Can i make a sail out seaweed?

Discover if seaweed can be used to make sails. Explore its properties, applications, and challenges in this in-depth guide to sustainable sailing.

The idea of crafting a sail from seaweed sounds like a whimsical notion pulled from a sailor’s tale or an eco-warrior’s dream. Yet, as sustainability becomes a cornerstone of modern innovation, the question merits serious exploration: Can I make a sail out of seaweed? Seaweed, or marine algae, is a renewable, biodegradable resource with a growing list of applications, from food to bioplastics. But can it withstand the rigors of the open sea as a sail material? This article dives deep into the properties of seaweed, its potential uses in sailing, the challenges it faces, and the future of this marine marvel in nautical applications. We’ll also examine seaweed’s broader role in sustainable marine industries and provide practical insights for enthusiasts and innovators alike.

Understanding Seaweed: The Ocean’s Versatile Resource

Seaweed is not a single plant but a diverse group of marine algae, encompassing thousands of species categorized into three main types: green, brown, and red. Each type has unique properties that make it suitable for various applications, but its potential in sailing is less straightforward.

- Green Seaweed: Often found in shallow waters, green seaweed like Ulva (sea lettuce) is nutrient-rich and commonly used in salads. Its thin, delicate structure makes it unsuitable for heavy-duty applications like sails.

- Brown Seaweed: Includes species like kelp (Laminaria) and Fucus. Brown seaweed is robust, with some species like giant kelp growing up to 50 meters long, suggesting potential for structural applications. However, its flexibility and strength are still limited compared to traditional sail materials.

- Red Seaweed: Known for species like Nori (used in sushi) and Gracilaria, red seaweed is valued for its gel-like extracts, such as agar and carrageenan, which are used in food and industrial applications.

Seaweed’s abundance, rapid growth, and minimal environmental impact make it an attractive material for sustainable innovation. It requires no freshwater, fertilizers, or arable land to grow, and it sequesters carbon dioxide, aiding in climate change mitigation. These qualities spark curiosity about its potential in sailing, but the question remains: can seaweed be transformed into a functional sail?

The Challenges of Using Seaweed as a Sail Material

To understand whether seaweed can serve as a sail material, we must first consider the requirements of a functional sail. Modern sails, typically made from synthetic materials like Dacron, nylon, or carbon fiber composites, are designed to:

- Withstand High Tensile Forces: Sails endure significant wind pressure, requiring high tensile strength.

- Resist Environmental Degradation: Exposure to UV rays, saltwater, and abrasion demands durability.

- Maintain Shape: Sails must hold a precise aerodynamic shape to optimize wind capture.

- Be Lightweight: Excess weight reduces efficiency and boat performance.

Seaweed, in its natural form, falls short of these requirements. Here are the primary challenges:

- Lack of Structural Integrity: Seaweed is flexible but lacks the tensile strength to withstand the forces exerted by strong winds. Even robust species like kelp tear easily under sustained pressure.

- Water Absorption: Seaweed is naturally hydrophilic, meaning it absorbs water. A waterlogged sail would become heavy, reducing efficiency and increasing the risk of damage.

- Degradation and Decay: Seaweed is biodegradable, which is environmentally beneficial but problematic for sails. Exposure to moisture and UV light accelerates decay, necessitating frequent replacements.

- Processing Complexity: Transforming seaweed into a sail-like material requires extensive processing to enhance strength, water resistance, and durability, which may negate its eco-friendly benefits.

These limitations suggest that raw seaweed is not a viable sail material. However, advancements in material science and processing techniques could bridge the gap, making it worth exploring how seaweed might be adapted for sailing applications.

Exploring Seaweed’s Potential in Sailing

While raw seaweed may not be suitable for sails, its derivatives and processed forms offer intriguing possibilities. Researchers and innovators are experimenting with seaweed-based materials that could one day contribute to sustainable sailing solutions. Below, we explore how seaweed can be processed and its potential applications in sailing.

Seaweed-Derived Materials for Sails

One promising avenue is the development of seaweed-based fibers and composites. For example, SeaCell, a textile fiber made from seaweed and cellulose, is already used in eco-friendly clothing. SeaCell combines the natural properties of seaweed—such as moisture-wicking and biodegradability—with the strength of cellulose. While SeaCell is not robust enough for sails in its current form, it demonstrates the potential for seaweed-based fibers in nautical applications.

Another approach involves creating composite materials by blending seaweed fibers with bio-based resins or synthetic reinforcements. These composites could offer improved strength and water resistance while retaining seaweed’s eco-friendly profile. For instance, researchers are exploring the use of alginate, a polysaccharide extracted from brown seaweed, as a binding agent in composite materials. Such innovations could lead to lightweight, durable sail materials that align with sustainable sailing goals.

Experimental Seaweed Sail: A Conceptual Design

To illustrate the potential, let’s consider a hypothetical process for creating a seaweed-based sail:

- Harvesting: Select robust seaweed species like giant kelp or Gracilaria, which offer flexibility and strength.

- Processing: Extract alginate or cellulose from seaweed to create fibers. These fibers can be spun into threads or woven into sheets.

- Reinforcement: Combine seaweed fibers with bio-based resins or synthetic materials to enhance tensile strength and water resistance.

- Testing: Construct a prototype sail and test it in controlled conditions to assess performance under wind and water exposure.

This process is speculative, as no commercially viable seaweed sail exists today. However, it highlights the steps needed to transform seaweed into a functional sail material.

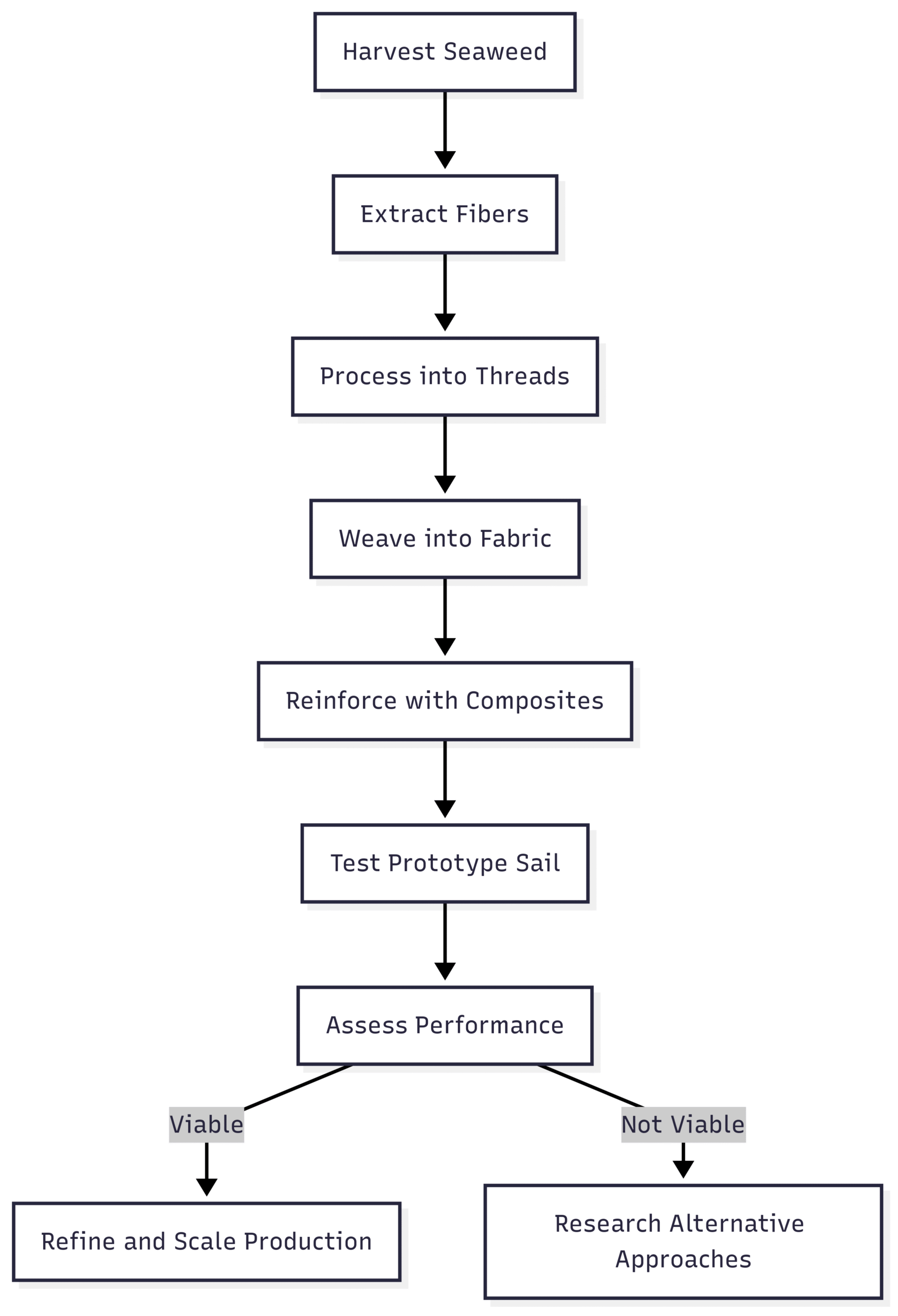

Chart: Seaweed Sail Development Process

Below is a flowchart outlining the conceptual process for developing a seaweed-based sail, visualized using syntax:

This chart illustrates the iterative nature of developing a seaweed sail, emphasizing the need for testing and refinement.

Pros and Cons of Seaweed Sails

To evaluate the feasibility of seaweed sails, let’s weigh their advantages and disadvantages:

Advantages

- Sustainability: Seaweed is a renewable resource that grows rapidly without requiring land or freshwater. Harvesting it has minimal environmental impact.

- Biodegradability: Unlike synthetic sails, which contribute to microplastic pollution, seaweed-based sails would decompose naturally, reducing waste.

- Carbon Sequestration: Seaweed absorbs carbon dioxide during growth, making it a climate-friendly material.

- Aesthetic Appeal: Seaweed sails could offer a unique, natural aesthetic, appealing to eco-conscious sailors.

Disadvantages

- Limited Durability: Even processed seaweed lacks the strength to withstand prolonged exposure to wind and waves.

- Water Absorption: Seaweed-based materials may retain moisture, compromising sail efficiency.

- High Maintenance: Biodegradable materials require frequent replacement, increasing costs and labor.

- Scalability Challenges: Producing seaweed-based sails at scale requires significant investment in processing technology.

Table: Comparing Seaweed Sails to Traditional Sail Materials

| Material | Strength | Durability | Water Resistance | Sustainability | Cost |

|---|---|---|---|---|---|

| Dacron | High | High | Excellent | Low (Synthetic) | Moderate |

| Nylon | Moderate | Moderate | Good | Low (Synthetic) | Low |

| Carbon Fiber | Very High | Very High | Excellent | Low (Synthetic) | High |

| Seaweed (Raw) | Low | Low | Poor | High | Low |

| Seaweed (Processed) | Moderate (Potential) | Moderate (Potential) | Moderate (Potential) | High | Unknown |

This table highlights the gap between seaweed and traditional sail materials, underscoring the need for technological advancements to make seaweed sails viable.

Seaweed in Other Marine Applications

While seaweed sails remain a distant prospect, seaweed is already making waves in other marine and industrial applications. These uses demonstrate its versatility and potential to contribute to sustainable nautical practices.

- Biodegradable Ropes: Seaweed extracts, particularly from species like Gracilaria dura and Gelidiella acerosa, are being developed into biodegradable ropes. These ropes offer an eco-friendly alternative to synthetic options for applications like fishing nets or mooring lines.

- Bioplastics: Seaweed-based bioplastics are gaining traction as a renewable alternative to petroleum-based plastics. These materials could be used for boat fittings, packaging, or other marine equipment.

- Fertilizers and Animal Feed: Nutrient-rich seaweed is used as organic fertilizer and animal feed, supporting sustainable aquaculture and agriculture.

- Cosmetics and Skincare: Seaweed extracts like carrageenan and alginate are common in moisturizing and anti-aging products, showcasing their versatility beyond marine applications.

These applications highlight seaweed’s potential as a sustainable resource, paving the way for further exploration in nautical contexts.

The Future of Seaweed Sails

The dream of seaweed sails is not entirely out of reach. Ongoing research in material science and sustainable technologies could unlock new possibilities. Here are three key areas of focus:

- Enhancing Seaweed Fibers: Scientists are investigating ways to strengthen seaweed fibers through chemical treatments or genetic engineering. For example, modifying the polysaccharide content of seaweed could improve its tensile strength.

- Composite Materials: Combining seaweed fibers with bio-based or synthetic materials could create hybrid sails with improved performance. For instance, blending seaweed with hemp or flax fibers could yield a stronger, more durable fabric.

- Sustainable Sailing Initiatives: The growing demand for eco-friendly sailing practices is driving investment in alternative materials. Organizations like the Sustainable Sailing Initiative are exploring natural fibers, including seaweed, for sails and other equipment.

Potential Cost Considerations

While seaweed is abundant and inexpensive to harvest, processing it into a sail-worthy material involves significant costs. These include:

- Harvesting and Processing: Labor-intensive processes like drying, extracting fibers, and weaving increase production costs.

- Research and Development: Developing seaweed-based composites requires investment in R&D.

- Scalability: Scaling production to meet commercial demand could be costly without established infrastructure.

As a rough estimate, a prototype seaweed sail (assuming future technological advancements) might cost $500–$1,000 for a small dinghy sail, compared to $200–$500 for a Dacron sail of similar size. These figures are speculative, as no commercial seaweed sails exist, but they reflect the potential economic challenges.

Practical Alternatives for Eco-Conscious Sailors

While seaweed sails are not yet practical, sailors can adopt other eco-friendly practices to reduce their environmental impact:

- Recycled Sails: Some manufacturers produce sails from recycled plastics, reducing waste while maintaining performance.

- Natural Fibers: Materials like hemp or flax offer biodegradable alternatives to synthetic sails, though they require careful maintenance.

- Energy-Efficient Boats: Hybrid or electric propulsion systems can complement sustainable sail materials, reducing reliance on fossil fuels.

Conclusion: The Horizon for Seaweed Sails

The question “Can I make a sail out of seaweed?” sparks curiosity and highlights the innovative spirit of sustainable sailing. While raw seaweed lacks the strength, durability, and water resistance needed for functional sails, advancements in material science offer hope for the future. Seaweed’s sustainability, biodegradability, and carbon-sequestering properties make it an exciting candidate for nautical applications, from ropes to bioplastics. Until seaweed sails become a reality, eco-conscious sailors can explore other sustainable practices and materials to navigate the seas responsibly.

As we sail toward a greener future, seaweed may yet find its place in the maritime world—not as a whimsical experiment, but as a symbol of innovation and environmental stewardship. So, grab your sailor’s cap and keep an eye on the horizon: the age of seaweed sails may be closer than we think.

Share Can I Make a Sail Out Seaweed? Guide with your friends and Leave a comment below with your thoughts.

Read 10 Best Tuna Fishing Boats: Guide to Choose the Perfect One until we meet in the next article.