Boat Ventilation Systems: Types & Requirements

Explore boat ventilation systems: types, requirements, and safety benefits. Learn how natural and powered systems prevent explosions and ensure comfort.

Ventilation systems are a cornerstone of safety and comfort on motorized vessels. These systems are designed to mitigate the risks posed by flammable gases, regulate temperature and humidity, and ensure a healthy environment for passengers and crew. Whether you’re operating a small pleasure craft or a large commercial vessel, understanding the types and requirements of boat ventilation systems is critical for safe boating. This article provides an in-depth exploration of boat ventilation systems, their components, legal requirements, safety considerations, and emerging innovations, offering vessel operators a comprehensive guide to maintaining a safe and comfortable onboard environment.

Why Ventilation Systems Are Essential for Motorized Vessels

Motorized vessels, particularly those powered by gasoline, face unique safety challenges due to the potential accumulation of flammable gases in enclosed spaces like engine compartments and bilges. Without proper ventilation, these gases can create hazardous conditions, including the risk of explosions or fires. Beyond safety, ventilation systems enhance onboard comfort by regulating temperature, reducing humidity, and preventing mold growth, which can damage a vessel’s interior. They also ensure compliance with legal mandates in many regions, protecting both operators and passengers from health risks such as carbon monoxide poisoning.

Key Functions of Boat Ventilation Systems

- Fire and Explosion Prevention: Gasoline vapors are highly flammable and can accumulate in confined spaces. Ventilation systems dilute and remove these vapors, significantly reducing the risk of ignition.

- Health and Safety: By expelling harmful gases like carbon monoxide, ventilation systems protect occupants from poisoning and respiratory issues.

- Comfort and Environmental Control: Proper airflow regulates temperature and humidity, creating a pleasant onboard environment.

- Legal Compliance: Many jurisdictions, such as Iowa state waters, mandate ventilation systems for gasoline-powered boats to ensure safety.

- Preventing Vessel Damage: Ventilation reduces moisture buildup, preventing mold, mildew, and wood rot that can compromise a vessel’s structural integrity.

Types of Boat Ventilation Systems

Boat ventilation systems are broadly categorized into two types: natural and powered. Each type has distinct mechanisms, advantages, and requirements, making them suitable for different vessel types and operating conditions.

Natural Ventilation Systems

Natural ventilation systems rely on the boat’s motion and external air pressure to circulate air through the vessel. These systems are simple, cost-effective, and require minimal maintenance, making them ideal for smaller vessels or those operating in moderate climates.

Components of Natural Ventilation Systems

- Intake Duct: Draws fresh air into the bilge or engine compartment. It is typically positioned at least midway to the bilge or below the carburetor air intake to ensure effective air circulation.

- Exhaust Duct: Removes stale air and fumes from the lowest part of the engine or fuel compartments. It extends from the bilge to the open atmosphere.

- Cowls: Hood-shaped coverings on ducts that enhance airflow by capturing wind as the boat moves.

How It Works

As the boat moves, air is scooped into the intake duct, circulated through the bilge or engine compartment, and expelled through the exhaust duct. The cowls amplify airflow, ensuring efficient ventilation without mechanical assistance.

Advantages

- Low cost and simple installation.

- No power consumption, preserving battery life.

- Minimal maintenance requirements.

Limitations

- Dependent on boat motion and wind direction, which may limit effectiveness when stationary or in calm conditions.

- Less control over airflow compared to powered systems.

Powered Ventilation Systems

Powered ventilation systems use electric blowers or fans to actively circulate air, offering greater reliability and control. These systems are mandatory for boats built after 1982 with enclosed engines or fixed fuel tanks, as they provide consistent airflow regardless of the vessel’s motion.

Components of Powered Ventilation Systems

- Blowers/Fans: Electrically powered devices that force air through ducts, ensuring robust circulation.

- Ducts: Similar to natural systems, these include intake and exhaust ducts, often fitted with cowls for efficiency.

- Control Mechanisms: Switches or timers to activate blowers, allowing operators to manage airflow.

How It Works

Blowers pull fresh air through the intake duct and expel fumes through the exhaust duct. Regulations require running the system for at least four minutes before starting the engine to clear gasoline vapors, significantly reducing explosion risks.

Advantages

- Consistent airflow, even when the boat is stationary.

- Greater control over ventilation, suitable for larger vessels or humid climates.

- Enhanced safety for boats with enclosed engines or fuel tanks.

Limitations

- Higher installation and maintenance costs.

- Power consumption can strain batteries, especially on smaller vessels.

- Noise from blowers may be a concern for some operators.

Comparison of Natural and Powered Ventilation Systems

| Feature | Natural Ventilation | Powered Ventilation |

|---|---|---|

| Mechanism | Relies on boat motion | Uses electric blowers |

| Cost | Low | Moderate to high |

| Power Consumption | None | Moderate |

| Maintenance | Minimal | Regular checks required |

| Effectiveness | Motion-dependent | Consistent, motion-independent |

| Best For | Smaller boats, open waters | Larger boats, enclosed spaces |

Legal Requirements for Boat Ventilation Systems

Regulations for boat ventilation systems vary by region, but many jurisdictions enforce strict standards to ensure safety. For example, in Iowa, every gasoline-powered powerboat (except open boats) must have a ventilation system to remove explosive gases from engine and fuel compartments. Similarly, the Small Vessel Regulations in many countries require:

- At least two ventilation ducts fitted with cowls: one intake and one exhaust.

- The exhaust duct must extend to the lower bilge to remove heavy gasoline vapors.

- The intake duct must reach at least midway to the bilge or below the carburetor air intake.

For boats with powered ventilation systems, operators must run the system for at least four minutes:

- After fueling.

- Before starting the engine.

For vessels without powered systems, such as personal watercraft, operators must manually inspect the engine compartment for gasoline vapors before ignition.

Historical Context

Since 1940, most gasoline-powered boats have been required to include ventilation systems due to the significant explosion risks posed by fuel vapors. Post-1982 regulations further mandated powered systems for boats with enclosed engines or fuel tanks, reflecting advancements in safety standards.

Choosing the Right Ventilation System for Your Boat

Selecting the appropriate ventilation system depends on several factors, including boat size, usage, climate, and operational preferences. Here’s a breakdown of key considerations:

- Boat Size: Larger vessels with enclosed compartments typically require powered systems for adequate airflow. Smaller, open boats may suffice with natural ventilation.

- Climate: Humid environments demand robust systems to prevent mold and mildew, while drier climates may allow simpler setups.

- Usage: Frequent or long-distance boating may benefit from powered systems for consistent performance.

- Ease of Use: Automatic controls in powered systems simplify operation but may increase costs.

- Noise: Blowers can be noisy, which may influence preferences for quieter natural systems.

- Maintenance: Natural systems require less upkeep, while powered systems need regular blower and electrical checks.

- Power Consumption: Powered systems draw battery power, a critical consideration for smaller vessels with limited electrical capacity.

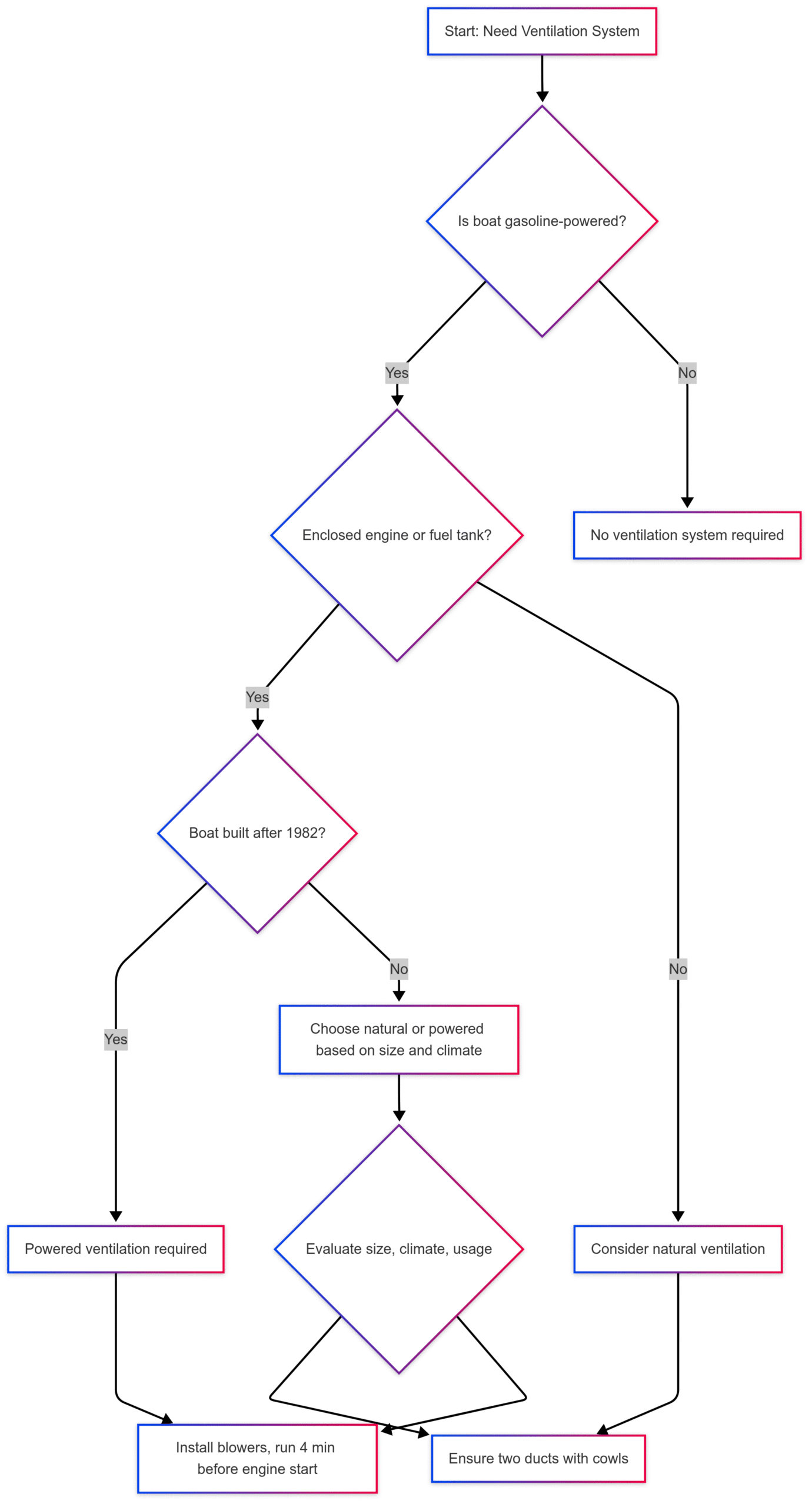

Example Decision Workflow

Below is a flowchart to guide the selection process:

Safety Considerations for Ventilation Systems

Ventilation systems are integral to fire safety and overall vessel operation. Key safety practices include:

- Pre-Start Ventilation: For powered systems, run blowers for at least four minutes before starting the engine to clear fumes.

- Regular Inspections: Check ducts, cowls, and blowers for blockages, wear, or damage.

- Fire Safety Integration: Ensure systems include fire dampers and smoke detectors to limit smoke spread in case of fire.

- Manual Checks for Natural Systems: Sniff for gasoline vapors in the engine compartment before starting, especially on vessels without powered ventilation.

Maintenance Tips

- Clean Ducts and Vents: Remove debris to maintain airflow.

- Inspect Blowers: Check for motor wear or electrical issues in powered systems.

- Test Controls: Ensure switches and timers function correctly.

- Schedule Professional Servicing: Engage marine technicians for annual inspections to ensure compliance and performance.

Innovations in Boat Ventilation Systems

Recent advancements have enhanced the efficiency and functionality of boat ventilation systems, aligning with broader trends in sustainability and automation.

Energy-Efficient Systems

Modern ventilation systems incorporate:

- Variable Speed Motors: Adjust blower speed to optimize energy use.

- Energy Recovery Systems: Recycle heat from exhaust air to reduce energy loss.

- Low-Power Blowers: Designed for minimal battery drain, ideal for smaller vessels.

Smart Ventilation Systems

Smart systems leverage technology for improved performance:

- Sensors: Detect humidity, temperature, or gas levels to adjust airflow automatically.

- Remote Monitoring: Allow operators to control systems via mobile apps.

- Data Analytics: Optimize air exchange based on real-time conditions, enhancing comfort and efficiency.

Example Products and Specifications

Below is a table of popular ventilation systems, including specifications and approximate prices (based on typical market data):

| Product Name | Type | Specifications | Approx. Price (USD) |

|---|---|---|---|

| Attwood Turbo 4000 Blower | Powered | 12V, 4.2A, 240 CFM, Waterproof | $50 – $80 |

| Rule 240 In-Line Blower | Powered | 12V, 3.0A, 135 CFM, Compact Design | $40 – $60 |

| Vetus Vent 103 | Natural | 3-inch duct, Stainless Steel Cowl | $30 – $50 |

| Caframo Sirocco II Fan | Powered | 12V, 0.4A, 185 CFM, Low Noise | $100 – $150 |

Note: Prices vary by retailer and region. Check with marine suppliers for current rates.

Practical Tips for Boat Operators

To maximize the effectiveness of your ventilation system:

- Follow Pre-Start Protocols: Always ventilate for four minutes before ignition on powered systems.

- Monitor Air Quality: Use portable gas detectors to check for fumes in enclosed spaces.

- Upgrade for Efficiency: Consider energy-efficient or smart systems for long-term savings and performance.

- Educate Crew: Ensure all onboard personnel understand ventilation procedures and safety checks.

Learning More About Boat Safety

Ventilation systems are just one aspect of safe boating. Comprehensive boater education, such as courses offered by ilearntoboat, can deepen your understanding of vessel operation and safety. These state-approved, gamified courses cover topics like navigation, emergency procedures, and equipment maintenance, empowering you to operate your vessel confidently and responsibly.

Conclusion

Boat ventilation systems are indispensable for ensuring safety, comfort, and compliance on motorized vessels. By understanding the differences between natural and powered systems, adhering to legal requirements, and staying informed about innovations, boaters can make informed decisions to protect their vessels and passengers. Whether you’re navigating a small pleasure craft or a large yacht, a well-maintained ventilation system is key to a safe and enjoyable experience on the water.

Share Boat Ventilation Systems: Types & Requirements with your friends and leave a comment below with your thoughts.

Read What Is the Difference Between Down Imaging and Sonar until we meet in the next article.