are aluminum boats good for saltwater

Discover why aluminum boats excel in saltwater fishing. Learn about corrosion resistance, maintenance tips, and top models like Lund and Thunder Jet.

Aluminum boats have surged in popularity among saltwater anglers and recreational boaters, thanks to their affordability, durability, and lightweight design. However, their suitability for the harsh saltwater environment depends on proper maintenance and understanding their unique properties. This article explores why aluminum boats are a compelling choice for saltwater use, how to protect them from corrosion, and highlights top models and practical experiences from boaters. Whether you’re a seasoned captain or a newcomer like Scott, planning to fish in Fort Walton Beach, Florida, this guide equips you with the knowledge to make an informed decision.

Why Aluminum Boats Shine in Saltwater

Aluminum boats offer distinct advantages that make them a strong contender for saltwater fishing and boating. Here’s a detailed look at their key benefits:

1. Corrosion Resistance

Aluminum’s natural corrosion resistance is a major draw for saltwater environments. Marine-grade alloys, such as 5083, 5086, and 5456, form a protective oxide layer when exposed to air, shielding the metal from further degradation. Unlike steel, which rusts, or fiberglass, which can suffer from corroding metal fittings, aluminum holds up well in saline conditions when properly maintained.

However, galvanic corrosion—caused by dissimilar metals in contact with an electrolyte like saltwater—poses a risk. Boaters can mitigate this with sacrificial anodes, typically made of zinc or magnesium, which corrode in place of the aluminum hull.

2. Lightweight Design

Aluminum is significantly lighter than steel and even fiberglass for boats of comparable size. This reduces fuel consumption, improves handling, and allows for a shallower draft, ideal for navigating coastal waters. For instance, a 21-foot Lund boat, like the one Scott’s father offered, is easier to trailer and launch compared to heavier alternatives, making it practical for frequent saltwater trips.

3. Durability and Malleability

Aluminum boats are renowned for their toughness. They can endure impacts from submerged objects like rocks or stumps, which might crack fiberglass hulls. Aluminum’s malleability allows it to dent rather than fracture, reducing the risk of leaks. These dents are often easier to spot and repair during routine maintenance, enhancing the boat’s longevity.

4. Low Maintenance

Compared to fiberglass boats, which require regular waxing and gel coat repairs, aluminum boats demand less upkeep. They don’t develop blisters or spiderweb cracks, and above the waterline, they often don’t need painting for functional purposes. However, saltwater use necessitates specific maintenance practices, such as rinsing with fresh water and inspecting anodes, to prevent corrosion.

5. Affordability

Aluminum boats are 20–50% cheaper than fiberglass counterparts due to advances in manufacturing and material costs. This affordability makes them accessible to a wide range of boaters, from hobbyists to commercial fishermen. For example, a basic 16-foot aluminum jon boat can cost as little as $5,000, while a fully equipped 24-foot Thunder Jet Alexis Pro might retail around $80,000, still competitive with fiberglass models.

6. Safety

The malleable nature of aluminum enhances safety by reducing the likelihood of catastrophic hull failure. Welded cleats and heavy-duty keel guards, as found on brands like Thunder Jet, add to their robustness. These features make aluminum boats forgiving for novice boaters while providing peace of mind in rough saltwater conditions.

Challenges of Using Aluminum Boats in Saltwater

While aluminum boats excel in many areas, they aren’t without challenges in saltwater. The primary concern is galvanic corrosion, which occurs when aluminum is in contact with a more noble metal (e.g., stainless steel or bronze) in saltwater. This electrochemical reaction can degrade the aluminum unless mitigated. Other considerations include:

- Trailer Material: Painted steel trailers, common with aluminum boats, corrode quickly in saltwater. Galvanized or aluminum trailers are more durable but costlier.

- Aesthetics: Aluminum boats may oxidize over time, leading to a slightly discolored appearance, though this is cosmetic and doesn’t affect performance.

- Ride Quality: Some aluminum boats, particularly those with flatter hulls (14–18° deadrise), can deliver a rougher ride in choppy seas compared to deep-V fiberglass boats.

How to Protect Aluminum Boats from Saltwater Corrosion

To maximize the lifespan of an aluminum boat in saltwater, diligent maintenance is essential. Here are proven strategies, backed by boater experiences and expert advice:

1. Rinse with Fresh Water

After every saltwater outing, rinse the boat thoroughly with fresh water to remove salt deposits. Boaters like Reddawg, who used an Alumacraft jon boat for seven years in saltwater, emphasize that consistent rinsing prevents corrosion. No special soap is needed; a standard hose-down suffices.

2. Use Sacrificial Anodes

Sacrificial anodes, typically zinc or magnesium, are critical for preventing galvanic corrosion. These anodes corrode preferentially, sparing the aluminum hull. Check and replace them regularly, as advised by Canazes9, who noted that wire-brushing white powdery corrosion off anodes maintains their effectiveness. For aluminum boats, magnesium anodes may be more suitable than zinc, as aluminum is less noble than zinc in some conditions.

3. Apply Protective Coatings

Marine-grade anti-fouling paints or powder coatings create a barrier against saltwater. Rogue Jet Boats, for instance, use powder coating baked at 420°F, claiming three times the corrosion resistance of standard paint. However, applying anti-fouling paint to aluminum requires a dielectric primer to prevent direct contact, as Boneman warned. Products like Interlux Trilux or Dolphinite Go Fast Bottom Paint, which TinCan planned to test, are formulated for aluminum but can cost $170–$200 per gallon.

4. Proper Storage

Store the boat in a dry, covered area when not in use to minimize exposure to saltwater and humidity. Trailering, as suggested by Blacklabmarine, is preferable to leaving the boat in a slip, especially for extended periods. Del’s experience docking a 16-foot Lund in a marina revealed minor seam corrosion after just two weeks, underscoring the risks of continuous immersion.

5. Regular Inspections

Inspect the hull, seams, and fittings regularly for signs of corrosion or damage. Prompt repairs prevent small issues from escalating. Proper sealing of joints with marine-grade sealant or caulk, as recommended in boating guides, further protects against water ingress.

6. Avoid Dissimilar Metals

Minimize the use of dissimilar metals like bronze or brass fittings, which accelerate galvanic corrosion. Trouty’s detailed explanation highlights how even insulated accessories can form a bimetallic cell in saltwater spray, emphasizing the need for equipotential bonding to the hull and anodes.

Real-World Experiences with Aluminum Boats in Saltwater

Boaters’ firsthand accounts provide valuable insights into using aluminum boats in saltwater. Scott, relocating to Fort Walton Beach, received a 21-foot Lund from his father. Forum members on a boating discussion board offered enthusiastic feedback:

- Wahoome used an aluminum jon boat in Biscayne Bay without corrosion issues, despite never rinsing it, though he eventually damaged the rivets through heavy use.

- Locomech has fished a 21-foot Lund center console in Narragansett Bay for 13 seasons, trailering and rinsing it to maintain its condition. The only issue was water-damaged wooden hatches.

- TinCan runs a 23-foot Pacific center console from Black Lab Marine in Long Island, keeping it in the water for nine months annually. With large zinc anodes and Nyalic coating, he reports no corrosion, though he plans to switch to Dolphinite paint for easier maintenance.

- Miami Vice praised a 24-year-old riveted aluminum boat docked in Miami Beach, noting its superior durability compared to fiberglass boats, provided zincs are monitored.

These experiences highlight that with proper care, aluminum boats can thrive in saltwater, even in demanding conditions like Miami’s warm, saline waters.

Top Aluminum Boat Models for Saltwater

Several brands stand out for their saltwater-ready aluminum boats. Below is a comparison of popular models, including specifications and estimated prices (based on market trends and user mentions):

| Model | Length | Beam | Hull Alloy | Key Features | Price (USD) |

|---|---|---|---|---|---|

| Lund 2075 Pro-V | 20’9” | 8’6” | 5052 H34 | Deep-V hull, high sides, electric downriggers | ~$45,000–$60,000 |

| Thunder Jet Alexis Pro | 24’ | 8’6” | 5086 (.250” bottom) | Hard top, 300HP Mercury V8, powder coating | ~$80,000–$100,000 |

| Pacific 23 CC (Black Lab) | 23’ | 8’6” | 5086 | T-top, tuna door, heavy-duty welded construction | ~$50,000 (w/o motor) |

| Alumacraft 1650 Jon Boat | 16’ | 6’3” | 5052 | Flat-bottom, trailerable, lightweight | ~$5,000–$10,000 |

Lund Boats

Lund, like the 21-footer offered to Scott, is celebrated for its solid construction and versatility. The 2075 Pro-V, made from 5052 H34 aluminum, is ideal for inshore and nearshore saltwater fishing but not rated for continuous immersion. Its deep-V hull handles chop well, though high sides may catch wind, as Mumblerone noted.

Thunder Jet Alexis Pro

Thunder Jet’s Alexis Pro is a premium option with a 5086 alloy hull, double-welded for strength. Its powder-coated finish and 300HP Mercury outboard make it a favorite for serious anglers in British Columbia. The boat’s triangular structure enhances stability, and optional hard tops add protection in rough seas.

Pacific 23 Center Console

Black Lab Marine’s Pacific 23, used by TinCan, is built for durability with 5086 alloy and heavy-duty welding. Its ability to stay in the water for extended periods with proper anodes makes it suitable for saltwater. The Dolphinite paint option promises low maintenance and improved efficiency.

Alumacraft Jon Boats

Alumacraft’s jon boats, like Reddawg’s, are budget-friendly and reliable for inshore saltwater use. Their flat-bottom design limits offshore capability but excels in bays and estuaries.

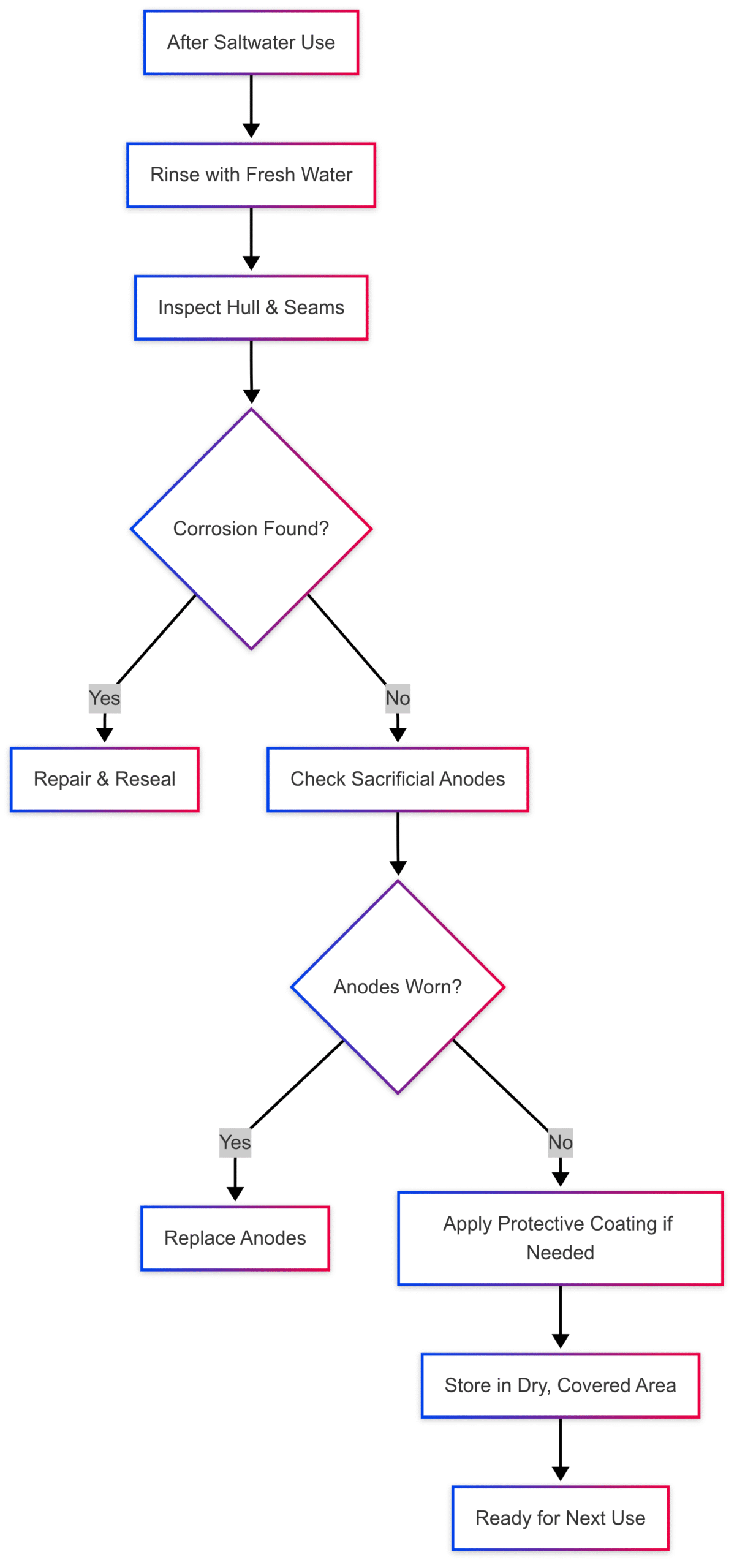

Chart: Aluminum Boat Maintenance Workflow

To visualize the maintenance process for aluminum boats in saltwater, here’s a flowchart:

This workflow ensures systematic care, minimizing corrosion risks and extending the boat’s lifespan.

Comparing Aluminum to Fiberglass and Steel

To contextualize aluminum’s suitability, here’s a comparison with other common hull materials:

| Material | Pros | Cons |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, affordable, durable | Susceptible to galvanic corrosion, rougher ride in some designs |

| Fiberglass | Smooth ride, moldable for storage, aesthetically versatile | Prone to cracks, high maintenance, heavier |

| Steel | Extremely strong, long-lasting | Heavy, rust-prone, costly |

Aluminum strikes a balance between cost, weight, and durability, making it a practical choice for saltwater, especially for trailerable boats.

Practical Tips for Saltwater Boating

For boaters like Scott, transitioning to saltwater fishing in Florida, consider these tips:

- Trailer Care: Ensure the trailer is galvanized or aluminum, as Brian N and Reddawg reported rapid rusting of painted steel trailers.

- Local Knowledge: Connect with local anglers, as Pcolaboy offered to guide Scott in Fort Walton Beach’s waters.

- Avoid Caustic Cleaners: Trouty warned that caustic cleaners react violently with aluminum, producing hydrogen and damaging the hull.

- Equipotential Bonding: Ensure all metal accessories are bonded to the hull and protected by anodes to prevent stray currents.

Conclusion

Aluminum boats are an excellent choice for saltwater fishing and boating, offering corrosion resistance, durability, and affordability. Brands like Lund, Thunder Jet, and Pacific deliver reliable performance, as evidenced by boaters’ long-term success in harsh environments like Miami Beach and Narragansett Bay. However, their longevity hinges on diligent maintenance, including fresh water rinsing, anode management, and proper storage. By following these practices, boaters can enjoy years of trouble-free saltwater adventures. For those considering an aluminum boat, contact reputable dealers like Alberni Power and Marine or Black Lab Marine to explore models tailored to your needs.

Happy Boating!

Share are aluminum boats good for saltwater with your friends and leave a comment below with your thoughts.

Read are aluminum boats better than fiberglass until we meet in the next article.