Cost for standing rigging replacement

Discover the true cost of replacing rod rigging on a sailboat, including materials, labor, and tips to save.

Standing rigging is the backbone of a sailboat’s structural integrity, ensuring the mast remains secure under the immense forces of wind and waves. For sailboat owners, replacing standing rigging—particularly rod rigging—is a significant maintenance task that can be both costly and complex. Whether you own a 35-foot J35 or a larger 44-foot vessel, understanding the costs involved and the factors influencing them is critical to making informed decisions. This guide provides a detailed breakdown of the costs associated with rod rigging replacement, explores material options, labor considerations, and offers practical tips to reduce expenses while maintaining safety and performance.

What Is Rod Rigging and Why Replace It?

Rod rigging consists of solid stainless steel or high-performance alloy rods that support the mast, offering superior strength and reduced stretch compared to traditional wire rigging. Commonly found on performance-oriented sailboats like the J35 or Swan 43, rod rigging is favored for its durability and aerodynamic profile. However, like all rigging, it has a finite lifespan—typically 10–20 years—depending on usage, environmental conditions, and maintenance. Signs of wear, corrosion, or fatigue at critical points, such as where rods enter fittings, necessitate replacement to prevent catastrophic failure.

Replacing rod rigging is not just about swapping old components for new ones. It involves assessing the boat’s rigging system, choosing appropriate materials, and accounting for labor, equipment, and additional services like mast removal. Costs can vary widely based on boat size, rigging complexity, material choice, and location. For example, a 35-foot sailboat like the J35 might cost $8,000–$15,000 for a full rod rigging replacement, while a 44-foot boat could exceed $20,000.

Factors Influencing Rod Rigging Replacement Costs

Several variables determine the cost of replacing rod rigging. Below is a detailed look at the primary factors:

1. Boat Size

Larger boats require more material and labor due to their extensive rigging systems. A 35-foot J35, for instance, has a relatively complex rig with multiple shrouds and stays, while a 44-foot yacht may have additional spreaders and fittings, increasing costs. As a rough guide:

- 30–35 feet: $8,000–$15,000

- 38–40 feet: $10,000–$18,000

- 44–50 feet: $15,000–$25,000

2. Rigging Complexity

The complexity of the rigging system significantly impacts costs. Single-spreader rigs with single lowers are simpler and less expensive, while double-spreader rigs with multiple shrouds, like those on a J35 or a 33RH, require more materials and labor. Specialized components, such as furlers or custom end fittings, further increase expenses. For example, a double-spreader rig with rod rigging might add $2,000–$5,000 to the total cost compared to a single-spreader wire rig.

3. Material Choice

Rod rigging is typically made from stainless steel, Nitronic 50 stainless steel, or synthetic materials like Dyneema. Each material has unique properties affecting cost, performance, and maintenance:

| Material | Cost per Foot | Strengths | Weaknesses |

|---|---|---|---|

| Stainless Steel | $10–$20 | Durable, corrosion-resistant, affordable | Heavier, moderate stretch |

| Nitronic 50 | $20–$40 | High tensile strength, low stretch | More expensive, specialized fittings |

| Synthetic (Dyneema) | $25–$50 | Lightweight, minimal stretch | Prone to chafe, requires frequent inspection |

- Stainless Steel: A cost-effective choice for cruising boats, stainless steel is robust and easy to maintain. It’s ideal for sailors prioritizing durability over performance.

- Nitronic 50: This high-performance alloy is lighter and stronger than standard stainless steel, making it popular for racing boats. Its higher cost reflects its superior resistance to elongation and fatigue.

- Synthetic Rigging: Made from high-strength fibers like Dyneema, synthetic rigging is the lightest option, offering excellent performance for racing. However, it’s prone to chafe and requires regular inspection, which may deter cruising sailors.

4. Labor Costs

Professional riggers charge $50–$150 per hour, with total labor costs ranging from $2,000 to $5,000 depending on the boat’s size and rigging complexity. The process includes removing the old rigging, installing new rods, tuning the rig, and potentially unstepping and stepping the mast. In high-cost areas like the San Francisco Bay Area, labor rates may skew higher, while regions like South Carolina may offer more competitive pricing.

5. Haul-Out and Mast Removal

Most rod rigging replacements require unstepping the mast, which involves crane services and haul-out fees. These costs typically range from $500 to $2,000, depending on the boatyard and location. For example, a rigger in Charleston, South Carolina, might charge $1,000 for crane services, while costs in the Bay Area could approach $2,000.

6. Additional Repairs

Inspections often reveal issues like corroded chainplates, worn spreader tips, or damaged fittings, which can add $1,000–$3,000 to the project. For instance, replacing chainplates on a 35-foot boat might cost $1,500, while addressing mast corrosion could add another $500–$1,000.

7. Location

Labor rates and rigger availability vary by region. Coastal areas with a strong sailing culture, like Annapolis or Seattle, often have competitive pricing due to the presence of multiple riggers. In contrast, remote locations may have higher costs due to limited access to specialists. For example, a Reddit user reported paying $8,000 for a 37-foot boat in Seattle, while another paid €2,800 for a 31-foot boat in Norway.

8. Permits and Inspections

Some boatyards or marinas require permits for rigging work, especially in environmentally sensitive areas. These permits typically cost $500–$1,000. Additionally, post-replacement inspections may be required to ensure compliance with safety standards, adding $200–$500 to the total cost.

9. Insurance

Insurance costs for rigging replacement are often 1–2% of the boat’s value. For a $100,000 vessel, this equates to $1,000–$2,000. Some policies cover replacement due to wear and tear, while others require specific causes like storm damage. Checking your policy can help offset costs.

Cost Breakdown for Rod Rigging Replacement

Here’s a summarized cost breakdown for a typical rod rigging replacement on a 35-foot sailboat like the J35:

| Cost Factor | Estimated Cost Range |

|---|---|

| Materials | $5,000–$10,000 |

| Labor | $2,000–$5,000 |

| Equipment (Tools, etc.) | $1,000–$2,000 |

| Haul-Out/Mast Removal | $500–$2,000 |

| Permits/Inspections | $500–$1,000 |

| Insurance | $1,000–$2,000 |

| Total | $10,000–$22,000 |

For a 44-foot boat, costs could escalate to $15,000–$25,000 due to increased material and labor requirements.

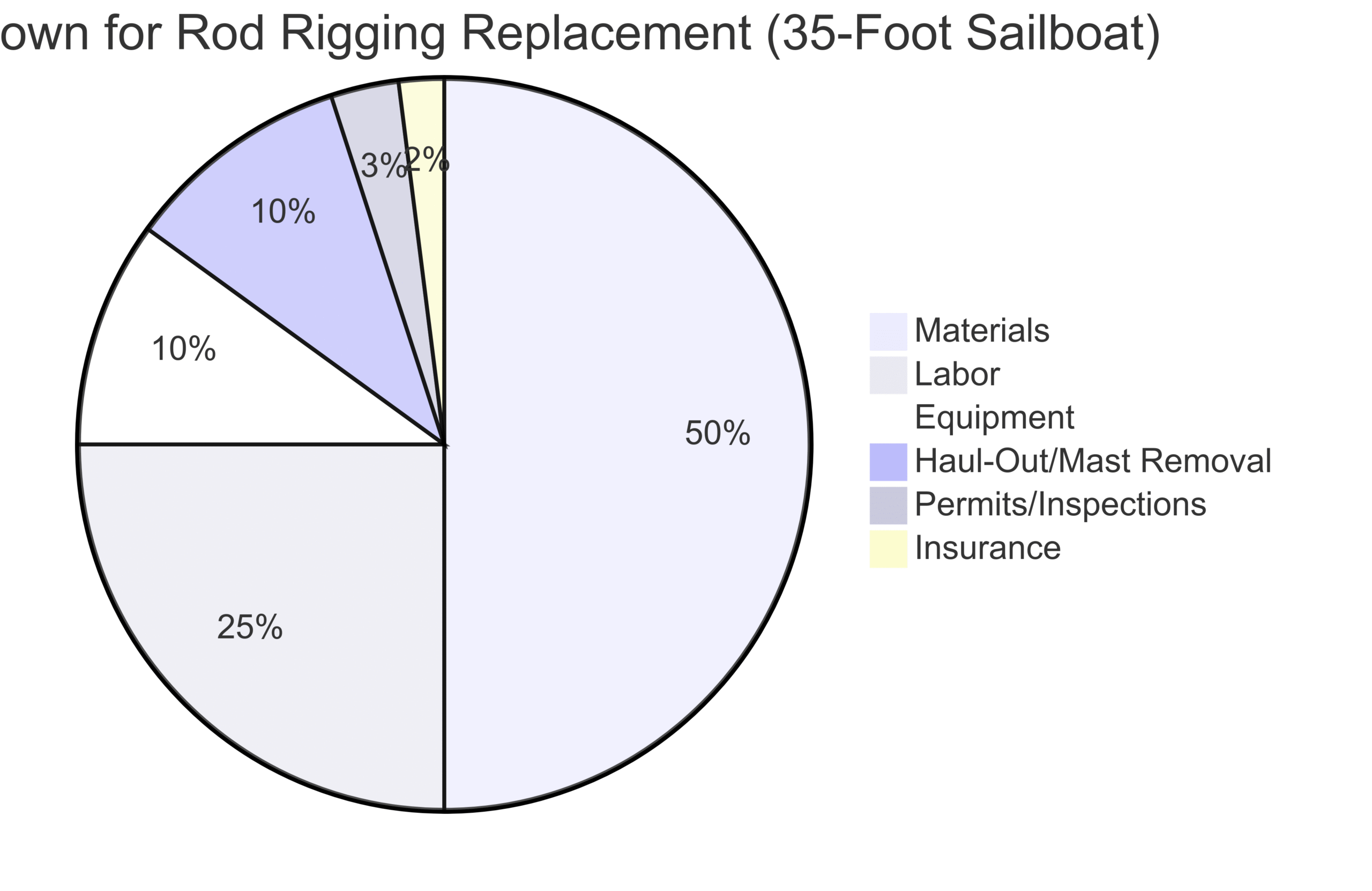

Mermaid Chart: Cost Breakdown Visualization

Below is a visual representation of the cost distribution for a rod rigging replacement on a 35-foot sailboat:

This chart illustrates that materials constitute the largest portion of the cost, followed by labor, emphasizing the importance of choosing cost-effective materials where possible.

DIY vs. Professional Replacement

DIY Rod Rigging Replacement

For cost-conscious sailors, replacing rod rigging themselves can save significant labor costs. A DIY project for a 35-foot boat might cost $6,000–$15,000 for materials and equipment alone. However, rod rigging is less DIY-friendly than wire rigging due to its rigidity and specialized fittings. Unlike wire, rods cannot be coiled easily, requiring careful handling and precise measurements. Companies like S3i or Colligo Marine can replicate rod rigging based on old samples, but the process demands expertise.

Pros of DIY:

- Saves $2,000–$5,000 in labor costs.

- Educational and rewarding for hands-on sailors.

- Allows customization of materials (e.g., switching to Dyneema).

Cons of DIY:

- Requires specialized tools (e.g., swage tools, turnbuckle wrenches).

- Risk of errors compromising safety.

- May void insurance coverage if not professionally certified.

A Reddit user shared their experience re-rigging a 34-foot boat with wire for $3,000 in materials, suggesting DIY is viable for simpler setups. However, rod rigging’s complexity often necessitates professional assistance.

Professional Replacement

Hiring a professional rigger ensures quality and safety but increases costs. For a J35, expect to pay $10,000–$15,000, including labor. Reputable riggers, like South Beach Riggers in Sausalito or Port Annapolis Marine, often require a 50% upfront deposit to cover materials and crane services. This is standard practice, as confirmed by multiple sailors on forums like Reddit and EricsonYachts.org.

Pros of Professional Replacement:

- Expertise ensures proper installation and tuning.

- Often includes warranties or insurance approval.

- Access to specialized equipment and fittings.

Cons of Professional Replacement:

- Higher costs, especially in high-demand areas.

- Scheduling delays (e.g., 6-month wait times in busy regions).

Material Alternatives: Rod vs. Wire vs. Synthetic

When replacing rod rigging, sailors can stick with rods or switch to wire or synthetic rigging, each with trade-offs:

1. Rod Rigging

- Best For: Performance-oriented boats (e.g., J35, Swan 43).

- Cost: $5,000–$10,000 for materials.

- Pros: Low stretch, aerodynamic, durable (10–20 years).

- Cons: Expensive, requires specialized riggers, limited availability.

Rod rigging can sometimes be refurbished rather than fully replaced. For example, a Swan 43 owner tested their aerofoil rod rigging with ultrasonic and dye penetrant methods, saving thousands by reusing existing rods with new end fittings.

2. Wire Rigging (1×19 or Dyform)

- Best For: Cruising boats prioritizing durability.

- Cost: $3,000–$7,000 for materials.

- Pros: Affordable, widely available, DIY-friendly with swageless fittings.

- Cons: Heavier, more stretch than rods.

Wire rigging, such as 1×19 stainless steel or Dyform, is a cost-effective alternative. A J35 owner noted that their boat was originally built with rods but often re-rigged with Dyform, suggesting compatibility with wire.

3. Synthetic Rigging (Dyneema)

- Best For: Racing boats or weight-conscious cruisers.

- Cost: $6,000–$12,000 for materials.

- Pros: Lightweight, low stretch, easy to handle.

- Cons: Prone to chafe, requires frequent inspection.

Synthetic rigging is gaining traction, especially in multihulls, but retrofitting it on a rod-rigged boat may require costly modifications to spreaders and mast terminations. A forum user highlighted that synthetic rigging’s chafe issues make it less practical for cruising unless protected with sheathing.

Tips to Reduce Replacement Costs

- Regular Inspections: Inspect rigging every 1–2 years using a magnifying glass to check for corrosion, cracks, or wear at fittings. Early detection can prevent full replacements. Manufacturers recommend replacing rigging every 10–15 years, but testing (e.g., ultrasonic or dye penetrant) can extend its life, as seen in the Swan 43 case.

- Get Multiple Quotes: Contact riggers in and outside your area. For example, a South Carolina sailor was advised to consult Randy Draftz at Charleston Yachting for competitive pricing.

- Consider Refurbishment: Instead of replacing all rods, reuse existing ones by cutting and reheading them with new fittings, potentially saving 30–50% on material costs.

- Switch to Wire or Synthetic: For cruising, wire rigging is cheaper and easier to source. For racing, synthetic rigging offers performance benefits but requires careful maintenance.

- DIY Where Feasible: Learn to use swageless fittings for wire or synthetic rigging to reduce labor costs. Online tutorials and a half-hour lesson from a rigger can make this accessible.

- Bundle Repairs: Since mast unstepping is costly, combine rigging replacement with other tasks like painting spars or replacing halyards, as one sailor did for $17,000 on a comprehensive refit.

Real-World Examples

- J35 (35 feet): Estimated cost of $10,000–$15,000 for rod rigging replacement, including materials ($6,000), labor ($3,000), and mast removal ($1,000).

- Swan 43 (43 feet): Refurbished rod rigging with testing for a fraction of the $15,000+ replacement cost.

- 37-foot Boat (Seattle): $8,000 for wire rigging replacement.

- 44-foot Boat: $10,000 for steel rigging, including installation, per a Reddit user.

- 33RH (Bay Area): $10,000 for rod rigging, including mast removal but excluding haul-out.

Insurance and Payment Considerations

Many riggers require a 50% upfront deposit to cover materials and crane services, a standard practice in the marine industry. For example, a 33RH owner paid 50% upfront for a $10,000 project, with weekly invoicing for the remainder. To protect yourself:

- Request a detailed contract outlining the scope of work and payment terms.

- Verify the rigger’s reputation through online reviews or recommendations (e.g., South Beach Riggers in Sausalito).

- Check if your insurance covers replacement costs, especially for high-value boats.

Conclusion

Replacing rod rigging on a sailboat is a significant investment, with costs ranging from $8,000 to $25,000 depending on boat size, material choice, and location. By understanding the factors driving these costs—materials, labor, equipment, and additional services—sailors can make informed decisions to balance performance, safety, and budget. Regular inspections, exploring material alternatives, and considering DIY options can significantly reduce expenses. Whether you stick with rod rigging for its performance benefits or switch to wire or synthetic for cost savings, proper planning and maintenance are key to keeping your sailboat safe and seaworthy.

Happy Boating!

Share Cost for standing rigging replacement with your friends and leave a comment below with your thoughts.

Read Replacing Standing Rigging with Mast Up: Do’s & Don’ts until we meet in the next article.

Your article helped me a lot, is there any more related content? Thanks!