Basics of Marine Diesel Engine Generators

Explore marine diesel engine generators: components, working principles, types, applications, and maintenance tips for reliable onboard power.

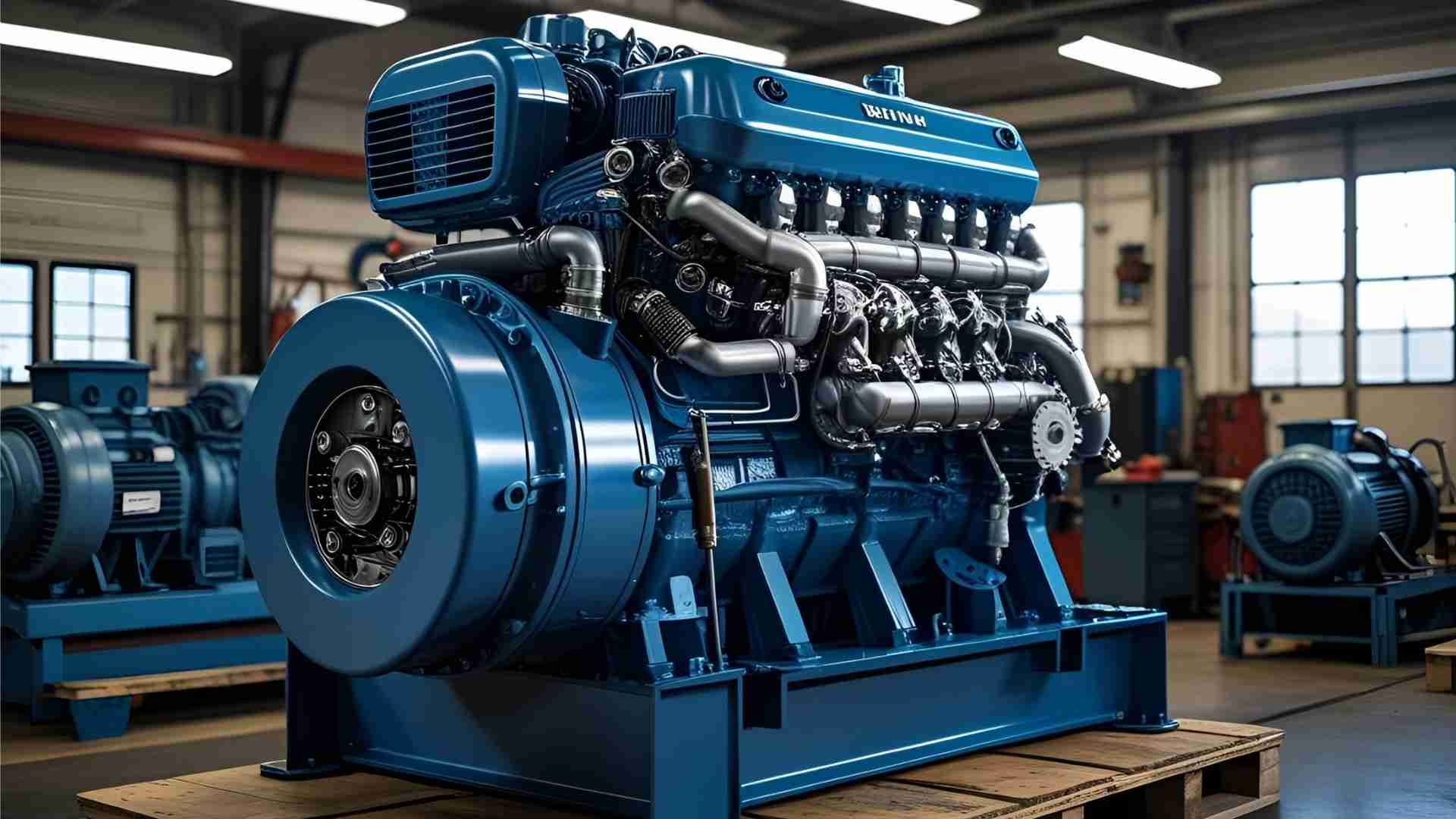

Marine diesel engine generators are the backbone of electrical power on seagoing vessels, from fishing boats to massive cargo ships. These robust machines convert diesel fuel’s chemical energy into mechanical energy and then into electricity, powering critical onboard systems like navigation, lighting, refrigeration, and propulsion. This guide dives deep into their core components, working principles, types, applications, maintenance, and technological advancements, offering practical insights for marine engineers, shipowners, and enthusiasts.

What Are Marine Diesel Engine Generators?

Marine diesel engine generators are specialized power units designed to operate in harsh marine environments. Unlike land-based generators, they are built to withstand saltwater corrosion, high humidity, and constant vibration while delivering reliable electricity. They serve as primary or backup power sources, ensuring vessels remain operational even in remote waters or during main power failures.

Key Features

- Reliability: Engineered for continuous operation in challenging conditions.

- Efficiency: Optimized for fuel economy and long service life.

- Safety: Equipped with features to prevent hazards like carbon monoxide leaks.

- Compact Design: Space-saving to fit tight engine rooms.

- Corrosion Resistance: Built with materials like stainless steel and protective coatings.

- Low Vibration and Noise: Three- or six-cylinder configurations minimize disturbances.

Core Components of Marine Diesel Generators

Understanding the components is crucial for operation and maintenance. Below is a detailed breakdown of a typical marine diesel generator, such as the Yanmar 6E18L model (6 cylinders, 180 mm bore, 280 mm stroke, long-stroke design).

1. Diesel Engine

The heart of the generator, the diesel engine converts fuel combustion into mechanical energy. Pistons move within cylinders, driven by the force of burning diesel, turning the crankshaft. For the 6E18L, the in-line six-cylinder configuration ensures balanced power delivery, typically operating at 720 or 900 RPM to match 50Hz or 60Hz electrical systems.

2. Alternator

Connected to the crankshaft, the alternator transforms mechanical energy into electrical energy via electromagnetic induction. As the crankshaft rotates, it spins the alternator’s rotor within a stator, generating alternating current (AC). An automatic voltage regulator (AVR) ensures stable voltage output.

3. Fuel System

The fuel system stores and delivers diesel to the engine. Key components include:

- Fuel Tank: Plate steel construction with filling cap, ventilation, and drainage plug.

- Fuel Pump: Pressurizes and delivers fuel to injectors.

- Fuel Filters: Remove impurities to protect the engine.

- Injectors: Spray atomized fuel into cylinders for combustion.

4. Cooling System

Marine engines generate significant heat, requiring robust cooling. Most use seawater or freshwater via heat exchangers or keel cooling. Components include:

- Cooling Water Pump: Circulates coolant.

- Thermostatic Valve: Regulates temperature.

- Intercooler: Cools air before entering cylinders, enhancing efficiency.

5. Exhaust System

The exhaust system safely expels combustion gases while reducing noise. It includes:

- Exhaust Manifold: Collects gases from cylinders.

- Silencer/Muffler: Attenuates noise with sound-absorbing materials.

- Piping: Directs gases away from occupied areas.

- After-Treatment Devices: Selective catalytic reduction (SCR) or diesel particulate filters (DPF) for emission control.

6. Control System

The control panel monitors and manages generator operation. Features include:

- Controller: Processes sensor data for start/stop, speed, and safety functions.

- Sensors: Measure oil pressure, coolant temperature, and voltage.

- Governor: Regulates engine speed by controlling fuel injection.

- Protection System: Triggers shutdowns for faults like overheating or low oil pressure.

7. Base Frame and Vibration Isolators

The base frame, made of steel, supports the engine and alternator, designed to withstand dynamic and static loads. Vibration isolators (spring or rubber mounts) reduce noise and protect components by minimizing vibration transmission to the vessel’s structure.

Component Layout (Yanmar 6E18L Example)

From the flywheel side:

- Operation Side (Left): Governor, air motor, fuel strainer, turbocharger, air cooler, thermostatic valve.

- Anti-Operation Side (Right): Lube oil pump, lube oil cooler, automatic backwashing strainer, cooling water pump.

This layout aids engineers in maintenance and troubleshooting, with cylinder #1 closest to the flywheel.

Working Principle of Marine Diesel Generators

Marine diesel generators operate on the four-stroke diesel engine cycle, converting fuel into electricity through a series of precise steps:

- Intake Stroke: The piston moves down, drawing air into the cylinder via the intake valve.

- Compression Stroke: The piston moves up, compressing air to high pressure and temperature (compression ratio typically 14:1 to 22:1).

- Power Stroke: Diesel is injected and ignites spontaneously due to the heat of compressed air. Expanding gases push the piston down, rotating the crankshaft.

- Exhaust Stroke: The piston moves up, expelling combustion gases through the exhaust valve.

The crankshaft’s rotation drives the alternator, producing electricity. The governor and AVR maintain consistent speed and voltage, ensuring stable power output.

Diagram: Four-Stroke Cycle

Types of Marine Diesel Generators

Marine generators vary by fuel type, engine cycle, and configuration. Below are the main distinctions:

1. Diesel vs. Gasoline Generators

- Diesel: Preferred for marine use due to higher efficiency, better fuel economy, and lower fire risk. Diesel engines are more durable and suited for continuous operation.

- Gasoline: Less common, used in smaller vessels. They are cheaper but less efficient and pose higher safety risks due to gasoline’s volatility.

2. Two-Stroke vs. Four-Stroke Engines

- Two-Stroke: Simpler design, higher power-to-weight ratio, but less fuel-efficient and noisier. Rarely used in marine generators.

- Four-Stroke: More complex, offering better efficiency, lower emissions, and longer lifespan. Standard in most marine applications.

3. Cylinder Configurations

- Three-Cylinder: Compact, smooth operation, ideal for smaller vessels.

- Six-Cylinder: Higher power output, reduced vibration, suited for medium to large ships.

Applications of Marine Diesel Generators

Marine diesel generators are versatile, supporting various vessel types and functions:

| Vessel Type | Applications |

|---|---|

| Fishing Boats | Power for lights, radar, and fish processing equipment |

| Cargo Ships | Backup power for navigation and refrigeration |

| Passenger Ferries | Lighting, HVAC, and communication systems |

| Oil Tankers | Explosion-proof configurations for hazardous areas |

| Yachts | Silent generators for luxury amenities |

Primary vs. Backup Power

- Primary Power: Supplies electricity for all onboard systems when no shore power is available.

- Backup Power: Activates during main power failures, ensuring critical systems remain operational.

- Propulsion: In diesel-electric systems, generators power electric motors for propulsion.

Choosing the Right Marine Diesel Generator

Selecting a generator involves assessing power needs, space, and operational requirements. Key considerations include:

1. Power Requirements

Calculate total electrical demand, including:

- Essential Loads: Navigation, communication, and safety systems.

- Non-Essential Loads: HVAC, refrigeration, and entertainment.

- Peak Loads: Account for high-demand equipment like propulsion motors.

Tip: Choose a generator with 10% power reserve to handle unexpected surges.

2. Generator Size and Redundancy

- Ensure capacity covers all loads even if one unit is offline.

- Use multiple generators for redundancy, preferably identical models for easier maintenance.

- Avoid low-load operation to prevent carbon buildup.

3. Engine and Brand

Top brands like Cummins, Perkins, Volvo Penta, and Weichai offer reliable engines. Consider:

- Fuel Efficiency: Lower consumption reduces operating costs.

- Certifications: Compliance with ABS, BV, or DNV standards.

- Service Network: Availability of spare parts and support.

4. Space and Installation

- Measure engine room dimensions to ensure fit.

- Ensure proper ventilation, exhaust routing, and vibration isolation.

- Use a stable foundation to minimize movement.

5. Cost-Effective Options

Chinese brands like Weichai and Hosem Power offer quality at lower costs, with shorter delivery times and local support.

Sample Specifications and Pricing

| Model | Power Output | Engine Brand | Cooling Type | Price (USD) |

|---|---|---|---|---|

| Cummins C50D6 | 50 kW | Cummins | Heat Exchanger | $15,000–$20,000 |

| Perkins 404D-22G | 20 kW | Perkins | Keel Cooling | $10,000–$12,000 |

| Weichai WP12C350 | 350 kW | Weichai | Heat Exchanger | $25,000–$30,000 |

| Yanmar 6E18L | 200 kW | Yanmar | Heat Exchanger | $22,000–$28,000 |

Note: Prices vary based on configuration, region, and supplier.

Maintenance Tips for Marine Diesel Generators

Regular maintenance ensures reliability and longevity. Follow manufacturer guidelines, but typical schedules include:

| Interval | Tasks |

|---|---|

| 50–250 Hours | Replace oil and fuel filters, check battery levels, drain fuel-water separator |

| 400 Hours | Adjust drive belts, clean radiator fins, drain fuel tank sediment |

| 800 Hours | Replace fuel-water separator, inspect turbocharger and air intake |

| 1200 Hours | Adjust valve clearances |

| 2000 Hours | Replace air filters and coolant, clean radiator and water passages |

| 2400 Hours | Inspect fuel injectors and turbocharger, perform comprehensive engine check |

Real-World Example

On a 10,000 DWT cargo vessel, engineers detected overheating in cylinder #4 of a 6E18L generator. The issue was a stuck thermostat valve. After isolating the engine, draining the cooling system, and replacing the valve, the generator resumed normal operation. This highlights the importance of component knowledge and PPE (helmet, gloves, safety glasses) during maintenance.

Safety Measures

Working with marine diesel generators involves risks like high temperatures, rotating parts, and electrical hazards. Follow these precautions:

- PPE: Wear helmets, safety glasses, gloves, steel-toe shoes, and flame-resistant clothing.

- Safety Labels: Check engine labels for warnings before maintenance.

- Isolation: Stop and isolate the generator before servicing.

- Ventilation: Ensure proper exhaust routing to prevent carbon monoxide buildup.

Advances in Marine Diesel Generator Technology

Recent innovations address environmental, efficiency, and operational demands:

- Digital Twins: Real-time simulations predict failures, reducing downtime.

- IMO Tier III Compliance: SCR systems cut NOx emissions by up to 70%.

- Condition-Based Maintenance (CBM): Sensors monitor wear, optimizing service intervals.

- Remote Monitoring: Satellite connectivity allows shipowners to track performance remotely.

These advancements align with IMO regulations and Class Society standards (DNV, Lloyd’s Register), ensuring compliance and sustainability.

Marine vs. Land-Based Generators

Marine generators differ significantly from land-based units:

| Feature | Marine Generators | Land-Based Generators |

|---|---|---|

| Corrosion Resistance | Anti-corrosion materials and coatings | Standard materials, less corrosion focus |

| Cooling System | Heat exchangers or keel cooling | Radiators |

| Space Design | Compact for tight engine rooms | Larger, less space-constrained |

| Certifications | ABS, BV, DNV compliance | General industrial standards |

Installation Considerations

Proper installation ensures performance and safety:

- Site Selection: Choose a well-ventilated, accessible location free from harsh weather.

- Foundation: Use a level, sturdy base with vibration isolators.

- Electrical Connections: Install an automatic transfer switch (ATS) and ensure proper grounding.

- Fuel System: Use high-quality fuel and install filters/separators.

- Exhaust: Route gases safely with a silencer to reduce noise.

Top Brands and Market Insights

Leading manufacturers include:

- Cummins Marine: Known for robust engines and global support.

- Perkins Marine: Reliable, fuel-efficient options for smaller vessels.

- Volvo Penta: High-performance generators with low emissions.

- Weichai Marine: Cost-effective, high-quality Chinese alternative.

- Hosem Power: Over 20 years of experience in marine generators.

Chinese brands are gaining traction due to competitive pricing and improved quality, capturing significant market share in Asia and beyond.

FAQs

What is the main function of a marine diesel generator?

What does 6E18L mean?

How often should maintenance be performed?

Are marine diesel generators eco-friendly?

Conclusion

Marine diesel engine generators are indispensable for safe and efficient vessel operation. From their robust components to advanced technologies, they ensure reliable power in the harshest conditions. By understanding their workings, selecting the right model, and adhering to maintenance and safety protocols, shipowners and engineers can maximize performance and compliance. As the maritime industry evolves toward sustainability, these generators continue to adapt, powering the future of global shipping.

Happy Boating!

Share Basics of Marine Diesel Engine Generators with your friends and leave a comment below with your thoughts.

Read Procedures for Starting and Stopping Generators on a Ship until we meet in the next article.