Explore the fundamentals of naval electrical engineering, covering power generation, distribution, safety systems, and modern trends in ship electrical systems.

Naval electrical engineering is the backbone of modern maritime operations, powering everything from navigation systems to onboard amenities. Unlike land-based electrical grids, ship electrical systems must operate autonomously, relying on onboard generation and storage to meet diverse energy demands. This article delves into the core components, principles, and emerging trends in naval electrical systems, offering a comprehensive guide to their design, operation, and maintenance.

Introduction to Naval Electrical Systems

Ship electrical systems are engineered to provide reliable, safe, and efficient power for all onboard operations. These systems encompass power generation, distribution, and consumption, tailored to the unique challenges of the marine environment. Autonomy is critical, as ships must function independently of external grids, except when connected to shore power in port. The complexity of these systems has grown significantly, evolving from basic auxiliary setups to sophisticated networks that integrate sustainable technologies and advanced automation.

The primary goal of naval electrical engineering is to ensure uninterrupted power for critical systems, including propulsion, navigation, communication, and safety equipment, while maintaining efficiency and compliance with international maritime regulations, such as those set by the International Maritime Organization (IMO) and SOLAS (Safety of Life at Sea).

Power Generation on Ships

Generators: The Heart of Power Production

At the core of a ship’s electrical system are its generators, which convert mechanical energy into electrical power. Most vessels rely on diesel generators, powered by internal combustion engines, due to their reliability and efficiency. Other options include gas turbines for high-speed vessels and steam turbines for larger ships, such as cruise liners or naval carriers.

Shaft generators, driven by the main propulsion engine, offer an economical alternative by harnessing rotational energy to produce electricity. However, international regulations mandate that at least one generator operates independently of the main propulsion system to ensure compliance during failures. For redundancy, many ships employ multiple generators—typically three—to handle varying loads and provide backup during maintenance or emergencies.

Generator Specifications:

- Type: Diesel, gas turbine, steam turbine, or shaft generator

- Power Output: Ranges from 500 kW for smaller vessels to 10 MW or more for large ships

- Voltage: Typically 440V (3-phase AC), with high-voltage systems (3.3 kV, 6.6 kV, or 11 kV) for larger vessels

- Redundancy: Minimum of two generators, often three for operational flexibility

Batteries: Backup and Beyond

Batteries play a critical role in naval electrical systems, serving as backup power sources for essential systems and starting main generators. They also support emergency lighting, communication systems, and navigation equipment during power outages. Common battery types include:

- Lead-Acid: Cost-effective, used for general backup

- Nickel-Cadmium (NiCd): Durable, with high discharge rates for critical applications

- Lithium-Ion: Lightweight, high energy density, increasingly used in hybrid and electric vessels

Batteries are typically rated for 24V DC for alarms and emergency systems, with larger banks providing temporary power during blackouts. Advanced vessels, like SYM Naval’s Castalia Electric Boat, leverage lithium-ion batteries for zero-emission propulsion, marking a shift toward sustainable energy storage.

Alternators: Converting Mechanical to Electrical Energy

Alternators, driven by prime movers (diesel engines or turbines), convert mechanical energy into electrical energy via electromagnetic induction. They are designed to maintain stable voltage and frequency, critical for sensitive onboard equipment. Regulation systems ensure consistent output, even under fluctuating loads, making alternators a linchpin in power generation.

Power Distribution: Delivering Energy Efficiently

Main Switchboard: The Central Hub

The main switchboard is the nerve center of a ship’s electrical system, receiving power from generators and distributing it to various loads. Located typically in the engine room or machinery control room, it is designed to optimize cable runs and minimize costs. The switchboard integrates protective devices like circuit breakers and fuses to safeguard against overloads and short circuits.

Main Switchboard Features:

- Voltage Handling: 440V (standard), up to 11 kV for large vessels

- Components: Circuit breakers, busbars, monitoring systems

- Location: Below the waterline or main deck for protection, requiring emergency alternatives

Distribution Panels and Wiring

Distribution panels allocate power to specific areas, such as lighting, machinery, or navigation systems. These panels are strategically placed near loads to reduce cable length and energy loss. Marine-grade cables, designed with specialized insulation and corrosion resistance, ensure reliable transmission in harsh environments. Watertight connectors and high IP ratings (e.g., IP44) protect against moisture and vibrations.

Transformers: Voltage Management

Transformers adjust voltage levels to meet the needs of diverse equipment. For example, while main systems operate at 440V, lighting and auxiliary systems may require 220V or 110V. High-voltage systems (3.3 kV or higher) are used in large vessels to reduce current and cable size, improving efficiency. Transformers also provide galvanic isolation, preventing corrosion caused by stray currents.

Key Components and Systems

Protective Devices: Circuit Breakers and Fuses

Circuit breakers and fuses are essential for protecting electrical systems from overloads and short circuits. Circuit breakers automatically interrupt power during faults, while fuses act as sacrificial components, melting to break circuits under excessive current. Both are calibrated to match the system’s load characteristics, ensuring safety without unnecessary interruptions.

Emergency Power Systems

Emergency generators and batteries are critical for maintaining power to essential systems during main power failures. These systems, located above the main deck to avoid flooding risks, support navigation lights, communication equipment, and emergency lighting. Regulations require automatic activation within seconds of a blackout, ensuring continuous operation of safety-critical systems.

Automation and Control Systems

Modern ships employ advanced automation for monitoring and managing electrical systems. Programmable logic controllers (PLCs) and microprocessors enable real-time diagnostics, load balancing, and fault detection. These systems reduce human error and enhance efficiency, particularly in vessels with centralized control rooms.

Communication and Navigation Systems

The bridge, a hub of electrical demand, relies on stable power for systems like radar, GPS, gyrocompasses, and communication equipment (e.g., GMDSS). These systems operate on dedicated networks with multiple redundancy layers to ensure reliability under adverse conditions.

Voltage Levels and Load Management

Ship electrical systems typically use 3-phase AC power at 440V, with high-voltage systems (3.3 kV, 6.6 kV, or 11 kV) for larger vessels. Lower voltages (220V, 110V) power lighting and auxiliary equipment, while 24V DC supports alarms and emergency systems. Load management is critical to prevent overloads and ensure efficient generator operation.

Electrical Load Balance Calculation:

- Identify Consumers: List all onboard electrical loads (e.g., motors, lighting, navigation).

- Categorize Loads: Classify as essential, important, or normal.

- Determine Nominal Power: Assign power ratings for each load.

- Apply Utilization Factors: Adjust for operational conditions (e.g., navigation, port).

- Calculate Total Demand: Sum adjusted power demands to size generators.

The following table illustrates a simplified load balance for a medium-sized vessel:

| Load Type | Nominal Power (kW) | Demand Factor | Effective Demand (kW) |

|---|---|---|---|

| Propulsion Motors | 500 | 0.8 | 400 |

| Navigation Systems | 50 | 1.0 | 50 |

| Lighting | 100 | 0.6 | 60 |

| HVAC Systems | 150 | 0.7 | 105 |

| Total Demand | 800 | 615 |

This calculation ensures generators are sized appropriately, avoiding oversizing (costly) or undersizing (risking shortages).

Naval Lighting Systems

Lighting systems are vital for safety, operations, and habitability. They include:

- General Lighting: Illuminates cabins, dining areas, and recreational spaces.

- Task Lighting: High-intensity lighting for operational areas like engine rooms.

- Navigation Lighting: Exterior lights for signaling (e.g., port, starboard, masthead).

- Emergency Lighting: Automatically activates during power failures.

- Evacuation Lighting: Low-level guides for escape routes.

Lighting systems are designed to ensure redundancy, with circuits arranged to prevent total loss in case of localized failures. For example, a fire in one compartment should not disable lighting in escape routes.

Electrical Outlets and Shore Power

Modern ships feature watertight electrical outlets with high IP ratings (e.g., IP44) to withstand marine conditions. These outlets support various voltages (110V, 220V) and include differential protection to prevent electrical faults. Shore power connections allow vessels to draw electricity from port facilities, reducing generator use and emissions. Galvanic isolation systems protect against corrosion caused by stray currents.

Activation and Operation of Electrical Systems

Starting a ship’s electrical system follows a structured protocol to ensure safety and efficiency:

- Pre-Start Inspection: Verify wiring, connections, and battery charge levels.

- Activate Main Switches: Enable the main switchboard.

- Start Generators: Begin with the auxiliary or main generator based on demand.

- Enable Circuits: Sequentially activate circuits by priority (e.g., navigation, propulsion).

- Synchronize Generators: Add additional generators as load increases.

Advanced energy management systems, like those in SYM Naval’s Castalia, optimize this process, prioritizing efficiency and sustainability.

Maintenance of Naval Electrical Systems

Preventive and corrective maintenance is critical for reliability and compliance with IMO and classification society standards. Key tasks include:

- Inspecting wiring and connections for corrosion or wear

- Conducting insulation and resistance tests

- Servicing generators and alternators

- Verifying battery performance and emergency systems

- Calibrating control and monitoring instruments

Regular maintenance prevents failures, extends equipment lifespan, and ensures compliance with safety regulations.

Trends in Naval Electrical Engineering

The naval industry is undergoing a transformation toward sustainability and efficiency. Key trends include:

- Fully Electric Propulsion: Vessels like SYM Naval’s Castalia use electric motors powered by batteries or hybrid systems, reducing emissions.

- DC Distribution Networks: Improve efficiency by reducing conversion losses.

- Renewable Energy Integration: Solar panels and wind-assisted propulsion (e.g., rigid sails) supplement traditional power sources.

- Advanced Automation: PLCs and digital control systems enhance system reliability and reduce crew workload.

- High-Density Energy Storage: Lithium-ion batteries and emerging technologies enable longer electric-only operation.

These innovations align with global efforts to reduce maritime transport’s environmental impact, with vessels like Castalia leading the charge toward zero-emission operations.

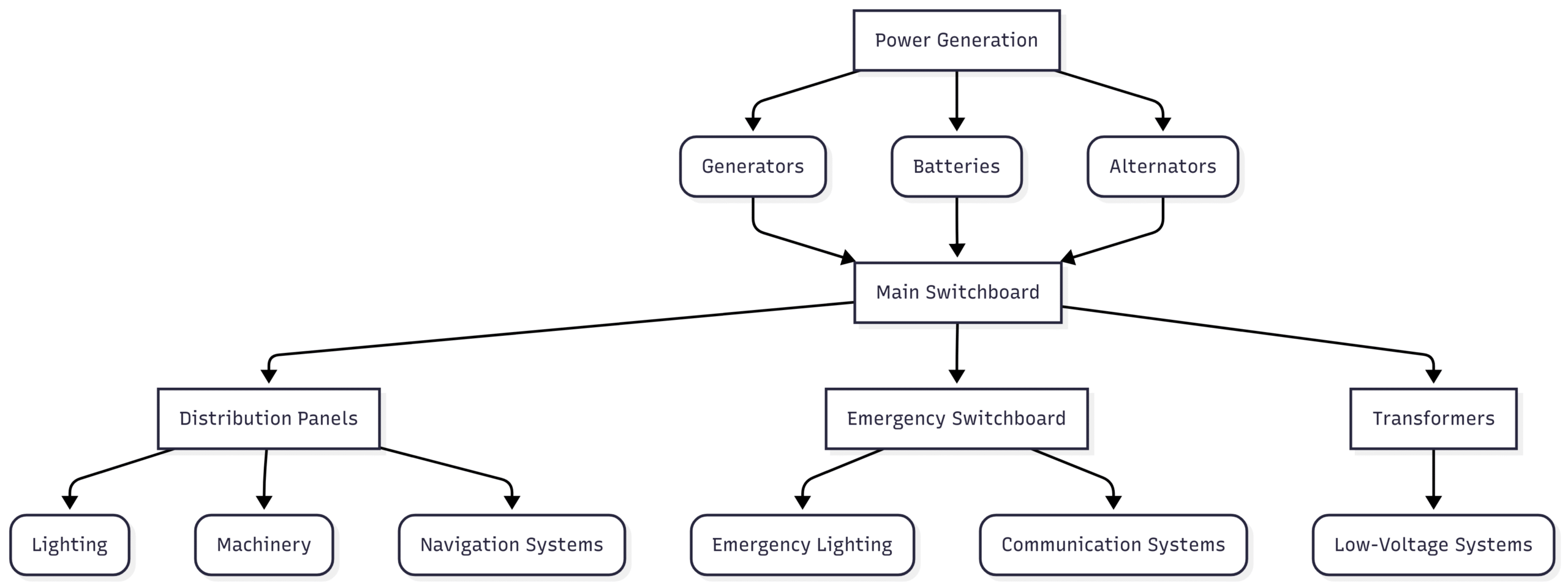

Chart: Ship Electrical System Overview

This chart illustrates the flow of power from generation to distribution, highlighting the role of emergency systems in maintaining critical operations.

Safety and Efficiency: The Core of Naval Electrical Systems

Understanding and maintaining naval electrical systems is essential for safe and efficient vessel operation. Parallel circuits provide redundancy, ensuring that failures in one path do not disrupt the entire system. Emergency power systems, including generators and batteries, act as a safety net during blackouts. Proper load balancing prevents overloads, while automation systems optimize performance.

For crew members and engineers, knowledge of these systems is not just technical—it’s a matter of safety. From navigation lights that signal a ship’s position to emergency lights that guide evacuation, every component plays a role in protecting lives and ensuring operational success.

Conclusion

Naval electrical engineering is a dynamic field that combines robust design, advanced technology, and rigorous maintenance to power modern vessels. From diesel generators to cutting-edge electric propulsion, these systems are the lifeblood of maritime operations. As the industry embraces sustainability through innovations like SYM Naval’s Castalia, the future of naval electrical systems promises greater efficiency, safety, and environmental responsibility. By understanding the fundamentals outlined in this article, stakeholders can navigate the complexities of ship electrical systems and steer toward a more sustainable maritime future.

Happy Boating!

Share Fundamentals of naval electrical engineering with your friends and leave a comment below with your thoughts.

Read Ways of starting and testing emergency generator on a Ship until we meet in the next article.