Everything You Need To Know About Dock Maintenance

Learn essential dock maintenance tips to ensure safety, prolong lifespan, and enhance appearance. From cleaning to repairs, keep your boat dock in top shape.

Boat docks are more than just functional platforms for accessing waterways—they’re vital investments that enhance your waterfront property, protect your boat, and elevate your nautical lifestyle. However, constant exposure to water, sun, wind, and marine life can take a toll, leading to rot, rust, or structural instability. Regular dock maintenance ensures safety, extends lifespan, and preserves aesthetic appeal, saving you from costly repairs or replacements. This comprehensive guide covers everything you need to know about maintaining your dock, from cleaning techniques to material-specific care, preventative measures, and seasonal strategies.

Why Dock Maintenance Matters

Docks face relentless environmental challenges. Wood rots, metal corrodes, and hardware loosens under the strain of waves, weather, and frequent use. Neglecting maintenance can lead to:

- Safety Hazards: Splinters, warped boards, or loose fasteners increase the risk of trips, falls, or even dock collapse.

- Boat Damage: Deteriorated bumpers or uneven surfaces can scratch or dent your vessel during docking.

- Reduced Property Value: A poorly maintained dock detracts from your home’s curb appeal and resale potential.

- Costly Repairs: Small issues, like minor rot or rust, can escalate into major structural problems if ignored.

Regular upkeep mitigates these risks, ensuring your dock remains a safe, functional, and attractive feature of your property. Whether you own a single residential dock or manage a commercial marina, a proactive maintenance routine is essential.

Understanding Your Dock’s Material

The maintenance your dock requires depends on its construction material. Each type—pressure-treated wood, hardwood, composite, or aluminum—has unique characteristics and care needs.

| Material | Pros | Cons | Maintenance Needs |

|---|---|---|---|

| Pressure-Treated Wood | Cost-effective, widely available | Prone to rot, warping, and splintering | Regular sealing, staining, and inspections |

| Hardwood (e.g., Ipe) | Durable, water- and pest-resistant, beautiful | Expensive, color fades without upkeep | Cleaning, oiling, occasional staining |

| Composite | Low maintenance, resistant to moisture/mildew | Higher upfront cost, can’t be painted/stained | Cleaning, minimal repairs |

| Aluminum | Durable, corrosion-resistant, lightweight | Less aesthetic appeal, can dent | Rust checks, cleaning, hardware maintenance |

Pressure-Treated Wood

This affordable option is treated with chemicals to resist decay but remains susceptible to moisture. Marine-grade, kiln-dried pressure-treated wood is ideal for docks. Regular sealing and staining are critical to prevent rot and extend lifespan.

Hardwood

Premium hardwoods like Ipe are dense, naturally resistant to water and pests, and visually striking. Without care, their rich colors fade to gray. Annual cleaning and oiling preserve their appearance and durability.

Composite

Made from wood fibers, plastics, and resins, composite decking (e.g., Trex) resists moisture, insects, and mildew. Modern capped composites require minimal upkeep beyond cleaning, but older uncapped versions may need painting or staining—always check manufacturer guidelines.

Aluminum

Popular for commercial docks, aluminum is durable and low-maintenance but lacks the natural look of wood. Regular inspections for corrosion and hardware maintenance are sufficient.

Understanding your dock’s material guides your maintenance strategy, ensuring you use the right products and techniques.

Essential Dock Maintenance Tasks

1. Regular Cleaning

A clean dock prevents deterioration and maintains safety. Debris, algae, and stains can make surfaces slippery or damage materials over time.

- Remove Debris: Sweep leaves, twigs, and dirt weekly using a broom or leaf blower to prevent buildup.

- Wash Decking: Use a soft-bristled brush, mild soap, and a garden hose to scrub surfaces. Focus on non-slip areas to preserve traction.

- Power Washing: If necessary, use a pressure washer with a fan-tip nozzle at 600–1,200 PSI, held 12–18 inches from the surface. Avoid high pressure on wood to prevent splintering, especially on cedar or pressure-treated docks.

- Eco-Friendly Solutions: Use biodegradable cleaners or homemade mixtures (e.g., 3:1 olive oil and white vinegar for stains, or baking soda paste for oil stains) to protect aquatic ecosystems.

2. Inspecting for Damage

Quarterly inspections identify issues early, saving you from extensive repairs. Check all components thoroughly:

- Wood: Look for rot, warping, cracks, or splinters, especially in water-exposed areas.

- Metal: Examine for rust or pitting, particularly on saltwater docks.

- Fasteners: Ensure bolts, screws, and screws are tight and corrosion-free.

- Bumpers & Rub Rails: Check for wear, as they protect against boat impacts.

- Pilings & Supports: Assess for shifting, erosion, or damage.

- Electrical Systems: Verify wiring and outlets, or outlets are intact and safe, with no exposed conductors.

3. Addressing Issues Promptly

Swift repairs prevent minor damage from becoming major hazards:

- Rot: Replace rotted wood with marine-grade lumber. Small patches can be filled with epoxy for temporary fixes.

- Rust: Remove with vinegar, dish soap, or commercial rust removers. Apply anti-corrosion coatings to metal parts.

- Loose Hardware: Tighten or replace fasteners. Use galvanized or stainless steel for durability.

- Splinters/Cracks: Sand or replace damaged boards to ensure safety.

- Electrical: Hire a professional for wiring issues to comply with safety codes.

4. Preventative Measures

Proactive steps extend your dock’s lifespan:

- Sealants & Stains: Apply marine-grade sealants or stains to wooden docks every 1–3 years to protect against moisture and UV rays. Water-based stains are eco-friendly.

- Dock Lifts: In harsh winter climates, use a dock lift to prevent ice damage.

- Rub Rails & Bumpers: Install marine-grade accessories to absorb boat impacts.

- Chafe Protection: Use covers for dock lines to reduce wear during storms.

5. Seasonal Maintenance

Tailor your maintenance to seasonal demands:

- Spring: Inspect for winter damage, clean thoroughly, and apply sealant/stain.

- Summer: Clean regularly, check for wear from heavy use, and ensure non-slip surfaces are intact.

- Fall: Conduct a comprehensive inspection, repair issues, and prepare for winter.

- Winter: Cover with tarps, secure against ice, and use winter-specific dock lines. Avoid walking on icy docks.

Material-Specific Maintenance Tips

Pressure-Treated Wood

- Cleaning: Use a garden hose and mild soap. Avoid high-pressure washing.

- Sanding: Sand before staining to smooth surfaces and ensure adhesion.

- Sealing/Staining: Apply every 1–2 years. Seal cuts and drilled holes to prevent water intrusion.

- Repairs: Replace rotted boards promptly. Use corrosion-resistant hardware.

Hardwood

- Cleaning: Scrub with eco-friendly soap. Oil annually to maintain color.

- Staining: Optional for aesthetics; use penetrating oils for protection.

- Repairs: Sand minor scratches. Replace severely damaged boards.

Composite

- Cleaning: Use soap and water. Avoid staining or painting capped composites.

- Repairs: Replace damaged sections per manufacturer instructions.

- Inspections: Check for mildew in uncapped composites.

Aluminum

- Cleaning: Rinse with fresh water to remove salt buildup.

- Inspections: Check for corrosion at joints and fasteners.

- Repairs: Replace dented sections. Apply anti-corrosion sprays.

Environmental Considerations

Docks impact local ecosystems, so adopt eco-friendly practices:

- Cleaning Products: Use biodegradable soaps or natural solutions like vinegar and baking soda.

- Construction: Build wide docks to minimize water disturbance. Place away from wildlife habitats.

- Staining: Opt for water-based stains to reduce aquatic contamination.

- Waste Management: Dispose of debris and chemicals responsibly.

Common Dock Problems and Fixes

| Problem | Cause | Solution |

|---|---|---|

| Rot | Prolonged water exposure, poor sealing | Replace rotted wood, apply sealant |

| Rust | Saltwater, humidity | Use vinegar or rust remover, coat with anti-corrosion spray |

| Warping | Sun exposure, moisture | Replace boards or use clamps to flatten |

| Discoloration | UV exposure, lack of oiling | Restain or oil to restore color |

| Loose Fasteners | Vibration, weathering | Tighten or replace with corrosion-resistant hardware |

When to Replace Your Dock

Regular maintenance extends dock life, but replacement may be necessary if:

- Excessive Rot/Rust: Widespread deterioration compromises structural integrity.

- Foundation Damage: Pilings or supports are unstable or can’t be set 4+ feet into the ground.

- Frequent Repairs: Ongoing issues indicate the dock is beyond economical repair.

Consult a professional to assess whether repair or replacement is more cost-effective.

Dock Maintenance Supplies and Costs

Quality supplies are crucial for effective maintenance. Below are common products, their uses, and approximate costs:

| Product | Use | Approx. Cost |

|---|---|---|

| Penofin Hardwood Formula | Protects hardwood docks (e.g., Ipe) | $50–$70/gallon |

| Spa-N-Deck (Flood) | Preserves pressure-treated wood | $40–$60/gallon |

| Marine-Grade Sealant | Waterproofs wood joints | $20–$40/quart |

| Rub Rails (Marine-Grade) | Protects against boat impacts | $5–$15/linear foot |

| Bumpers/Fenders | Absorbs docking impacts | $20–$100 each |

| Corrosion-Resistant Hardware | Replaces bolts/screws | $0.50–$2 each |

| Biodegradable Cleaner | Eco-friendly cleaning | $10–$25/bottle |

Note: Prices vary by region and supplier. Check local retailers like Decks & Docks for availability.

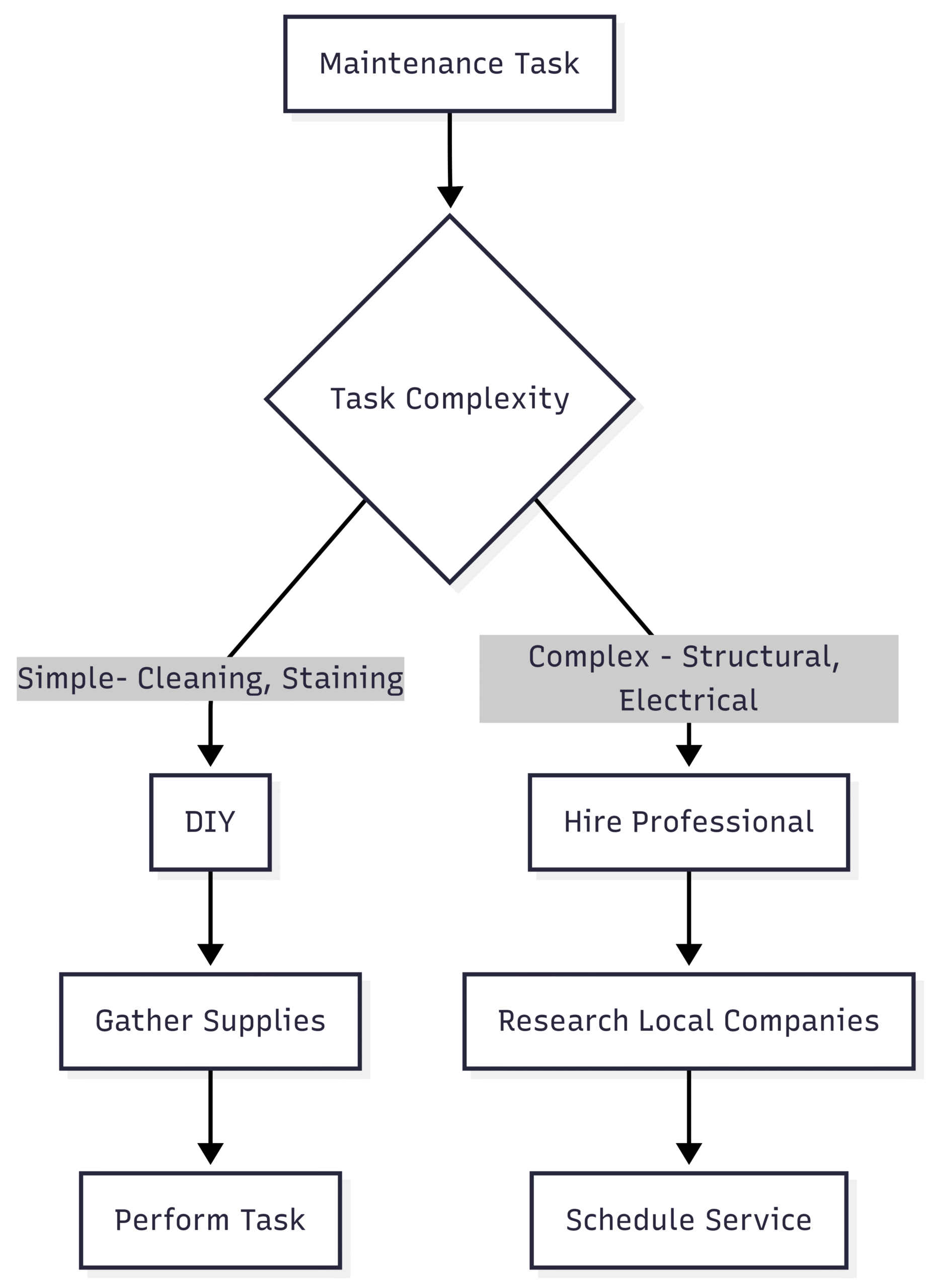

Hiring Professionals vs. DIY

While many maintenance tasks are DIY-friendly, complex repairs or inspections may require professionals:

- DIY: Suitable for cleaning, minor repairs, and staining. Requires time, tools, and basic skills.

- Professionals: Ideal for structural repairs, electrical work, or annual inspections. Research reputable local companies for quality service.

Chart: DIY vs. Professional Decision

Regional Considerations: Florida Docks

In coastal regions like Florida, docks face unique challenges from saltwater, hurricanes, and high humidity. Additional tips include:

- Use Pressure-Treated Lumber: Designed for harsh coastal conditions.

- Corrosion-Resistant Hardware: Essential for saltwater exposure.

- Storm Prep: Secure docks before hurricanes and inspect post-storm.

- Permits: Ensure compliance with local dock regulations (e.g., Florida DEP permits).

Conclusion

Dock maintenance is a critical responsibility for any waterfront property owner. By cleaning regularly, inspecting for damage, addressing issues promptly, and adopting preventative measures, you can ensure your dock remains safe, functional, and visually appealing for years. Tailor your approach to your dock’s material, prioritize eco-friendly practices, and consider professional help for complex tasks. With the right care, your dock will continue to serve as a gateway to unforgettable moments on the water.

Resources:

- Decks & Docks for supplies and expert advice.

- Duncan Seawall for Florida-specific maintenance guides.

- Local marine contractors for professional inspections.

Happy Boating!

Share Everything You Need To Know About Dock Maintenance with your friends and leave a comment below with your thoughts.

Read 6 Tips for Preventing Boat Hull Damage: Ultimate Guide until we meet in the next article.