Explore the stages of ship design—concept, basic, functional, detailed, production, and commissioning—with detailed insights and visuals.

Ship design is a complex, iterative process that transforms a client’s vision into a seaworthy vessel. Each stage—concept design, basic design, functional design, detailed design, production design, and commissioning—builds on the previous one, refining the vessel’s specifications to ensure safety, performance, and compliance with regulations. This article provides a comprehensive overview of these stages, highlighting key activities, technical considerations, and their significance in delivering a functional ship.

Concept Design: Defining the Vision

The concept design phase is the foundation of the shipbuilding process, where the vessel’s purpose and primary characteristics are established. This stage involves close collaboration with the client—whether a shipping company, government, or private entity—to define operational requirements.

Key Activities

- Mission Requirements: The client specifies the ship’s purpose, such as cargo transport, passenger services, or specialized operations (e.g., research or military). For cargo vessels like tankers or containerships, requirements include deadweight tonnage (DWT) or twenty-foot equivalent unit (TEU) capacity. For passenger ships, the focus is on passenger capacity and amenities.

- Performance Parameters: Speed, range, and operational conditions (e.g., routes or environmental challenges) are outlined.

- Preliminary Design: Naval architects develop initial hull forms, general arrangement plans, and estimates for stability, propulsion, and equipment needs (e.g., cargo cranes or rudders).

- Techno-Economic Evaluation: The design is assessed for technical feasibility (e.g., stability, structural integrity) and economic viability (e.g., construction and operational costs).

Technical Considerations

The concept design ensures the vessel meets fundamental criteria:

- Buoyancy: The ship must float without sinking, adhering to Archimedes’ Principle (lightweight + deadweight = displacement).

- Stability: The design must ensure the vessel remains upright under worst-case scenarios.

- Structural Integrity: The hull and structure must withstand global and local loads.

- Propulsion and Maneuverability: The ship must achieve required speeds and navigate effectively.

- Regulatory Compliance: The design aligns with International Maritime Organization (IMO) standards, classification society rules, and environmental regulations.

Tools and Techniques

Modern naval architects use computational tools to optimize designs. Algorithms analyze historical vessel data to refine hull forms and estimate performance metrics like resistance and fuel efficiency. Line drawings and preliminary 3D models are created using Computer-Aided Design (CAD) software.

Example

For a 10,000 TEU containership, the concept design might specify:

- Length Overall (LOA): ~330 meters

- Beam: ~48 meters

- Draft: ~14.5 meters

- Speed: 22 knots

- Fuel Type: Low-sulfur fuel to meet IMO emissions standards

The techno-economic evaluation ensures the design is feasible within the client’s budget while meeting performance goals.

Basic Design: Shaping the Framework

The basic design phase refines the concept design into a more detailed blueprint, locking in critical aspects of the vessel. This stage is pivotal, as major design decisions become nearly irreversible.

Key Activities

- Hull Form Finalization: The hull shape is refined based on hydrodynamic analysis, ensuring optimal resistance and stability.

- General Arrangement: Detailed layouts for cargo holds, engine rooms, accommodations, and tankage are developed.

- Stability and Strength Calculations: Initial assessments of buoyancy, stability, and structural integrity are performed.

- Propulsion and Systems: Engine types, fuel systems, and steering mechanisms are selected.

- Regulatory Approvals: The design is submitted to classification societies (e.g., Lloyd’s Register, DNV) for validation.

Technical Scope

The basic design covers:

- Hull Representation: Virtual models using CAD or Computational Fluid Dynamics (CFD) tools.

- Structural Design: Midship sections, deck plans, and bulkhead layouts are drafted.

- Hydrodynamics: Resistance, powering, and maneuverability calculations ensure performance.

- Systems Integration: Preliminary designs for electrical, piping, HVAC, and navigation systems are developed.

- Bill of Materials: A list of required materials is compiled.

Example Table: Basic Design Specifications for a Bulk Carrier

| Parameter | Specification |

|---|---|

| Length Overall (LOA) | 225 meters |

| Beam | 32 meters |

| Draft | 14 meters |

| Deadweight Tonnage (DWT) | 75,000 tons |

| Main Engine | MAN B&W 6G70ME-C |

| Speed | 14.5 knots |

| Fuel Capacity | 2,500 cubic meters |

Significance

The basic design phase involves multidisciplinary collaboration, with naval architects, mechanical engineers, and electrical engineers working together. The deliverables are critical for securing client approval and classification society certification.

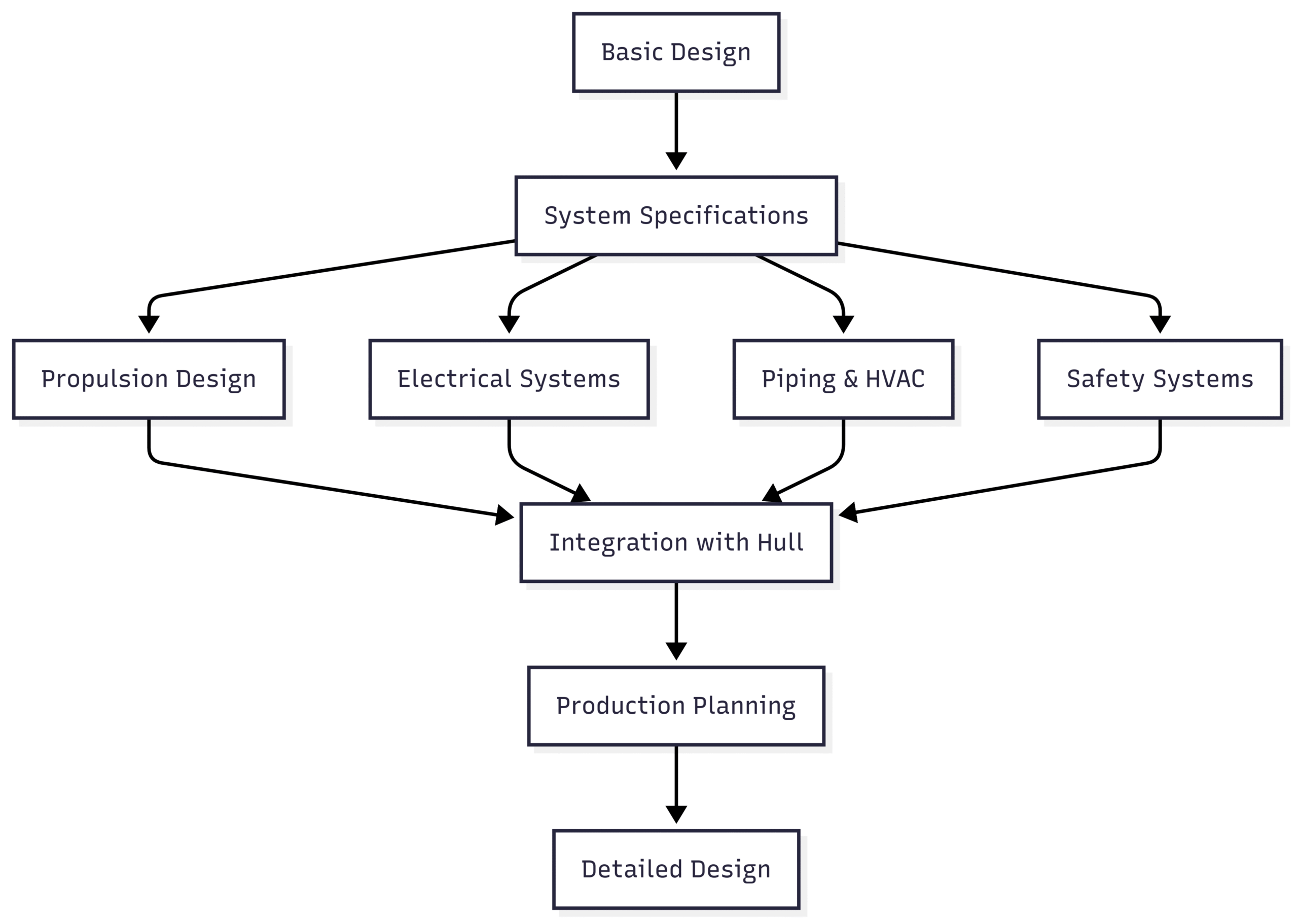

Functional Design: Integrating Systems

The functional design phase focuses on integrating the ship’s systems with its structure, ensuring all components work cohesively. This stage bridges the conceptual framework with practical implementation.

Key Activities

- Systems Design: Detailed plans for propulsion, electrical, piping, HVAC, and communication systems are developed.

- Structural Optimization: The hull and structural components are refined to minimize weight while maintaining strength.

- Production Planning: Strategies for efficient construction are outlined, including fabrication and assembly processes.

Technical Scope

- Propulsion Systems: Engine specifications, propeller design, and shaft alignment are finalized.

- Electrical Systems: Power distribution, load calculations, and backup systems are planned.

- Piping and HVAC: Fluid and air systems are designed for efficiency and reliability.

- Safety Systems: Firefighting, life-saving, and emergency systems are integrated.

Chart: Functional Design Workflow

Example

For a cruise ship, the functional design might include:

- Propulsion: Twin azipod systems for enhanced maneuverability.

- Electrical: 10 MW power generation for passenger amenities.

- HVAC: High-capacity systems to maintain comfort in passenger cabins.

This phase ensures the ship’s systems are optimized for performance and compliance with safety standards.

Detailed Design: Finalizing the Blueprint

The detailed design phase produces the final plans and specifications required for construction. Every component is meticulously documented, ensuring the ship is ready for fabrication.

Key Activities

- Detailed Drawings: Comprehensive drawings for all structural elements, including welds, seams, and brackets.

- Material Specifications: Final selection of materials, insulation, and coatings.

- Structural Analysis: Finite Element Analysis (FEA) assesses the structure under various loads.

- System Finalization: All machinery, electrical, and piping systems are fully specified.

- Regulatory Compliance: Drawings and reports are submitted to classification societies for approval.

Technical Scope

- Structural Details: Every structural component, from bulkheads to deck plating, is detailed.

- Hydrodynamic Refinement: Stability, seakeeping, and resistance calculations are finalized.

- Outfitting: Deck equipment, cranes, and navigation systems are specified for procurement.

- 3D Modeling: Comprehensive models integrate structural, hydrodynamic, and systems data.

Example Table: Detailed Design Deliverables

| Deliverable | Description |

|---|---|

| Structural Drawings | Midship, bulkheads, shell expansion |

| Stability Booklet | Trim and stability calculations |

| Piping Schematics | Fluid and gas flow diagrams |

| Electrical Load Analysis | Power distribution and consumption plans |

| Material Specifications | Steel grades, insulation, paint types |

Significance

The detailed design phase ensures the ship is construction-ready, with all components optimized for performance, safety, and cost. Errors at this stage can lead to costly rework during construction.

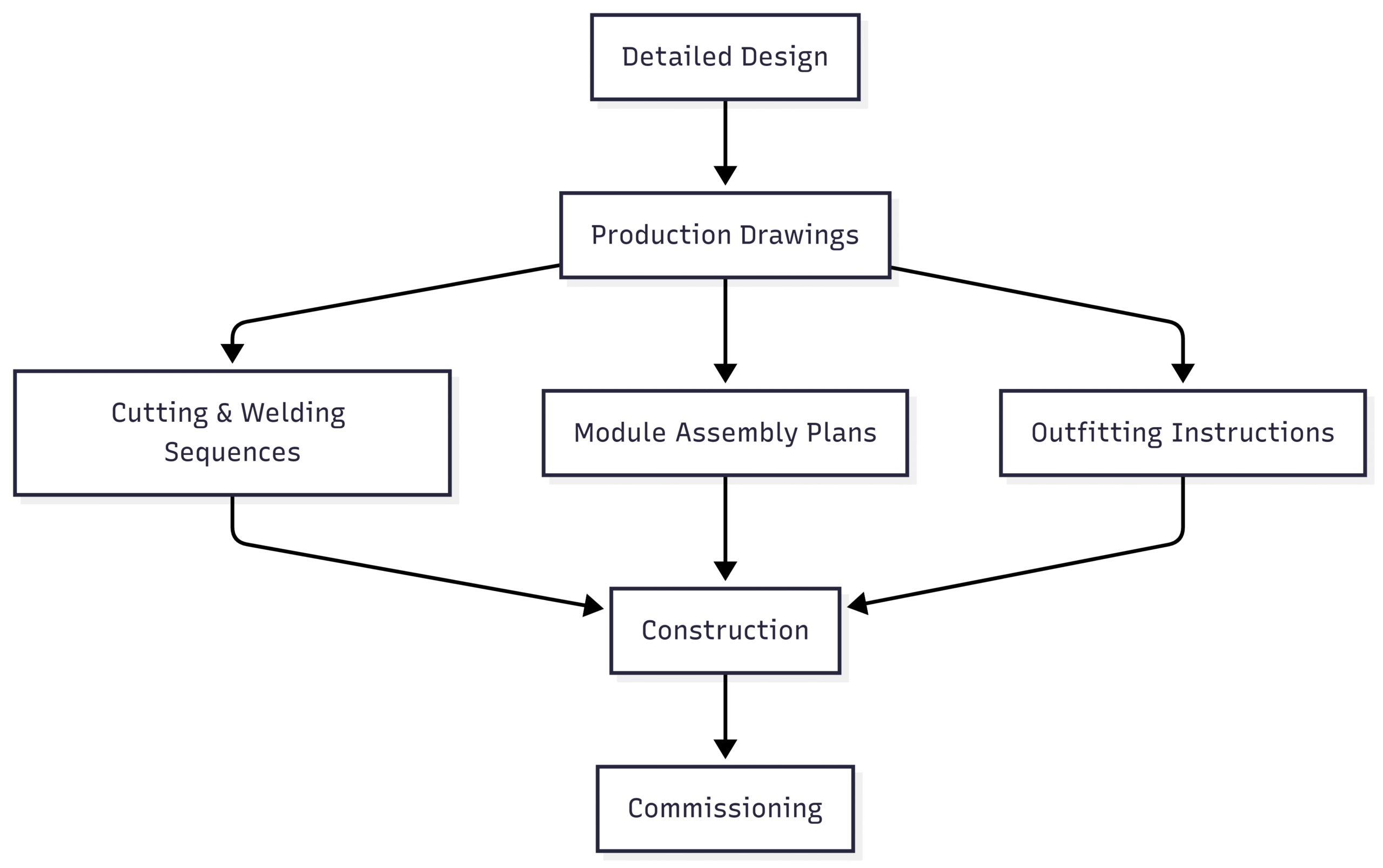

Production Design: Preparing for Construction

The production design phase translates detailed plans into actionable instructions for the shipyard. This stage focuses on the logistics of building the vessel.

Key Activities

- Production Drawings: Detailed instructions for cutting, welding, and assembly.

- Construction Planning: Schedules for fabrication, module erection, and outfitting.

- Work Instructions: Clear guidelines for shipyard workers to follow.

Technical Scope

- Module Assembly: The ship is divided into blocks or modules for efficient construction.

- Fabrication Sequences: Cutting and welding plans optimize material use.

- Outfitting: Installation procedures for machinery, piping, and deck equipment.

Chart: Production Design Process

Example

For a tanker, production drawings might specify:

- Steel Cutting: CNC machines cut hull plates to precise dimensions.

- Welding: Automated welding for longitudinal seams.

- Module Erection: Assembly of cargo hold modules in drydock.

Construction: Building the Vessel

The construction phase brings the design to life. Using the production drawings, the shipyard fabricates and assembles the vessel.

Key Activities

- Fabrication: Cutting and shaping steel plates and components.

- Assembly: Joining modules to form the hull and superstructure.

- Outfitting: Installing machinery, piping, electrical systems, and deck equipment.

- Testing: Initial tests of systems (e.g., propulsion, electrical) during construction.

Challenges

- Precision: Ensuring components align perfectly to avoid structural issues.

- Timeline: Adhering to schedules to meet delivery deadlines.

- Quality Control: Regular inspections to ensure compliance with design specifications.

Commissioning: Launching the Ship

The commissioning phase marks the ship’s transition from construction to operation. It involves rigorous testing and final approvals.

Key Activities

- Sea Trials: Testing the ship’s performance, including speed, stability, and maneuverability.

- System Checks: Verifying propulsion, electrical, and safety systems.

- Regulatory Approvals: Obtaining final certification from classification societies.

- Ceremonial Events: Keel-laying or launching ceremonies may occur.

Example

For a passenger ferry, commissioning might include:

- Speed Trials: Confirming the vessel achieves 20 knots.

- Safety Drills: Testing lifeboat deployment and fire suppression systems.

- Certification: Approval from DNV for passenger safety compliance.

Cost Considerations

Ship design and construction costs vary widely based on vessel type and complexity. Below is an indicative cost breakdown for a mid-sized bulk carrier (75,000 DWT):

| Component | Estimated Cost (USD) |

|---|---|

| Hull Fabrication | $20–25 million |

| Propulsion Systems | $10–15 million |

| Electrical Systems | $5–8 million |

| Outfitting & Equipment | $8–12 million |

| Design & Engineering | $3–5 million |

| Total | $46–65 million |

Note: Costs are approximate and vary based on shipyard location, materials, and market conditions. For precise pricing, consult shipyard quotes or industry reports.

Conclusion

The ship design process is a meticulous journey from vision to reality, involving concept, basic, functional, detailed, production, and commissioning stages. Each phase refines the vessel’s specifications, ensuring it meets technical, economic, and regulatory requirements. By leveraging advanced tools like CAD and CFD, naval architects optimize designs for safety, performance, and efficiency. Whether building a cargo giant or a luxury cruise ship, this structured approach ensures the vessel is ready to navigate the seas effectively.

Happy Boating!

Share Different Stages of Ship Design Explained with your friends and leave a comment below with your thoughts.

Read What is Onshore Power Supply (OPS) until we meet in the next article.