What makes the OMC outdrives so undesirable?

Discover why OMC Cobra outdrives are less desirable, exploring common issues like corrosion, shift problems, and maintenance challenges.

The OMC Cobra outdrive, once a staple in the boating world, has garnered a reputation for being less desirable compared to competitors like Mercruiser. While Outboard Marine Corporation (OMC) produced innovative designs, including the Cobra outdrive, a combination of technical issues, maintenance challenges, and the company’s eventual bankruptcy have led to widespread skepticism among boaters. This article delves into the core reasons behind the unpopularity of OMC Cobra outdrives, providing a comprehensive analysis of their common problems, historical context, and comparisons with other systems. We’ll also explore practical solutions, maintenance tips, and whether these outdrives are worth considering for modern boaters.

A Brief History of OMC and the Cobra Outdrive

Outboard Marine Corporation, founded in the early 20th century, was a significant player in the marine industry, known for its Johnson and Evinrude outboard motors. In the 1970s, OMC ventured into the stern drive market, introducing the Cobra outdrive in the early 1980s after Mercruiser’s patents expired. The Cobra was designed to compete with Mercruiser’s Alpha One and Volvo Penta’s stern drives, incorporating a u-joint design similar to its competitors. Despite initial promise, the Cobra faced challenges that impacted its reputation, compounded by OMC’s poor business decisions, including the problematic FICHT outboard engine, which contributed to the company’s bankruptcy in 2000.

The Cobra outdrive was intended to address issues with OMC’s earlier Stringer drives, which were criticized for their ball gear design and susceptibility to wear. However, the Cobra introduced its own set of problems, and the lack of ongoing support after OMC’s collapse made maintenance a significant hurdle for owners.

Common Problems with OMC Cobra Outdrives

The OMC Cobra outdrive is plagued by several recurring issues that contribute to its undesirable status. Below, we outline the primary problems, their causes, effects, and troubleshooting methods, drawing from boating forums and expert insights.

1. Water Intrusion and Corrosion

Cause: The bellows and seals in the Cobra outdrive, critical for keeping water out, degrade over time due to exposure to harsh marine environments. Poor maintenance or improper storage exacerbates this issue.

Effect: Water intrusion leads to corrosion of internal components like gears, bearings, and shafts, causing performance degradation, unusual noises, and potential failure. Corrosion can render the outdrive inoperable, requiring costly repairs.

Troubleshooting and Prevention:

- Regularly inspect bellows and seals for cracks or wear, replacing them every 2-3 years or as needed.

- Ensure proper gear lube levels using high-quality marine-grade lubricants, checking for milky lube that indicates water contamination.

- Store the boat in a dry environment or tilt the outdrive up when not in use to minimize water exposure.

Example: A boater on a forum reported that neglected bellows on their 1987 Cobra led to severe corrosion, destroying the upper gear housing and requiring a $2,000 repair.

2. Shift Cable and Linkage Problems

Cause: The shift cable and linkage system in the Cobra outdrive is prone to wear, corrosion, or improper adjustment. The design, including the Electronic Shift Assist (ESA) system, is complex and sensitive to misalignment.

Effect: Worn or misadjusted shift cables result in difficulty shifting into forward or reverse, or complete failure to engage gears. This can leave boaters stranded or unable to maneuver effectively.

Troubleshooting and Prevention:

- Inspect the shift cable for corrosion or fraying, replacing it if drag exceeds 2.5 lbs (measured with a fish scale).

- Adjust the shift linkage using OMC-specific tools, following updated instructions from sources like Hastings’ guides.

- Regularly lubricate the linkage and check the ESA system for functionality.

Example: A 2017 forum post described a Cobra owner losing reverse due to a corroded shift cable, costing them multiple weekends and significant expense to repair.

3. Trim and Tilt System Issues

Cause: The hydraulic trim and tilt system in Cobra outdrives can develop leaks in the cylinders, hoses, or pump. Air in the system or electrical issues with the pump motor can also cause problems.

Effect: Boaters may experience slow, erratic, or complete failure of the trim and tilt function, impacting the ability to adjust the outdrive for optimal performance or shallow water navigation.

Troubleshooting and Prevention:

- Check hydraulic fluid levels and inspect for leaks in hoses and cylinders, replacing damaged components.

- Bleed the hydraulic system to remove air, ensuring smooth operation.

- Test the trim pump motor and electrical connections for faults, replacing relays or switches as needed.

Example: A boater noted replacing trim hoses twice in 15 years on a Cobra, highlighting the system’s susceptibility to wear in saltwater environments.

4. Overheating

Cause: Overheating can stem from restricted water flow (e.g., clogged water pump or hoses), a faulty thermostat, or exhaust system issues. The Cobra’s water pump design, while accessible, is sensitive to impeller wear.

Effect: Overheating damages the engine and outdrive components, leading to reduced performance and potential catastrophic failure.

Troubleshooting and Prevention:

- Inspect and replace the water pump impeller every 2-3 seasons, especially if operating in silty or sandy waters.

- Check the thermostat and hoses for blockages, ensuring proper water circulation.

- Flush the cooling system after each use in saltwater to prevent corrosion.

Example: A forum user reported overheating issues due to a worn impeller, which was resolved by replacing it without removing the lower unit—a rare advantage of the Cobra design.

5. Gear Problems

Cause: Worn gears, damaged shift components (e.g., cone clutch or shift shoe), or improper gear lube filling can lead to gear issues. Incorrect filling, such as using the bottom plug, starves upper gears of lubrication.

Effect: Symptoms include grinding noises, difficulty shifting, or complete gear failure, rendering the outdrive inoperable.

Troubleshooting and Prevention:

- Inspect gears and shift components during annual maintenance, replacing worn parts.

- Follow OMC’s specific gear lube filling procedure, using the correct fill and vent plugs to ensure proper lubrication.

- Consider aftermarket lower units from brands like SEI if OEM parts are unavailable.

Example: A boater purchased a 1987 boat with a Cobra outdrive for $500, only to find the upper gears “toast” due to improper lube filling, requiring a costly replacement.

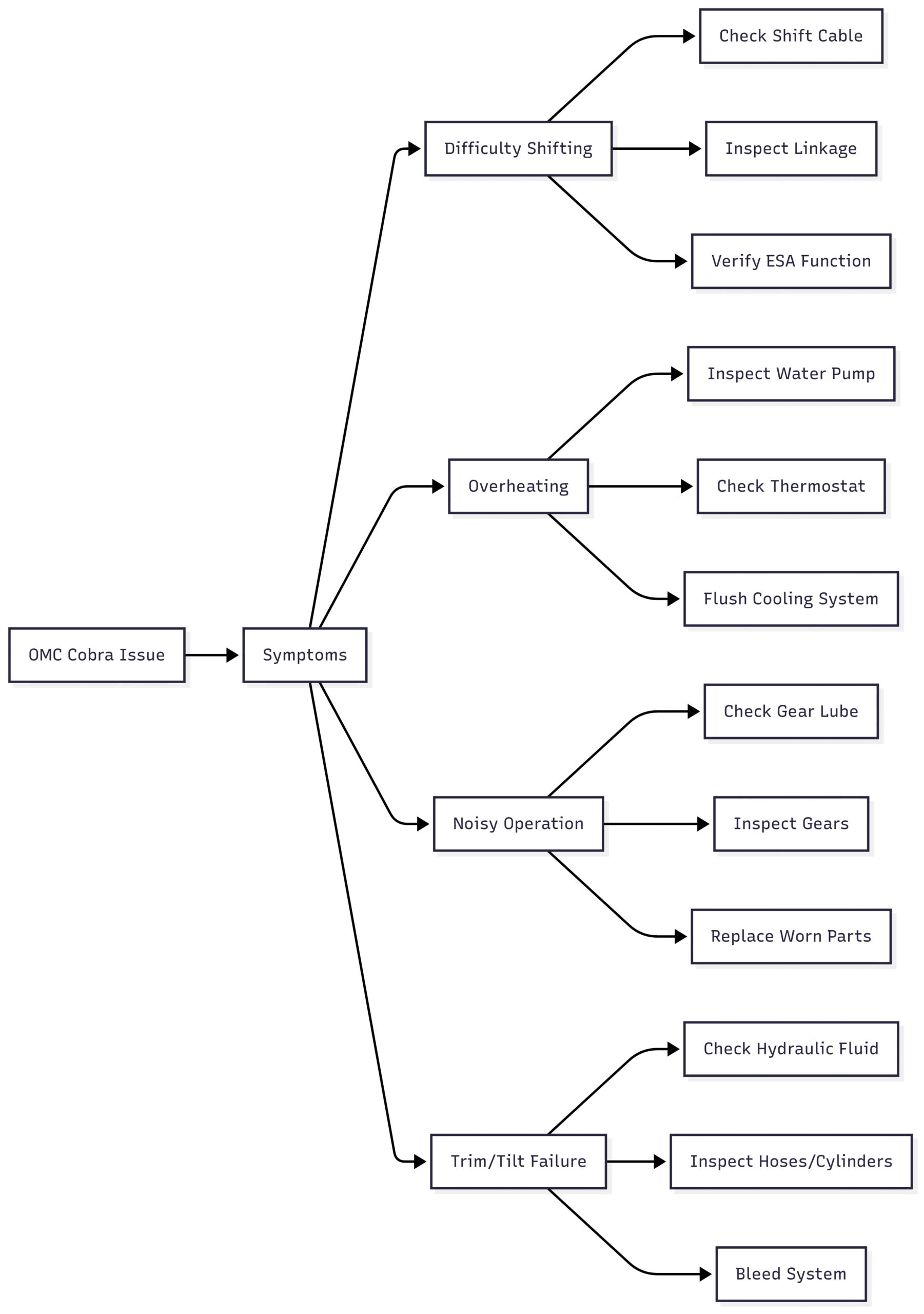

Chart: OMC Cobra Outdrive Problem Flowchart

Below is a flowchart to guide boaters in diagnosing common Cobra outdrive issues.

Comparison with Mercruiser and Volvo Penta

To understand why OMC Cobra outdrives are less desirable, it’s useful to compare them with competitors like Mercruiser’s Alpha One and Volvo Penta’s SX drives.

| Feature | OMC Cobra | Mercruiser Alpha One | Volvo Penta SX |

|---|---|---|---|

| Design | U-joint, complex shift mechanism | U-joint, simpler shift design | U-joint, modern design |

| Parts Availability | Limited, aftermarket options | Widely available | Widely available |

| Mechanic Support | Scarce, specialized knowledge needed | Abundant, standardized training | Abundant, standardized training |

| Maintenance Ease | Moderate (easy impeller access) | Easy | Easy |

| Durability | Prone to corrosion, gear issues | Reliable with proper maintenance | Highly reliable |

| Transom Design | Larger hole, flexible seal | Bolted, smaller hole | Bolted, similar to OMC |

| Cost of Replacement | $2,000-$4,000 (aftermarket) | $3,000-$5,000 | $3,500-$6,000 |

Analysis: The Cobra’s transom design allows easier impeller replacement and avoids some Mercruiser-specific issues like rotted steering arm bolts. However, its complex shift mechanism and limited parts availability make it less appealing. Mercruiser’s widespread support and simpler design make it the preferred choice, while Volvo Penta’s SX drive benefits from modern engineering and compatibility with OMC transom mounts.

Why the Negative Reputation?

The OMC Cobra’s reputation stems from a combination of technical and market factors:

- Company Bankruptcy: OMC’s collapse in 2000 left Cobra owners without factory support, making parts and service scarce. While aftermarket suppliers like SEI provide some components, availability is not guaranteed long-term.

- Complex Design: The Cobra’s shift mechanism, including the ESA system, requires precise adjustment and specialized tools, deterring many mechanics. Forum users frequently cite the difficulty of finding technicians willing to work on Cobras.

- Historical Context: OMC’s earlier Stringer drives were notoriously unreliable, with ball gears wearing out after 200 hours and a clunky tilt mechanism. The Cobra, while an improvement, inherited this negative perception.

- Market Dominance by Mercruiser: Mercruiser’s early patents on stern drive technology forced OMC to design workarounds, resulting in less robust systems. Mercruiser’s market saturation and extensive dealer network further marginalized OMC.

- FICHT Engine Fallout: OMC’s failed FICHT outboard engine, plagued by reliability issues, damaged the brand’s reputation, casting a shadow over the Cobra outdrive despite its separate design.

Real-World Experiences from Boaters

Boating forums reveal a polarized view of OMC Cobra outdrives. Some owners, like LouC, praise their Cobra for smooth shifting and durability when properly maintained, citing 15 years of reliable service in saltwater with minimal repairs. Others, like thajeffski, warn against purchasing Cobra-equipped boats due to repair challenges and high costs, with one user spending multiple weekends fixing a shift issue after mechanics refused to work on it.

A common theme is the difficulty of finding parts and qualified mechanics. One boater, Aquadobie12, bought a 1987 boat with a Cobra for $500, only to discover severe gear damage due to improper maintenance, highlighting the risks of neglected units. Conversely, SEA CUBE Fishing noted that a well-maintained Cobra can be “bulletproof,” emphasizing the importance of proper setup.

Maintenance Tips for OMC Cobra Owners

For those considering or owning a Cobra outdrive, proactive maintenance is critical to mitigate its issues:

- Annual Inspections: Check bellows, seals, and shift cables annually, replacing worn components promptly.

- Proper Lubrication: Use OMC’s specified gear lube and filling procedure to prevent gear wear. A service manual from sources like outboardbooks.com is invaluable.

- Specialized Tools: Invest in OMC alignment tools for shift cable adjustments to ensure smooth operation.

- Regular Flushing: Flush the cooling system after each use to prevent corrosion, especially in saltwater.

- Find a Knowledgeable Mechanic: Seek out mechanics experienced with OMC systems, as general marine technicians may lack the expertise.

Should You Buy a Boat with an OMC Cobra Outdrive?

The decision to purchase a boat with a Cobra outdrive depends on several factors:

- Budget: Cobra-equipped boats are often cheaper due to their reputation, as seen with Aquadobie12’s $500 purchase. However, repair costs can quickly offset this savings, with aftermarket lower units costing $1,500-$2,500.

- Mechanical Skills: Boaters comfortable with DIY repairs and parts sourcing may find Cobras manageable, as demonstrated by owners who successfully maintain their drives.

- Availability of Support: If local mechanics are unwilling to service Cobras, as reported by Blazah, maintenance becomes a significant challenge.

- Intended Use: For light, freshwater use, a well-maintained Cobra may suffice. In demanding conditions or saltwater, the risk of corrosion and parts scarcity increases.

For most boaters, a Mercruiser or Volvo Penta-equipped boat is a safer choice due to better support and reliability. However, if the Cobra boat is in excellent condition and significantly cheaper, it may be worth considering with thorough inspection and a maintenance plan.

Potential Costs of Ownership

Below is a table estimating common repair costs for OMC Cobra outdrives, based on forum reports and aftermarket pricing:

| Repair | Estimated Cost (USD) | Notes |

|---|---|---|

| Bellows Replacement | $200-$400 | Includes parts and labor |

| Shift Cable Replacement | $150-$300 | Requires precise adjustment |

| Gear Housing Repair/Replacement | $1,500-$2,500 | Aftermarket units from SEI |

| Trim Cylinder Replacement | $300-$600 | Varies by extent of hydraulic system damage |

| Water Pump Impeller | $50-$150 | DIY-friendly, accessible without removing lower unit |

| Full Outdrive Replacement | $2,000-$4,000 | Aftermarket or refurbished OEM units |

Conclusion

The OMC Cobra outdrive’s undesirable reputation stems from a combination of technical issues—water intrusion, shift cable problems, trim and tilt failures, overheating, and gear issues—compounded by OMC’s bankruptcy and the resulting scarcity of parts and service. While the Cobra offers advantages like easy impeller access and a robust transom design, its complex maintenance requirements and limited support make it less appealing than competitors like Mercruiser and Volvo Penta. For boaters willing to invest in proper maintenance and source parts, the Cobra can be reliable, but for most, the risks outweigh the benefits. When considering a Cobra-equipped boat, weigh the initial cost savings against potential repair expenses and ensure access to knowledgeable mechanics or DIY skills.

Share What makes the OMC outdrives so undesirable? with your friends and leave a comment below with your thoughts.

Read Star Tron vs. Sta-Bil Fuel Stabilizer: Detailed Comparison until we meet in the next article.