Checklist – Before Departure – Engine Room

Ensure a safe boating trip with our comprehensive engine room checklist. Learn key pre-departure checks for fluid levels, belts, electrical systems, and safety gear.

Boating offers an unparalleled sense of freedom, but it comes with the responsibility of ensuring your vessel is in top condition before setting sail. The engine room is the heart of any boat, and a thorough pre-departure inspection can prevent mechanical failures, enhance safety, and ensure a smooth journey. This detailed guide provides a comprehensive checklist for inspecting your engine room, covering fluid levels, belts, hoses, electrical systems, safety equipment, and more. Whether you’re embarking on a short trip or an extended voyage, these checks are essential for a safe and enjoyable boating experience.

Why Engine Room Checks Matter

The engine room houses critical systems that power and control your vessel. A single overlooked issue—such as a leaking hose, low oil level, or faulty electrical connection—can lead to breakdowns, costly repairs, or even dangerous situations at sea. Regular pre-departure checks reduce these risks by identifying potential problems early. By following a structured checklist, you can ensure all systems are functioning correctly, comply with safety regulations like SOLAS (Safety of Life at Sea), and maintain a detailed maintenance log for long-term vessel health.

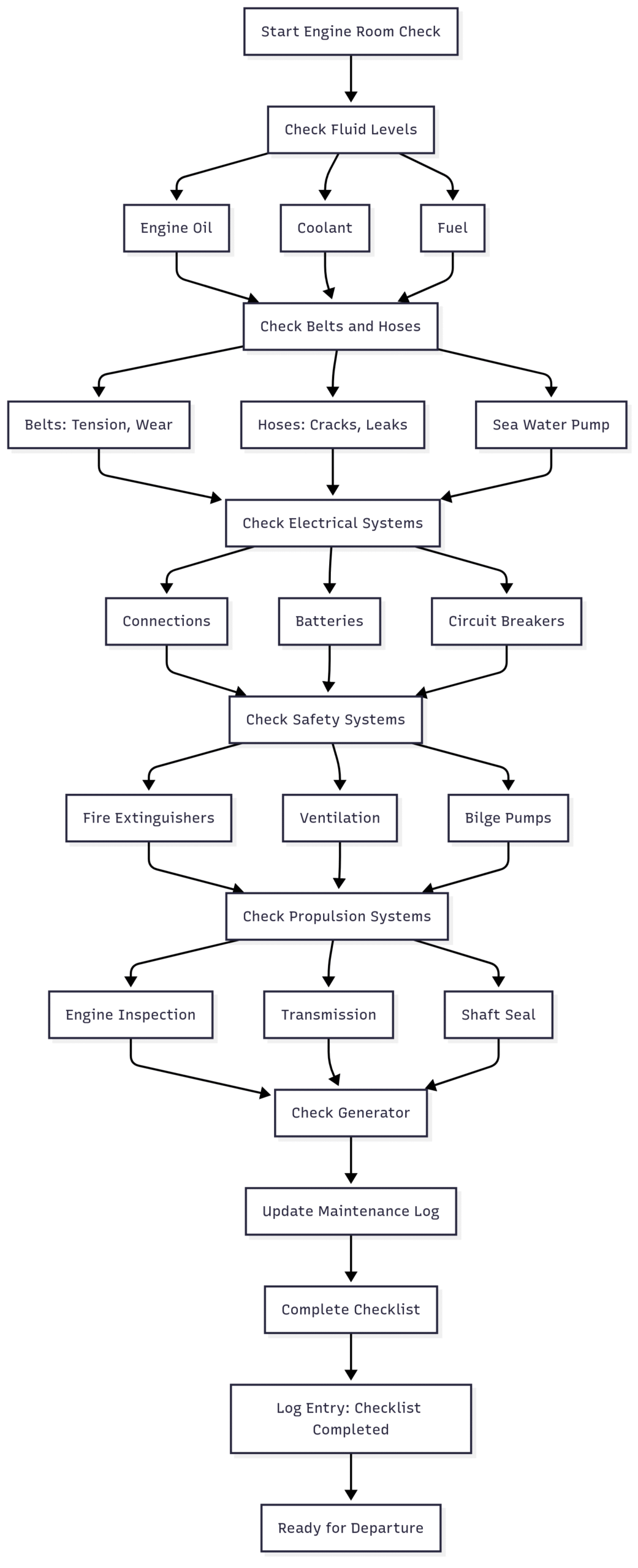

This article outlines a step-by-step engine room checklist, incorporating best practices from marine experts and industry standards. We’ll also include a practical checklist table and a visual workflow using a Mermaid chart to streamline your inspection process. Let’s dive into the key areas to inspect before departure.

Engine Room Checklist: Key Areas to Inspect

1. Fluid Levels

Fluids are the lifeblood of your engine, ensuring proper lubrication, cooling, and fuel delivery. Checking fluid levels is a critical first step.

- Engine Oil: Verify the oil level using the dipstick, ensuring it’s within the manufacturer’s recommended range. Inspect the oil’s condition—dark or gritty oil may indicate the need for a change. Record the service date on the oil filter for tracking.

- Coolant: Check the coolant level in the engine’s cooling system. Ensure the coolant cap is secure and free of leaks. Top off with the appropriate coolant type if needed.

- Fuel: Confirm the fuel tank is adequately filled, ideally to capacity for longer trips. Follow the “1/3 rule”: one-third for the outbound trip, one-third for the return, and one-third in reserve. Inspect fuel lines and connections for leaks or wear.

2. Belts and Hoses

Belts and hoses are vital for engine operation, transferring power and circulating fluids. Wear or damage can lead to system failures.

- Belts: Examine belts for proper tension, alignment, and signs of wear such as cracks, fraying, or glazing. Check for belt dust, which may indicate misalignment or excessive wear. Adjust or replace as needed.

- Hoses: Inspect hoses for cracks, swelling, or leaks, especially at connection points. Ensure hose clamps are tight, with double clamps used below the waterline for added security.

- Sea Water Pump: Check the sea water pump for leaks through the weep hole, which could indicate a failing seal. Inspect the impeller for wear and replace if necessary.

3. Electrical Systems

Reliable electrical systems are essential for engine operation and onboard safety.

- Connections: Inspect all electrical connections for tightness and corrosion. Loose or corroded connections can cause power failures or fire hazards.

- Batteries: Check battery terminals for cleanliness and secure connections. Measure battery voltage to ensure it’s within the normal range (typically 12.6V for a fully charged battery). Inspect battery cables to and from the alternator for wear.

- Circuit Breakers: Verify that circuit breakers are in the correct position and not tripped. Test switches at the breaker panel to ensure functionality.

- Alternator: Check the alternator belt for proper tension and alignment. Look for excessive dust buildup, which may indicate belt slippage.

4. Safety and Auxiliary Systems

Safety equipment and auxiliary systems must be in working order to handle emergencies and ensure proper engine room operation.

- Fire Extinguishers: Ensure fire extinguishers are fully charged, accessible, and within their service date. Check mounting brackets for security.

- Ventilation: Verify that the engine room ventilation system is operational and fire dampers are open. Run blowers for at least four minutes before starting the engine to clear fumes.

- Bilge and Bilge Pumps: Inspect the bilge for water, debris, or signs of leaks. Test the bilge pump by lifting the float switch to confirm it activates. Ensure bilge alarms are functional.

- Sea Strainers and Seacocks: Check sea strainers for debris and clean if necessary. Ensure seacocks are operational and have appropriately sized softwood bungs nearby for emergency use.

5. Propulsion and Mechanical Systems

The propulsion system, including the engine and transmission, must be thoroughly inspected to ensure reliable performance.

- Engine Inspection: Look for drips, leaks, belt dust, or fuel/oil streaks on the engine block. Start the engine and observe the exhaust outlet for proper water flow and any unusual smells or colors.

- Transmission: Check the gear cooler, oil level, transmission pump, and output flange for leaks or wear. Test forward and reverse gears while still tied to the dock.

- Shaft Seal and Stuffing Box: Inspect the shaft seal and stuffing box for leaks or excessive wear. Ensure the stern tube and seal lubrication system are in order.

- Control Cables: Verify that control cables are not kinked and that end fittings are securely fastened. Test throttle response in neutral.

6. Generator (Genset) Checks

If your vessel is equipped with a generator, perform these additional checks:

- Filters: Record service dates on replaceable filters (oil, fuel, etc.).

- Connections and Belts: Inspect electrical connections, circuit breakers, and belts for proper tension and wear.

- Fluids: Check oil and coolant levels.

- Battery and Alternator: Verify battery condition and alternator belt tension.

7. Additional Systems

Other critical systems require attention to ensure overall vessel readiness.

- Exhaust System: Inspect the exhaust hose, muffler, and elbow for cracks, leaks, or corrosion. Confirm proper water flow through the exhaust system.

- Sacrificial Anode: Check the anode in the heat exchanger and replace it when 50% depleted.

- Cooling Systems: Ensure freshwater and seawater cooling system valves are correctly set, and pressures/temperatures are within normal ranges.

- Thrusters and Steering Gear: Verify that bow/stern thrusters are operational and retractable thrusters are secured. Test the steering gear in coordination with the Officer of the Watch (OOW).

- Alarms and Communication: Test bilge alarms, engine room telephone, and telegraph systems. Ensure all alarms are connected and functional.

8. Documentation and Logging

Maintaining accurate records is essential for tracking maintenance and ensuring compliance with regulations.

- Maintenance Log: Record all maintenance activities, including oil changes, filter replacements, and service dates. Log engine hours after starting the engine.

- Pre-Departure Checklist: Use a standardized checklist to ensure all checks are completed. Upon completion, enter in the vessel’s Engine Log Book: “BEFORE DEPARTURE CHECKLIST COMPLETED,” including the date, time, port, and signatures of the Engineer on Duty and Chief Engineer.

Pre-Departure Checklist Table

Below is a concise table summarizing the key engine room checks, with columns for completion status and notes.

| Check | Status (✓/N/A) | Notes |

|---|---|---|

| Engine Oil Level | Within range, condition checked | |

| Coolant Level | Cap secure, no leaks | |

| Fuel Level and Lines | No leaks, 1/3 rule applied | |

| Belts (Tension, Wear) | No cracks, fraying, or glazing | |

| Hoses and Clamps | Double clamps below waterline | |

| Electrical Connections | Tight, no corrosion | |

| Battery Voltage and Terminals | 12.6V, clean and secure | |

| Circuit Breakers | Not tripped, switches tested | |

| Fire Extinguishers | Charged, accessible | |

| Ventilation System | Blowers run, dampers open | |

| Bilge and Bilge Pumps | No water/debris, pump functional | |

| Sea Strainers and Seacocks | Clean, bungs available | |

| Transmission (Oil, Gear Cooler) | No leaks, gears tested | |

| Shaft Seal/Stuffing Box | No leaks, lubricated | |

| Exhaust System | No cracks, proper water flow | |

| Sacrificial Anode | Replace if 50% depleted | |

| Control Cables | Not kinked, securely fastened | |

| Generator (Filters, Fluids, Belts) | Service dates recorded | |

| Alarms and Communication Systems | Tested and functional | |

| Maintenance Log Updated | Engine hours logged |

Workflow: Engine Room Inspection Process

To visualize the inspection process, the following flowchart outlines the sequence of checks:

Additional Pre-Departure Considerations

While the engine room is the focus, a holistic pre-departure routine includes checks beyond the engine room to ensure vessel readiness.

Below Deck

- Stowage: Secure loose items to prevent movement during transit, as required by SOLAS. Check hatches, windows, and portholes for secure closure to prevent water ingress.

- Tanks: Verify water and fuel tank levels (ideally full) and ensure the holding tank is not full. Arrange for a pump-out if necessary.

- Safety Systems: Test carbon monoxide and gas detection systems. Lift floorboards to check for water accumulation or leaks.

On Deck

- Gear Stowage: Secure loose gear, canvas covers, and cushions. Check for trip hazards and trailing ropes that could entangle the propeller.

- Anchor: Ensure the anchor is ready for deployment, with the warp attached to a strong point.

- Shore Power: Disconnect shore power to avoid damage to marina equipment.

- Safety Gear: Confirm that life jackets, first-aid kits, and other safety equipment are accessible and in good condition.

Passage Plan and Navigational Readiness

- Weather Check: Review the weather forecast and reassess the passage plan if conditions change.

- Navigation: Test VHF radio (using the harbor channel, not Ch16), check navigation instruments, and ensure a backup chart is available. Log the passage plan with a shore contact or tracking app.

- Communication: Perform a radio check with the harbor master and ensure mobile phones are charged.

Dockside and Crew

- Dockside Checks: Inspect lines for easy slipping, ensure all yacht items are onboard, and dispose of rubbish. Check for debris in the water that could foul the propeller.

- Crew Briefing: Conduct a safety briefing, fit life jackets, and assign departure roles. Share the passage plan and estimated travel time with crew and guests.

Engine Start and Final Checks

Once all checks are complete, start the engines while still tied to the dock for final verification:

- Warning Lights: Ensure no engine warning lights remain illuminated.

- Gauges: Monitor oil pressure, temperature, and battery voltage for normal readings.

- Exhaust: Listen for irregularities in exhaust sound and confirm water is circulating properly.

- Propeller and Thrusters: Test propeller movement, forward/reverse gears, and bow/stern thrusters.

- Fluid Leaks: Visually inspect for oil or coolant leaks.

Specifications and Costs (If Applicable)

While specific costs for maintenance items vary by vessel size and region, here are approximate price ranges for common components based on industry standards:

- Oil Filter: $10–$30

- Fuel Filter: $15–$50

- Sacrificial Anode: $20–$100

- Fire Extinguisher (Marine-Grade): $50–$150

- Hose Clamps (Stainless Steel): $5–$20 each

- Battery (Marine Deep Cycle): $100–$300

Regular maintenance, such as oil changes ($50–$150) and impeller replacement ($20–$50), should be budgeted annually. For major repairs or replacements (e.g., belts, hoses, or alternators), costs can range from $100 to $1,000+, depending on the part and labor.

Tips for Effective Engine Room Checks

- Develop a Custom Checklist: Adapt the provided checklist to your vessel’s specific systems and requirements.

- Use the WOBBLES Acronym: Water, Oil, Belts, Bilges, Look, Electrics, Seacocks—a simple way to remember key checks.

- Schedule Regular Maintenance: Follow manufacturer guidelines for oil changes, filter replacements, and anode checks to prevent unexpected failures.

- Train Your Crew: Ensure all crew members are familiar with the checklist and safety procedures.

- Keep Tools Handy: Maintain a toolkit with basic tools, spare parts, and through-hull plugs for quick repairs.

Conclusion

A thorough pre-departure engine room checklist is the cornerstone of safe and enjoyable boating. By systematically inspecting fluid levels, belts, hoses, electrical systems, safety equipment, and propulsion components, you can minimize risks and ensure your vessel is ready for the journey. Use the provided table and flowchart to streamline your process, and maintain a detailed maintenance log to track your vessel’s health over time. With preparation and diligence, you’ll set sail with confidence, knowing your engine room is in top condition.

Happy Boating!

Share Checklist – Before Departure – Engine Room with your friends and leave a comment below with your thoughts.

Read Top 10 Marine Auxiliary Machinery Systems Explained until we meet in the next article.