Compliance of Marine Boilers With MARPOL Air Pollution Regulations

Learn how marine boilers comply with MARPOL Annex VI to reduce SOx and NOx emissions using advanced fuels, scrubbers, and efficient combustion.

The maritime industry plays a vital role in global trade, with over 80% of the world’s goods transported by sea. However, ships contribute significantly to air pollution, releasing sulfur oxides (SOx), nitrogen oxides (NOx), and other harmful emissions. To address this, the International Maritime Organization (IMO) introduced the International Convention for the Prevention of Pollution from Ships (MARPOL), specifically Annex VI, which regulates air pollution from ships. Marine boilers, integral to a ship’s machinery for generating steam and heat, are directly impacted by these regulations due to their fuel combustion processes. This article explores how modern marine boilers comply with MARPOL Annex VI, focusing on fuel quality, exhaust gas treatment, alternative fuels, combustion efficiency, and monitoring systems, while providing practical insights into their implementation.

Understanding MARPOL Annex VI

MARPOL Annex VI, adopted in 1997 and enforced since 2005, sets stringent limits on SOx and NOx emissions from ship exhausts and prohibits deliberate emissions of ozone-depleting substances. The 2008 amendments introduced a global sulfur cap and tiered NOx emission standards, with more stringent requirements in designated Emission Control Areas (ECAs). The global sulfur cap was reduced to 0.50% mass/mass (m/m) in 2020, while ECAs enforce a stricter 0.10% m/m limit. NOx emissions are regulated under Tier I, II, and III standards, with Tier III applying to ships built after 2016 operating in NOx ECAs.

Marine boilers, which burn fuel to produce steam for propulsion, heating, or auxiliary power, must align with these standards. Non-compliance can result in hefty fines, port detentions, and reputational damage. To meet these regulations, shipowners and manufacturers have adopted innovative technologies and strategies, transforming boiler design and operation.

Fuel Quality Compliance

Global Sulfur Cap and ECA Requirements

The cornerstone of MARPOL Annex VI compliance is fuel quality. The global sulfur cap of 0.50% m/m applies to all ships operating outside ECAs, while the 0.10% m/m limit applies within ECAs, such as the North American ECA and the U.S. Caribbean Sea ECA. Modern marine boilers are engineered to operate on compliant fuels, such as Marine Gas Oil (MGO) and Ultra-Low Sulfur Heavy Fuel Oil (ULSHFO), which meet these sulfur thresholds.

MGO, with its low sulfur content, requires minimal equipment upgrades, making it a popular choice for ECA compliance. ULSHFO, a blend of heavy fuel oil (HFO) and low-sulfur distillates, offers a cost-effective alternative but varies in consistency across suppliers, necessitating careful fuel management. Boilers must handle these fuels without compromising performance, requiring robust fuel systems to prevent issues like wax formation in cold climates.

Fuel Flexibility and Switching

To navigate varying regional regulations, modern boilers are designed with fuel flexibility, allowing seamless switching between HFO, MGO, and ULSHFO. This is critical when entering or exiting ECAs, where sulfur limits change. Automated fuel changeover systems ensure compliance without interrupting operations. These systems adjust fuel viscosity and temperature to maintain combustion efficiency, reducing the risk of non-compliance during transitions.

| Fuel Type | Sulfur Content | Use Case | Challenges |

|---|---|---|---|

| MGO | ≤0.10% m/m | ECA zones | Low flashpoint, cold flow issues |

| ULSHFO | ≤0.50% m/m | Global | Inconsistent quality, wax formation |

| HFO | >0.50% m/m | With scrubbers | High sulfur, requires treatment |

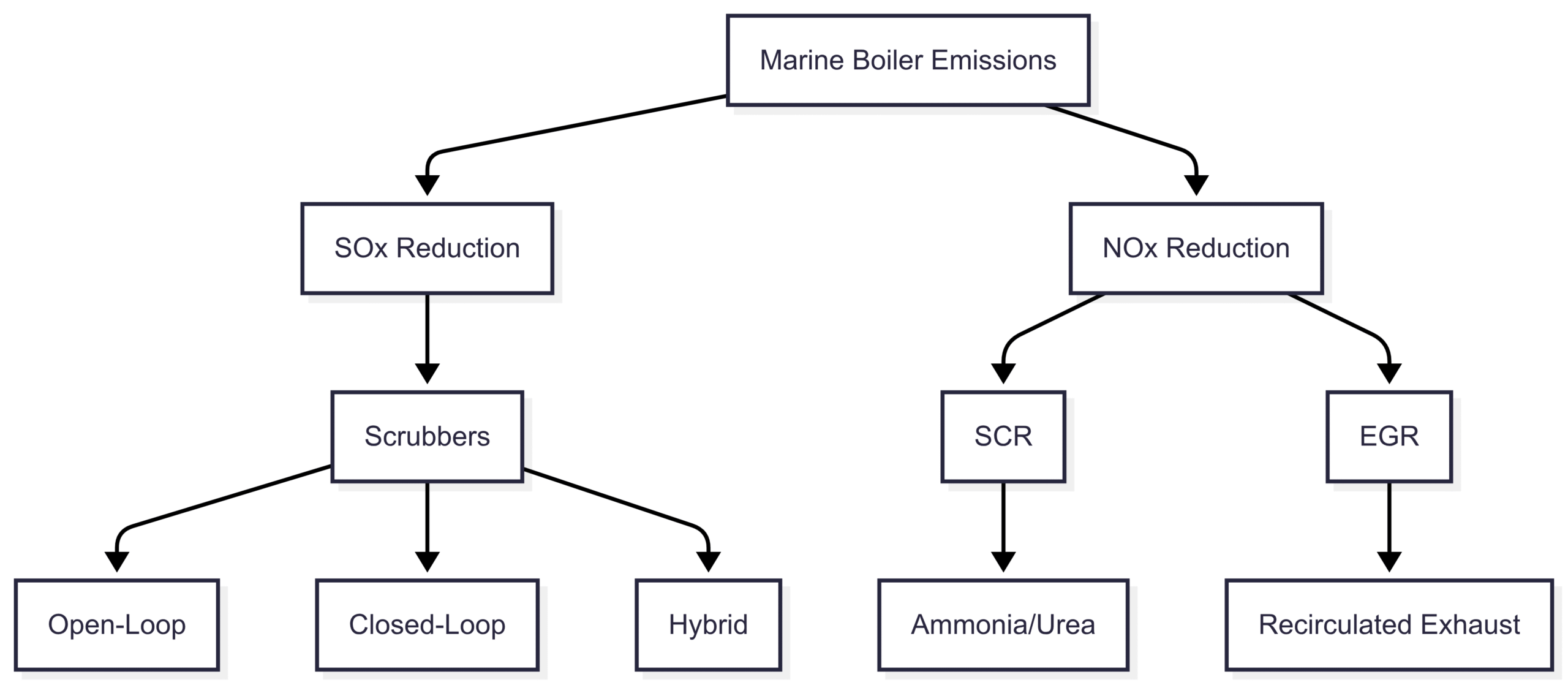

Exhaust Gas Treatment Systems

Scrubbers for SOx Reduction

Exhaust gas cleaning systems, or scrubbers, are a key solution for SOx compliance, allowing ships to use high-sulfur HFO while meeting emission standards. Scrubbers remove sulfur compounds from exhaust gases before release into the atmosphere. There are three main types:

- Open-Loop Scrubbers: Use seawater to wash exhaust gases, discharging treated water back into the sea. Cost-effective but restricted in some ports due to environmental concerns.

- Closed-Loop Scrubbers: Use a chemical solution (e.g., caustic soda) to neutralize sulfur, with minimal discharge. Ideal for zero-discharge zones but require chemical storage.

- Hybrid Scrubbers: Combine open- and closed-loop functionality, offering flexibility for varying regulations.

Scrubbers increase back pressure in boiler systems, which can affect combustion. Manufacturers like Alfa Laval offer retrofit packages to modify burners and compensate for this pressure, ensuring optimal performance. The choice of scrubber depends on operational routes, port regulations, and capital investment.

Selective Catalytic Reduction (SCR) for NOx Reduction

To meet Tier III NOx standards in ECAs, many boilers integrate Selective Catalytic Reduction (SCR) systems. SCR uses ammonia or urea as a reductant to convert NOx into nitrogen and water vapor via a catalyst. This technology achieves up to 90% NOx reduction, making it essential for new ships and retrofits in NOx ECAs. However, SCR systems require precise control to avoid ammonia slip (excess ammonia emissions) and regular catalyst maintenance.

Exhaust Gas Recirculation (EGR)

Exhaust Gas Recirculation (EGR) is another NOx reduction method, recirculating a portion of exhaust gases back into the combustion chamber. This lowers combustion temperatures, reducing NOx formation by up to 50%. EGR is simpler than SCR but less effective, often used in combination with other technologies. Its integration into boilers requires careful design to maintain thermal efficiency.

Alternative Fuels for Cleaner Operations

Liquefied Natural Gas (LNG)

LNG is a clean-burning fuel that significantly reduces SOx, NOx, and particulate matter emissions. LNG-capable boilers require modifications to fuel handling, storage, and combustion systems due to LNG’s cryogenic nature and high explosiveness. Double-wall piping with gas detection, specialized gas valve trains, and extraction air fans are mandatory for safety. LNG boilers may experience reduced steam output due to lower radiation heat transfer compared to HFO, necessitating design reviews to ensure capacity.

Biofuels and Blends

Biofuels, derived from renewable sources, offer a carbon-neutral alternative with low sulfur content. Modern boilers are increasingly compatible with biofuel blends, such as biodiesel mixed with MGO, as a transitional strategy. These fuels require minimal modifications but demand careful monitoring of cold flow properties to prevent clogging in colder climates.

Emerging Fuels: Hydrogen, Ammonia, and Methanol

Research into hydrogen, ammonia, and methanol as marine fuels is gaining momentum. These fuels produce zero or near-zero emissions but pose significant challenges:

- Hydrogen: Requires high-pressure or cryogenic storage and specialized burners.

- Ammonia: Carbon-free but toxic, requiring stringent safety measures.

- Methanol: Easier to handle but requires corrosion-resistant materials.

Boilers designed for these fuels are still in development, with ongoing trials to address safety and scalability. Their adoption will depend on infrastructure availability and regulatory support.

| Fuel Type | SOx Emissions | NOx Emissions | Challenges | Price (USD/ton) |

|---|---|---|---|---|

| LNG | Near-zero | Low | Storage, safety | 600–800 |

| Biofuels | Low | Moderate | Cold flow, cost | 900–1200 |

| Hydrogen | Zero | Low | Infrastructure | N/A (emerging) |

| Ammonia | Zero | Low | Toxicity | N/A (emerging) |

| Methanol | Low | Moderate | Corrosion | 400–600 |

Note: Prices are approximate and vary by region and supplier.

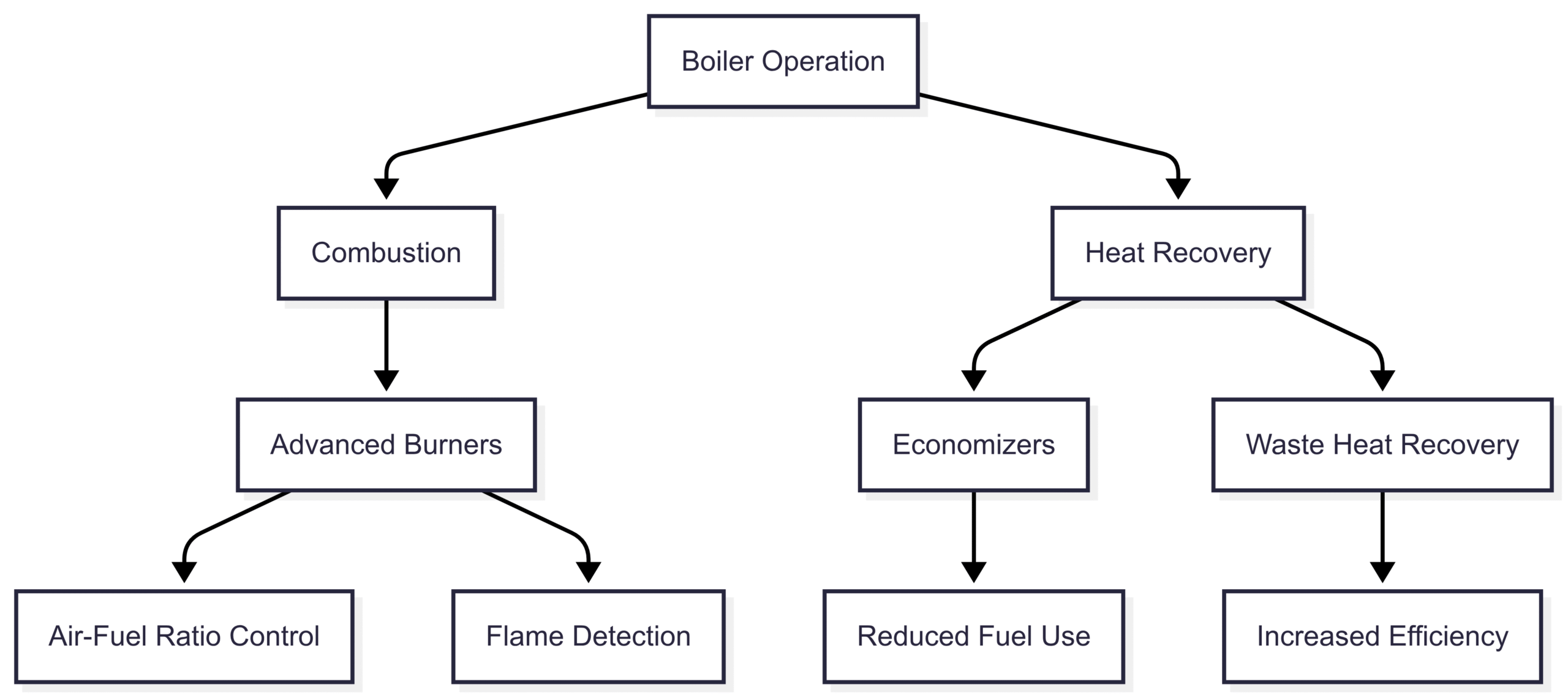

Enhancing Combustion Efficiency

Advanced Burner Design

Modern marine boilers feature advanced burners that optimize combustion, reducing unburned fuel and emissions. These burners adjust air-fuel ratios dynamically, ensuring complete combustion even with varying fuel types. For MGO, which has a lower flashpoint, burners incorporate safety features like flame detection and post-purge cycles to prevent gas buildup and explosions.

Heat Recovery Systems

Waste heat recovery units and economizers capture heat from exhaust gases, improving boiler efficiency by up to 10%. This reduces fuel consumption and emissions, aligning with MARPOL’s goals. For example, Alfa Laval’s Aalborg boilers integrate economizers that recover heat for auxiliary systems, lowering operational costs.

Monitoring, Reporting, and Verification (MRV)

Data Collection and Analysis

MARPOL Annex VI mandates continuous monitoring of emissions and fuel consumption. Modern boilers are equipped with sensors and control systems that track SOx, NOx, and operational parameters in real time. These systems ensure compliance and provide data for MRV requirements, which are critical for audits and inspections.

Record Keeping and Automation

Accurate record keeping is essential for compliance. Automated logging systems reduce human error by recording fuel usage, emission levels, and operational data. Software solutions integrate with ship management systems, providing detailed reports for regulatory bodies. For example, systems like Alfa Laval’s Touch Control interface streamline data management, ensuring compliance with minimal crew intervention.

Industry-Wide Implications

The shift toward MARPOL Annex VI compliance reflects the maritime industry’s commitment to reducing its environmental footprint. Shipowners face a choice between investing in compliant fuels, retrofitting scrubbers, or adopting alternative fuels like LNG. Each strategy impacts boiler operation, requiring careful planning and consultation with original equipment manufacturers (OEMs).

Cost-Benefit Analysis

| Strategy | Initial Cost (USD) | Operational Cost | Benefits |

|---|---|---|---|

| Scrubbers | 1–5M | Moderate | Use cheaper HFO, ECA compliance |

| LNG Conversion | 5–10M | Low | Near-zero emissions, long-term savings |

| MGO/ULSHFO | 0.5–1M | High | Minimal retrofitting, easy switch |

| Biofuels | 0.5–2M | High | Carbon-neutral, sustainable |

Note: Costs vary by vessel size and retrofit complexity.

Future Outlook

The IMO’s Marine Environment Protection Committee (MEPC) continues to refine MARPOL Annex VI. Recent discussions at MEPC 82 highlight efforts to strengthen NOx regulations, with proposed amendments to Regulation 13 and the NOx Technical Code expected to take effect in 2027. These changes will likely drive further innovation in boiler technology, emphasizing alternative fuels and advanced emission controls.

Conclusion

Compliance with MARPOL Annex VI is a multifaceted challenge for marine boilers, requiring a combination of fuel quality management, exhaust gas treatment, alternative fuels, and advanced combustion technologies. Shipowners must balance initial costs, operational efficiency, and regulatory requirements to make informed decisions. By integrating scrubbers, SCR, EGR, and cleaner fuels like LNG and biofuels, modern boilers achieve significant emission reductions while maintaining performance. As the industry evolves, ongoing research into hydrogen, ammonia, and methanol, coupled with robust monitoring systems, will pave the way for a sustainable maritime future.

Happy Boating!

Share Compliance of Marine Boilers With MARPOL Air Pollution Regulations with your friends and leave a comment below with your thoughts.

Read Your Guide to Tackle Emergency Situations On Board Ships until we meet in the next article.