Discover the history of classic fiberglass boats, their timeless designs, and how modern fiberglass revives 1950s-60s icons.

The classic fiberglass boat represents a perfect fusion of nostalgia, craftsmanship, and modern innovation. Born in the post-World War II era, these vessels captured the essence of mid-20th-century leisure and luxury, with their sleek lines and elegant designs. Today, fiberglass technology breathes new life into these iconic boats, blending vintage aesthetics with contemporary durability. This article explores the rich history of classic boats from the 1950s and 1960s, the rise of fiberglass as a game-changing material, and how manufacturers like Lancer Craft are reimagining these timeless designs for modern enthusiasts. We’ll also delve into the restoration process, key considerations for ownership, and the environmental and economic benefits of preserving these maritime treasures.

The Golden Age of Boating: 1950s and 1960s

The 1950s and 1960s marked a transformative period for recreational boating. After World War II, a burgeoning middle class and a desire for leisure fueled a boating boom across North America and Europe. Boating became a symbol of freedom, adventure, and status, with families and enthusiasts flocking to lakes, rivers, and coastal waters. During this era, wooden boats dominated the market, crafted from premium materials like mahogany, teak, and oak. These boats were not just vessels but works of art, showcasing meticulous craftsmanship and elegant designs that remain iconic today.

Iconic Boat Models of the Era

Several boat models from this period became legendary for their style and performance. Here are a few standout examples:

- Chris-Craft Constellation: Known for its spacious cabins and luxurious finishes, the Constellation was a favorite for extended cruising. Its polished wood and chrome accents epitomized mid-century sophistication.

- Riva Aquarama: An Italian masterpiece, the Aquarama combined sleek lines with high-performance engines, making it a status symbol in the Mediterranean. Its twin Lamborghini engines and handcrafted woodwork set it apart.

- Century Coronado: A versatile “pulling workhorse,” the Coronado was celebrated for its robust Chrysler Golden Lion 325 engine and suitability for day-cruising or overnight stays.

- Lyman Islander: Popular in the Great Lakes region, the Islander offered a practical yet stylish design, ideal for family outings.

These boats were defined by their graceful curves, gleaming wood finishes, and attention to detail. However, wooden boats came with significant drawbacks. Wood was prone to rot, warping, and damage from marine organisms, requiring constant maintenance, including sanding, varnishing, and sealing. As maintenance costs and efforts mounted, the boating industry sought a more durable alternative, paving the way for fiberglass.

The Rise of Fiberglass in Boat Manufacturing

Fiberglass, or glass-reinforced plastic (GRP), emerged as a revolutionary material in the late 1940s. Composed of fine glass fibers woven into a matrix and bonded with a polymer resin (typically polyester or epoxy), fiberglass offered unmatched durability, lightweight construction, and corrosion resistance. By the 1950s, boat manufacturers began adopting fiberglass, recognizing its potential to transform the industry.

Why Fiberglass Changed the Game

Fiberglass brought several advantages over wood:

- Durability: Unlike wood, fiberglass resists rot, warping, and marine organism damage, making it ideal for harsh marine environments.

- Lightweight Design: Fiberglass boats are lighter than their wooden counterparts, improving fuel efficiency and handling.

- Low Maintenance: Fiberglass requires minimal upkeep—no regular sanding, painting, or varnishing, saving owners time and money.

- Design Flexibility: Fiberglass can be molded into complex, streamlined shapes, enabling innovative hull designs that enhance speed and maneuverability.

By the 1960s, fiberglass had become the material of choice for many manufacturers. Its ability to replicate intricate designs while reducing production costs made it a game-changer, allowing boats to be both beautiful and practical.

Transition from Wood to Fiberglass

The shift from wood to fiberglass was gradual but transformative. By the late 1960s, many manufacturers, including Century, transitioned their iconic models to fiberglass construction. For example, the Century Coronado, originally a wooden boat produced from 1955 to 1968, began incorporating fiberglass in 1967 to meet growing demand for low-maintenance vessels. This transition preserved the aesthetic appeal of classic designs while addressing the practical limitations of wood.

Reviving Classic Designs with Modern Fiberglass

Today, the nostalgia for 1950s and 1960s boats has sparked a revival, with manufacturers using advanced fiberglass techniques to recreate these iconic designs. Companies like Lancer Craft Boats have led the charge, producing fiberglass replicas that capture the essence of vintage boats while incorporating modern technology.

The Role of Molds in Replication

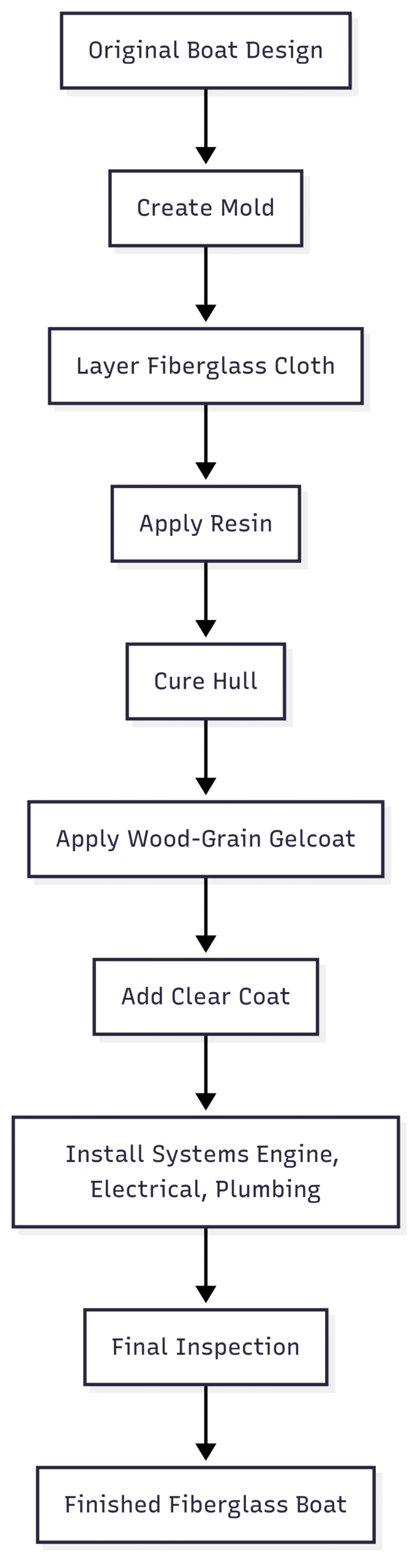

Modern fiberglass boats are crafted using molds based on original designs. These molds ensure that every curve and detail of the classic boat is faithfully reproduced. The process involves:

- Creating the Mold: A precise mold is made from the original boat or detailed blueprints, capturing its exact shape.

- Layering Fiberglass: Fiberglass cloth or mat is layered into the mold, bonded with resin, and cured to form a solid, lightweight hull.

- Finishing Touches: A gelcoat layer is applied to protect the surface and achieve a glossy finish. For classic replicas, a wood-grain gelcoat can mimic the look of polished wood.

This method allows manufacturers to produce boats that are virtually indistinguishable from their wooden predecessors, yet far more durable and easier to maintain.

Wood-Grain Effect: Blending Old and New

One of the most impressive advancements in fiberglass technology is the ability to replicate the look of wood. Using a wood-grain gelcoat, manufacturers apply a wood-colored layer followed by a clear coat to achieve a convincing wooden appearance. This technique ensures that modern fiberglass boats retain the nostalgic charm of their 1950s and 1960s counterparts without the maintenance challenges of wood.

Lancer Craft’s Classic: A Modern Tribute to the Century Coronado

Lancer Craft Boats exemplifies the revival of classic designs with their fiberglass model, the Lancer Craft Classic, inspired by the Century Coronado. The Coronado, known for its robust construction and timeless aesthetics, featured a powerful Chrysler Golden Lion 325 engine and was ideal for both day-cruising and overnight adventures. Lancer Craft’s Classic pays homage to these qualities while embracing modern engineering.

Key Features of the Lancer Craft Classic

| Feature | Description |

|---|---|

| Hull Material | 100% composite fiberglass, ensuring durability and low maintenance. |

| Engine | Ilmor Marine engine, offering high performance and reliability. |

| Length | 21–26 feet, depending on the model, suitable for various boating activities. |

| Seating Capacity | Accommodates 6–8 passengers, ideal for family outings or social gatherings. |

| Aesthetics | Wood-grain gelcoat finish, replicating the polished wood look of the Coronado. |

| Price Range | $80,000–$150,000 (varies based on customization and engine options). |

Lancer Craft collaborates with Ilmor Engineering, a leader in high-performance marine engines, to equip the Classic with a state-of-the-art powertrain. Ilmor’s engines, known for powering Indy-winning vehicles, deliver exceptional performance, ensuring the Classic matches the Coronado’s legacy as a “pulling workhorse.” The result is a boat that combines vintage style with modern functionality, appealing to both nostalgia-driven enthusiasts and performance-focused boaters.

Chart: Fiberglass Boat Manufacturing Process

This chart illustrates the streamlined process of creating a fiberglass replica, ensuring precision and durability at every step.

The Art of Fiberglass Boat Restoration

While modern fiberglass replicas offer a low-maintenance alternative to wooden boats, many enthusiasts own vintage fiberglass boats from the 1960s and 1970s that require restoration. Prolonged exposure to sunlight, saltwater, and wear can degrade fiberglass boats, leading to issues like gelcoat deterioration, blisters, and delamination. Restoring these boats is both an art and a science, requiring careful attention to detail to restore their aesthetic and structural integrity.

Signs Your Boat Needs Restoration

Before embarking on a restoration project, it’s essential to identify signs of wear and damage:

- Gelcoat Deterioration: Fading, chalkiness, or hairline cracks in the gelcoat indicate UV and environmental damage.

- Blisters: Osmotic blisters below the gelcoat can compromise structural integrity if untreated.

- Soft Spots: Spongy areas on the deck suggest water damage or delamination in the core material.

- Cracks: Deep cracks in the gelcoat or fiberglass indicate potential structural issues.

- Corrosion: Rust or corrosion around hardware can damage surrounding fiberglass.

- Performance Issues: Sluggish handling or leaks may signal hull or system problems.

If any of these signs are present, consulting a marine professional is advisable to assess the extent of the damage and recommend appropriate repairs.

Step-by-Step Restoration Process

Restoring a fiberglass boat involves a systematic approach to address both cosmetic and structural issues. Here’s a detailed guide:

- Assessment: Inspect the entire boat, documenting cracks, blisters, soft spots, and delamination. This step determines the scope of the project.

- Safety Precautions: Work in a well-ventilated area and wear protective gear, including gloves, safety glasses, and a respirator, especially when sanding fiberglass.

- Cleaning: Use marine detergent to remove dirt, grease, and contaminants, preparing the surface for repairs.

- Removing Old Gelcoat/Paint: Strip damaged gelcoat or paint using a chemical stripper or mechanical sander, working in small sections for precision.

- Repairs:

- Blisters: Drain fluid, dry the area, and fill with a fiberglass repair kit.

- Cracks/Holes: Clean and fill with fiberglass resin and cloth, ensuring structural integrity.

- Delamination: Remove affected sections, replace with new fiberglass layers, and ensure proper adhesion.

- Sanding: Sand the repaired areas with coarse-to-fine grit sandpaper for a smooth finish.

- Reapplying Gelcoat: Apply gelcoat evenly with a brush or sprayer, following manufacturer instructions. Multiple coats may be needed.

- Wet Sanding and Buffing: Wet sand the cured gelcoat with fine-grit sandpaper, then buff with a polishing compound for a glossy finish.

- Painting: Apply marine-grade paint if desired, ensuring even coverage.

- Reinstalling Hardware: Securely fasten and seal hardware to prevent water ingress.

- Final Inspection: Check for missed spots and ensure all repairs meet quality standards.

- Maintenance Plan: Establish a routine for cleaning, polishing, and inspecting the boat to prevent future damage.

Tools and Materials for Restoration

| Category | Items |

|---|---|

| Safety Equipment | Gloves, safety glasses, dust mask/respirator |

| Cleaning Supplies | Marine detergent, scrub brushes, sponges |

| Repair Tools | Sanding blocks, electric sander, utility knives, rollers, brushes |

| Repair Materials | Fiberglass mat/cloth, resin, hardener, gelcoat, fillers |

| Paint Supplies | Marine-grade paint, paint trays, rollers, painter’s tape |

| Finishing Supplies | Buffing pads, polishing compound |

| Miscellaneous | Screwdrivers, wrenches, mixing containers, stir sticks, chemical strippers |

Using high-quality materials, such as Poli Glow® for gelcoat restoration, can enhance results. Poli Glow®’s system, including Poli Prep™, Poli Ox™, and Poli Glow®, removes oxidation and provides a durable, high-gloss finish.

Benefits of Fiberglass Classic Boats

Owning a fiberglass classic boat—whether a modern replica or a restored vintage model—offers numerous advantages:

- Durability: Fiberglass resists environmental damage, ensuring longevity.

- Low Maintenance: Minimal upkeep compared to wooden boats.

- Performance: Lightweight construction improves fuel efficiency and handling.

- Customization: Modern manufacturing allows for personalized designs and features.

- Nostalgia: Fiberglass replicas capture the aesthetic of classic boats, appealing to enthusiasts.

Environmental and Economic Advantages

Restoring or purchasing a fiberglass classic boat also has broader benefits:

| Benefit | Description |

|---|---|

| Resource Conservation | Extends boat lifespan, reducing demand for new materials. |

| Waste Reduction | Prevents boats from ending up in landfills. |

| Energy Savings | Restoration consumes less energy than manufacturing new boats. |

| Cost Efficiency | Restoration is often cheaper than buying new, maximizing investment value. |

| Job Creation | Supports skilled artisans and marine technicians in the restoration industry. |

| Reduced Carbon Footprint | Lowers emissions by avoiding new boat production and transport. |

DIY vs. Professional Restoration

Deciding between a DIY restoration and hiring a professional depends on several factors:

- Skill Level: Minor repairs like gelcoat touch-ups are suitable for DIY, but complex tasks like delamination repairs require expertise.

- Tools: Advanced repairs may need specialized equipment, which professionals typically have.

- Time: DIY projects can be time-intensive, while professionals offer efficiency.

- Cost: DIY saves on labor but risks costly mistakes; professionals ensure quality.

- Safety: Electrical or structural repairs are safer with professional oversight.

For small projects, enthusiasts with basic skills can use products like Poli Glow® for effective results. However, extensive restorations or safety-critical repairs are best left to marine professionals.

Long-Term Care for Fiberglass Boats

To maintain a fiberglass classic boat, adopt a consistent care routine:

- Regular Inspections: Check for cracks, corrosion, or leaks.

- Cleaning: Use marine cleaners to remove salt and grime.

- Gelcoat Care: Polish and wax regularly to protect the finish.

- Anti-Fouling: Apply anti-fouling paint to prevent marine growth.

- Engine Maintenance: Service the engine per manufacturer guidelines.

- Storage: Use a cover or store in a sheltered area to protect from UV and moisture.

A maintenance logbook can track care activities and enhance resale value by demonstrating diligent upkeep.

Key Considerations for Buying a Classic Fiberglass Boat

Before purchasing a classic fiberglass boat, consider the following:

- Hull Inspection: Check for cracks, blisters, or soft spots. A professional surveyor familiar with vintage boats is recommended.

- Core Material: Ensure the core (if present) is free from delamination or water damage.

- Engine and Systems: Assess the condition of the engine, electrical, and plumbing systems. Inboard engines may require more maintenance.

- Restoration vs. Project: Decide between a fully restored boat or a project boat requiring work.

- Sea Trial: Test all systems, including engine and sails (if applicable), before purchase.

Sample Pricing for Classic Fiberglass Boats

| Boat Model | Condition | Price Range |

|---|---|---|

| Lancer Craft Classic | New, fiberglass | $80,000–$150,000 |

| Restored Century Coronado | Fully restored | $50,000–$100,000 |

| Vintage Fiberglass Boat | Project boat | $10,000–$30,000 |

Prices vary based on condition, customization, and market demand.

The Legacy of Classic Fiberglass Boats

Classic fiberglass boats bridge the gap between maritime history and modern innovation. They preserve the elegance and craftsmanship of the 1950s and 1960s while offering the practicality of contemporary materials. Whether through modern replicas like the Lancer Craft Classic or meticulously restored vintage models, these boats continue to captivate enthusiasts. Their enduring appeal lies in their ability to evoke nostalgia while delivering performance and reliability.

For those eager to own a piece of this legacy, companies like Engel & Völkers Yachting offer a curated selection of classic boats, ensuring enthusiasts find a vessel that matches their passion for maritime heritage. By embracing fiberglass technology, the boating world keeps the spirit of the golden age alive, allowing new generations to experience the timeless allure of classic boats on the water.

Happy Boating!

Share History of classic fiberglass boats? with your friends and leave a comment below with your thoughts.

Read Best Sport Fishing Boat: The Quest for the Catch until we meet in the next article.

Classic fiberglass boats are a true blend of style, history, and performance. This guide beautifully explains their rise, appeal, and the timeless quality that makes them so desirable. If you’re passionate about boating or considering investing in one, this article offers helpful insights on maintenance, restoration, and finding the perfect classic fiberglass boat. Highly recommended for enthusiasts and collectors alike!