Digital Resources for the Ship Engineering Department

Discover essential digital resources for ship engineering, optimizing engine room management, fuel efficiency, and maritime compliance.

The ship engineering department is the heart of any maritime vessel, ensuring that propulsion systems, power generation, and critical machinery operate seamlessly to keep ships moving across the globe. As maritime operations grow increasingly complex, digital resources have emerged as indispensable tools for ship engineers. These technologies enhance efficiency, reduce operational risks, and ensure compliance with stringent international regulations. This article delves into the critical digital resources transforming ship engineering, from engine performance monitoring to digital twin technology, and explores their impact on modern maritime operations. Additionally, it highlights resources available to students in the School of Engineering, equipping the next generation of engineers with cutting-edge tools.

The Role of the Ship Engineering Department

The ship engineering department oversees the vessel’s mechanical and electrical systems, including propulsion, power distribution, fuel management, and auxiliary machinery. Key roles include:

- Chief Engineer: Leads the department, ensuring all systems comply with regulations.

- Second and Third Engineers: Manage daily operations and maintenance tasks.

- Engine Room Ratings: Support routine maintenance and repairs.

These professionals ensure compliance with standards set by the International Maritime Organization (IMO) and Classification Societies like DNV and Lloyd’s Register. The complexity of these tasks demands precision, and digital tools have become essential for minimizing human error and optimizing performance.

The Digital Transformation of Ship Engineering

Digitalization has revolutionized maritime operations, reducing manual intervention and enabling data-driven decision-making. From real-time monitoring to predictive maintenance, digital resources empower engineers to maintain operational reliability while meeting environmental and regulatory requirements. Below, we explore the key digital tools shaping the ship engineering landscape.

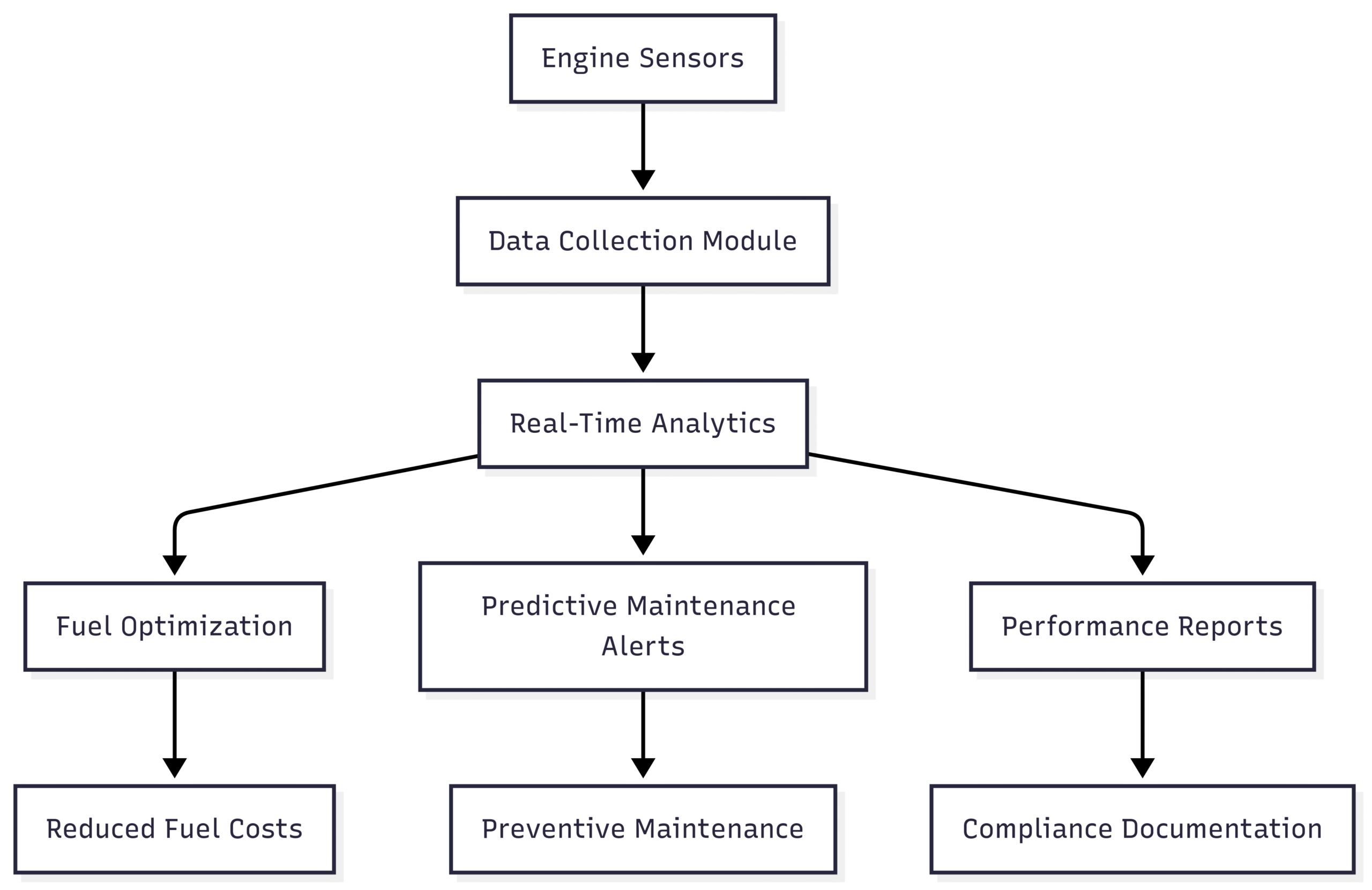

1. Engine Performance Monitoring Systems (EPMS)

Engine Performance Monitoring Systems (EPMS) provide real-time insights into engine parameters such as fuel consumption, cylinder pressure, and engine load. These systems enable engineers to optimize performance and reduce fuel costs.

Key Features:

- Fuel Optimization: Monitors fuel injection and combustion efficiency to minimize waste.

- Performance Analysis: Tracks deviations from standard metrics to identify inefficiencies.

- Predictive Maintenance: Alerts engineers to potential issues before they escalate.

Example: ABB’s Marine Engine Monitoring System enabled a shipping company to reduce fuel consumption by 8% across its fleet by adjusting engine settings in real time based on EPMS data.

Specifications:

- Data Points Monitored: Fuel flow, exhaust gas temperature, cylinder pressure, engine RPM.

- Integration: Compatible with most marine engines (e.g., MAN, Wärtsilä).

- Cost: Approximately $50,000–$100,000 per vessel for installation and licensing.

2. Computerized Maintenance Management Systems (CMMS)

CMMS platforms streamline maintenance by automating schedules, managing spare parts, and maintaining digital records for audits. These systems reduce downtime and ensure compliance with regulatory standards.

Key Benefits:

- Automated Schedules: Eliminates manual tracking of maintenance tasks.

- Inventory Control: Monitors spare parts availability in real time.

- Compliance Reporting: Generates reports for IMO and Classification Society audits.

Case Study: A bulk carrier using AMOS CMMS reduced unplanned downtime by 25% through timely maintenance alerts and efficient spare parts management.

Specifications:

- Modules: Maintenance scheduling, inventory management, work order tracking.

- Integration: Interfaces with ERP systems and onboard sensors.

- Cost: $20,000–$50,000 annually for fleet-wide licensing.

Table: CMMS Features Comparison

| Feature | AMOS CMMS | DNV GL ShipManager | ABS Nautical Systems |

|---|---|---|---|

| Maintenance Scheduling | Yes | Yes | Yes |

| Spare Parts Tracking | Yes | Yes | Yes |

| Mobile Access | Yes | Limited | Yes |

| Regulatory Reporting | Yes | Yes | Yes |

| Cost (Annual) | $20,000+ | $25,000+ | $30,000+ |

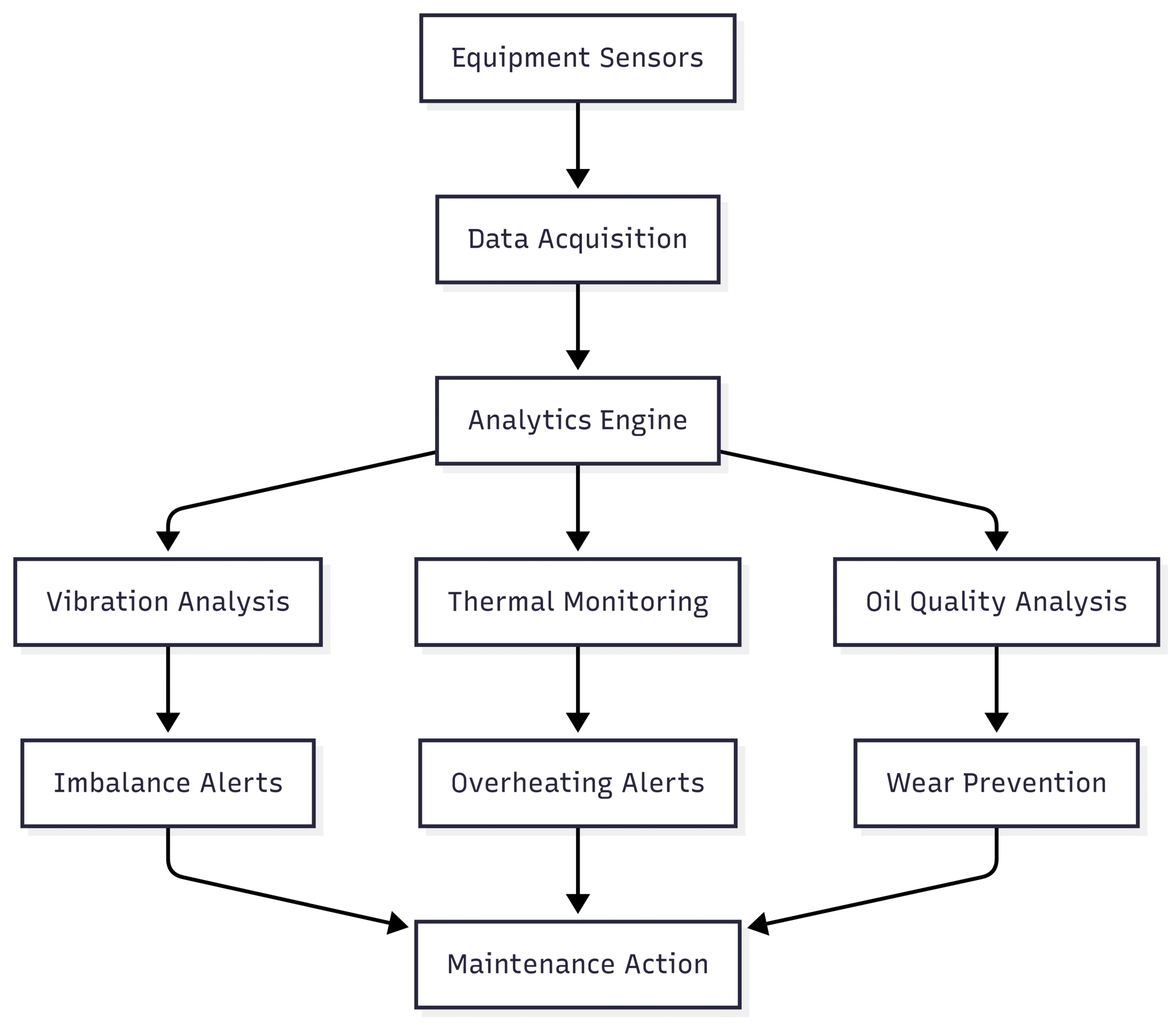

3. Condition-Based Monitoring (CBM) Systems

CBM systems use sensors and analytics to monitor equipment health, detecting issues like vibrations or overheating before they lead to failures.

Applications:

- Vibration Monitoring: Identifies imbalances in pumps and compressors.

- Thermal Imaging: Detects overheating in electrical panels and engine components.

- Oil Analysis: Monitors lubricant quality to prevent wear.

Example: SKF’s CBM Solution reduced machinery failures by 40% for a fleet of LNG carriers by providing real-time alerts on critical components.

Specifications:

- Sensors: Vibration, temperature, oil quality sensors.

- Data Analytics: Machine learning for predictive diagnostics.

- Cost: $30,000–$80,000 per vessel for installation.

4. Power Management Systems (PMS)

PMS platforms automate power generation and distribution, ensuring reliable operation of propulsion, navigation, and auxiliary systems.

Key Features:

- Load Balancing: Distributes electrical load across generators.

- Generator Control: Automates start/stop based on demand.

- Blackout Prevention: Maintains power supply during high-load conditions.

Case Study: An oil tanker equipped with Kongsberg PMS reduced fuel consumption by 15% by optimizing power generation during cargo operations.

Specifications:

- Components: PLCs, SCADA systems, generator controllers.

- Integration: Compatible with hybrid and electric propulsion systems.

- Cost: $40,000–$120,000 per vessel.

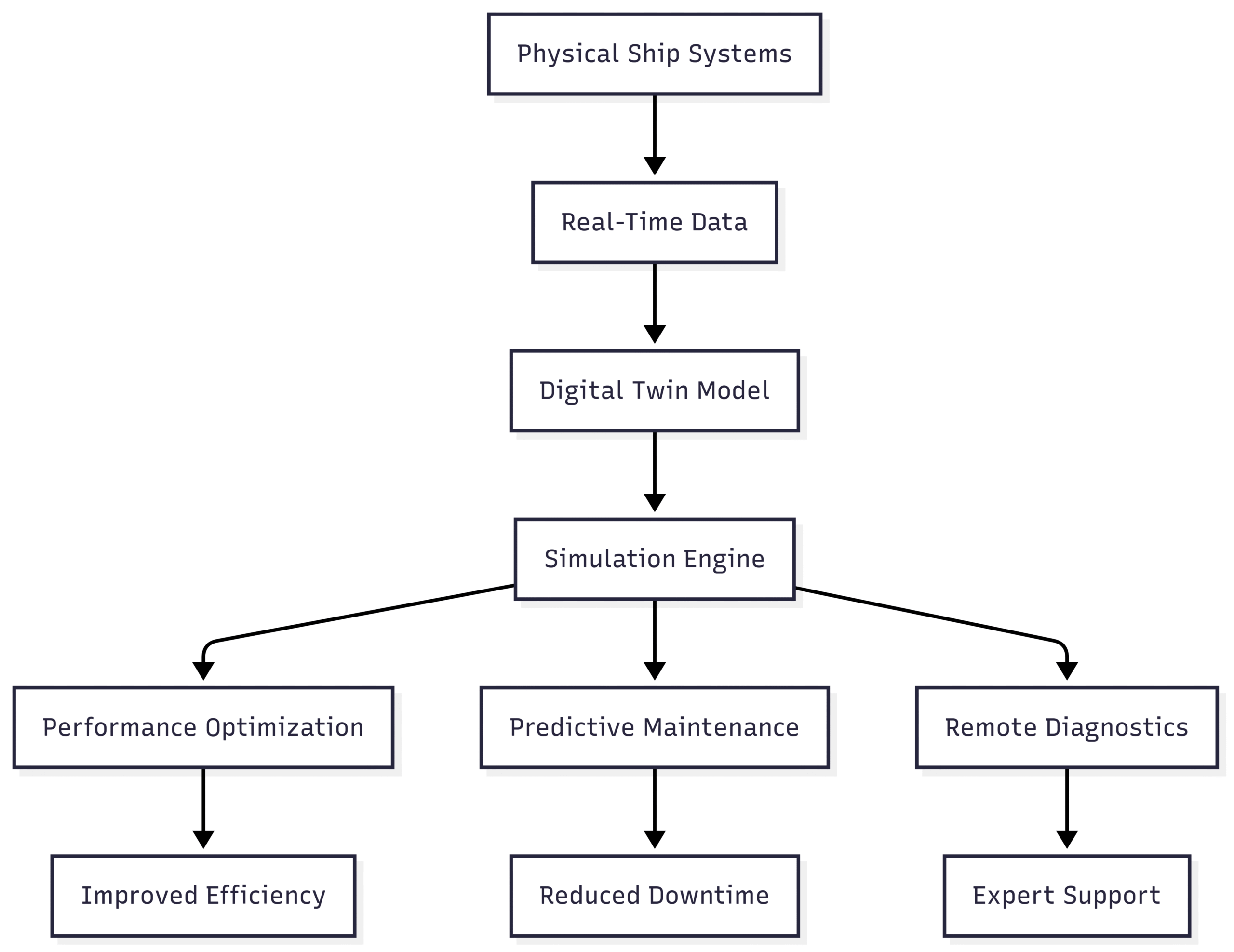

5. Digital Twin Technology

Digital twins create virtual replicas of ship systems, allowing engineers to simulate scenarios, predict failures, and optimize performance without disrupting operations.

Applications:

- Virtual Testing: Simulates engine performance under various conditions.

- Predictive Maintenance: Forecasts failures based on simulations.

- Remote Troubleshooting: Enables collaboration with shore-based experts.

Example: Wärtsilä’s Digital Twin Platform reduced maintenance costs by 20% for a container ship fleet through predictive analytics.

Specifications:

- Platform: Cloud-based or onboard servers.

- Data Inputs: Real-time sensor data, historical performance metrics.

- Cost: $100,000–$200,000 for initial setup and licensing.

6. Fuel Management and Emissions Monitoring Systems

Fuel Management Systems (FMS) and Emissions Monitoring Systems (EMS) ensure compliance with IMO regulations like MARPOL Annex VI while optimizing fuel efficiency.

Features:

- Fuel Tracking: Monitors fuel flow and tank levels.

- Emissions Reporting: Tracks CO₂, SOx, and NOx emissions.

- Fuel Quality Management: Tests fuel to prevent engine damage.

Case Study: A Ro-Ro vessel using Eniram’s Fuel Performance System reduced fuel consumption by 10% while meeting EEXI and CII requirements.

Specifications:

- Sensors: Fuel flow meters, emission analyzers.

- Compliance: MARPOL Annex VI, EEXI, CII.

- Cost: $25,000–$60,000 per vessel.

7. Technical Documentation and Digital Libraries

Digital documentation platforms provide centralized access to technical manuals, service bulletins, and regulatory updates.

Benefits:

- Quick Access: Instant retrieval of manuals and guides.

- Interactive Guides: Includes troubleshooting tutorials.

- Regulatory Updates: Keeps engineers informed of compliance changes.

Example: Shipdex Libraries reduced manual search times by 50% for shipowners.

Specifications:

- Format: Cloud-based, searchable databases.

- Content: Manuals, repair guides, regulatory documents.

- Cost: $5,000–$15,000 annually per fleet.

8. Remote Support and Diagnostic Tools

Remote diagnostic tools connect onboard engineers with shore-based experts via satellite communication, enabling rapid troubleshooting.

Advantages:

- Real-Time Support: Resolves issues without port delays.

- Expert Consultation: Access to specialized technical teams.

- Reduced Downtime: Faster repairs minimize disruptions.

Example: MAN PrimeServ Assist diagnosed a turbocharger fault in under two hours for a container ship.

Specifications:

- Connectivity: Satellite-based, secure VPN.

- Tools: Remote desktop, live video feeds.

- Cost: $10,000–$30,000 annually for support contracts.

9. Maritime E-Learning Platforms

E-learning platforms provide training on engine operations, maintenance, and compliance, ensuring engineers stay updated with industry advancements.

Features:

- STCW-Approved Courses: Covers safety and technical protocols.

- Simulations: Virtual engine room training.

- Progress Tracking: Monitors course completion.

Example: Seagull Maritime Academy reduced onboard training costs by 30% through simulations.

Specifications:

- Access: Online, mobile-compatible.

- Content: Engine operations, regulatory compliance.

- Cost: $500–$2,000 per user annually.

Resources for Engineering Students

Students in the School of Engineering have access to additional digital resources to prepare for careers in ship engineering and related fields. Note: Many resources require on-campus access or a VPN connection.

- Department Facilities: Dedicated VLAN with pre-configured workstations. Visit the Facilities section for details.

- Google Apps for Education: Includes Gmail, shared calendars, and Google Drive with significant storage. Graduates retain access if compliant with usage guidelines.

- Microsoft Azure for Education: Provides access to Windows Servers, Visual Studio, and other Microsoft tools via the SHIP.EDU account.

- ACM Digital Library: Offers technical journals and papers through Shippensburg University’s library portal.

- Microsoft Office 365: Includes Word, Excel, PowerPoint, and more for enrolled students.

- MobilePrint: Enables printing from any device to campus printers.

- Technical Assistance: Systems Manager support via [email protected] or MCT152.

- Essential Software: Includes Cadence, Solidworks, JetBrains IDEs, and more for student devices.

- Pre-Configured Software: Downloadable packages for lab-compatible configurations.

- Virtual Machines: Preconfigured Linux VMs for flexible use.

- ISO Repository: Network share with ISO images for Linux distros.

- Password Reset: Self-service password reset for departmental accounts using SHIP.EDU credentials.

- AnyConnect VPN: Provides off-campus access to university resources.

Conclusion

Digital resources have transformed ship engineering, enabling engineers to optimize performance, reduce costs, and ensure compliance with global standards. From EPMS and CMMS to digital twins and e-learning platforms, these tools enhance operational reliability and sustainability. For students, access to advanced resources like Google Apps, Microsoft Azure, and virtual machines prepares them for the demands of the maritime industry. By embracing these technologies, ship engineers and students alike can drive innovation and efficiency in maritime operations, ensuring a safer and more sustainable future.

Happy Boating!

Share Digital Resources for the Ship Engineering Department with your friends and leave a comment below with your thoughts.

Read A Guide to Ship Surveys and Inspections until we meet in the next article.