Can You Recycle Or Reuse Boat Shrinkwrap

Learn how to recycle or reuse boat shrink wrap effectively. Discover eco-friendly options, costs, and programs to reduce plastic waste.

Boating enthusiasts know the ritual: every fall, boats are hauled out of the water and cocooned in shrink wrap to protect them from harsh winter elements. This plastic shield, typically made from low-density polyethylene (LDPE), guards against snow, ice, rain, and UV damage. But come spring, when the wrap is removed, a critical question arises: what happens to all that plastic? With an average of 20 pounds of shrink wrap used for a 20-foot boat—equivalent to about 1,730 grocery bags—the environmental impact is significant. Fortunately, boat shrink wrap can be recycled or, in some cases, reused, offering eco-conscious boaters options to reduce waste. This article explores the processes, challenges, and alternatives for recycling and reusing boat shrink wrap, providing practical steps, cost insights, and innovative solutions to keep plastic out of landfills.

The Environmental Challenge of Boat Shrink Wrap

The boating industry relies heavily on shrink wrap to protect vessels during off-season storage or transport. Manufacturers also use it to shield new boats during delivery. However, the plastic waste generated is substantial. According to the U.S. Environmental Protection Agency, less than 10% of plastic waste in the U.S. has been recycled over the past 40 years, with most ending up in landfills or incinerators. Boat shrink wrap, despite being recyclable, often faces the same fate due to improper preparation or lack of accessible recycling programs.

Max Kraimer, program manager at Clean Ocean Access, a Rhode Island-based nonprofit, highlights the scale of the issue: “It takes about 20 pounds of plastic to wrap a 20-foot boat.” Multiply that by thousands of boats winterized annually, and the volume of plastic waste becomes staggering. Donna Morrow from the Maryland Department of Natural Resources adds, “You can’t just recycle this stuff. It has bands, straps, zippers, and vents made of different materials that must be removed for the wrap to be recycled.” Without proper preparation, even well-intentioned recycling efforts can fail, with “shrink wrap dumpsters” at marinas often ending up in landfills.

The good news? Innovative programs and practical steps are emerging to tackle this problem. By recycling or reusing shrink wrap, boaters can significantly reduce their environmental footprint while potentially saving money. Let’s dive into the options.

Recycling Boat Shrink Wrap: A Step-by-Step Guide

Recycling boat shrink wrap is feasible but requires careful preparation to meet the standards of most recycling programs. Here’s how to do it effectively:

1. Prepare the Shrink Wrap

Recycling facilities typically require shrink wrap to be clean, dry, and free of non-plastic materials. This means removing all attachments, such as:

- Straps and ropes: Used to secure the wrap.

- Zippers and doors: Often made from different plastics or metals.

- Vents: Allow air circulation but are not recyclable with the wrap.

- Wooden supports: Used in framing the cover.

To prepare the wrap, cut just above the band along the boat’s perimeter to separate the plastic from any cinching lines. Rinse off dirt, mud, or leaves, and spread the wrap out in the sun to dry thoroughly. Wet or contaminated plastic is often rejected by recyclers.

2. Check Local Recycling Programs

Not all recycling centers accept boat shrink wrap, so it’s essential to verify local options. Many marinas and boatyards participate in specialized programs. For example:

- Rhode Island Marine Trades Association (RIMTA): One of the pioneers in shrink wrap recycling, RIMTA has diverted hundreds of thousands of pounds of plastic from landfills over 13 years. They provide large plastic bags (recycled with the wrap) for $12 each, covering delivery and pickup costs.

- Marine Trades Association of Maryland: Offers similar collection programs, partnering with recyclers to process shrink wrap.

- Clean Ocean Access: Since January 2020, this organization has collected 292,474 pounds of shrink wrap in New England, working with TerraCycle to turn it into resin for products like garbage bags and composite wood.

Contact your marina, boatyard, or local recycling center to confirm if they accept shrink wrap and their specific requirements. Some programs, like Michigan’s annual Recycling Run or Woods Hole Sea Grant in Cape Cod, operate seasonally or regionally.

3. Bundle and Tie

Once cleaned and stripped of non-plastic components, fold the shrink wrap into manageable 4- to 5-foot lengths, roll it tightly (like a sleeping bag), and tie it with a strip of shrink wrap—never use rope or string, as these contaminate the batch. Alternatively, companies like Dr. Shrink offer EZ-Fill Bags, which hold approximately 800 square feet of shrink wrap, making transport easier.

4. Drop Off or Arrange Pickup

Some programs require you to deliver the bundled shrink wrap to a designated drop-off location, while others, like RIMTA, coordinate pickups through recycling partners like PF Trading. Confirm logistics with your chosen program to ensure compliance.

5. Understand the Recycling Process

Once collected, shrink wrap is baled and sent to recycling facilities. Clean Ocean Access, for instance, partners with TerraCycle to process LDPE into resin, which is then used to manufacture products like:

- Plastic garbage bags

- Flexible packaging

- Food containers

- Composite wood for decking or outdoor furniture

This “downcycling” reduces the need for virgin plastic, though challenges remain. Alanna Keating, BoatUS Foundation’s director of outreach, notes, “The recycling landscape has changed. The demand for recycled plastic isn’t what it used to be.” Despite this, programs like RIMTA and Clean Ocean Access are making strides toward a circular economy, where shrink wrap could be recycled into new shrink wrap, though such products are not yet commercially available.

6. Verify Plastic Type

Most boat shrink wrap is made from #4 LDPE, widely accepted by recyclers. However, some facilities only take specific colors (e.g., white shrink wrap). Dr. Shrink, a leading manufacturer, confirms its wrap is #4 LDPE, compatible with most recycling centers. Always check with your recycler to confirm acceptable materials.

The following table summarizes key recycling programs and their offerings:

| Program | Location | Services | Cost |

|---|---|---|---|

| RIMTA | Rhode Island | Provides $12 bags for collection, partners with PF Trading for pickup | $12 per bag |

| Clean Ocean Access | Northeast U.S. | Collects shrink wrap, partners with TerraCycle for processing | Grant-funded, no direct cost |

| Marine Trades Association of MD | Maryland | Coordinates collection and recycling with local partners | Varies by marina |

| Michigan Recycling Run | Michigan | Annual statewide collection for shrink wrap | Free for participants |

| Woods Hole Sea Grant | Cape Cod, MA | Accepts clean shrink wrap from April 1 to June 30 | Free drop-off |

Reusing Boat Shrink Wrap: A Cost-Saving Alternative

Reusing shrink wrap is a less common but viable option for cost-savvy and eco-conscious boaters. With careful handling, a single wrap can last three to five years, saving thousands of dollars compared to annual rewrapping or purchasing reusable covers. Here’s how to reuse shrink wrap effectively:

1. Careful Removal

To reuse shrink wrap, remove it without causing tears. Start on a dry day with a dry cover. Make an incision at the stern to loosen the back, then carefully roll the wrap forward and off the boat. Tie messenger lines where cinching lines are cut to aid reassembly next season. Take photos at each step to document the frame, padding, and wrap orientation.

2. Patching Tears

Minor tears can be repaired with strong, wide shrink wrap tape or spare LDPE pieces. For best results, use white shrink wrap tape designed for marine applications, available for $10–$20 per roll (100 feet).

3. Mark and Store

Label the wrap with the boat’s name and orientation (e.g., “Bow” or “Stern”) to simplify reinstallation. Store it in a dry, protected area to prevent degradation.

4. Consult Professionals

If unsure about removal or reinstallation, consult a marine service professional. They can guide you through the process or handle it for a fee, typically $200–$500 depending on boat size and complexity.

Reusing shrink wrap is environmentally friendly because it reduces the need for new plastic. Max Kraimer explains, “Shrink wrap is made from natural gas, directly fracked and turned into plastic. Reusing it every few years produces less carbon than manufacturing reusable covers, which often involve complex plastic blends.” A reused wrap can save $500–$1,500 annually, depending on boat size and professional wrapping costs (typically $15–$25 per foot).

Alternatives to Shrink Wrap: Reusable Boat Covers

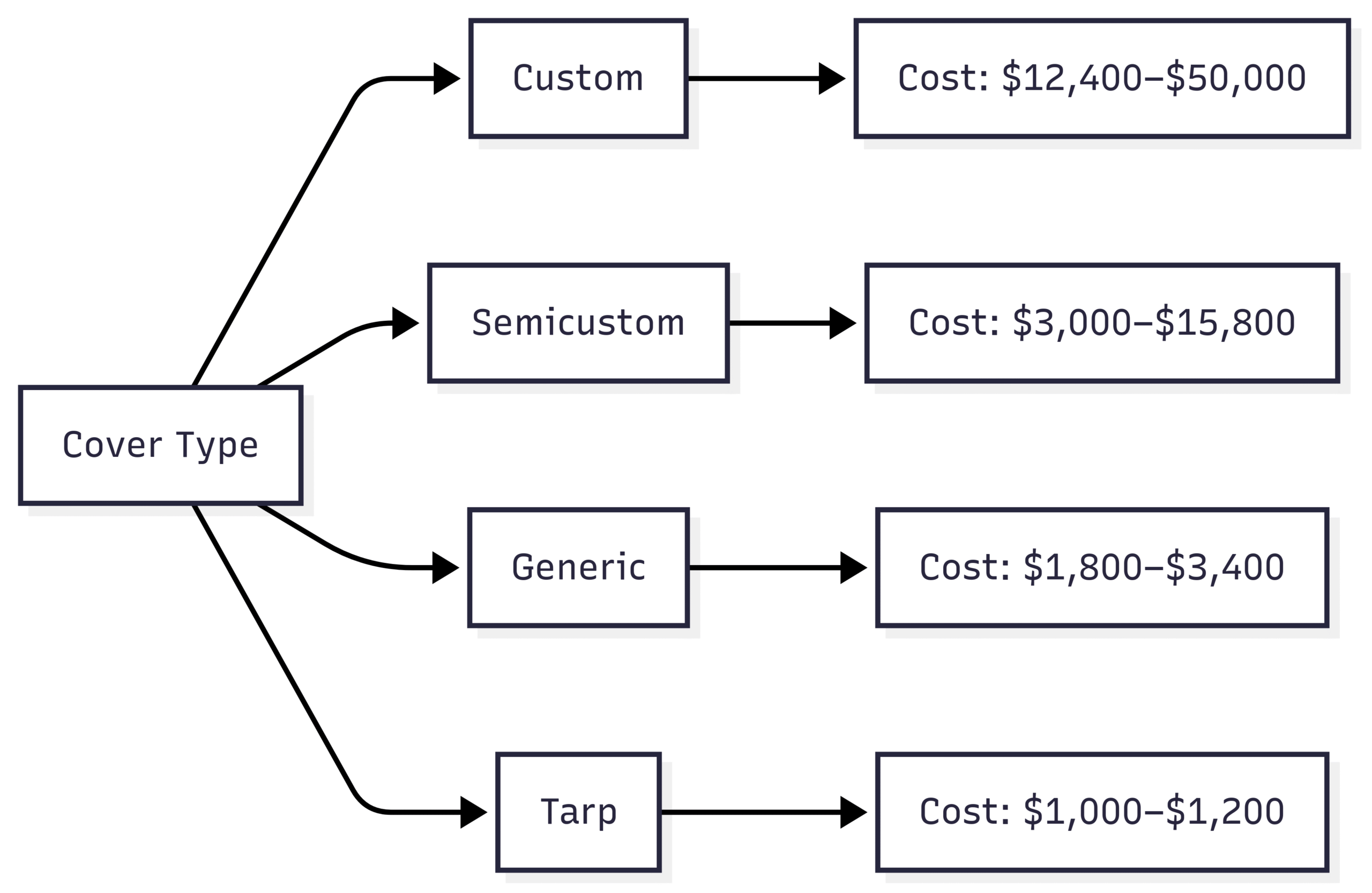

For boaters seeking long-term solutions, reusable boat covers offer a practical alternative to single-use shrink wrap. These come in four types, each with distinct costs and benefits:

1. Custom Covers

- Description: Tailored to a specific boat, often installed by professionals. Features include vents, zippers, and durable materials like Sunbrella or WeatherMax.

- Cost: $62–$250 per square foot.

- Pros: Perfect fit, long lifespan (10+ years with proper care), custom features.

- Cons: High initial cost, requires careful storage and maintenance.

2. Semicustom Covers

- Description: Designed for specific boat makes and models, available in various sizes and profiles.

- Cost: $15–$79 per square foot.

- Pros: More affordable than custom covers, good fit for common boat types.

- Cons: Less tailored, may require adjustments for optimal fit.

3. Generic Covers

- Description: Sold based on length and width, fitting a range of boats.

- Cost: $9–$17 per square foot.

- Pros: Cost-effective, widely available.

- Cons: Requires more effort to ensure proper fit, shorter lifespan (5–10 years).

4. Tarps

- Description: Inexpensive polyethylene covers fitting various shapes and sizes.

- Cost: $5–$6 per square foot.

- Pros: Low cost, easy to source.

- Cons: Short lifespan (1–3 years), prone to leaks and wear.

The following chart illustrates the cost comparison of cover options for a 20-foot boat (assuming 200 square feet of coverage):

Reusable covers, while initially more expensive, can outlast single-use shrink wrap, which costs $300–$500 per season for a 20-foot boat. However, most reusable covers are made from virgin plastics and are not recyclable, unlike LDPE shrink wrap. Proper installation, cleaning, and storage are critical to maximizing their lifespan.

The Bigger Picture: Toward a Circular Economy

The ultimate goal for many organizations is a “circular economy” for boat shrink wrap, where used plastic is recycled into new shrink wrap. Clean Ocean Access envisions a closed-loop system, but current technology and market demand limit this possibility. “Boaters don’t yet have the option to buy shrink wrap with recycled content,” says Kraimer. Innovations in recycling and increased demand for recycled resin could change this.

The BoatUS Foundation, partnering with groups like NOAA’s Marine Debris Program, RIMTA, and Clean Ocean Access, is working to connect stakeholders and promote solutions nationwide. Alanna Keating emphasizes, “There’s no single answer to every environmental issue. We need a suite of options—recycling, reusing, and exploring alternatives like sustainable shrink wrap.”

Some landfills convert #4 LDPE into renewable energy, with 654 modern U.S. landfill projects accepting this material. However, recycling remains the preferred option to reduce waste and conserve resources.

Practical Tips for Boaters

To minimize the environmental impact of boat shrink wrap, consider these strategies:

- Ask Your Marina: Many participate in Clean Marina programs and offer recycling services or guidance.

- Explore Sustainable Shrink Wrap: Inquire about #4 LDPE options designed for energy conversion or recycling.

- Invest in Reusable Covers: Balance cost and durability to find the best fit for your boat.

- Participate in Collection Programs: Join regional initiatives like RIMTA or Michigan’s Recycling Run.

- Educate Yourself: Resources like BoatUS’s “What You Need To Know About Boat Covers For Winter Storage” or videos from QACTV (demonstrating recycling preparation) and Bill On The Water (offering reuse tips) provide valuable guidance.

Conclusion

Boat shrink wrap doesn’t have to end up in a landfill. By recycling or reusing it, boaters can reduce plastic waste and save money. Recycling requires careful preparation—cleaning, removing non-plastic components, and bundling according to program guidelines. Reusing shrink wrap demands meticulous removal and storage but can extend the wrap’s life for multiple seasons. For those seeking alternatives, reusable covers offer durability, though at a higher upfront cost. Programs like RIMTA, Clean Ocean Access, and TerraCycle are paving the way for a more sustainable boating industry, but challenges like limited recycling infrastructure and market demand persist. By taking proactive steps and supporting innovative programs, boaters can protect their vessels and the environment, ensuring cleaner waters for future seasons.

Happy Boating!

Share Can You Recycle Or Reuse Boat Shrinkwrap with your friends and leave a comment below with your thoughts.

Read Buying Etiquette: How To Make an Offer on a Boat until we meet in the next article.

Your article helped me a lot, is there any more related content? Thanks!

Great article! It’s super helpful to know that boat shrink wrap can be recycled or reused instead of just tossed away. The tips on finding local recycling programs and creative reuse ideas are awesome. Easy to read and practical—definitely saving this guide for next season!