An Introduction to Ship’s Turbine Generator

Discover how ship’s turbine generators power maritime vessels with steam, their components, advantages, and modern applications in this detailed guide.

Marine turbine generators are a cornerstone of maritime engineering, converting steam’s thermal energy into mechanical and electrical power to propel ships and support onboard systems. These systems, rooted in a rich history of innovation, remain vital in specific maritime applications like LNG carriers and naval vessels. This article explores their operation, components, advantages, challenges, and future in modern shipping.

Historical Evolution of Marine Steam Turbines

Marine steam turbines emerged in the late 19th century, revolutionizing ship propulsion. Charles Parsons’ 1894 Turbinia demonstrated their potential, achieving unprecedented speeds through direct-drive steam turbines. This marked a shift from reciprocating steam engines, which dominated earlier maritime propulsion. By the early 20th century, steam turbines became the preferred choice for large vessels due to their high power output and smoother operation.

The transition from reciprocating engines to turbines was driven by efficiency and size advantages. Unlike bulky side-lever or walking beam engines, turbines offered compact designs and reduced vibration. However, their high rotational speeds required reduction gears or turbo-electric systems to match propeller needs, a challenge Parsons addressed with innovative gearing solutions.

By the mid-20th century, diesel engines began surpassing steam turbines in commercial shipping due to superior fuel efficiency and operational flexibility. Despite this, steam turbines retained relevance in niche applications, particularly in LNG carriers and nuclear-powered naval ships, where their unique advantages shine.

How Ship’s Turbine Generators Work

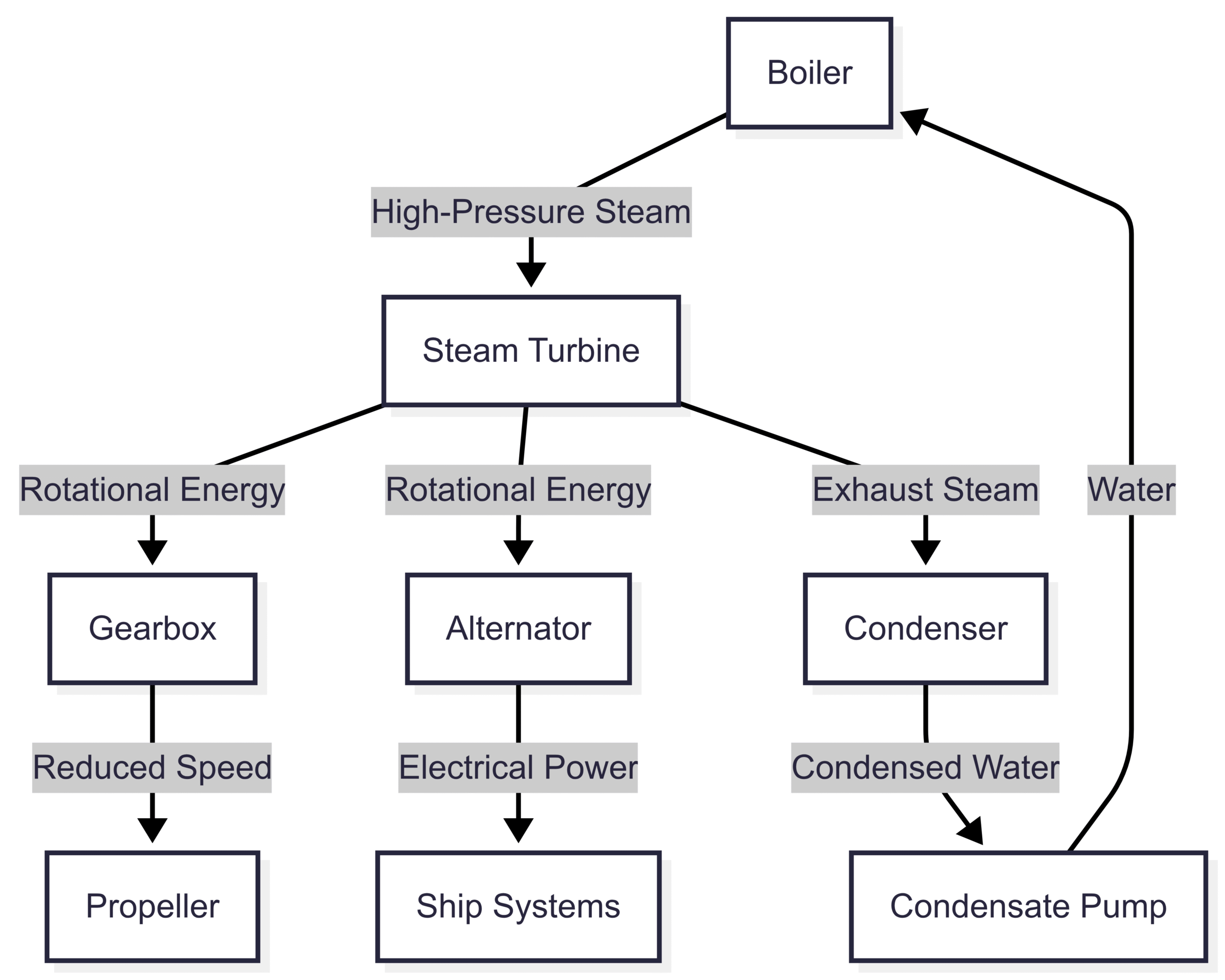

Marine turbine generators operate on the principle of steam expansion, converting thermal energy into mechanical work, which is then transformed into electrical or propulsive power. The process involves several key stages:

- Steam Generation: A ship’s boiler heats water using fuels like heavy fuel oil or boil-off gas (in LNG carriers) to produce high-pressure, high-temperature steam. Modern boilers are designed for efficiency, often incorporating waste heat recovery systems to maximize energy use.

- Turbine Rotation: The steam is directed onto turbine blades, causing the rotor to spin. The turbine converts thermal energy into mechanical energy, with high-pressure (HP), intermediate-pressure (IP), and low-pressure (LP) stages often used in series to optimize efficiency.

- Power Transmission: The turbine’s high rotational speed is reduced through a gearbox to match the propeller’s optimal speed, typically 50–150 rpm. This ensures efficient thrust generation for propulsion.

- Electricity Generation: In turbine generators, the turbine shaft drives an alternator, converting mechanical energy into electrical power for onboard systems like lighting, navigation, and communication.

- Condensation and Recycling: Exhaust steam is cooled in a condenser, transforming it back into water. A condensate pump returns this water to the boiler, enhancing system efficiency by reusing water in a closed loop.

Key Components of Turbine Generator Systems

Marine turbine generators are complex systems with critical components designed for durability and efficiency in harsh maritime environments. Below is a detailed breakdown:

| Component | Function | Material |

|---|---|---|

| Steam Boiler | Produces high-pressure steam by heating water with fuel or waste heat. | High-grade steel, titanium alloys |

| Steam Turbine | Converts steam’s thermal energy into mechanical rotation. | Stainless steel, nickel alloys |

| Alternator | Generates electrical power from turbine’s mechanical energy. | Copper windings, steel frame |

| Gearbox | Reduces turbine speed for propeller compatibility. | Hardened steel gears |

| Condenser | Cools exhaust steam into water for reuse, improving efficiency. | Titanium, corrosion-resistant alloys |

| Condensate Pump | Pumps condensed water back to the boiler. | Stainless steel |

| Steam Control Governor | Regulates turbine speed by controlling steam flow. | Precision steel components |

| Steam Control Valve | Adjusts steam flow from boiler to turbine for optimal performance. | High-pressure steel alloys |

| Vacuum Pump for Glands | Maintains turbine casing vacuum to prevent efficiency losses. | Stainless steel, brass |

| Vacuum Pump Header Tank | Cools vacuum pump handling high-temperature steam. | Corrosion-resistant steel |

These components are constructed from materials like high-grade steel and titanium alloys to withstand high temperatures, pressures, and corrosive marine environments. Their robust design ensures longevity and reliability.

Applications in Modern Shipping

Marine turbine generators are used in both propulsion and auxiliary power generation, with specific applications in:

- LNG Carriers: These vessels use boil-off gas from cargo as fuel, making steam turbines a cost-effective choice. Approximately 30% of global LNG carriers rely on steam turbines, leveraging the availability of boil-off gas to power boilers.

- Naval Ships: Nuclear-powered aircraft carriers, submarines, and destroyers use steam turbines due to their high power output and reliability. Nuclear reactors provide a consistent heat source, eliminating fuel storage concerns.

- Specialized Vessels: Some cruise ships and icebreakers employ steam turbines for their ability to deliver steady power during long voyages or in extreme conditions.

- Auxiliary Power: Turbine generators supply electricity for onboard systems, ensuring continuous operation of critical equipment like navigation and communication systems.

Advantages of Marine Turbine Generators

Marine turbine generators offer several benefits that make them suitable for specific maritime applications:

- High Power Output: Capable of delivering substantial power (up to 100 MW in large naval vessels), ideal for large ships requiring significant thrust or electrical capacity.

- Reliability: Proven technology with a long history of robust performance in demanding conditions.

- Fuel Flexibility: Can use various fuels, including heavy fuel oil, boil-off gas, or nuclear energy, adapting to operational needs.

- Smooth Operation: Minimal vibration ensures quieter operation, enhancing crew and passenger comfort.

- Waste Heat Recovery: Integration with waste heat recovery systems boosts overall efficiency by up to 10–15%, reducing fuel consumption.

Challenges and Limitations

Despite their advantages, marine turbine generators face challenges:

- Lower Fuel Efficiency: Specific fuel consumption (SFC) is higher than diesel engines, typically 200–250 g/kWh compared to 180–200 g/kWh for diesel. This increases operational costs, especially for long voyages.

- Size and Weight: Turbine systems are bulkier and heavier than diesel or gas turbine alternatives, requiring larger engine rooms.

- Complex Maintenance: High-pressure steam systems demand specialized maintenance, increasing downtime and costs.

- Operational Complexity: Requires skilled operators with expertise in steam systems, adding to training expenses.

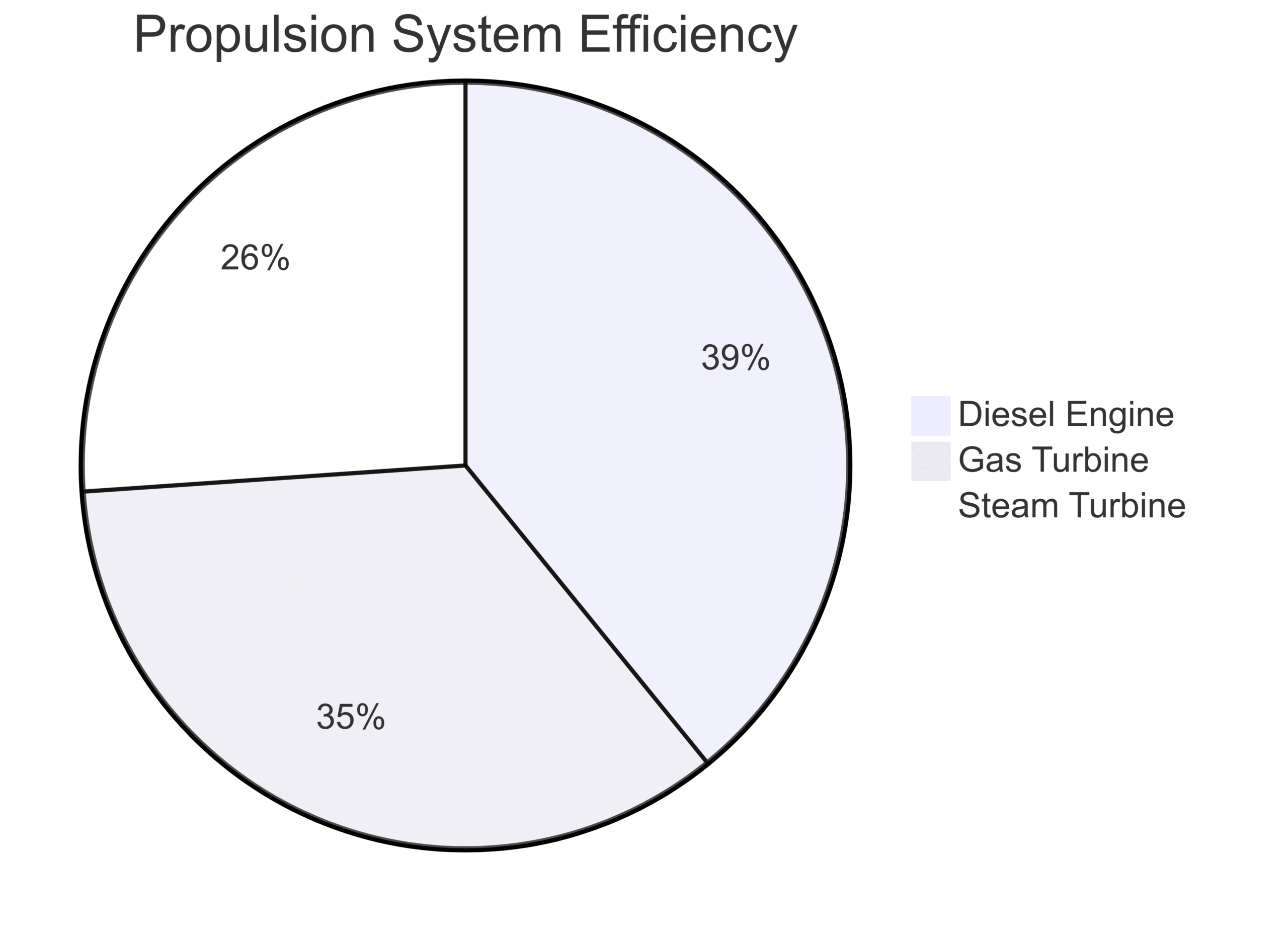

Comparison with Other Propulsion Systems

Marine turbine generators compete with diesel and gas turbines, each with distinct characteristics:

| Feature | Steam Turbine | Diesel Engine | Gas Turbine |

|---|---|---|---|

| Thermal Efficiency | 25–35% | 40–50% | 35–45% (higher in combined cycle) |

| Start-Up Time | Slow (30–60 min to raise steam) | Fast (5–10 min) | Very fast (1–5 min) |

| Fuel Flexibility | Heavy fuel oil, boil-off gas, nuclear | Diesel, MGO, LNG | Natural gas, MGO, low-sulfur fuels |

| Maintenance Complexity | High (specialized steam systems) | Moderate | Moderate (high-temp components) |

| Power-to-Weight Ratio | Moderate | High | Very high |

| Applications | LNG carriers, naval ships | Most commercial vessels | Naval ships, ferries |

Environmental Considerations

Marine turbine generators are relatively eco-friendly when paired with clean energy sources like nuclear power or boil-off gas. They emit lower greenhouse gases (CO2) compared to diesel engines but contribute to NOx and SOx emissions when using heavy fuel oil. Compliance with IMO Tier III regulations requires technologies like selective catalytic reduction (SCR) to reduce emissions.

Future advancements focus on integrating biofuels, synthetic fuels, and renewable energy sources to align with sustainability goals. Waste heat recovery and improved turbine designs could reduce emissions by 10–20%, ensuring compliance with stricter environmental standards.

Technological Innovations

Recent advancements in marine turbine generators include:

- Ultra-Steam Turbines: Mitsubishi Heavy Industries’ ultra-steam turbines improve efficiency by optimizing steam flow and reducing energy losses.

- Advanced Control Systems: Automated governors and throttle valves enhance precision, reducing fuel consumption by 5–10%.

- Material Innovations: Use of advanced composites and nickel-based alloys improves durability and corrosion resistance.

- Hybrid Systems: Combining steam turbines with gas turbines or electric propulsion increases efficiency and flexibility.

Future Directions

The future of marine turbine generators lies in their adaptation to a greener maritime industry. Key trends include:

- Low-Emission Fuels: Adoption of biofuels and synthetic fuels to reduce NOx and SOx emissions.

- Hybrid Propulsion: Integration with electric or renewable energy systems to enhance efficiency.

- Digitalization: Advanced monitoring and predictive maintenance systems to minimize downtime and improve performance.

- Nuclear Propulsion: Expanded use in naval applications due to zero-emission potential.

These innovations ensure steam turbines remain competitive in niche markets despite the dominance of diesel engines.

Maintenance and Operational Practices

Maintaining marine turbine generators involves:

- Regular Inspections: Checking turbine blades, boilers, and condensers for wear and corrosion.

- Warming-Up Procedures: Gradual heating to prevent thermal stress, typically taking 30–60 minutes, involving slow steam admission and temperature monitoring.

- Lubrication: Ensuring bearings and gears are properly lubricated to reduce friction.

- Safety Systems: Automatic overspeed trip mechanisms and pressure relief valves to prevent damage.

Challenges include managing high-pressure steam systems and ensuring component longevity in corrosive environments. Advanced monitoring technologies mitigate these issues by detecting anomalies early.

Key Producers and Market Insights

Leading manufacturers of marine turbine generators include:

- General Electric (GE): Known for high-efficiency turbines for naval and commercial vessels.

- Mitsubishi Heavy Industries (MHI): Pioneers in ultra-steam turbines for LNG carriers.

- MAN Energy Solutions: Offers robust turbine systems for specialized applications.

- Rolls-Royce (BAE Systems): Focuses on naval turbine solutions.

- Kawasaki Heavy Industries (KHI): Provides turbines for LNG carriers and tankers.

These companies invest in R&D to enhance efficiency and meet environmental regulations, maintaining a competitive edge in a niche market.

Conclusion

Ship’s turbine generators remain a vital technology in maritime engineering, offering high power output, reliability, and fuel flexibility for specific applications like LNG carriers and naval ships. While they face challenges like lower fuel efficiency and complex maintenance, advancements in materials, control systems, and eco-friendly fuels ensure their continued relevance. As the maritime industry embraces sustainability, turbine generators will evolve to meet stricter environmental standards, solidifying their role in modern shipping.

Happy Boating!

Share An Introduction to Ship’s Turbine Generator with your friends and leave a comment below with your thoughts.

Read Prevention of Pollution by Sewage from Ships until we meet in the next article.