Learn about emergency steering gear drills on ships, SOLAS requirements, procedures, and best practices for safe navigation.

Emergency steering gear drills are a critical component of maritime safety, ensuring that ships remain navigable even when primary steering systems fail. Mandated by international regulations, these drills prepare crews to handle emergencies, maintain compliance, and prevent accidents like collisions or groundings. This comprehensive guide explores the importance of emergency steering drills, regulatory requirements, detailed procedures, real-world challenges, and best practices for effective execution, offering a thorough understanding for ship operators, crew members, and maritime professionals.

What Is Emergency Steering Gear?

The emergency steering gear is a backup system designed to control a ship’s rudder when the main steering system fails. Located in a separate compartment, typically the aft steering gear room, it operates independently to ensure continued maneuverability. Depending on the vessel’s design, it may function manually, hydraulically, or electrically. Common types include:

- Rotary Vane Steering Gear: Compact and efficient, using a rotating vane to move the rudder.

- Ram-Type Steering Gear: Utilizes hydraulic rams to push or pull the rudder stock.

Causes of Main Steering Gear Failure

Primary steering failures can arise from:

- Mechanical Breakdowns: Wear and tear or component failure in gears or linkages.

- Hydraulic Malfunctions: Leaks, pump failures, or loss of hydraulic fluid pressure.

- Electrical Failures: Power supply issues or faults in control circuits.

- Communication Loss: Disruption of signals between the bridge and steering gear room.

Emergency steering gear drills ensure crews are equipped to handle these scenarios, restoring control swiftly to avoid maritime disasters.

Regulatory Framework for Emergency Steering Drills

The International Maritime Organization (IMO) governs emergency steering drills under the Safety of Life at Sea (SOLAS) Convention, specifically Chapter V, Regulation 26. Key requirements include:

- Frequency: Drills must occur at least every three months.

- Scope: Must involve direct operation from the steering gear compartment, testing communication systems, and verifying alternative power supplies (if applicable).

- Crew Training: All relevant personnel must be proficient in emergency procedures.

- Documentation: Drill details, including date and procedures, must be logged.

Additional oversight comes from flag states and classification societies, which may impose stricter standards. Non-compliance can lead to detentions during Port State Control (PSC) inspections, as seen in cases like a Rotterdam vessel detained for crew unfamiliarity with emergency steering.

Importance of Emergency Steering Drills

Regular drills offer multiple benefits:

- Crew Preparedness: Equips personnel to respond confidently in emergencies.

- Regulatory Compliance: Avoids penalties and ensures adherence to SOLAS.

- Risk Mitigation: Reduces the likelihood of accidents, protecting lives and property.

- Operational Reliability: Verifies the functionality of critical systems.

Neglecting drills can have dire consequences. For instance, a vessel losing steering control in narrow straits risks grounding or collision, endangering crew, cargo, and the environment.

Step-by-Step Guide to Conducting an Emergency Steering Drill

An effective drill requires meticulous planning and execution. Below is a detailed procedure:

1. Pre-Drill Preparation

- Notify Crew: Inform all departments (bridge, engine room, deck) about the drill schedule.

- Inspect Equipment: Verify the emergency steering gear’s operational condition, checking for leaks, loose linkages, or electrical faults.

- Brief Personnel: Review objectives, procedures, and safety protocols.

- Assign Roles: Designate personnel for the bridge team, steering gear room team, and communication support.

2. Drill Initiation

- Simulate Failure: Announce a main steering gear failure scenario.

- Establish Communication: Use VHF radios, sound-powered telephones, or ship’s intercom to connect the bridge and steering gear room.

- Activate Emergency System: Switch to emergency steering mode, engaging manual or alternative controls.

- Test Steering: Verify rudder response to helm orders (e.g., “hard port,” “midship”).

3. Testing Alternative Systems

- Local Control: Operate steering directly from the steering gear compartment.

- Backup Power: Test emergency generators or alternative power supplies, ensuring seamless operation.

- System Checks: Confirm hydraulic or electric systems function within design parameters.

- Rudder Movement: Ensure rudder angles align with indicators and gyro repeaters.

4. Communication and Coordination

- Verify Communication: Test all systems (normal telephone, sound-powered phone, VHF) for clarity and reliability.

- Alarm Testing: Activate steering failure alarms and confirm bridge acknowledgment.

- Helm Orders: Ensure bridge commands are accurately executed in the steering gear room.

5. Post-Drill Evaluation

- Debrief: Gather feedback from participants, discussing successes and challenges.

- Identify Issues: Note any equipment malfunctions or procedural gaps.

- Log Details: Record the drill in the ship’s logbook, including date, duration, and observations.

- Correct Deficiencies: Schedule maintenance or additional training to address weaknesses.

Emergency Steering Drill Checklist

To ensure thorough execution, use the following checklist:

| Task | Responsible Team | Status |

|---|---|---|

| Inform Master and Chief Engineer | Bridge, Technical | [ ] |

| Engage Alternative Steering, Disengage Autopilot | Bridge, Technical | [ ] |

| Sound Emergency Signal (if applicable) | Bridge, Watch Officer | [ ] |

| Reduce Speed or Stop Engines (as needed) | Bridge | [ ] |

| Display ‘Not Under Command’ Signal, Update AIS | Bridge, Watch Officer | [ ] |

| Broadcast Warning to Nearby Vessels | Bridge, Watch Officer | [ ] |

| Notify Office | Office | [ ] |

| Ascertain Cause of Failure | Bridge, Technical | [ ] |

| Report Casualty | Bridge, Office | [ ] |

| Prepare for Anchoring (if needed) | Bridge, Emergency Squad | [ ] |

| Check Navigational Hazards | Bridge | [ ] |

| Monitor Nearby Vessels | Bridge | [ ] |

| Maintain Log of Events | Bridge | [ ] |

| Preserve VDR/SVDR Records | Technical | [ ] |

Common Challenges and Solutions

Drills often reveal operational or human-related issues. Here are common challenges and their solutions:

- Inadequate Crew Familiarity

- Solution: Conduct regular training, including hands-on sessions with the emergency steering system. Rotate roles to build cross-functional skills.

- Communication Failures

- Solution: Standardize communication protocols and test all systems during drills. Maintain backup options like VHF radios.

- Mechanical or Hydraulic Issues

- Solution: Implement a robust planned maintenance system (PMS) to catch issues early. Conduct pre-drill inspections.

- Delayed Response Times

- Solution: Practice time-bound scenarios to improve efficiency. Simulate high-pressure situations to build muscle memory.

Real-World Example: A Lesson from Rotterdam

During a PSC inspection in Rotterdam, a bulk carrier was detained because the crew could not demonstrate proficiency in emergency steering procedures. The bridge team failed to communicate effectively with the steering gear room, and the emergency system took over 10 minutes to activate—far exceeding safe response times. This incident underscores the need for rigorous drills beyond mere compliance, ensuring crews are ready for real emergencies.

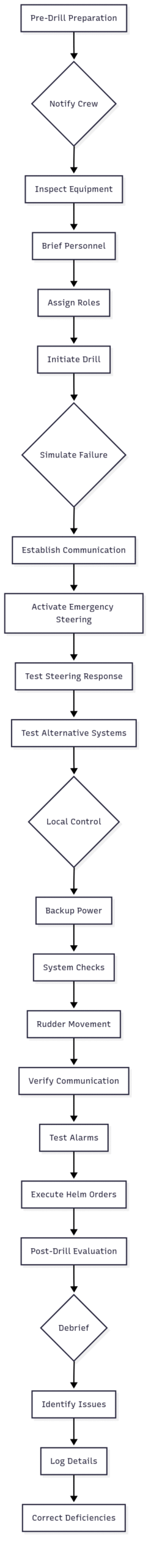

Chart: Emergency Steering Drill Workflow

Below is a flowchart illustrating the emergency steering drill process, created using syntax for clarity.

This chart visualizes the sequential steps, ensuring all critical tasks are addressed systematically.

Technical Specifications of Emergency Steering Gear

While specifications vary by vessel, typical features include:

| Component | Specification |

|---|---|

| Type | Rotary vane or ram-type |

| Power Source | Hydraulic (primary), electric (backup) |

| Control Method | Manual helm wheel or local hydraulic pump |

| Rudder Angle | ±35° (standard), ±45° (high-performance) |

| Response Time | 28 seconds for 30° rudder movement (SOLAS) |

| Communication | VHF, sound-powered phone, intercom |

| Power Supply | Emergency generator via switchboard |

Pricing Considerations

Emergency steering gear costs depend on vessel size and system complexity. Approximate ranges:

- Small Vessels (e.g., tugs): $50,000–$100,000

- Mid-Size Ships (e.g., bulk carriers): $150,000–$300,000

- Large Vessels (e.g., container ships): $500,000–$1,000,000

Maintenance contracts typically cost 5–10% of the system price annually. For precise pricing, consult manufacturers like Rolls-Royce, Kongsberg, or Wärtsilä.

Best Practices for Effective Drills

To maximize drill effectiveness:

- Simulate Realistic Scenarios: Include power failures, hydraulic leaks, or communication breakdowns.

- Rotate Crew Roles: Ensure all personnel gain experience in bridge and steering gear room tasks.

- Conduct Risk Assessments: Account for weather, traffic, and vessel speed before drills.

- Use Protective Gear: Provide ear protection in noisy steering gear rooms.

- Debrief Thoroughly: Document lessons learned and update maintenance schedules.

FAQs About Emergency Steering Drills

What is the SOLAS requirement for emergency steering drills?

Drills must occur every three months, with testing within 12 hours before departure.

What should drills include?

Operation from the steering gear room, communication tests, and alternative power checks.

How often are drills conducted?

Quarterly, or more frequently per company policy.

What is the emergency steering procedure?

Isolate the main system, engage emergency controls, follow bridge orders, and log the process.

Why are drills critical?

They ensure crew readiness, compliance, and system reliability, preventing accidents.

Conclusion: Drills as a Lifeline

Emergency steering gear drills are more than regulatory checkboxes—they are a lifeline in critical situations. By adhering to SOLAS requirements, conducting thorough drills, and addressing challenges proactively, ship operators can ensure their vessels remain safe and navigable. Regular practice, clear communication, and robust maintenance are the cornerstones of effective emergency steering, safeguarding crews, cargo, and the marine environment.

Through diligent preparation and execution, emergency steering drills empower maritime professionals to handle real failures with confidence, reinforcing the industry’s commitment to safety and operational excellence.

Happy Boating!

Share Emergency Steering Drill Actions: Training and Real Failure with your friends and leave a comment below with your thoughts.

Read 10 Essential Safety Procedures Every Seafarer Must Know until we meet in the next article.