Learn expert maintenance of marine diesel engine generator fuel oil systems. Comprehensive guide on inspections, cleaning, and best practices for reliability.

Marine diesel engine generators are the backbone of a vessel’s power supply, driving critical systems like navigation, lighting, and communication. At the heart of these engines lies the fuel oil system, a complex network that ensures fuel is delivered efficiently for combustion. Without diligent maintenance, even minor issues in this system can escalate into engine failure, costly repairs, or operational delays. This guide provides a comprehensive, actionable approach to maintaining the fuel oil system, tailored for marine engineers, cadets, and fleet managers, ensuring reliability, efficiency, and compliance with international maritime standards.

Why Fuel Oil System Maintenance Matters

The fuel oil system is critical to the performance of marine diesel generators. Neglecting it risks:

- Power Disruptions: Inconsistent fuel delivery can lead to engine misfiring or blackouts, compromising vessel operations.

- Costly Repairs: Small issues, like clogged filters, can damage injectors or pumps, leading to expensive overhauls.

- Environmental Impact: Poor combustion increases emissions, violating regulations like IMO 2020.

- Vessel Downtime: A single failure can halt operations, incurring demurrage costs or supply chain disruptions.

A well-maintained fuel oil system ensures reliable power, reduces downtime, extends engine life, and promotes environmental responsibility. For example, a container ship in the Malacca Strait suffered a partial blackout due to a clogged fuel strainer, costing $45 day of demurrage. Routine maintenance could have prevented this.

Understanding the Fuel Oil System

The fuel oil system in marine diesel generators comprises several components working together to deliver clean, pressurized fuel to the engine:

- Fuel Oil Supply Pump: Transfers fuel from storage to service tanks.

- Fuel Oil Heaters and Viscosity Controllers: Heat Heavy Fuel Oil (HFO) or Marine Diesel Oil (MDO) to optimal viscosity for combustion.

- Fuel Filters and Strainers: Remove impurities to protect injectors.

- Fuel Injection Pumps and Racks: Deliver precise fuel quantities to cylinders.

- Return Fuel Lines and Regulating Valves: Manage excess fuel and maintain system pressure.

Most vessels use HFO or MDO, requiring heating (130–150°C for HFO) and filtration to ensure proper combustion. Post-IMO 2020, Very Low Sulphur Fuel Oil (VLSFO) is common, introducing new maintenance challenges due to varying fuel stability.

Daily Maintenance: The Foundation of Reliability

Daily checks are the first line of defense against fuel system issues. These tasks, performed by watchkeeping engineers, ensure the system operates within manufacturer specifications.

Key Daily Checks

| Task | Purpose | Action |

|---|---|---|

| Fuel Level Check | Ensure adequate fuel supply | Verify levels in service tank; drain water from service and settling tanks. |

| Leak Inspection | Prevent fuel loss and fire hazards | Inspect fuel lines and connections for leaks or corrosion. |

| Fuel Quality Assessment | Avoid contamination-related damage | Check for water, debris, or microbial growth in fuel samples. |

| Pressure and Temperature Monitoring | Detect system anomalies | Ensure fuel pressure and temperature align with manufacturer specs. |

| Lube Oil Levels | Ensure proper engine lubrication | Check sump, governor, and rocker arm lubrication levels. |

| Condensate Drainage | Prevent corrosion and blockages | Drain condensate from scavenge manifold and air coolers. |

Pro Tip: Use a checklist to standardize daily inspections. Automated monitoring systems, like those from Wärtsilä, can log pressure and temperature data for real-time alerts.

Fuel Strainer Cleaning

Fuel strainers remove solid impurities, protecting the injection system. Vessels often use dual strainers for continuous operation during cleaning. Here’s the step-by-step procedure:

- Switch Active Side: Use the changeover handle to isolate the strainer to be cleaned.

- Drain Residual Fuel: Open the air bleed valve, then the drain valve.

- Disassemble: Remove cover bolts and extract the filter element.

- Clean Element: Soak in light oil or cleaning fluid, scrub with a nylon brush, and blow with compressed air (0.3–0.5 MPa).

- Inspect: Use a light to check for dirt, scratches, corrosion, or broken mesh.

- Reassemble: Reverse the process, ensuring all seals are intact.

- Bleed Air: Return the handle to “both sides in use” and bleed air from the strainer.

Safety Note: Wear PPE (gloves, face shield, flame-resistant coveralls) when handling hot fuel systems.

Routine Maintenance Schedules

Beyond daily checks, marine diesel generators follow structured maintenance schedules based on running hours, as mandated by the ISM Code and manufacturer guidelines. These are integrated into the vessel’s planned maintenance system (PMS), often managed via software that syncs with shore offices for oversight.

250-Hour Routine

- Clean Filters: Lube oil, fuel oil, and turbocharger air filters to prevent clogs.

- Inspect Lubrication: Ensure fuel racks, linkages, and pump operating gear are lubricated.

1000-Hour Routine

- Crankcase Inspection: Check for wear or contamination.

- Fuel Injector Testing: Remove, pressure-test, and adjust injectors for proper atomization.

- Turbocharger Oil Change: Replace oil on blower and turbine sides.

- Tappet Clearance Check: Ensure proper valve operation.

- Performance Testing: Record engine performance under load.

2000-Hour Routine

- Crankshaft Alignment: Measure and plot deflections, comparing to original figures. Misalignment due to ship hogging or sagging can strain bearings.

4000-Hour Routine (Half Decarbonization)

- Cylinder Head Overhaul: Remove, clean carbon deposits, and replace gaskets/O-rings.

- Valve Maintenance: Inspect and lap inlet/exhaust valves; overhaul starting air valves.

- Clean Cooling Spaces: Remove scale from cylinder head cooling water spaces.

- Piston and Liner Inspection: Check for abnormal wear or combustion issues.

- Lube Oil Renewal: Replace if analysis indicates degradation.

8000-Hour Routine (Full Decarbonization)

- Piston Overhaul: Withdraw, clean, and inspect pistons; replace rings if worn.

- Bearing Inspection: Check big end bearings for wear.

- Turbocharger Overhaul: Replace ball bearings and clean components.

- Exhaust System Cleaning: Remove carbon from piping and silencer.

25000-Hour Routine

- Connecting Rod Bolts: Renew to ensure structural integrity.

Note: Maintenance intervals may vary based on engine load, fuel quality, or manufacturer recommendations. Light-load engines may require more frequent exhaust and piston cleaning due to fouling risks.

Fuel Injection Pump Maintenance

The fuel injection pump is critical for precise fuel delivery. Inspections every 300–500 hours prevent combustion issues.

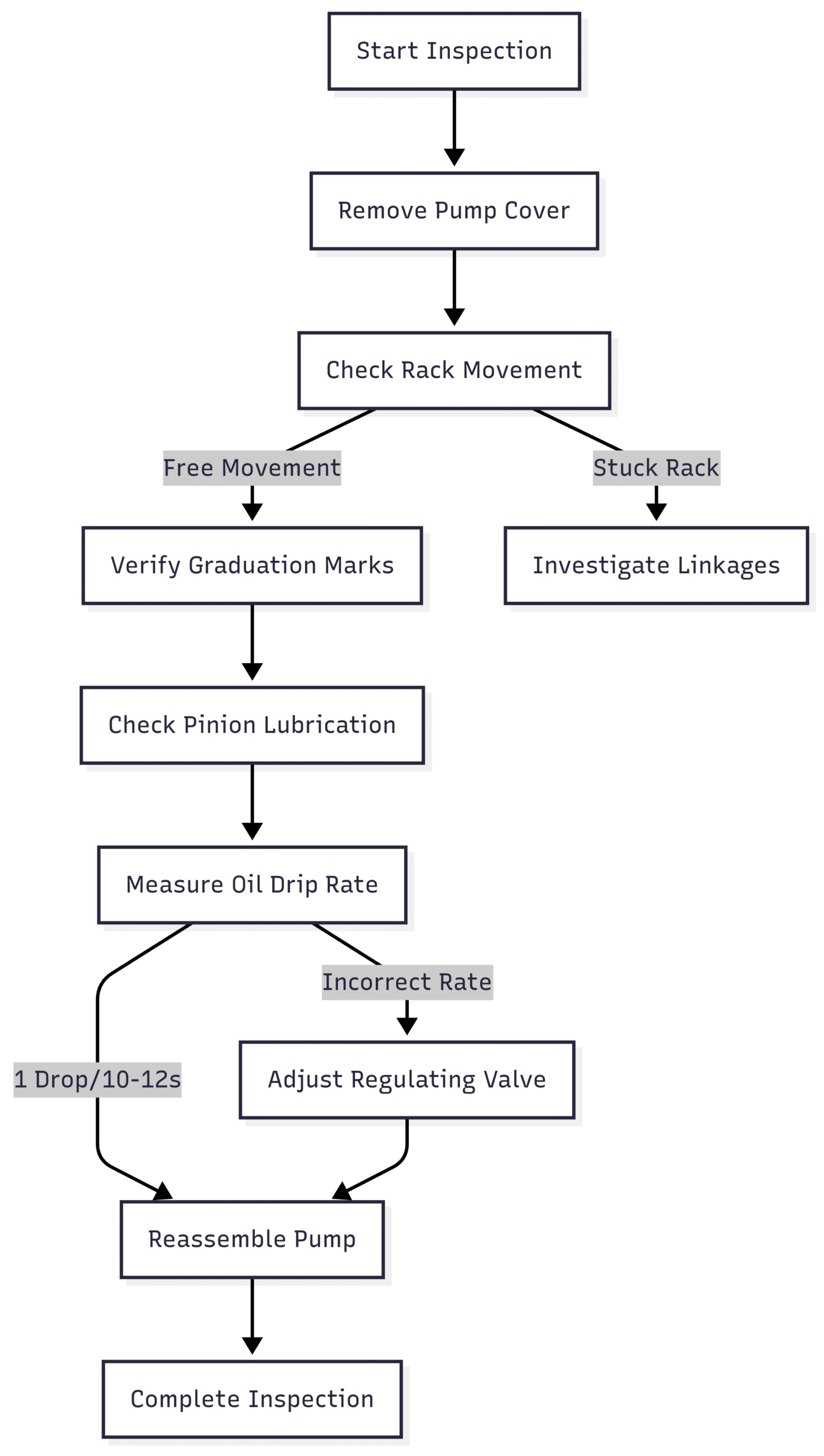

Inspection Checklist

- Rack Movement: Ensure free movement to avoid uneven cylinder firing.

- Graduation Marks: Verify consistent positioning across cylinders.

- Pinion Lubrication: Confirm oil reaches the pinion sleeve (HFO engines).

- Oil Drip Rate: Check for one drop every 10–12 seconds. Adjust regulating valve if needed.

Chart: Fuel Injection Pump Maintenance Flow

Challenges and Solutions in Fuel System Maintenance

Poor Fuel Quality

VLSFO, mandated by IMO 2020, varies in stability, leading to sludge or incompatibility issues. Solution: Use onboard fuel compatibility testing kits and increase filter checks.

Human Error in Adjustments

Manual valve and viscosity adjustments risk errors. Solution: Install digital control units with flow sensors and alarms for real-time monitoring.

Sludge Accumulation

Oxidation and polymerization cause sludge buildup. Solution: Use automated self-cleaning filters and manufacturer-approved fuel additives.

Advanced Technologies and Future Trends

The maritime industry is embracing automation and predictive maintenance to enhance fuel system reliability:

- FuelFlex Systems: Allow seamless switching between fuel types (e.g., HFO, MDO, VLSFO).

- Smart Strainers: Signal cleaning needs based on pressure differentials.

- Remote Monitoring: Platforms like Wärtsilä’s Expert Insight integrate with Inmarsat for real-time diagnostics, reducing maintenance hours by 30% and unscheduled failures by 70% (DNV data).

Table: Emerging Technologies in Fuel System Maintenance

| Technology | Benefit | Provider |

|---|---|---|

| FuelFlex Systems | Handles multiple fuel types | Wärtsilä, MAN |

| Smart Strainers | Automated cleaning alerts | Alfa Laval |

| Remote Monitoring Platforms | Real-time diagnostics | Wärtsilä, Inmarsat |

Compliance with International Standards

The International Safety Management (ISM) Code mandates structured maintenance programs. Manufacturers like MAN and Wärtsilä provide specific schedules, integrated into PMS software. Shore-based superintendents monitor compliance via data exports, ensuring engines meet class and administration standards.

FAQ: Fuel Oil System Maintenance

How often should fuel strainers be cleaned?

Weekly or when pressure drops are detected.

What causes irregular fuel pressure?

Clogged strainers, faulty valves, or air in the system.

How to verify viscosity controller performance?

Check fuel temperature at engine inlet (130–150°C for HFO).

Are automated filters better than manual cleaning?

Automated filters save time but require regular checks for reliability.

Can air in the fuel line cause damage?

Yes, it leads to misfiring and injector damage.

What’s the risk of over-lubricating fuel pumps?

Excess oil can dilute fuel or leak into the combustion chamber.

Conclusion

Maintaining the fuel oil system of marine diesel engine generators is a critical responsibility for marine engineers. From daily checks to periodic overhauls, each task ensures reliable power, minimizes downtime, and extends engine life. As automation and predictive diagnostics advance, the human element—discipline, knowledge, and attention to detail—remains essential. By adhering to manufacturer guidelines and international standards, engineers can keep vessels operational, efficient, and environmentally compliant, ensuring smooth sailing in even the most demanding conditions.

Happy Boating!

Share Maintenance of the Fuel Oil System in Marine Diesel Engine Generators with your friends and leave a comment below with your thoughts.

Read Maintenance of Lubricating Oil Systems in Marine Diesel Engine Generators until we meet in the next article.