Is Boat Shrink Wrapping Worth the Cost

Owning a boat is a significant investment, and protecting it from environmental damage is a priority for every boat owner. Harsh weather, UV radiation, dirt, debris, and even rodents can wreak havoc on a vessel during off-season storage or overland transport. One popular solution is shrink wrapping, a process that encases a boat in a tight, protective plastic film. However, shrink wrapping comes with a recurring cost that can range from moderate to substantial, depending on various factors. This article explores whether boat shrink wrapping is worth the expense by examining its benefits, drawbacks, alternatives, and cost considerations. We’ll also provide detailed insights to help you decide if shrink wrapping aligns with your boat’s needs and budget.

What Is Boat Shrink Wrapping?

Shrink wrapping involves covering a boat with a sheet of low-density polyethylene (LDPE) film, which is then heated to shrink tightly around the vessel’s contours. The result is a custom-fit, waterproof barrier that protects the boat from external elements. Typically, the wrap extends slightly below the rub rail or further down the hull, ensuring comprehensive coverage. Shrink wrapping is most commonly used for:

- Winter storage: Protecting boats stored out of the water during cold months.

- Overland transport: Shielding boats from road debris, wind, and weather during transit.

LDPE is favored for its durability, UV resistance, and ability to form a taut, impermeable seal. The process, while effective, requires precision and is often performed by professionals, though some boat owners opt for a DIY approach.

The Shrink Wrapping Process

Shrink wrapping is a multi-step process that demands careful execution to avoid damage and ensure proper protection. Below is an overview of the key steps:

- Winterization (if applicable): Before wrapping, engines and plumbing must be winterized to prevent damage from freezing temperatures.

- Build a Support Structure: A grid of poles (typically 2x4s) and webbed strapping is erected along the boat’s centerline at approximately 4-foot intervals. The structure ensures the wrap doesn’t sag and supports the film’s weight.

- Cut and Drape the Film: The LDPE film is cut to size, unfolded, and draped over the support grid, covering the boat’s surface.

- Heat Application: Using a propane-fired heat gun, the film is heated to shrink tightly around the boat. A tunnel-like hem is created along the hull, containing a drawstring line to secure the wrap.

- Sealing and Finishing: Excess film is folded, sealed with shrink-wrap tape, and heated to ensure a snug fit. Vents and zippered doors are installed for ventilation and access.

While DIY shrink wrapping is possible, it’s labor-intensive and risky, especially for larger boats. Professional services are often recommended for consistent results.

Benefits of Shrink Wrapping

Shrink wrapping offers several advantages that make it a popular choice for boat protection. Below are the primary benefits:

Superior Weather Protection

Shrink wrapping provides exceptional defense against harsh weather conditions, including rain, snow, ice, and wind. The tight, waterproof seal prevents moisture from seeping into the boat, reducing the risk of structural damage, rust, or corrosion. This is particularly critical in regions with severe winters, where prolonged exposure to snow and ice can degrade a boat’s materials.

UV Resistance

Unlike many traditional covers, shrink wrap offers robust UV protection, shielding the boat’s finish from sun damage. Prolonged UV exposure can cause fading, cracking, or discoloration of gel coats and paint. Shrink wrap’s UV-resistant properties help maintain the boat’s aesthetic and structural integrity.

Custom Fit and Secure Seal

The shrink-wrapping process creates a tailored fit that conforms to the boat’s unique shape. This minimizes low spots where water or snow could pool, a common issue with tarps or fabric covers. The secure seal also deters rodents and pests, which can nest in uncovered or loosely covered boats during storage.

Transport Durability

For boats being transported overland, shrink wrap acts as a robust barrier against road debris, wind, and weather. A specialized “bullet wrap” made of heavier-duty material is available for trailered boats, ensuring the cover withstands highway conditions.

Drawbacks of Shrink Wrapping

Despite its benefits, shrink wrapping has notable downsides that boat owners must consider. These include cost, potential risks, and environmental concerns.

Cost of Shrink Wrapping

Shrink wrapping is a recurring expense, as the plastic film is typically single-use and must be replaced annually. Costs vary based on boat size, location, and additional features. Below is a breakdown of average costs:

| Boat Type/Size | Cost per Foot | Additional Costs |

|---|---|---|

| Powerboats (20–30 ft) | $12–$18 | Entrance: $30–$40, Vents: $4 each |

| Powerboats (30–50 ft) | $18–$25 | Anti-moisture bags: $8 each |

| Sailboats (20–30 ft) | $12–$18 | Mast up: +$2–$3 per foot |

| Sailboats (30–50 ft) | $18–$25 | Anti-mold spray: $50 |

| In-water wrapping | +$100–$150 | |

| Larger boats (>50 ft) | Custom quote | Tuna towers, flybridges: Custom pricing |

For example, shrink wrapping a 30-foot powerboat might cost $540–$750, while a 50-foot sailboat with a mast could exceed $1,400. Additional features like vents or entrances increase the total.

DIY Costs: DIY shrink wrapping requires purchasing materials and tools, including:

- LDPE film: $200–$400 for a 30-foot boat.

- Heat gun: $300–$500.

- Propane: $25–$70.

- Support materials (poles, strapping, tape): $100–$200.

Total DIY costs for a 30-foot boat typically range from $900–$1,200 for the first season, with subsequent seasons costing $300–$400 for materials alone. However, the upfront investment and learning curve often make professional services more cost-effective.

Risks of Shrink Wrapping

Improper shrink wrapping can lead to several issues:

- Damage to Painted Finishes: Excessive heat or improper application can damage painted hulls, particularly those with linear polyurethane paints like AwlGrip or Imron. Owners of painted boats should consult paint manufacturers before shrink wrapping.

- Mold and Mildew: Inadequate ventilation can trap moisture inside the wrap, fostering mold and mildew growth. Installing vents (at $4 each) mitigates this risk but adds to the cost.

- Installation Errors: DIY or inexperienced installers may apply uneven heat, create weak spots, or fail to secure the wrap properly, leading to tears or leaks.

Environmental Concerns

Shrink wrap is single-use plastic, contributing to waste. While some companies offer recycling programs, they’re not universally available, and disposal can be costly. Reusing shrink wrap is possible with careful removal, potentially lasting up to five seasons, but effectiveness may diminish over time.

Alternatives to Shrink Wrapping

Before committing to shrink wrapping, consider alternative protection methods. Each has its own cost structure, benefits, and limitations.

Indoor Storage

Indoor storage offers the highest level of protection, shielding boats from weather, UV rays, and pests. Facilities may be heated or unheated, with heated options requiring less winterization. Benefits include:

- Maximum Protection: No exposure to elements.

- Enhanced Security: Locked facilities reduce theft risk.

Costs: Indoor storage is pricier, averaging $50 per foot for the season. For a 30-foot boat, expect to pay $1,500, with costs varying by location and amenities.

Considerations: Availability may be limited for larger boats, and costs can exceed shrink wrapping for extended storage periods.

Canvas Covers

Custom or semi-custom canvas covers are a reusable, one-time investment. Made from breathable, marine-grade fabric, they offer year-round protection and are ideal for trailering or storage.

Costs:

- Custom Covers: $1,500–$3,000, depending on boat size and design.

- Semi-Custom Covers: $300–$800 for similar boat models.

Benefits:

- Longevity: Can last 5–10 years or more.

- Breathability: Reduces mold and mildew risk.

- Accessibility: Easy to remove and reapply for off-season maintenance.

Drawbacks: Less effective against severe weather compared to shrink wrap, and initial costs are higher.

Tarps

Tarps are the most budget-friendly option, costing $50–$200 depending on size and quality. They’re suitable for small boats stored in mild climates or sheltered locations.

Benefits:

- Low Cost: Affordable for budget-conscious owners.

- Flexibility: Can be used in various settings.

Drawbacks:

- Limited Protection: Prone to tearing, pooling water, or UV degradation.

- Maintenance: Requires frequent checks to ensure security.

Vinyl Boat Wraps

Vinyl wraps, distinct from shrink wraps, are adhesive films applied directly to the hull for aesthetic or branding purposes. They offer some protection but are not a direct substitute for winter storage covers.

Costs:

| Boat Length | Side Height | Price Guide |

|---|---|---|

| 12–16 ft | ≤700mm | $800 |

| 16–20 ft | ≤700mm | $1,000 |

| 16–20 ft | >700mm | $1,300 |

| 20–24 ft | ≤700mm | $1,200 |

| 24–29 ft | ≤700mm | $1,800 |

| 30–35 ft | ≤700mm | $2,700 |

Benefits:

- Aesthetic Appeal: Enhances appearance or promotes branding.

- Durability: Marine-grade vinyl resists UV and salt.

Drawbacks: Not designed for winter storage; primarily cosmetic.

Cost Comparison

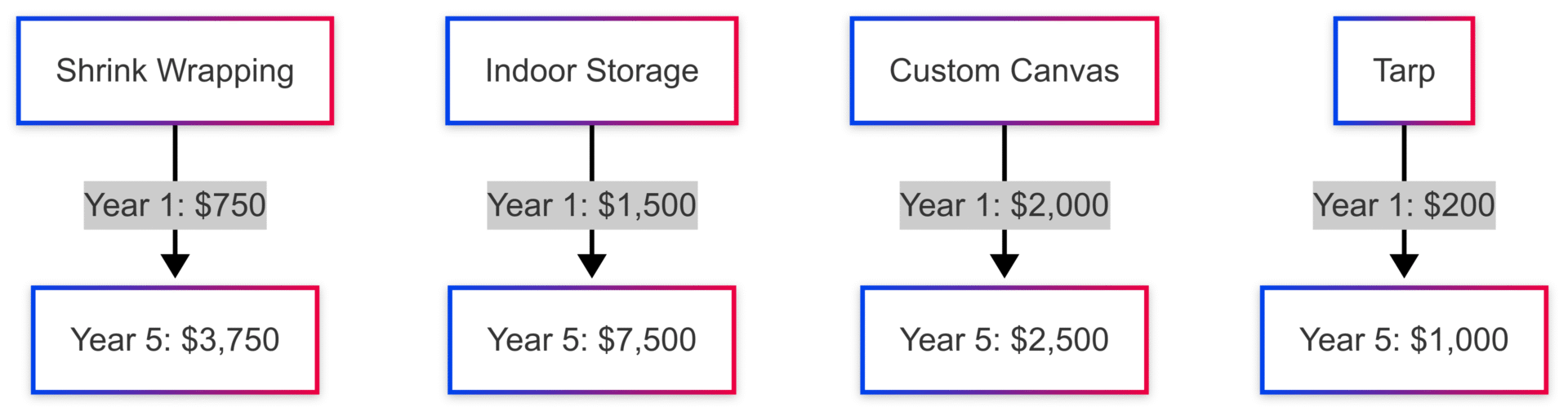

To evaluate whether shrink wrapping is worth the cost, compare it with alternatives for different boat sizes. Below is a table summarizing estimated costs for a 30-foot boat over one and five seasons:

| Method | Initial Cost | Annual Cost | 5-Year Cost | Notes |

|---|---|---|---|---|

| Shrink Wrapping | $540–$750 | $540–$750 | $2,700–$3,750 | Recurring cost; single-use plastic |

| Indoor Storage | $1,500 | $1,500 | $7,500 | Maximum protection; limited access |

| Custom Canvas Cover | $1,500–$2,000 | $0–$100 | $1,500–$2,500 | Reusable; breathable |

| Tarp | $100–$200 | $100–$200 | $500–$1,000 | Budget option; less durable |

Chart: Cost Comparison Over Time

Factors Influencing the Decision

Choosing whether to shrink wrap your boat depends on several factors:

- Boat Size: Larger boats (>30 ft) benefit more from shrink wrapping or indoor storage due to exposure risks. Smaller boats have more affordable options like tarps or canvas covers.

- Storage Location: Boats stored outdoors in harsh climates need robust protection like shrink wrap or indoor storage. Sheltered or mild environments may suffice with tarps.

- Weather Exposure: Severe wind, rain, or snow favors shrink wrapping’s waterproof seal. Mild conditions reduce the need for extensive coverage.

- Budget: If upfront costs are a concern, canvas covers or tarps offer long-term savings. Shrink wrapping suits those prioritizing convenience and protection.

- Accessibility: Canvas covers allow easy access for off-season maintenance, while shrink wrap requires cutting for entry, necessitating re-wrapping.

- Boat Features: Towers, masts, or painted hulls increase shrink-wrapping costs and risks, potentially making alternatives more appealing.

Real-World Insights

Boat owners’ experiences highlight the variability in shrink-wrapping costs and preferences. Some report paying $10–$15 per foot in competitive markets, while others face $25–$40 per foot in high-demand areas like Lake Tahoe. DIY efforts can save money but require significant time and skill. For instance, one owner spent $725 on tools and materials to wrap a 30-foot boat, breaking even after two seasons. Another coordinated a group effort, wrapping six boats for $275 each by pooling resources.

Reusing shrink wrap is a cost-saving strategy, with some owners achieving up to five seasons from a single wrap by carefully removing and storing it. However, opinions vary on its effectiveness over time, as reused wraps may not seal as tightly.

Environmental Considerations

The environmental impact of shrink wrapping is a growing concern. Single-use LDPE film generates significant plastic waste, and recycling options are limited. Some owners mitigate this by reusing wraps or opting for reusable canvas covers. If sustainability is a priority, explore recycling programs or alternative covers to reduce your ecological footprint.

Making the Decision

To determine if shrink wrapping is worth the cost, assess your boat’s specific needs:

- For Large Boats in Harsh Climates: Shrink wrapping or indoor storage is ideal due to superior protection. If indoor storage is unavailable or too costly, shrink wrapping is the better choice.

- For Small Boats in Mild Climates: Tarps or canvas covers are cost-effective and sufficient for basic protection.

- For Frequent Access: Canvas covers are preferable, as shrink wrap limits accessibility.

- For Budget Constraints: Tarps or group DIY shrink wrapping offer the lowest costs.

- For Transport: Shrink wrapping, particularly bullet wraps, is essential for overland travel.

Consider using platforms like Neighbor, a peer-to-peer storage marketplace, to find affordable indoor or outdoor storage options. This can complement or replace shrink wrapping, depending on your needs.

Conclusion

Boat shrink wrapping is a valuable option for protecting your vessel from weather, UV rays, and pests, particularly during winter storage or transport. Its custom fit and robust protection make it ideal for larger boats in harsh conditions. However, the recurring cost, potential risks, and environmental impact warrant careful consideration. Alternatives like indoor storage, canvas covers, or tarps offer varying levels of protection and cost savings, depending on your boat’s size, storage conditions, and budget.

By weighing the benefits, drawbacks, and costs outlined in this article, you can make an informed decision about whether shrink wrapping is worth it for your boat. Evaluate your priorities—protection, accessibility, cost, or sustainability—and choose the option that best safeguards your investment while aligning with your financial and environmental goals.

Happy Boating!

Share The Average Cost to Shrink Wrap a Boat (per foot) with your friends and leave a comment below with your thoughts.

Read The Average Cost of Replacing Risers and Manifolds until we meet in the next article.

Hello friends, its wonderful paragraph on the topic of tutoringand entirely defined, keep it up all the time.