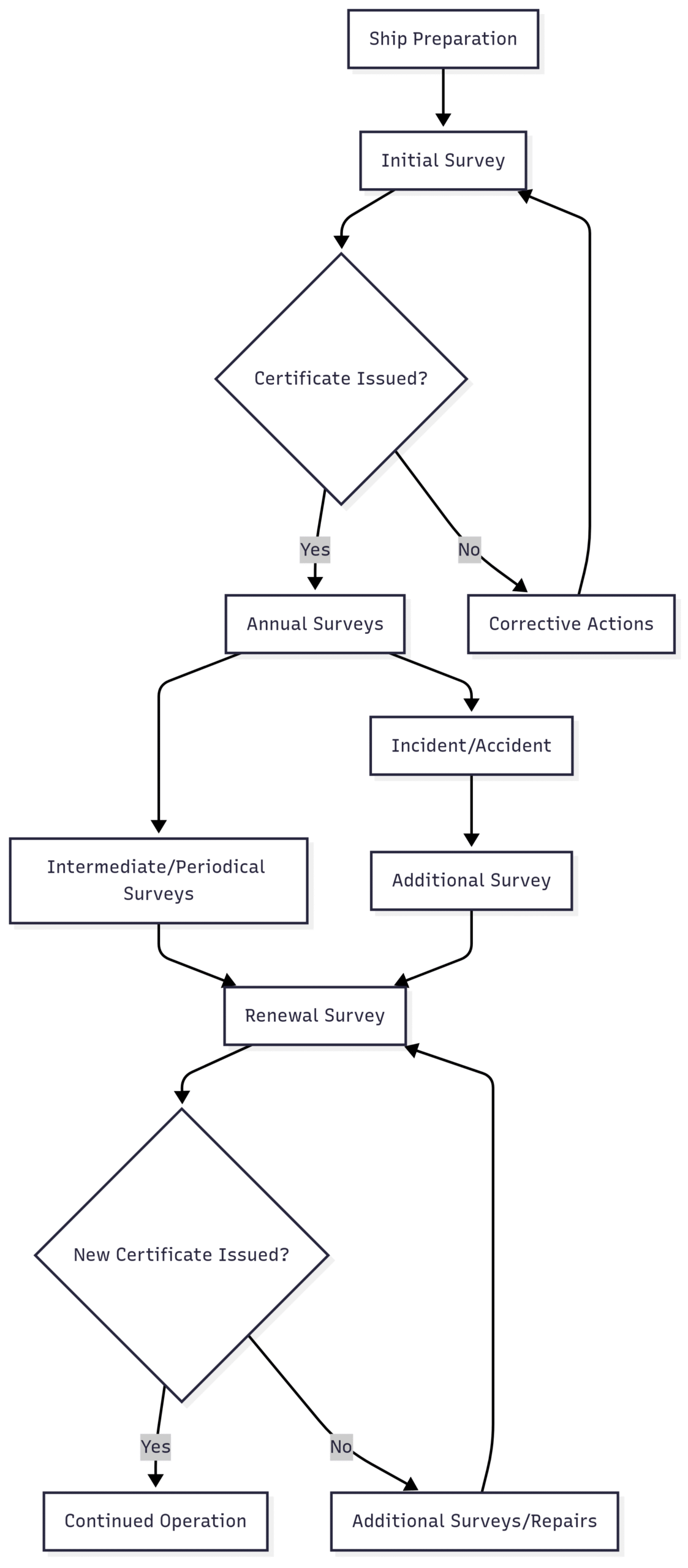

Chart: Ship Survey Workflow

Below is a visual representation of the ship survey process, illustrating the steps from preparation to certification.

This chart outlines the cyclical nature of surveys, with corrective actions and additional surveys triggered as needed to maintain compliance.

Cost Considerations

The cost of ship surveys varies based on vessel size, type, and survey complexity. While specific pricing for services like SuperGrok or xAI’s API is unavailable here, typical survey costs include:

| Survey Type | Estimated Cost Range (USD) |

|---|---|

| Initial Survey | $5,000–$20,000 |

| Annual Survey | $2,000–$10,000 |

| Dry Dock Survey | $10,000–$50,000 |

| Safety Construction | $3,000–$15,000 |

| Load Line Survey | $2,500–$12,000 |

| Remote Survey | $1,500–$8,000 |

These estimates depend on factors like surveyor expertise, location, and vessel condition.

Conclusion

Ship surveys and inspections are indispensable for ensuring maritime safety, regulatory compliance, and operational efficiency. By addressing structural, mechanical, and procedural aspects, these processes protect crews, cargo, and the environment while supporting the maritime industry’s economic viability. From annual checks to specialized surveys like dry dock or polar code assessments, each type plays a unique role in maintaining a vessel’s seaworthiness. Innovations like remote surveys and AI tools are enhancing efficiency, but the core principles of thoroughness and expertise remain unchanged. By staying inspection-ready and leveraging professional services, ship owners and operators can navigate the complex regulatory landscape with confidence, ensuring their vessels remain safe, compliant, and ready for the high seas.

Happy Boating!

Share A Guide to Ship Surveys and Inspections with your friends and leave a comment below with your thoughts.

Read Guidance on becoming a marine engineer? until we meet in the next article.