Carbon Intensity Indicator (CII): Insights & support

Understand the Carbon Intensity Indicator (CII) for ships, its calculation, compliance challenges, and actionable decarbonization strategies.

The shipping industry, a cornerstone of global trade, accounts for approximately 3% of global greenhouse gas (GHG) emissions. With increasing pressure to combat climate change, the International Maritime Organization (IMO) has introduced the Carbon Intensity Indicator (CII) as a pivotal metric to enhance the energy efficiency of ships and reduce their environmental impact. This article provides an in-depth exploration of the CII, its regulatory framework, compliance challenges, and actionable strategies for shipowners to meet requirements while advancing toward a sustainable maritime future.

Understanding the Carbon Intensity Indicator (CII)

The CII is an operational efficiency metric designed to measure a ship’s carbon dioxide (CO2) emissions relative to its transport work. Expressed in grams of CO2 per cargo-carrying capacity and nautical mile, it applies to cargo, RoRo, and cruise ships of 5,000 gross tonnage (GT) and above. The CII is a core component of the IMO’s Initial Strategy on Reduction of GHG Emissions from Ships, aiming to cut the shipping industry’s carbon intensity by 40% by 2030 and total GHG emissions by 50% by 2050, compared to 2008 levels.

How CII Works

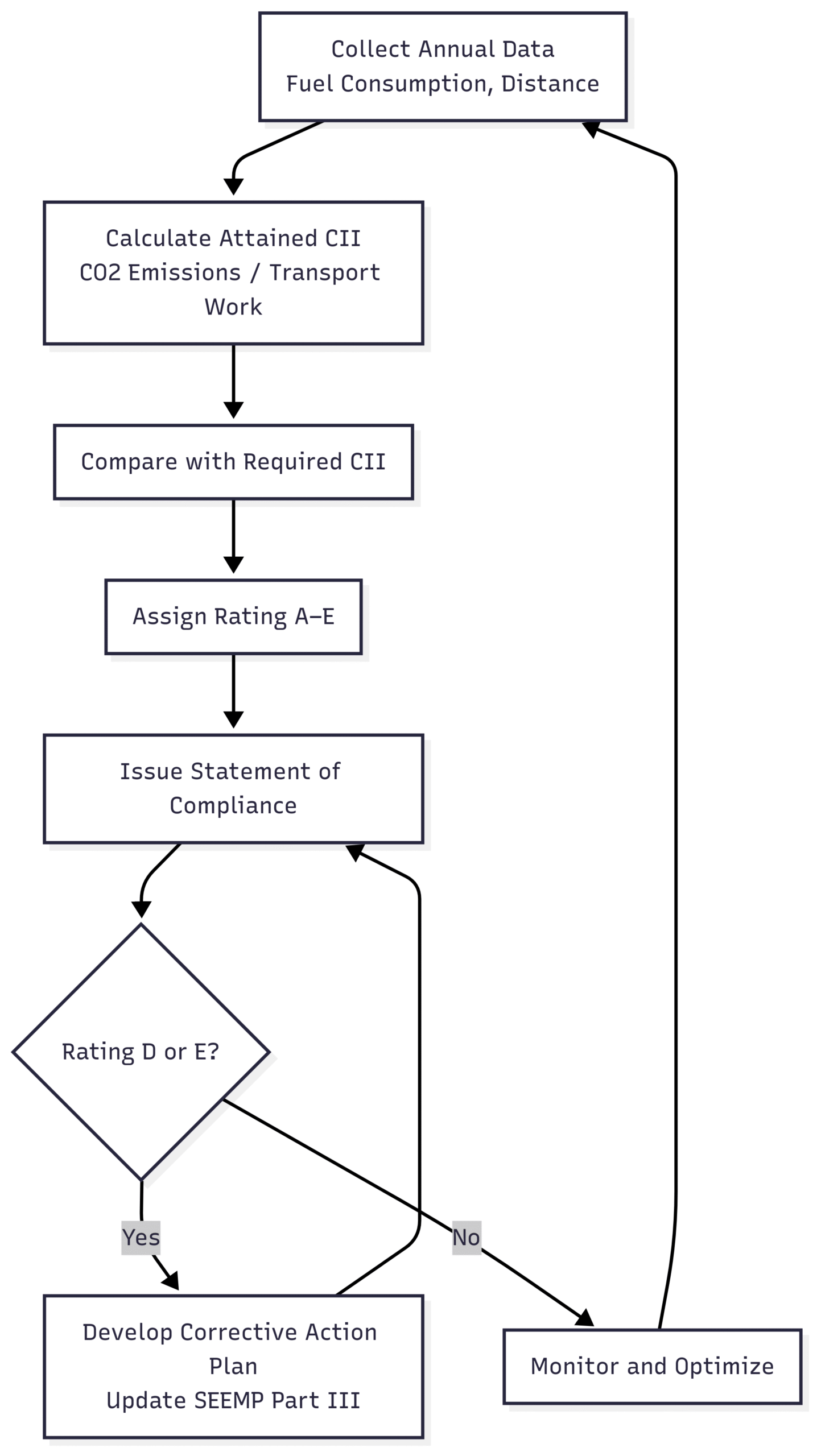

The CII process involves four key steps:

- Calculation: Shipowners calculate the attained CII using annual fuel consumption and distance traveled, sourced from the IMO Data Collection System (DCS).

- Rating: Ships receive an annual rating from A (most efficient) to E (least efficient) based on their attained CII compared to a required CII set by the IMO for each vessel type.

- Verification: The attained CII is verified annually, and a Statement of Compliance (SoC) is issued, which must be kept on board for five years.

- Improvement: Ships rated D for three consecutive years or E for one year must submit a corrective action plan as part of their Ship Energy Efficiency Management Plan (SEEMP) Part III.

The CII formula is:

Attained CII = Total CO2 Emissions / (Transport Work)

Where:

- Total CO2 Emissions = Annual fuel consumption × CO2 emission factor

- Transport Work = Cargo-carrying capacity (deadweight or gross tonnage, depending on ship type) × Distance sailed (nautical miles)

Correction factors and voyage adjustments, such as those for ice-class ships or cargo heating systems, may be applied to refine the calculation.

Relationship with EEXI

The CII is closely linked to the Energy Efficiency Existing Ship Index (EEXI), a design-based metric that evaluates a ship’s technical efficiency. While EEXI focuses on a vessel’s design parameters, CII assesses operational performance. Together, they form a dual approach to reducing GHG emissions, with EEXI addressing hardware improvements and CII targeting operational strategies.

Regulatory Framework and Reporting

The CII regulation, effective since January 2023, mandates annual reporting of CII data alongside DCS submissions by March 31 each year. The attained CII and its corresponding rating (A–E) are documented in the SoC. The IMO has set progressively stricter CII thresholds through 2030 to drive continuous improvement.

The following table outlines the CII rating system and its implications:

| Rating | Description | Action Required |

|---|---|---|

| A | Major Superior | Maintain efficiency; eligible for incentives from ports or charterers. |

| B | Minor Superior | Continue optimization to sustain or improve rating. |

| C | Moderate | Monitor performance to avoid slipping to lower ratings. |

| D | Minor Inferior | If sustained for three years, submit a corrective action plan via SEEMP Part III. |

| E | Inferior | Submit a corrective action plan after one year to improve efficiency. |

The SEEMP Part III serves as a roadmap for compliance, detailing strategies to achieve or maintain a C rating or better. For ships with poor ratings, the corrective action plan must analyze the causes of non-compliance and propose actionable improvements.

Chart: CII Compliance Process

This chart illustrates the cyclical nature of CII compliance, emphasizing annual data collection, calculation, rating, and continuous improvement.

Challenges in CII Compliance

Achieving and maintaining CII compliance presents several operational, regulatory, and commercial challenges:

- Inconsistent Operational Profiles

A ship’s CII rating can vary due to factors like voyage length, port waiting times, or cargo requirements. Short voyages or frequent port calls often result in higher fuel consumption per nautical mile, negatively impacting the CII. For example, a vessel on a short, high-frequency route may struggle to maintain a consistent rating compared to one on longer voyages. - Fleet Management Constraints

Compliance requires ongoing monitoring and adjustments, such as reducing speed or altering routes, which can disrupt commercial schedules. Older vessels, which are less efficient, face greater challenges in achieving favorable ratings. Retrofitting or replacing these ships is costly, and uniform decarbonization strategies are difficult to apply across diverse fleets. - Regulatory Uncertainty

The IMO’s long-term decarbonization goals extend beyond current CII requirements, creating uncertainty for shipowners. Future regulations may demand stricter emissions targets, making it challenging to justify investments in technologies that could become obsolete. This uncertainty complicates ROI calculations for retrofits or newbuilds. - Commercial and Financial Impacts

Poor CII ratings can harm a ship’s marketability, as charterers increasingly favor vessels with strong environmental performance. Additionally, lower ratings may lead to higher fuel costs, slower voyages, or restricted port access, impacting profitability.

Decarbonization Strategies for CII Compliance

To meet CII requirements, shipowners must adopt a combination of operational adjustments, energy-efficient technologies (EETs), hull and propulsion upgrades, and alternative fuels. Below are the most effective strategies:

1. Operational Adjustments

Operational measures are often the most accessible way to improve CII ratings without significant capital investment:

- Speed Optimization: Reducing speed (slow steaming) significantly lowers fuel consumption due to the cubic relationship between speed and emissions. For example, a 10% speed reduction can yield up to 27% fuel savings.

- Voyage Planning: Optimizing routes to minimize distance and avoid congestion reduces fuel use.

- Trim and Draft Optimization: Adjusting a ship’s trim and draft enhances hydrodynamic efficiency.

- Engine Load Management: Operating engines at optimal loads improves fuel efficiency.

- Ballast Management: Efficient ballast operations reduce unnecessary weight, lowering fuel consumption.

- Cold Ironing (AMP): Using shore power during port stays eliminates onboard fuel use.

- Variable Frequency Drives (VFDs): These optimize energy use in pumps and fans.

2. Energy-Efficient Technologies (EETs)

EETs are critical for reducing fuel consumption and CO2 emissions. Tools like Vessel EQ by Azolla (https://eq.azolla.sg/) help shipowners evaluate EET options:

- Pre-Swirl Ducts: Improve propeller inflow, reducing energy loss.

- Wake Equalizing Ducts: Enhance wake flow to boost propulsion efficiency.

- Rudder Bulbs: Reduce drag and improve rudder performance.

- Propeller Boss Cap Fins (PBCF): Minimize hub vortex losses.

- Flettner Rotors and Turbo-Sails: Harness wind energy to supplement propulsion.

- Wind-Assisted Propulsion Systems (WAPS): Reduce reliance on fossil fuels.

- LED Lighting: Lowers onboard energy consumption.

3. Hull Modifications

Hull upgrades enhance hydrodynamic performance, reducing fuel use:

- Hull Coatings: Low-friction coatings minimize drag.

- Bulbous Bow Modifications: Optimize bow shape for specific operating conditions.

- Hull Cleaning and Painting: Regular maintenance prevents biofouling, which increases drag.

- Hull Air Lubrication Systems: Inject air beneath the hull to reduce friction.

4. Propulsion System Upgrades

Upgrading propulsion systems improves efficiency and reduces emissions:

- Propeller Upgrades: Advanced designs enhance thrust efficiency.

- Hybrid and Electric Propulsion: Combine traditional and electric systems for flexibility.

- Shaft Generators: Recover energy from the main engine.

- Exhaust Gas Recirculation (EGR): Reduces emissions by recycling exhaust gases.

- Waste Heat Recovery Systems: Capture and reuse engine heat for power generation.

5. Alternative Fuels

Transitioning to low-carbon fuels is a long-term solution for CII compliance:

- Liquefied Natural Gas (LNG): Emits less CO2 than traditional fuels.

- Biofuels: Renewable fuels with lower carbon footprints.

- Ammonia and Hydrogen: Emerging zero-carbon options, though infrastructure is still developing.

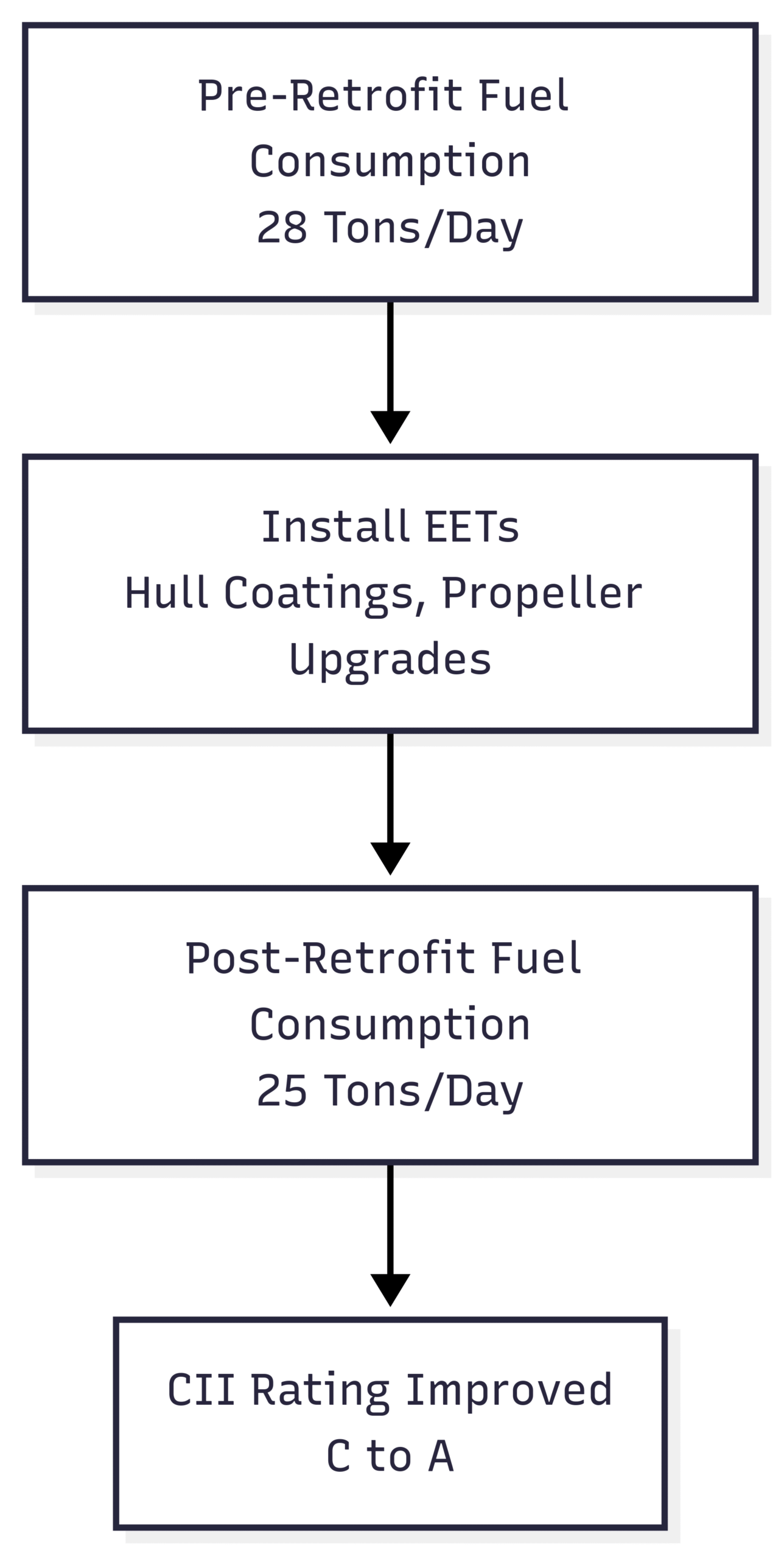

Implementation Case Study

A 106,000 DWT bulk carrier retrofitted with EETs during dry docking demonstrated significant improvements:

- Fuel Consumption Reduction: Post-retrofit data showed a 15% reduction in laden fuel consumption, attributed to hull coatings, propeller upgrades, and a wake equalizing duct.

- Comparative Analysis: Compared to a sister vessel with standard dry docking, the retrofitted ship achieved 12% lower fuel consumption, translating to a higher CII rating.

The following table summarizes the fuel savings:

| Vessel | Condition | Fuel Consumption (Tons/Day) | CII Rating Improvement |

|---|---|---|---|

| Retrofitted Vessel | Post-EET Dry Docking | 25 | B to A |

| Sister Vessel | Standard Dry Docking | 28 | C |

Chart: Fuel Savings Post-EET Retrofit

Simplifying CII Optimization with Tools

Tools like Vessel EQ simplify CII compliance by enabling shipowners to:

- Evaluate the impact of EETs on fuel consumption and emissions.

- Assess CO2 abatement potential.

- Simulate CII rating improvements based on operational or technical changes.

These tools provide data-driven insights, helping operators make informed decisions to optimize fleet performance and meet regulatory targets.

DNV’s Support for CII Compliance

DNV, a leading classification society, offers comprehensive services to support CII compliance:

- Class Services: Automatic CII calculations based on DCS data, accessible via the Emissions Insights dashboard on the Veracity platform. This tool allows real-time monitoring of preliminary CII ratings.

- Advisory Services: Expert guidance on decarbonization strategies, including EET selection, alternative fuel adoption, and SEEMP Part III corrective action plans.

Broader Implications of CII

The CII is more than a regulatory requirement; it’s a catalyst for transforming the shipping industry. High CII ratings (A or B) enhance a ship’s marketability, attract eco-conscious charterers, and may unlock incentives like reduced port fees. Conversely, poor ratings can lead to financial penalties, restricted port access, and reputational damage.

The IMO’s progressive tightening of CII thresholds through 2030 underscores the need for proactive investment in sustainability. Shipowners who adopt innovative technologies and operational practices will not only comply with regulations but also gain a competitive edge in a decarbonizing market.

Conclusion

The Carbon Intensity Indicator represents a critical step toward sustainable shipping. By integrating operational adjustments, energy-efficient technologies, hull and propulsion upgrades, and alternative fuels, shipowners can achieve compliance while reducing their environmental footprint. Tools like Vessel EQ and services from organizations like DNV provide essential support for navigating the complexities of CII compliance. As the maritime industry faces stricter emissions targets, proactive adoption of decarbonization strategies will ensure long-term competitiveness and alignment with global climate goals.

Happy Boating!

Share Carbon Intensity Indicator (CII): Insights & support with your friends and leave a comment below with your thoughts.

Read 3 Phase Induction Motor – Construction and Working until we meet in the next article.