Back-Fire (Blow-Back) in Marine Boilers

Learn about backfire in marine boilers: causes, consequences, prevention, and emergency response. Ensure safe and efficient ship operations.

Marine boilers are the backbone of a vessel’s operations, supplying steam for propulsion, power generation, heating, and auxiliary systems. These systems are critical for maintaining fuel efficiency, reducing emissions, and ensuring crew safety. However, one significant hazard associated with marine boilers is backfire, also known as blowback. This phenomenon occurs when fuel ignites prematurely or in unintended areas, leading to rapid gas expansion that can damage equipment, disrupt operations, and pose severe safety risks. This article explores the causes, consequences, and preventive measures for backfire in marine boilers, providing maritime operators with actionable insights to ensure safe and efficient vessel performance.

Understanding Backfire in Marine Boilers

Backfire in marine boilers refers to the sudden ignition of accumulated fuel or flammable gases in the burner or furnace before proper mixing with air. This results in a rapid, sometimes explosive, expansion of gases, forcing flames and hot gases backward through the burner or fuel supply lines. The consequences can range from minor equipment damage to catastrophic explosions, endangering both the vessel and its crew.

Backfire typically occurs in oil-fired boilers, which are commonly used as auxiliary or main propulsion systems on ships with engines exceeding 3000 kW. These boilers rely on a precise balance of fuel, oxygen, and ignition—components of the fire triangle—to function safely. Disruptions in this balance, such as incorrect air-to-fuel ratios or inadequate purging, can create conditions ripe for backfire.

Types of Marine Boilers

To contextualize backfire, it’s essential to understand the two primary types of boilers used on ships:

- Oil-Fired Boilers: These boilers use burners equipped with electric motors, ignition electrodes, and nozzles to atomize and ignite fuel. They are versatile, supporting functions like fuel heating and jacket water warming. However, their reliance on precise combustion makes them susceptible to backfire.

- Exhaust or Economizer Boilers: These systems utilize the high-temperature exhaust from the main diesel engine to heat fluid (water or thermal oil) within tubes. While less prone to backfire due to the absence of direct fuel combustion, blockages in exhaust pathways can still create pressure issues.

Backfire is predominantly associated with oil-fired boilers, where improper combustion conditions are more likely to occur.

Causes of Backfire in Marine Boilers

Understanding the root causes of backfire is critical for prevention. Below are the primary factors contributing to this hazardous condition:

- Fuel-Rich Mixture (Incomplete Combustion)

Insufficient air supply during combustion leads to incomplete burning of fuel, leaving unburnt fuel or vapors in the furnace. This creates a highly flammable mixture that can ignite explosively upon the next ignition attempt. - Accumulated Unburnt Fuel

If fuel from a previous firing cycle fails to combust fully, it accumulates in the furnace. A subsequent ignition attempt can ignite this residual fuel, causing a backfire. This is often linked to faulty components like leaky fuel oil solenoid valves, which allow fuel to drip into the furnace after shutdown. - Restricted Flue Gas Path

Soot, debris, or carbon deposits in the flue gas pathway can obstruct exhaust flow, causing pressure buildup. This imbalance can force flames and gases back toward the burner, resulting in a backfire. - Flame Failure

If the flame extinguishes during operation due to burner malfunctions or improper fuel atomization, unburnt fuel accumulates. A subsequent ignition attempt can trigger a backfire. - Delayed or Faulty Ignition

Malfunctioning ignition systems, such as worn electrodes or misaligned burners, can delay ignition. This allows fuel to accumulate, increasing the risk of an explosive ignition. - Excessive Boiler Load Fluctuations

Sudden changes in boiler load can destabilize combustion conditions, causing pressure fluctuations that may lead to gas reversal and backfire. - Inadequate Pre-Purging

In manual firing modes, insufficient pre-purging fails to clear accumulated fuel vapors from the furnace. Attempting ignition without proper purging can ignite these vapors, causing a backfire. - Nozzle Leakage or Low Oil Pressure

Leaky nozzles or low fuel pump pressure can result in poor fuel atomization, allowing fuel to drip into the furnace or burn inefficiently, creating conditions for backfire.

Case Study: A Real-World Backfire Incident

To illustrate the causes, consider a documented incident on a vessel at anchorage:

- Timeline: A fire was reported in the engine room, followed by multiple explosions. The crew activated emergency protocols, including boundary cooling and shutting down the boiler. The fire was extinguished using portable dry chemical extinguishers after the explosions ceased.

- Damage: The burner head assembly, air damper, fuel oil solenoid, ignition transformer, flame eye detector, oil heater element, pressure gauge, thermometer, and air blower motor were damaged. Surrounding engine room fittings were discolored.

- Root Cause: Unburnt fuel accumulated in the furnace due to a leaky fuel oil solenoid valve, which was repeatedly overhauled without replacement due to a lack of spares. The crew was unaware of a manufacturer’s safety bulletin recommending burner modifications to prevent backfire.

- Contributory Cause: Insufficient pre-purging failed to clear the combustible mixture, leading to a backfire during re-ignition.

This incident highlights the dangers of inadequate maintenance, lack of communication regarding safety bulletins, and improper purging procedures.

Consequences of Backfire

Backfire in marine boilers can have severe repercussions, impacting equipment, personnel, and operations:

- Equipment Damage

The explosive force of a backfire can damage critical components, including burners, fuel lines, furnace refractories, and surrounding fittings. For example, the incident above resulted in extensive damage to the burner assembly and associated systems. - Personnel Injuries

Backfires pose significant risks to crew members near the boiler, with potential for burns, blast injuries, or exposure to toxic gases. The high-pressure expulsion of flames can also ignite nearby materials, increasing the risk of fire. - Operational Disruptions

Backfires often necessitate immediate boiler shutdown, leading to costly delays for inspections and repairs. These disruptions can affect vessel schedules and cargo operations. - Fire Hazards

Escaping flames from a backfire can ignite flammable materials in the engine room, potentially causing widespread fires that threaten the vessel’s safety.

Impact Table

| Consequence | Description | Impact Level |

|---|---|---|

| Equipment Damage | Damage to burners, fuel lines, and refractories | High |

| Personnel Injuries | Risk of burns, blast injuries, or exposure to toxic gases | Critical |

| Operational Disruptions | Shutdowns for repairs, delaying vessel schedules | Moderate |

| Fire Hazards | Potential for onboard fires due to escaping flames | Critical |

Preventing Backfire in Marine Boilers

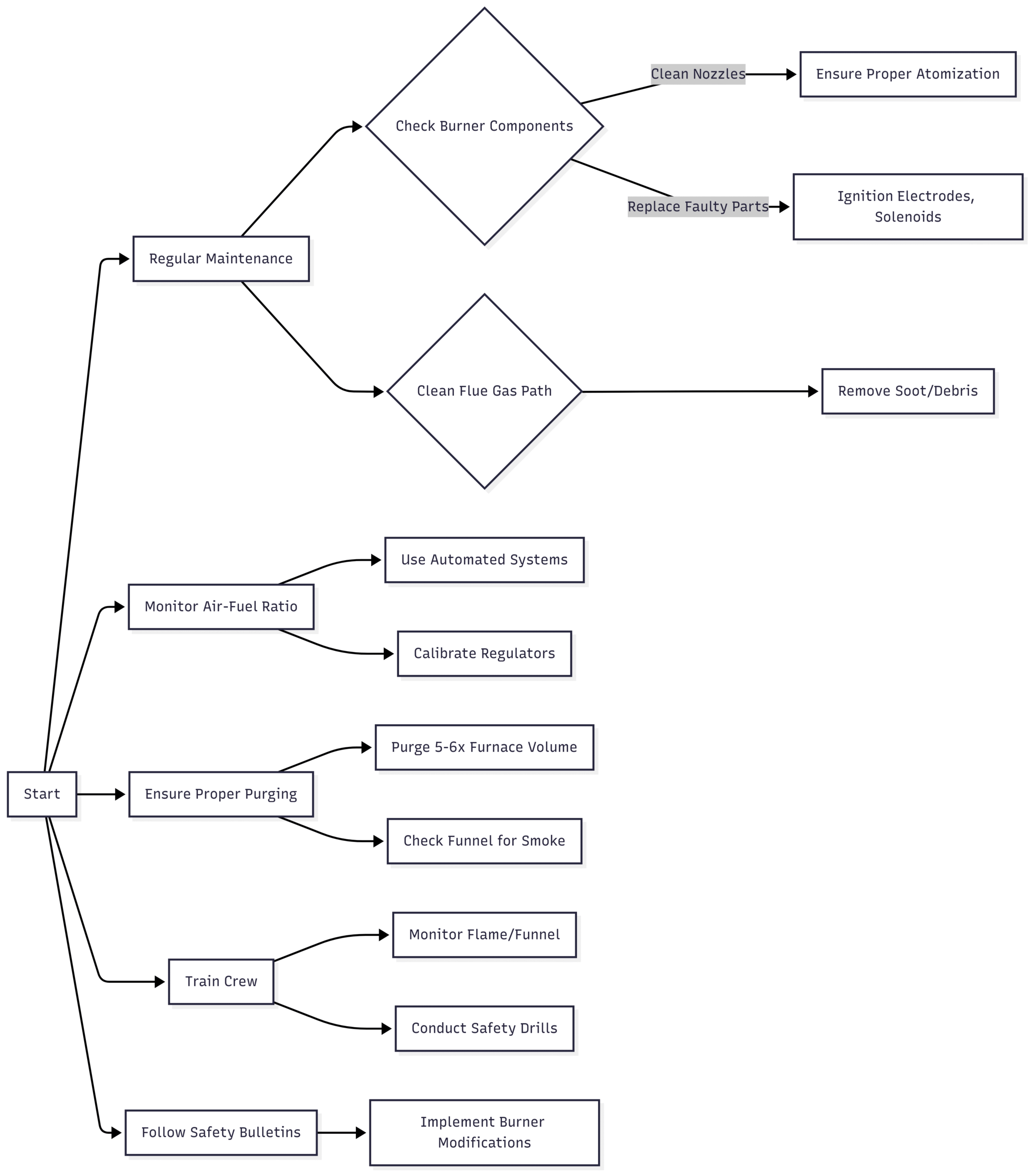

Preventing backfire requires a combination of regular maintenance, operational diligence, and crew training. Below are detailed preventive measures:

- Regular Maintenance and Inspection

- Burner Maintenance: Clean burners and nozzles to ensure proper fuel atomization. Replace worn components like ignition electrodes or fuel solenoids promptly.

- Flue Gas Path Cleaning: Regularly remove soot and debris from exhaust pathways to prevent pressure buildup.

- Furnace Inspections: Periodically inspect furnace refractories for cracks or damage that could disrupt combustion.

- Optimal Air-Fuel Ratio

- Use automated monitoring systems to maintain the correct air-fuel ratio, ensuring complete combustion.

- Regularly calibrate air regulators and micro-switches to prevent improper air supply.

- Proper Ignition Timing

- Inspect and maintain ignition systems, including spark plugs and transformers, to ensure reliable ignition.

- Adjust ignition timing to prevent delays that allow fuel accumulation.

- Monitoring Boiler Load

- Implement gradual load adjustments to maintain stable combustion conditions.

- Use advanced control systems to automatically adjust fuel and air supply during load changes.

- Adequate Pre-Purging

- In manual firing modes, ensure pre-purging lasts at least 5–6 times the furnace volume (typically 5 minutes) with dampers fully open.

- Check for hot spots or smoke in the funnel during purging to confirm the furnace is clear of combustible gases.

- Crew Training and Awareness

- Train engineers to monitor flame patterns, funnel smoke (dull black indicates proper combustion), and pressure fluctuations.

- Conduct regular safety drills to prepare the crew for boiler emergencies.

- Ensure awareness of manufacturer safety bulletins, incorporating them into engine room familiarization and handover notes.

- Fuel System Maintenance

- Regularly check fuel oil solenoid valves for leaks and replace faulty units rather than relying on temporary repairs like lapping.

- Treat fuel oil as per manufacturer recommendations to ensure proper combustion.

- Economizer Maintenance

- If equipped, regularly water-wash and inspect economizers to prevent exhaust gas backpressure.

Preventive Action Flowchart

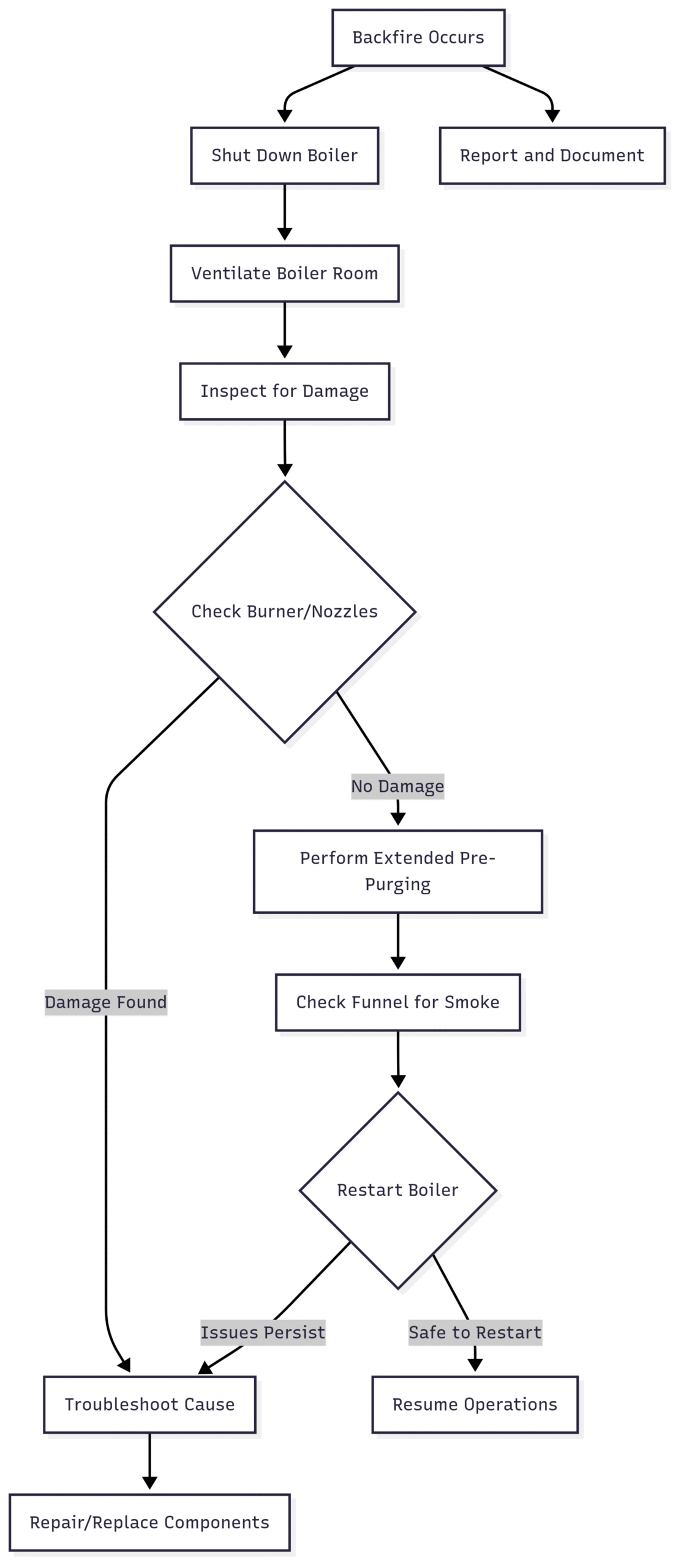

Emergency Response to Backfire

Despite preventive measures, backfire incidents may occur. A swift and structured response is critical to minimize damage and ensure safety:

- Shut Down the Boiler: Immediately stop the burner to halt fuel supply and prevent further combustion.

- Ventilate the Boiler Room: Open vents to clear flammable gases and reduce the risk of secondary explosions.

- Inspect for Damage: Check burners, fuel lines, nozzles, and surrounding areas for signs of damage or fuel accumulation.

- Troubleshoot Before Restarting: Identify and rectify the cause of the backfire (e.g., leaky solenoid valve or blocked flue).

- Perform Extended Pre-Purging: Run a purge cycle for at least 5 minutes with dampers fully open before attempting to restart.

- Report and Document: Log the incident, including causes, damage, and corrective actions, for maintenance records and safety audits.

- Restart Protocol: Only restart the boiler after a thorough inspection and clearance by qualified personnel.

Emergency Response Flowchart

Lessons Learned from Backfire Incidents

Backfire incidents underscore the importance of proactive maintenance and adherence to safety protocols. Key lessons include:

- Regular Monitoring: Duty engineers must routinely check burner flames and funnel smoke to ensure proper combustion. Dull black smoke indicates optimal combustion, while black or white smoke suggests unburnt fuel accumulation.

- Component Maintenance: Fuel oil system components, particularly solenoid valves, must be checked and replaced if faulty. Temporary repairs, such as lapping a leaking valve, are insufficient.

- Adherence to Safety Bulletins: Manufacturers’ safety recommendations, such as burner modifications, must be communicated to ship staff and incorporated into operational protocols.

- No Bypassing Safety Procedures: Never reduce purging time or bypass safety checks, as this significantly increases the risk of backfire.

Specifications and Costs of Key Boiler Components

To prevent backfire, maintaining high-quality boiler components is essential. Below is a table outlining typical specifications and approximate costs for critical parts in oil-fired marine boilers (costs are indicative and may vary by supplier and region):

| Component | Specifications | Approximate Cost (USD) |

|---|---|---|

| Burner Head Assembly | Stainless steel, 500–2000 kW capacity | $5,000–$15,000 |

| Fuel Oil Solenoid Valve | 24V DC, 1–2 inch diameter, brass/stainless steel | $200–$500 |

| Ignition Transformer | 10–15 kV output, 50/60 Hz | $300–$800 |

| Flame Eye Detector | UV/IR sensor, 24V DC | $500–$1,200 |

| Air Blower Motor | 1–5 HP, 3-phase, 440V | $1,000–$3,000 |

| Oil Heater Element | 5–20 kW, stainless steel | $500–$1,500 |

| Pressure Gauge | 0–16 bar, analog/digital | $50–$150 |

| Thermometer | -50 to 500°C, digital/analog | $30–$100 |

Note: For precise pricing, consult suppliers like Aalborg, Saacke, or Weishaupt, or refer to advanced automation solutions in boiler management.

Conclusion

Backfire in marine boilers is a serious hazard that can compromise vessel safety, damage equipment, and disrupt operations. By understanding its causes—such as fuel accumulation, improper air-fuel ratios, and inadequate purging—maritime operators can implement effective preventive measures. Regular maintenance, proper ignition timing, crew training, and adherence to safety bulletins are critical to minimizing risks. In the event of a backfire, a structured emergency response ensures swift resolution and prevents escalation. By prioritizing these practices, ships can maintain safe, efficient, and reliable boiler operations, safeguarding both crew and cargo.

For further resources, maritime operators can explore advanced training modules tailored for marine engineers, available through specialized maritime education platforms.

Happy Boating!

Share Back-Fire (Blow-Back) in Marine Boilers with your friends and leave a comment below with your thoughts.

Read Different Stages of Ship Design Explained until we meet in the next article.