Emergency Exits on Commercial Ships

Explore emergency exits on commercial ships, their design, placement, regulations, and importance for safe evacuation in maritime emergencies.

Emergency exits on commercial ships are vital safety features designed to ensure the swift and secure evacuation of passengers and crew during crises such as fires, flooding, or collisions. These exits, often referred to as means of escape (MOE), guide individuals to muster stations or survival craft, playing a critical role in maritime safety. Governed by stringent international regulations, such as those set by the International Maritime Organization (IMO), emergency exits are meticulously designed, strategically placed, and rigorously maintained to mitigate risks and save lives. This article provides an in-depth exploration of emergency exits on commercial ships, covering their design, placement, regulatory compliance, maintenance, and the challenges faced in ensuring their effectiveness.

Importance of Emergency Exits in Maritime Safety

The maritime environment presents unique challenges that make emergency exits indispensable. Unlike land-based structures, ships operate in dynamic and often harsh conditions, including rough seas, extreme weather, and confined spaces. A fire, flood, or structural failure at sea can escalate rapidly, leaving little time for evacuation. Emergency exits, therefore, serve as lifelines, guiding passengers and crew to safe assembly points or life-saving appliances like lifeboats and liferafts.

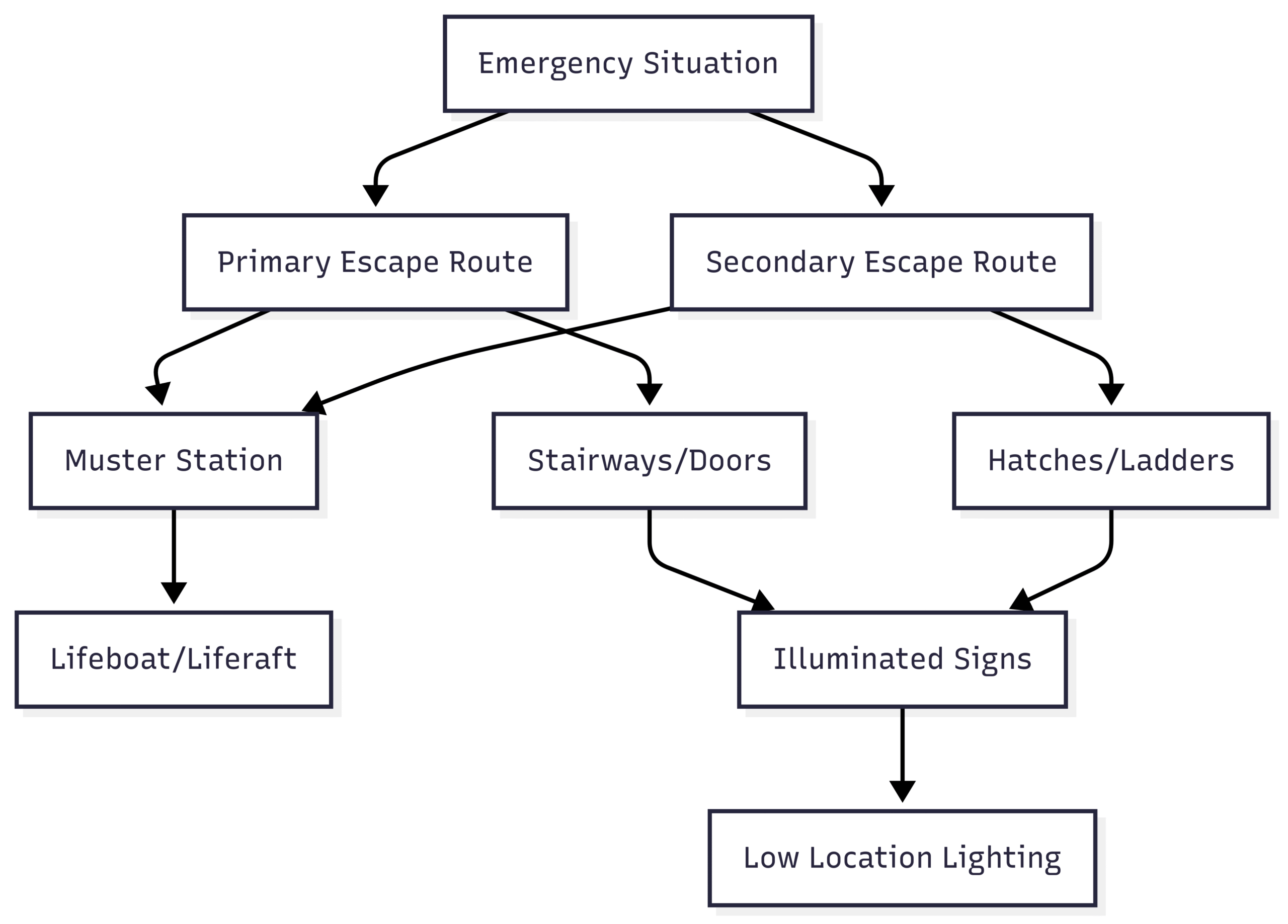

The primary goal of emergency exits is to provide clear, unobstructed, and redundant pathways to safety. By incorporating primary and secondary escape routes, ships ensure that even if one path is compromised, an alternative remains available. These routes are supported by advanced signage, lighting, and structural designs that comply with international standards, ensuring accessibility and visibility under adverse conditions.

Design and Components of Emergency Exits

Emergency exits on commercial ships are carefully engineered to facilitate rapid evacuation. Their design is governed by regulations such as the International Convention for the Safety of Life at Sea (SOLAS) and guidelines from classification societies like Lloyd’s Register and DNV. Below are the key components and design principles of emergency exits:

Types of Emergency Exits

- Vertical Exits (Stairways)

- Serve as the primary means of moving between decks.

- Constructed from steel, equipped with handrails and non-slip surfaces for safety.

- Must be wide enough to accommodate the maximum number of evacuees, as per the Fire Safety Systems Code (FSSC).

- Horizontal Exits (Doors and Hatches)

- Provide access to open decks, muster stations, or lifeboat embarkation points.

- Include fire-rated doors and watertight hatches to protect against fire and flooding.

- Designed to be easy to open, even under pressure, to ensure quick egress.

- Emergency Escape Routes

- Dedicated pathways leading to muster stations or survival craft.

- Marked with clear, illuminated signs and directional arrows for easy navigation.

- Lifeboat and Liferaft Access Points

- Located on open decks for rapid boarding during abandon-ship scenarios.

- Equipped with davits or launching systems to facilitate the deployment of survival craft.

- Emergency Windows and Hatches

- Serve as secondary exits in cabins or enclosed spaces when primary routes are blocked.

- Often feature quick-release mechanisms for ease of use.

Design Considerations

- Redundancy: Regulations mandate at least two means of escape from key areas like accommodation spaces and machinery rooms to prevent entrapment.

- Accessibility: Exits must be reachable from all areas of the ship, with no dead-end corridors to ensure uninterrupted evacuation.

- Protection: Fire-rated doors, watertight hatches, and protected enclosures safeguard escape routes from hazards like fire, smoke, or flooding.

- Construction Materials: Steel is commonly used for stairways and ladders due to its durability and fire resistance.

Marking and Signage

Clear and visible signage is critical for guiding evacuees, especially in low-visibility conditions caused by smoke or power outages. Key features include:

- Emergency Exit Signs: Use photoluminescent materials or LED lighting to remain visible in low-light conditions. Often labeled as “Assembly Point” or “Embarkation Station” to reflect maritime evacuation procedures.

- Low Location Lighting (LLL): Installed near the floor to illuminate escape routes during power failures.

- Directional Arrows: Guide evacuees toward exits and muster stations.

- “EMERGENCY EXIT, KEEP CLEAR” Markings: Large, legible labels on hatches and doors to prevent obstructions.

The International Organization for Standardization (ISO) standard ISO 7010:2019 governs the design of safety signs, specifying shapes, colors (often green for exits), and pictograms for universal recognition.

Strategic Placement of Emergency Exits

The placement of emergency exits is a critical factor in ensuring efficient evacuation. Exits must be strategically located to account for the ship’s layout, passenger and crew distribution, and potential hazards. Below are the key areas where emergency exits are typically placed:

Accommodation Areas

- Requirement: At least two exits, positioned as far apart as possible, to provide alternative escape routes.

- Design: Corridors leading to exits must be free of obstructions and well-lit, with direct access to muster stations or open decks.

- Example: On a cruise ship, cabins have exits leading to main corridors, which connect to stairways or open decks.

Engine Room and Machinery Spaces

- Requirement: At least two escape routes, with one leading to an upper deck via a protected enclosure.

- Design: Enclosed escape trunks or ladderways are used, especially in Category A machinery spaces, to protect against fire or toxic gas leaks.

- Challenge: Hull shape or equipment may prevent escape trunks from reaching the lowest deck, requiring inclined ladders or platforms.

Bridge and Control Rooms

- Requirement: Direct access to external decks for quick evacuation of navigational personnel.

- Design: Exits lead to muster stations or lifeboat embarkation areas, ensuring rapid egress.

Cargo Holds and Enclosed Spaces

- Requirement: Escape routes to prevent entrapment in hazardous conditions like fires or gas leaks.

- Design: Emergency ladders or hatches provide access to open decks.

Galley and Mess Areas

- Requirement: Clearly marked exits due to fire hazards in galleys.

- Design: Direct access to main escape routes ensures efficient evacuation of kitchen and dining staff.

Lifeboat and Liferaft Access Points

- Requirement: Direct or clearly marked routes to embarkation points.

- Design: Free of obstructions, with signage and lighting to guide evacuees.

Ship-Specific Considerations

- Passenger Ships: Require evenly distributed exits to manage high passenger volumes.

- Cargo Ships: Focus on crew areas and cargo storage, ensuring compliance with safety regulations.

- Tankers: Exits are positioned to avoid high-risk zones containing hazardous cargo.

Regulatory Framework

Emergency exits on commercial ships are governed by a robust regulatory framework to ensure compliance with global safety standards. The key regulations include:

SOLAS (International Convention for the Safety of Life at Sea)

- Chapter II-2: Addresses fire protection, detection, and extinction, including requirements for escape routes.

- Regulation II-2/13.4.1.1.1 and 13.4.2.1.1 mandate two means of escape from Category A machinery spaces, with one located within a protected enclosure.

- Chapter III: Specifies life-saving appliances and evacuation procedures.

IMO Unified Interpretations

- MSC.1/Circ.1511/Rev.1: Clarifies that the “lower part” of a machinery space refers to the lowest deck level, platform, or passageway. Inclined ladders outside protected enclosures must have a maximum inclination of 60° and a clear width of at least 600 mm.

- IACS UI SC 277: Aligns with MSC.1/Circ.1511/Rev.1, applicable to ships constructed on or after February 1, 2016.

Classification Society Rules

Organizations like Lloyd’s Register and DNV provide additional guidelines to ensure compliance with SOLAS and enhance safety through best practices.

Port State Control (PSC) Requirements

PSC authorities focus on vessels constructed after February 1, 2016, to ensure compliance with IACS UI SC 277. Non-compliant arrangements, such as escape trunks not extending to the lowest deck, may lead to detention. PSC inspections often include evacuation drills, particularly for rescuing injured persons from machinery spaces.

| Regulation | Key Requirement | Applicability |

|---|---|---|

| SOLAS II-2/13.4.1.1.1 | Two means of escape from Category A machinery spaces, one in a protected enclosure. | All commercial ships. |

| MSC.1/Circ.1511/Rev.1 | Defines “lower part” as lowest deck or platform; limits ladder inclination to 60°. | Ships constructed after Feb 1, 2016. |

| IACS UI SC 277 | Aligns with MSC.1/Circ.1511/Rev.1 for escape trunk design. | Ships constructed after Feb 1, 2016. |

| ISO 7010:2019 | Standardizes safety signs, including emergency exit signs. | Global maritime industry. |

Maintenance and Inspection

Regular maintenance and inspection are crucial to ensure emergency exits remain functional. Key activities include:

- Physical Checks: Inspect stairways, doors, hatches, and ladders for damage, corrosion, or obstructions.

- Lighting and Signage: Test emergency lighting and photoluminescent signs to ensure visibility in low-light conditions.

- Evacuation Drills: Conduct regular drills to verify crew proficiency and exit accessibility. Drills may involve evacuating an injured person on a stretcher from machinery spaces.

- PSC Inspections: Maritime authorities review safety systems and crew performance to ensure compliance with SOLAS and other standards.

Failure to maintain exits can lead to delays or hazards during emergencies, potentially resulting in regulatory penalties or detentions.

Training and Drills

Effective training and drills are essential to prepare passengers and crew for emergencies. Key components include:

- Crew Training: Comprehensive programs covering exit locations, operation of safety systems, and passenger assistance techniques.

- Passenger Briefings: Conducted before departure, informing passengers about exit locations, life jacket use, and muster station procedures.

- Regular Drills: Simulate scenarios like fires or flooding to familiarize crew with evacuation protocols and test safety systems. Drills should be recorded in the ship’s Safety Management System (SMS).

Training ensures a coordinated response, reducing panic and improving evacuation efficiency.

Challenges and Solutions

Emergency exits face several challenges that can hinder their effectiveness. Below are common issues and their solutions:

Blocked Exits

- Challenge: Equipment or debris may obstruct exits.

- Solution: Enforce strict storage policies and conduct regular inspections to keep routes clear.

Poor Visibility

- Challenge: Smoke or power outages reduce visibility.

- Solution: Install and maintain photoluminescent signs and low location lighting.

Crowding

- Challenge: Congestion at exits can delay evacuation.

- Solution: Design multiple exits and conduct drills to optimize passenger flow.

Safety vs. Security Conflicts

- Challenge: Security measures like locked doors may impede access to exits.

- Solution: Install emergency override mechanisms and train crew on managing security systems during evacuations.

Industry Practices and Innovations

Escape Trunks in Machinery Spaces

In many ships, escape trunks in engine rooms do not extend to the lowest deck due to structural constraints or equipment placement. Instead, inclined ladders or platforms provide access to the trunk. To address regulatory concerns, ship operators must provide technical justifications for such arrangements, which are reviewed by flag administrations. These justifications may cite:

- Hull shape limitations.

- Equipment or machinery blocking the area.

- Maintenance access requirements.

Advanced Signage Solutions

Companies like T-ISS offer innovative safety signage, including LED escape signs with photoluminescent properties. These signs comply with IMO standards and EU Wheelmark certification, ensuring durability and visibility in harsh maritime conditions. Non-electrical signs and low location lighting further enhance safety during power outages.

| Product | Features | Price Range (USD) |

|---|---|---|

| T-ISS LED Escape Signs | Photoluminescent, IMO-compliant, durable for marine environments. | $100–$300 per unit |

| SafeSign Non-Electrical Signs | Photoluminescent, corrosion-resistant, low maintenance. | $50–$150 per unit |

| Low Location Lighting Systems | Illuminates escape routes, IMO-compliant, power-independent. | $500–$2,000 per system |

Future Directions and IMO Discussions

The IMO’s Sub-Committee on Ship Design and Construction (SDC 11) recently discussed revising MSC.1/Circ.1511/Rev.1 to clarify escape route requirements, particularly for machinery spaces. While no consensus was reached on redefining the “lower part” of a space, the issue has been referred to the Sub-Committee on Implementation of IMO Instruments (III 11) for further consideration. This reflects ongoing efforts to refine regulations and address practical challenges in escape route design.

Recommendations for Ship Operators

To ensure compliance and enhance safety, ship operators should:

- Develop technical justifications for non-standard escape trunk arrangements and seek flag administration approval.

- Update the Safety Management System to include rescue drill procedures.

- Conduct regular evacuation drills, including scenarios with injured persons.

- Invest in high-quality, IMO-compliant signage and lighting systems.

Conclusion

Emergency exits on commercial ships are a cornerstone of maritime safety, ensuring that passengers and crew can evacuate swiftly and safely during crises. By adhering to SOLAS regulations, maintaining robust maintenance and training programs, and addressing challenges like blocked exits or poor visibility, ship operators can significantly reduce risks. Innovations in signage and ongoing regulatory discussions further enhance the effectiveness of these critical systems. With proper design, placement, and maintenance, emergency exits safeguard lives, making them an indispensable feature of modern commercial vessels.

Happy Boating!

Share Emergency Exits on Commercial Ships with your friends and leave a comment below with your thoughts.

Read MAN’s dual-fuel methanol engine passes class test in China until we meet in the next article.