Discover the role of Segregated Ballast Tanks (SBTs) in oil tankers, their design, MARPOL regulations, and impact on marine safety and environmental protection.

In the maritime industry, oil tankers play a critical role in global trade, transporting vast quantities of crude oil and refined products across oceans. However, their operations pose significant environmental risks, particularly from oil pollution. Segregated Ballast Tanks (SBTs) have emerged as a cornerstone of modern tanker design, addressing these risks by preventing oil contamination of ballast water and ensuring ship stability. Mandated by the International Maritime Organization (IMO) under the MARPOL Convention, SBTs are a regulatory and engineering triumph, balancing operational efficiency with environmental stewardship. This article explores the design, functionality, regulatory framework, and broader impact of SBTs, offering a comprehensive guide for maritime professionals, students, and enthusiasts.

What Are Segregated Ballast Tanks?

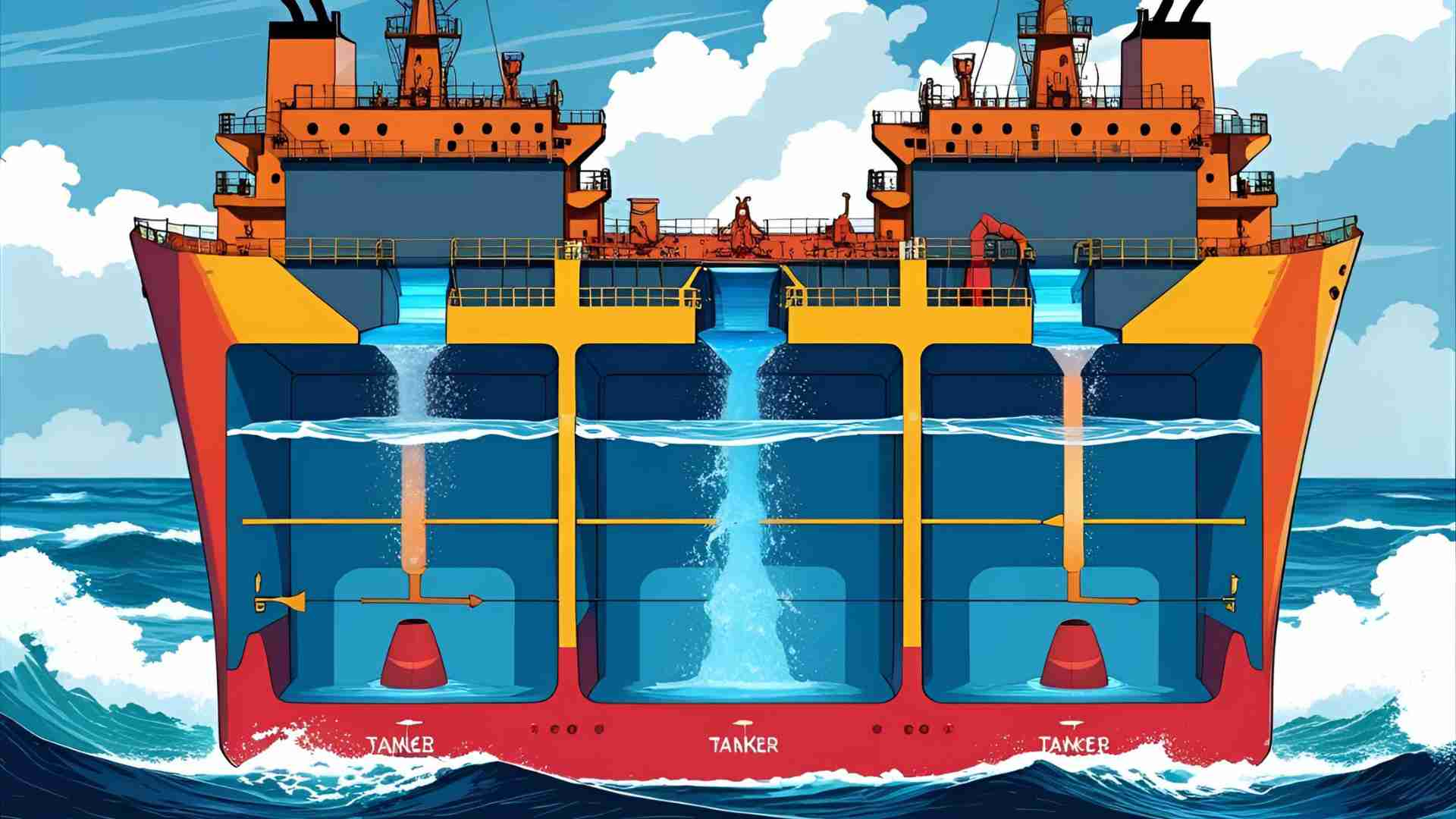

Segregated Ballast Tanks (SBTs) are dedicated compartments on oil tankers designed exclusively for holding ballast water. Unlike traditional systems where cargo tanks doubled as ballast tanks, SBTs are entirely separate from cargo and fuel oil systems. This isolation ensures that ballast water—used to stabilize a ship during voyages—remains free from oil contamination, significantly reducing the risk of marine pollution when discharged.

Key Features of SBTs

- Complete Separation: SBTs have independent piping, pumps, and valves, ensuring no contact with cargo or fuel systems.

- Environmental Protection: By preventing oil-water mixing, SBTs eliminate the discharge of oily ballast water into the sea.

- Regulatory Compliance: MARPOL Annex I mandates SBTs for oil tankers of 20,000 deadweight tonnage (DWT) and above, delivered after June 1, 1982.

- Strategic Placement: SBTs are often integrated into double-hull designs, positioned along the sides and bottom of the ship to enhance protection against collisions or groundings.

Comparison with Other Ballast Systems

To understand SBTs’ significance, it’s helpful to compare them with other ballast tank types used in oil tankers:

| Type | Definition | Pollution Risk | MARPOL Requirement |

|---|---|---|---|

| Segregated Ballast Tank (SBT) | Dedicated tanks for ballast water, fully separated from cargo/fuel systems. | None | Mandatory for tankers ≥ 20,000 DWT (Reg. 18, Annex I). |

| Clean Ballast Tank (CBT) | Cargo tanks cleaned before use for ballast, with discharge monitored. | Medium (if cleaning is inadequate). | Allowed in older vessels, less common today. |

| Dedicated Clean Ballast Tank (DCBT) | Cargo tanks assigned for ballast but still part of the cargo system. | Lower than CBT, higher than SBT. | Transitional system before SBTs became standard. |

SBTs stand out as the safest and most environmentally friendly option, eliminating the need for cleaning and reducing pollution risks.

Why Are SBTs Important?

SBTs address critical challenges in tanker operations, balancing safety, stability, and environmental concerns. Their importance can be distilled into three primary areas:

1. Preventing Marine Pollution

Before SBTs, tankers often used cargo tanks for ballast water, leading to oil residues mixing with the water. When discharged, this oily mixture polluted marine ecosystems, harming marine life and coastal environments. SBTs eliminate this risk by ensuring ballast water remains clean, aligning with global efforts to protect oceans.

2. Ensuring Ship Stability

Ballast water is essential for maintaining a ship’s stability, especially in lightship conditions (when carrying minimal or no cargo). Without adequate ballast, tankers face issues such as:

- Propeller Exposure: Insufficient submersion reduces propulsion efficiency.

- Hull Stress: Uneven weight distribution increases shear and torsion loads, risking structural damage.

- Instability: Lack of ballast can cause excessive rolling or listing, compromising safety.

SBTs provide a controlled and safe means to add ballast, optimizing trim and draft to enhance hydrodynamic performance and reduce fuel consumption.

3. Regulatory Compliance

The IMO’s MARPOL Convention, specifically Annex I, sets stringent standards for oil tankers to prevent pollution. Regulation 18 mandates SBTs for tankers of 20,000 DWT and above, ensuring compliance with international environmental laws. Additionally, SBTs complement other regulations, such as double-hull requirements (Regulation 19) and restrictions on heavy grade oil (HGO) carriage (Regulation 21).

Historical Context: Evolution of Ballast Systems

The concept of ballasting is ancient, with early ships using solid materials like sandbags or rocks to maintain stability. As maritime technology advanced, liquid ballast—typically seawater—replaced solid ballast for its ease of handling. However, in early oil tankers, cargo tanks were used for ballast, leading to significant pollution issues.

The 1973 MARPOL Convention, supplemented by the 1978 Protocol, marked a turning point. The introduction of SBTs under the 1978 MARPOL Protocol addressed the shortcomings of earlier systems by mandating dedicated ballast tanks. The 1983 amendments further refined this by banning oil carriage in forepeak tanks, the most vulnerable part of a ship in collisions. High-profile incidents, such as the Erika (1999) and Prestige (2002) oil spills, underscored the need for SBTs and accelerated the phase-out of single-hull tankers, reinforcing their adoption.

Design and Functionality of SBTs

SBTs are engineered to optimize both safety and efficiency. Their design and operation involve several key components:

Design Features

- Location: SBTs are strategically placed along the ship’s sides and bottom, often within double-hull structures, to protect cargo tanks from damage during collisions or groundings.

- Construction: Tanks are built with corrosion-resistant materials and coatings, given their exposure to seawater. Common locations include topside tanks, lower hopper tanks, double-bottom tanks, and fore/aft peak tanks.

- Piping and Pumps: A dedicated ballast system ensures no cross-contamination with cargo systems. Ballast pumps handle the loading and discharge of water, controlled by valves and monitored by sensors.

Operational Workflow

- Ballasting: During lightship conditions, seawater is pumped into SBTs to achieve optimal stability and trim.

- Monitoring: Sensors track water levels, gas content, and pump performance to ensure safe operations. Loadicator software calculates ballast volumes to maintain stability.

- Deballasting: Before loading cargo, ballast water is discharged in compliance with environmental regulations, ensuring no oil contamination.

Chart: SBT Operation Workflow

MARPOL Regulations and SBTs

The MARPOL Convention, particularly Annex I, forms the regulatory backbone for SBTs. Key provisions include:

- Regulation 18: Mandates SBTs for oil tankers of 20,000 DWT (crude oil) and 30,000 DWT (product carriers) delivered after June 1, 1982.

- Regulation 19: Requires double-hull designs for new tankers (post-July 1993) to complement SBTs, enhancing protection against oil spills.

- Regulation 20: Outlines the phase-out of single-hull tankers, with accelerated timelines post-Erika and Prestige incidents.

- Regulation 21: Bans the carriage of heavy grade oil (HGO) in single-hull tankers, with exemptions for certain vessels under strict conditions.

Phase-Out Schedule for Single-Hull Tankers

The transition to double-hull tankers with SBTs was phased in to avoid disrupting global trade:

| Category | Description | Phase-Out Date |

|---|---|---|

| Category 1 | Pre-MARPOL tankers (≥20,000 DWT for crude/fuel oil, ≥30,000 DWT for other oils) | April 5, 2005 (ships delivered ≤1982) or anniversary date in 2005 (post-1982). |

| Category 2 | MARPOL tankers with SBTs (same DWT criteria as Category 1) | 2005–2010, based on delivery year (e.g., 2007 for 1980–1981, 2010 for ≥1984). |

| Category 3 | Smaller tankers (5,000–20,000/30,000 DWT) | 2005–2010, based on delivery year (e.g., 2007 for 1980–1981, 2010 for ≥1984). |

Condition Assessment Scheme (CAS)

For single-hull tankers (Categories 2 and 3) aged 15 years or older, the CAS allows continued operation beyond 2010, subject to rigorous inspections. Operations cannot extend past 25 years from delivery or 2015, whichever is earlier.

Safety Enhancements Beyond SBTs

SBTs are part of a broader suite of safety measures for tankers, as outlined by IMO conventions:

- SOLAS (Safety of Life at Sea): Includes fire safety provisions and equipment duplication (e.g., steering gear, navigational systems) to ensure operational reliability.

- Inert Gas Systems: Mandatory for tankers ≥20,000 DWT, these systems fill empty tanks with non-flammable gas to prevent explosions.

- Emergency Towing Arrangements: Required for tankers ≥20,000 DWT since 1996 to facilitate rescue operations.

- Enhanced Inspections: Since 1995, tankers aged five years and older undergo rigorous surveys to detect corrosion or structural issues.

- Mandatory Ship Reporting: Automatic Identification Systems (AIS) and reporting protocols improve tracking and navigation safety.

Ballast Tank Protection and Maintenance

Seawater’s corrosive nature poses a challenge for SBTs. Effective protection and maintenance are critical to ensure longevity and compliance:

Corrosion Protection Methods

- Tank Coatings: Heavy-duty epoxy coatings (300 microns thick) shield steel surfaces from seawater. Regular inspections ensure coating integrity.

- Sacrificial Anodes: Zinc or aluminum anodes are used to reduce corrosion, though magnesium is avoided due to hydrogen generation risks.

- Controlled Atmosphere: Inert gas systems reduce oxygen levels in tanks to below 4%, cutting corrosion rates by up to 84%.

Inspection Protocols

- Corrosion Assessment: Localized corrosion exceeding 75% of allowable margins requires structural repairs.

- Coating Checks: Inspect for rust, weld line damage, or coating failures.

- Structural Integrity: Look for cracks, buckling, or damage to strengthening arrangements.

Regular inspections, guided by historical records and sister vessel data, ensure timely repairs and compliance with IMO standards.

SBTs in Lightship Conditions

In lightship conditions, SBTs are critical for:

- Reducing Free Surface Effect: Properly filled SBTs minimize water sloshing, enhancing stability.

- Optimizing Hydrodynamics: Correct ballast distribution improves draft and trim, reducing fuel consumption.

- Enhancing Safety: Lowering the center of gravity improves stability in rough seas.

Chart: Ballast Conditions

Environmental and Operational Benefits

SBTs offer significant advantages:

- Environmental Protection: Clean ballast discharge prevents oil pollution, preserving marine ecosystems.

- Operational Efficiency: Improved stability reduces fuel consumption and wear on propulsion systems.

- Regulatory Compliance: Ensures adherence to MARPOL and other IMO standards, avoiding penalties.

- Safety: Reduces risks of structural failure or instability in adverse conditions.

Challenges and Considerations

While SBTs are highly effective, challenges include:

- Maintenance Costs: Coatings, anodes, and inspections require ongoing investment.

- Space Utilization: Dedicated SBTs reduce cargo capacity compared to older designs.

- Retrofitting: Converting older tankers to include SBTs can be costly and complex.

Frequently Asked Questions

What is the primary benefit of SBTs?

SBTs prevent oil pollution by isolating ballast water from cargo and fuel systems, ensuring clean discharge.

Are SBTs mandatory for all ships?

No, they are required for oil tankers ≥20,000 DWT (crude oil) or ≥30,000 DWT (product carriers) under MARPOL Annex I.

How do SBTs differ from clean ballast tanks?

SBTs are fully separated from cargo systems, eliminating cleaning needs, while CBTs are cleaned cargo tanks with a higher pollution risk.

How do SBTs enhance ship stability?

SBTs optimize weight distribution, reducing hull stress and improving performance in rough seas.

Conclusion

Segregated Ballast Tanks represent a pivotal advancement in oil tanker design, aligning safety, efficiency, and environmental protection. By preventing oil pollution, ensuring compliance with MARPOL regulations, and enhancing ship stability, SBTs have transformed maritime operations. Their integration with double-hull designs, inert gas systems, and rigorous inspection protocols underscores the industry’s commitment to sustainability and safety. For maritime professionals, understanding SBTs is essential for navigating modern regulations and contributing to a cleaner, safer marine environment.

Key Takeaway

SBTs are not just a regulatory requirement but a critical tool for sustainable shipping. Ensuring their proper design, maintenance, and operation is vital for minimizing environmental impact and maximizing tanker performance.

Happy Boating!

Share Segregated Ballast Tanks on Tankers with your friends and leave a comment below with your thoughts.

Read Emergency Bilge Suction Valve in Ships’ Engine Rooms until we meet in the next article.