Learn about crankcase explosions in marine diesel engines: causes like hot spots, prevention with safety devices, and strategies to ensure crew safety.

Crankcase explosions in marine diesel engines are rare but catastrophic events that pose significant risks to crew safety, vessel operability, and equipment integrity. These explosions occur when a flammable oil mist ignites within the engine’s crankcase, often triggered by hot spots or mechanical failures. With the potential to cause structural damage, fires, or even loss of life, understanding their causes, implementing prevention strategies, and equipping engines with robust safety systems are critical for maritime operations. This comprehensive guide explores the mechanics of crankcase explosions, their primary causes, effective prevention measures, and essential safety devices, providing actionable insights for marine engineers and ship operators.

What is a Crankcase Explosion?

A crankcase explosion is a violent combustion event within the crankcase of an internal combustion engine, typically a marine diesel engine. The crankcase houses critical components like the crankshaft, connecting rods, and bearings, lubricated by oil to reduce friction. Under certain conditions, this oil can vaporize, form a flammable mist, and ignite, leading to a sudden pressure surge and explosion. The consequences can range from minor structural damage to catastrophic engine failure, fires, or secondary explosions that endanger the entire vessel.

The phenomenon is governed by the fire triangle: fuel (lubricating oil), oxygen (present in the crankcase atmosphere), and heat (from a hot spot or spark). For an explosion to occur, these elements must exist in the right proportions, known as the combustible range between the Lower Explosive Limit (LEL) and Upper Explosive Limit (UEL). The process typically unfolds in two stages:

- Primary Explosion: A localized ignition of oil mist causes a minor pressure surge, sending a shockwave through the crankcase. This can crack engine components or trigger safety devices like relief valves.

- Secondary Explosion: If fresh air enters the crankcase after the primary explosion (e.g., through leaks or open doors), it can mix with additional oil vapor, leading to a more severe explosion.

The severity of crankcase explosions was highlighted by historical incidents, such as the 1947 explosion aboard the MV Reina Del Pacifico, which claimed 28 lives and prompted the introduction of stringent SOLAS (Safety of Life at Sea) regulations. Despite advancements, crankcase explosions remain a concern, with an estimated 65–100 incidents annually in the global maritime fleet, underscoring the need for vigilance and robust safety measures.

Causes of Crankcase Explosions

Crankcase explosions stem from a sequence of mechanical or operational failures that create the conditions for ignition. Below are the primary causes:

1. Hot Spots

Hot spots are localized areas within the crankcase that reach abnormally high temperatures (200–400°C), sufficient to vaporize lubricating oil. Common triggers include:

- Bearing Failure: Worn or misaligned crankshaft bearings, often due to inadequate lubrication or surface irregularities, generate excessive friction and heat.

- Blow-by: Combustion gases leaking past worn piston rings or stuffing boxes introduce hot gases into the crankcase, raising temperatures.

- Scavenge Fires: Fires in the engine’s scavenge spaces (in two-stroke engines) can radiate heat to the crankcase.

- Overloaded Engines: Operating beyond design limits increases thermal stress on components.

The flash point of crankcase lubricating oil is typically around 220°C, but fuel oil contamination can lower it, increasing the risk. Hot spots vaporize oil, which then condenses into a fine mist in cooler areas, creating a flammable atmosphere.

2. Blow-by

Blow-by occurs when combustion gases escape past piston rings or cylinder liners into the crankcase, introducing fuel vapors and air. This is more likely in engines with:

- Worn or damaged piston rings.

- Scored or damaged cylinder liners.

- High engine loads or speeds.

These gases can mix with oil vapors, forming a combustible mixture that ignites upon encountering a hot spot.

3. Oil Mist Formation

When lubricating oil contacts a hot spot, it evaporates into a vapor that condenses into a white, flammable oil mist with droplets smaller than 10 microns. This mist is highly explosive within the LEL–UEL range and can ignite if it recirculates to the hot spot or encounters a spark.

4. Ignition Sources

The ignition source is often the hot spot itself, which may reach temperatures of 850°C, sufficient to ignite the oil mist. Alternatively, sparks from failing bearings or mechanical impacts can serve as the trigger.

Consequences of Crankcase Explosions

Without intervention, crankcase explosions can cause:

- Structural Damage: Crankcase rupture, cracked engine blocks, or blown-out doors.

- Component Failure: Bent connecting rods, damaged pistons, or seized engines.

- Fires: Escaping flames or oil leaks can ignite, spreading to the engine room.

- Loss of Propulsion: A disabled engine can leave a vessel stranded.

- Crew Injuries or Fatalities: High-pressure gases, flames, or debris pose lethal risks.

The absence of safety devices like crankcase explosion relief valves (CERVs) exacerbates these outcomes, potentially leading to catastrophic secondary explosions.

Prevention Strategies

Preventing crankcase explosions requires a combination of proactive maintenance, operational discipline, and advanced monitoring systems. Below are key strategies:

1. Regular Maintenance

Routine inspections and maintenance are the first line of defense. Critical tasks include:

- Bearing Inspections: Check for wear, misalignment, or surface irregularities. Replace bearings as per manufacturer schedules.

- Piston Ring and Liner Checks: Ensure proper sealing to minimize blow-by.

- Clearance Measurements: Verify adequate clearances between mating parts (e.g., piston/liner, bearings).

- Oil Quality Analysis: Test lubricating oil for contamination or degradation, as fuel oil dilution lowers the flash point.

2. Proper Lubrication

Lubrication prevents overheating and wear. Best practices include:

- Using high-quality lubricating oil with a flash point above 200°C.

- Maintaining optimal oil levels and pressure.

- Regularly replacing oil filters to prevent clogs.

- Monitoring oil condition to detect fuel contamination.

3. Engine Load Management

Avoid overloading the engine by operating within its designed parameters. Overloading increases thermal and mechanical stress, accelerating wear and hot spot formation.

4. Monitoring Systems

Advanced sensors and detectors provide early warnings of hazardous conditions:

- Oil Mist Detectors (OMDs): Continuously sample crankcase air for oil mist concentrations. If levels exceed safe thresholds, OMDs trigger alarms or slow the engine. Example: The Graviner OMD uses photoelectric cells to compare crankcase vapors against clean air.

- Lube Oil Temperature Sensors: Detect rising oil temperatures, indicating potential hot spots.

- Bearing Temperature Sensors: Monitor bearing health to prevent overheating.

- Vibration and Sound Monitoring: Detect irregular engine behavior or abnormal noises.

5. Crew Training

Engine room personnel must be trained to recognize warning signs, such as:

- Dense white mist from breather pipes or drain cocks.

- Irregular engine running or vibrations.

- Hot spots (detectable by touch or infrared thermometers).

- Alarms from OMDs or temperature sensors.

Training should cover emergency response protocols, including slowing or stopping the engine and avoiding premature crankcase access.

Safety Systems

Marine diesel engines are equipped with specialized safety devices to mitigate crankcase explosion risks. These systems either prevent ignition or contain the effects of an explosion.

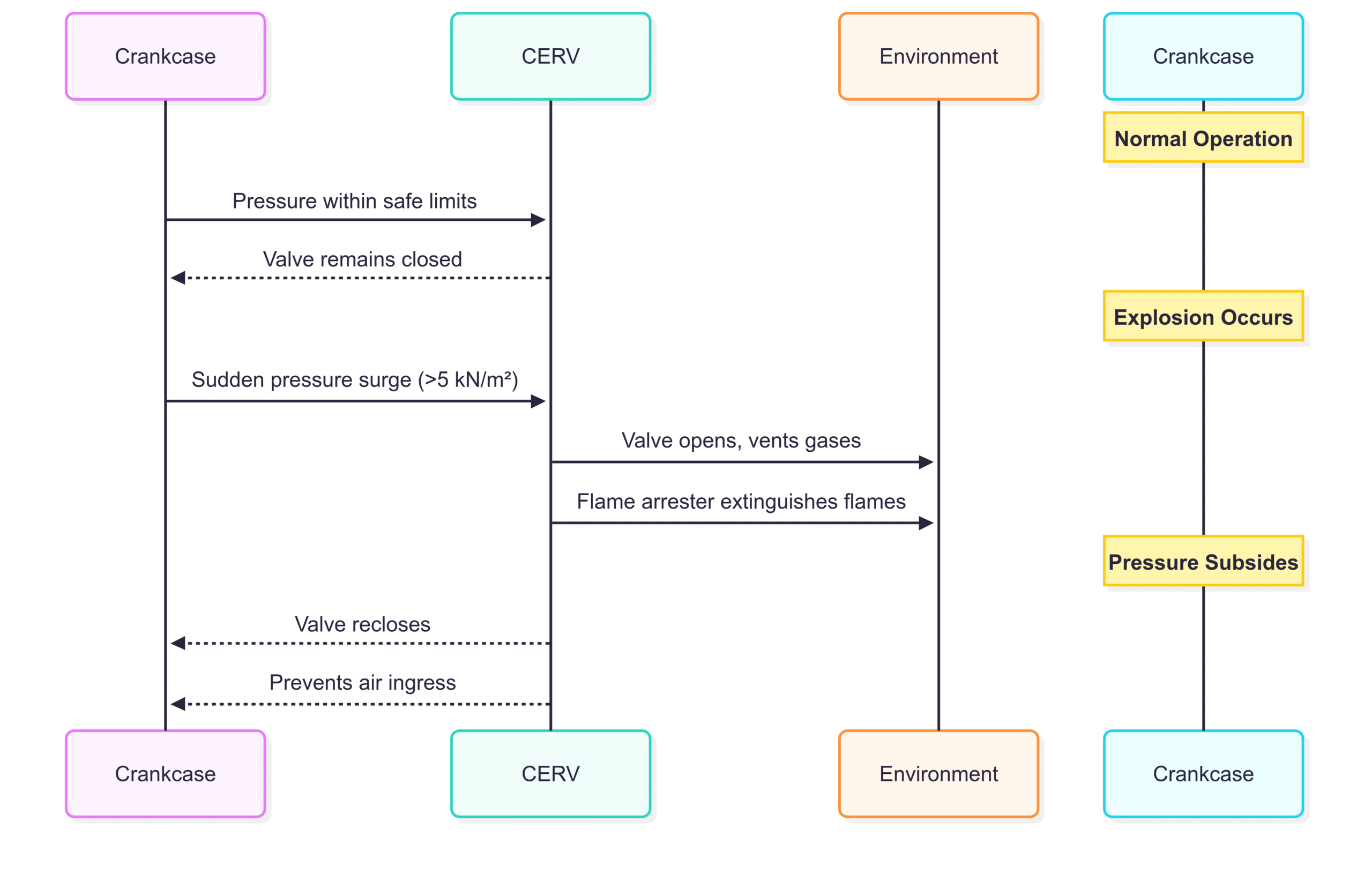

1. Crankcase Explosion Relief Valves (CERVs)

CERVs are spring-loaded valves installed on the crankcase to relieve pressure during an explosion. Their key functions are:

- Pressure Relief: Open at a preset pressure (e.g., 0.2–1.0 bar or 5 kN/m²) to vent high-pressure gases, preventing structural failure.

- Flame Arresting: Incorporate wire gauze or perforated plates to cool and extinguish flames, preventing external ignition.

- Resealing: Close automatically after pressure relief to block air ingress, reducing the risk of secondary explosions.

CERV Components:

| Component | Description |

|---|---|

| Valve Body | Durable housing (e.g., steel or aluminum) to withstand high pressures. |

| Valve Plate | Spring-loaded disc that opens under pressure. |

| Flame Arrestor | Mesh or gauze that cools escaping flames. |

| Spring | Calibrated to open at a specific pressure and reclose after relief. |

| Deflector | Directs escaping gases downward to protect personnel. |

CERV Specifications:

- Pressure Release: 5 kN/m² (typical).

- Free Area: Minimum 45 cm² per valve; total area ≥ 115 cm² per m³ of crankcase volume.

- Regulations: SOLAS requires ≥ 1 CERV per cylinder for engines with bores > 300 mm.

Diagram: CERV Operation

2. Oil Mist Detectors (OMDs)

OMDs monitor the crankcase atmosphere for oil mist, alerting crew before concentrations reach explosive levels. The Graviner OMD, for example, uses two tubes:

- Reference Tube: Contains clean air for baseline comparison.

- Measuring Tube: Samples crankcase vapors. Oil mist reduces light transmission, triggering an alarm.

OMD Specifications:

- Sampling points: One per cylinder.

- Maximum sampling tube length: 12.5 meters.

- Maintenance: Daily functionality tests; periodic cleaning of lenses and mirrors.

3. Crankcase Exhaust Fans

Fans remove accumulated gases and oil mist, maintaining safe crankcase conditions. They work in tandem with breather pipes, which vent excess pressure and include flame traps to prevent flame propagation.

4. Breather Pipes

Breather pipes prevent pressure buildup and are fitted with flame arrestors to contain potential fires. They must be appropriately sized and routed to safe locations.

5. Inert Gas Systems

Some engines use inert gas flooding to displace oxygen, preventing combustion. Post-activation, the crankcase must be ventilated before inspection.

Post-Explosion Procedures

If a crankcase explosion occurs, swift and cautious action is essential:

Immediate Response:

- Slow or stop the engine to reduce load and heat.

- Engage the turning gear with indicator cocks open to prevent seizure.

- Avoid opening crankcase doors until the engine has cooled (to prevent air ingress and secondary explosions).

Inspection and Repair:

- Conduct a thorough inspection of bearings, pistons, connecting rods, and the crankcase.

- Replace damaged components and the flame arrestor in the CERV.

- Test oil quality and renew if contaminated.

Documentation:

- Record the incident and findings for regulatory compliance and future prevention.

Statistical Insights

Between 1993 and 2001, Class LR reported 143 crankcase explosion incidents, equating to roughly 65–100 cases annually worldwide. These figures likely underestimate the true frequency, as minor incidents may go unreported. Modern engines, equipped with advanced safety systems, have reduced the incidence rate, but the risk persists, particularly in older or poorly maintained vessels.

Table: Crankcase Explosion Incident Trends (Estimated)

| Period | Reported Incidents (Class LR) | Global Estimate | Annual Average |

|---|---|---|---|

| 1993–2001 | 143 | ~715 | ~65–100 |

| Modern Era | Lower (due to safety systems) | Unknown | ~50–75 (estimated) |

Regulatory Framework

SOLAS regulations mandate safety measures for crankcase explosion prevention, including:

- Installation of CERVs on engines with cylinder bores > 300 mm.

- Use of OMDs or equivalent monitoring systems.

- Regular maintenance and crew training.

- Explosion-proof crankcase fittings (e.g., lights, vents).

Compliance ensures vessel safety and avoids penalties during port state inspections.

Emerging Technologies

Recent innovations aim to further mitigate crankcase explosion risks:

- Smart Sensors: IoT-enabled OMDs and temperature sensors with predictive maintenance capabilities.

- Advanced Materials: Bearings with embedded thermal sensors to detect early overheating.

- Automated Shutdown Systems: Engines that halt automatically upon OMD or CERV activation.

Conclusion

Crankcase explosions in marine diesel engines are a preventable hazard that demands proactive management. By understanding the causes—hot spots, blow-by, and oil mist ignition—operators can implement robust prevention strategies, including regular maintenance, proper lubrication, and vigilant monitoring. Safety devices like CERVs and OMDs, backed by SOLAS regulations and crew training, significantly reduce risks. While modern technology has lowered incident rates, the potential for catastrophic damage remains, making diligence and preparedness essential for safe engine room operations. By prioritizing these measures, ship operators can protect their crews, vessels, crew, and vessels, and the environment while ensuring reliable maritime operations.

Happy Boating!

Share Crankcase Explosion: Causes, Prevention Strategies & Safety with your friends and leave a comment below with your thoughts.

Read How to Prevent Starting Air Line Explosion on Ships? until we meet in the next article.