Discover the top five trends in marine propulsion, from hybrid systems to alternative fuels, driving efficiency and decarbonization in shipping.

The maritime industry stands at a critical juncture, facing mounting pressure to reduce greenhouse gas emissions, improve fuel efficiency, and comply with stringent global regulations. The International Maritime Organization (IMO) has set ambitious targets: a 40% reduction in greenhouse gas emissions by 2030 and net-zero emissions by 2050, relative to 2008 levels. As ships, responsible for transporting nearly 90% of global goods, emit significant CO2—over 6,000 tons per long-haul voyage for a single cargo vessel—innovations in marine propulsion are pivotal to achieving these goals. This article delves into the top five trends reshaping marine propulsion: hybrid and electric systems, alternative fuels, wind-assisted propulsion, digital technologies, and other efficiency-enhancing innovations. These advancements are not just technological breakthroughs but critical steps toward a sustainable and cost-effective shipping industry.

1. Hybrid and Electric Propulsion Systems

Hybrid and electric propulsion systems are revolutionizing marine operations by combining efficiency, flexibility, and reduced environmental impact. These systems are particularly suited for vessels operating in emission-sensitive areas, such as ports, coastal regions, and Emission Control Areas (ECAs).

Hybrid Propulsion: Flexibility Meets Efficiency

Hybrid systems integrate traditional internal combustion engines (typically diesel) with electric motors and battery packs. This combination allows vessels to switch between power sources based on operational needs, optimizing fuel consumption and reducing emissions. For instance, ships can operate on battery power in ports for zero-emission maneuvering or use diesel engines for long-haul voyages. The flexibility of hybrid systems makes them ideal for ferries, offshore supply vessels, and cruise ships.

- Benefits:

- Up to 20% fuel savings in optimal conditions.

- Reduced emissions of CO2, NOx, and SOx.

- Silent operation in electric mode, improving passenger and crew comfort.

- Example: The Norwegian ferry Color Hybrid uses a 5 MWh battery pack, enabling emission-free operation for up to 60 minutes in port, significantly reducing local air pollution.

Fully Electric Propulsion: Zero-Emission Voyages

Fully electric propulsion systems eliminate emissions entirely during operation, making them a cornerstone of decarbonization for short-sea shipping, ferries, and harbor craft. Advances in lithium-ion battery technology and shore-based charging infrastructure have made electric vessels increasingly viable.

- Key Developments:

- High-energy-density batteries allow extended range and power.

- Battery Management Systems (BMS) enhance safety and longevity.

- Shore-side charging stations reduce reliance on onboard fossil fuels.

- Example: The Yara Birkeland, the world’s first fully electric and autonomous container ship, operates in Norwegian waters with zero emissions, powered by an 6.8 MWh battery system sourced from hydropower.

- Case Study: Crowley Maritime’s eWolf, the first all-electric tugboat in the U.S., operates at the Port of San Diego with a 70-ton bollard pull, replacing a diesel tug that consumed over 30,000 gallons of fuel annually.

Challenges and Future Outlook

While electric propulsion excels in short-range applications, range limitations and high initial costs remain barriers for deep-sea vessels. However, ongoing advancements in battery density and charging infrastructure are expanding their applicability. By 2030, the global market for electrified vessels is projected to reach $14.2 billion, driven by demand for ferries, tugs, and small cargo ships.

2. Alternative Fuels: Powering the Transition to Zero-Carbon

The shift to low- and zero-carbon fuels is a cornerstone of maritime decarbonization. In 2023, over 50% of newbuilding orders were for vessels capable of operating on alternative fuels like LNG, methanol, ammonia, and hydrogen, compared to 33% in 2022, according to DNV’s Alternative Fuels Insight platform. These fuels are critical for compliance with regulations like the EU Emissions Trading System (ETS) and FuelEU Maritime, which incentivize cleaner operations.

Liquefied Natural Gas (LNG): A Transitional Fuel

LNG is the most widely adopted alternative fuel, used in 81% of alternative-fuel vessel orders in 2022. By cooling natural gas to -260°F, LNG reduces to 1/600th of its gaseous volume, making it practical for marine use. It produces 20–30% less CO2 than heavy fuel oil and significantly reduces SOx and NOx emissions, aligning with IMO 2020 sulfur cap requirements.

- Real-World Adoption: CMA CGM’s Jacques Saadé, one of the largest LNG-powered container ships, achieves up to 20% lower greenhouse gas emissions.

- Challenges: Methane slip (unburned methane emissions) remains a concern, prompting research into bio-LNG and synthetic LNG for further emission reductions.

Hydrogen: The Zero-Emission Promise

Hydrogen fuel cells generate electricity through a chemical reaction, producing only water and heat. With an energy content of 120.2 MJ/kg, hydrogen is highly efficient, but its low volumetric density requires significant storage space and cryogenic systems (below -253°C).

- Applications: Hydrogen is ideal for ferries and auxiliary power systems. The Hydroville passenger ferry in Belgium and the EU-funded FLAGSHIPS project demonstrate hydrogen’s potential.

- Example: SWITCH Maritime’s Sea Change, a 75-passenger hydrogen fuel cell ferry, operates in San Francisco, showcasing zero-emission capabilities.

- Challenges: Storage complexity, fire risks, and limited supply chains hinder widespread adoption. The U.S. Department of Energy’s Horizons Clean Hydrogen Hub program is investing up to $7 billion to address these barriers.

Ammonia: A Carbon-Free Contender

Ammonia, a zero-carbon fuel, is gaining traction due to its higher energy density (50% more energy per cubic meter than hydrogen) and simpler storage requirements. It remains liquid at room temperature under moderate pressure, reducing infrastructure costs.

- Developments: MAN Energy Solutions and Wärtsilä are developing ammonia-ready two-stroke and four-stroke engines, with commercial availability expected by 2025–2026. BeHydro’s Evolve 6EL23 hydrogen dual-fuel engine and Wärtsilä’s Wärtsilä 25 ammonia engine have received approvals in principle from Lloyd’s Register.

- Case Study: Fortescue’s FFI Green Pioneer, a platform supply vessel retrofitted with ammonia-compatible engines, highlights the fuel’s potential for large vessels.

- Challenges: Toxicity and safety concerns require robust handling protocols.

Biofuels: Leveraging Existing Infrastructure

Biofuels, derived from renewable sources like crop waste and algae, can reduce lifecycle emissions by up to 80% when used in diesel engines. Their compatibility with existing infrastructure makes them a practical transitional fuel.

- Adoption: In 2022, 13% of alternative-fuel vessel orders opted for methanol, a biofuel-compatible option. A 2021 DOE investment of $61.4 million is accelerating biofuel development.

- Potential: Studies, such as one from Frontiers in Marine Science (2022), highlight the use of Sargassum biomass for bioethanol and biodiesel production, offering a sustainable feedstock.

Fuel Comparison Table

| Fuel Type | CO2 Reduction | Key Advantages | Challenges | Adoption Rate (2022) |

|---|---|---|---|---|

| LNG | 20–30% | Mature infrastructure, lower SOx/NOx | Methane slip, fossil-based | 81% of orders |

| Hydrogen | 100% (fuel cell) | Zero emissions, high energy content | Storage complexity, limited supply | Emerging |

| Ammonia | 100% | High density, simpler storage | Toxicity, safety concerns | Pilot projects |

| Biofuels | Up to 80% | Compatible with diesel engines | Feedstock availability, cost | 13% (methanol) |

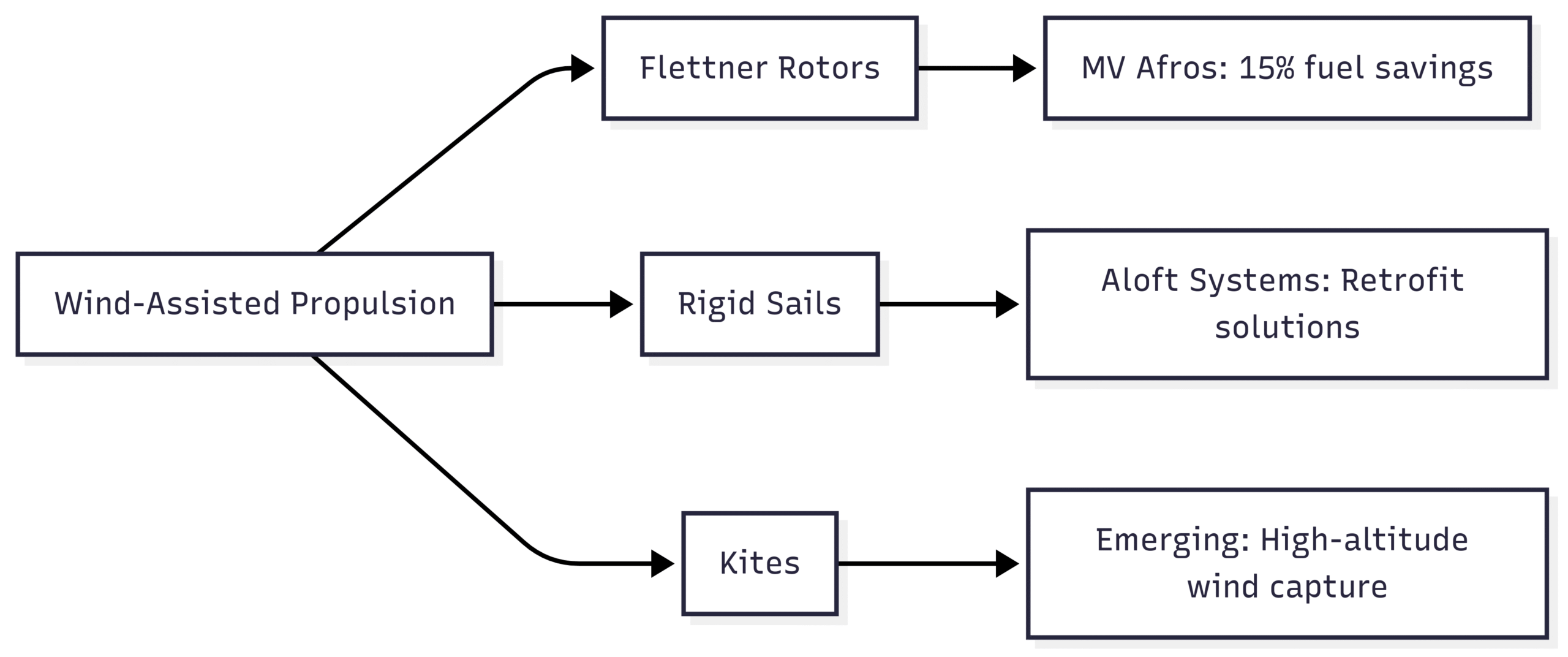

3. Wind-Assisted Propulsion: Harnessing Nature’s Power

Wind-assisted propulsion is experiencing a renaissance, offering a low-cost, low-emission complement to traditional engines. Technologies like Flettner rotors, rigid sails, and kites leverage wind energy to reduce fuel consumption by 5–20%, according to the International Windship Association.

Key Technologies

- Flettner Rotors: Rotating cylinders that use the Magnus effect to generate thrust. The MV Afros bulk carrier, equipped with Anemoi Marine Technologies’ rotors, saves up to 15% fuel.

- Rigid Sails: Automated, lightweight sails that adjust to wind conditions. Aloft Systems’ containerized sail systems are easily retrofitted to existing fleets.

- Kites: High-altitude kites capture stronger winds, reducing engine load. These are still in early development but show promise for bulk carriers.

Adoption and Impact

Wind propulsion is outpacing alternative fuels in some metrics, with 31 large oceangoing vessels (2 million dwt capacity) equipped with wind-assist systems. Eight wind-ready ships are operational, and 22 more are pending installation. The IMO recognizes wind propulsion as a viable strategy for meeting Energy Efficiency Design Index (EEDI) and Carbon Intensity Indicator (CII) targets.

Chart: Wind-Assisted Propulsion Technologies

4. Digital Technologies: Smart Propulsion for a Smart Future

Digital technologies are transforming marine propulsion by enabling real-time optimization, predictive maintenance, and regulatory compliance. These tools enhance efficiency and reduce operational costs, aligning with IMO’s CII and Energy Efficiency Existing Ship Index (EEXI) requirements.

Digital Twin Technology

Digital twins create virtual replicas of ships, allowing operators to monitor performance, simulate scenarios, and optimize propulsion systems. By integrating sensor data, digital twins enable predictive maintenance and fuel efficiency improvements.

- Example: Wärtsilä’s Fleet Operations Solution uses digital twins to reduce fuel consumption by up to 5%.

Remote Monitoring and Predictive Maintenance

AI and machine learning analyze engine data to predict maintenance needs, minimizing downtime and extending equipment life. ABB’s Ability Marine Advisory System reports fuel savings of 5–10% through real-time engine tuning.

Advanced Navigation Systems

Enhanced navigation and communication systems improve route planning and situational awareness, reducing fuel use. These systems integrate weather data, traffic patterns, and engine performance to optimize voyages.

Impact on Compliance

Digital tools support compliance with environmental regulations by providing accurate emissions data and optimizing fuel use. Charterers benefit from better visibility into Scope 3 emissions, a growing focus for sustainability reporting.

5. Other Notable Innovations

Beyond the core trends, several innovations are enhancing propulsion efficiency and sustainability:

- Air Lubrication Systems: These systems release microbubbles under the hull to reduce drag, saving up to 10% fuel. Mitsubishi’s MALS on the Fujitrans World car carrier is a prime example.

- Waste Heat Recovery Systems: Capture engine heat to generate additional power, improving overall efficiency by 5–8%.

- Ballast-Free Ship Designs: Eliminate ballast water, reducing invasive species risks and improving fuel efficiency.

- 3D Printing: Enables on-demand production of spare parts, reducing inventory costs and downtime.

- Nuclear Propulsion: Offers high power and zero emissions for specialized vessels like icebreakers, though high costs and regulations limit civilian adoption.

Onboard Carbon Capture (OCC)

OCC systems capture CO2 emissions from exhaust gases, storing them for offloading or conversion. While promising, OCC lacks IMO incentives for EEDI, EEXI, or CII compliance. Pilot projects in 2024 will test scalability and integration.

Industry Trends and Drivers

The maritime industry’s propulsion revolution is driven by regulatory and economic pressures. In 2023, newbuilding orders reached a peak of 1,914 vessels, with over half featuring dual-fuel engines capable of using LNG, methanol, or ammonia. The EU ETS, effective from January 2024, and FuelEU Maritime, starting in 2025, are accelerating the adoption of low-carbon technologies. Shipowners are future-proofing fleets to avoid stranded assets, as vessels built today will operate through 2050.

Retrofit Solutions

Retrofitting existing vessels is critical, given their 20–30-year lifespans. Projects like Fugro’s methanol engine conversion and Eidesvik’s ammonia fuel cell retrofit demonstrate viable pathways. MAN Energy Solutions and Alfa Laval’s methanol retrofit kits for four-stroke engines, along with Cummins’ QSK60 retrofit, are expanding options for older fleets.

Challenges and Considerations

Each propulsion trend faces unique hurdles:

- Hybrid/Electric: High capital costs and range limitations.

- Alternative Fuels: Scalability, safety, and infrastructure gaps.

- Wind Propulsion: Dependence on wind conditions and retrofit costs.

- Digital Technologies: Data security and integration complexity.

- Other Innovations: Regulatory approval and market readiness.

Despite these challenges, the economic case for sustainable propulsion is strong. Fuel savings, compliance with regulations, and competitive advantages drive investment. For instance, wind-assisted systems can reduce fuel costs by 6–20%, while digital tools offer 5–10% savings.

Conclusion

The top five trends in marine propulsion—hybrid and electric systems, alternative fuels, wind-assisted propulsion, digital technologies, and complementary innovations—are steering the maritime industry toward a sustainable future. These advancements address the urgent need to decarbonize shipping, which accounts for nearly 3% of global CO2 emissions. By adopting these technologies, shipowners can achieve compliance, reduce costs, and contribute to a cleaner planet. As the industry navigates this transformation, staying informed and adaptable is crucial for maritime professionals.

Call to Action: Explore case studies, compliance tools, and propulsion benchmarks at the Marine Propulsion Technology Hub to stay ahead in this dynamic field.

Happy Boating!

Share The top five trends in marine propulsion with your friends and leave a comment below with your thoughts.

Read Boat xtend Smartwatch 4K HD Wallpapers until we meet in the next article.