Learn essential maintenance for marine diesel generator lube oil systems. Optimize performance, prevent failures, and ensure compliance with expert tips.

Marine diesel engine generators are the backbone of maritime operations, powering everything from propulsion systems to auxiliary equipment on vessels ranging from tugboats to massive container ships. At the heart of these engines lies the lubricating oil system, a critical component that ensures smooth operation by reducing friction, dissipating heat, cleaning internal parts, and preventing corrosion. Neglecting this system can lead to catastrophic engine failures, costly downtime, and safety risks at sea. For instance, a bulk carrier in the Indian Ocean suffered a two-day delay costing over USD 60,000 due to a blocked bypass strainer from skipped maintenance. Proper maintenance of the lubricating oil system is not just a routine task—it’s a cornerstone of operational reliability and regulatory compliance.

This comprehensive guide explores the maintenance procedures for lubricating oil systems in marine diesel engine generators, with a focus on Cummins QSC 8.3 and QSL 9 engines, commonly used in marine applications. From daily checks to advanced troubleshooting, we’ll cover the essential steps to keep your system in peak condition, supported by practical examples, specifications, and visual aids like charts.

Why Lubricating Oil System Maintenance Matters

The lubricating oil system serves multiple vital functions:

- Friction Reduction: Oil creates a protective film between moving parts, preventing metal-to-metal contact that causes wear.

- Heat Dissipation: It absorbs and transfers heat away from critical components like bearings and pistons.

- Contaminant Removal: Oil carries debris to filters, preventing sludge buildup.

- Corrosion Protection: Additives in the oil neutralize acidic byproducts, safeguarding engine components.

- Sealing: Oil enhances the seal between piston rings and cylinder walls, maintaining compression efficiency.

Poor maintenance can lead to oil contamination, reduced viscosity, or low pressure, resulting in engine overheating, bearing failure, or even complete engine shutdown. In maritime operations, where delays can cost thousands of dollars per hour and safety is paramount, a well-maintained lube oil system is non-negotiable.

Understanding the Lubricating Oil System

The lubricating oil system in a marine diesel generator comprises several key components working in unison to ensure optimal engine performance:

- Sump Tank: Stores the oil, typically located in the double bottom of the ship, surrounded by cofferdams to detect leaks.

- Lube Oil Pump: Circulates oil under pressure to engine components. In Cummins QSC 8.3 and QSL 9 engines, a gear-driven pump ensures consistent flow.

- Oil Cooler: Regulates oil temperature, cooled by a low-temperature freshwater system.

- Filters and Strainers: Remove contaminants, including mechanical filters, bypass centrifugal strainers, and automatic backwashing filters in modern systems.

- Purifier: Separates water and insoluble particles from the oil, maintaining its quality.

- Thermostatic Valve: Maintains optimal oil temperature, typically 45°C at the engine inlet.

- Piping and Valves: Facilitate oil circulation and system control.

Some systems incorporate a settling tank for batch cleaning, while others connect the sump directly to the purifier for continuous cleaning. The Cummins QSC 8.3 and QSL 9 engines, for example, rely on a robust system with a gear-driven pump and plate-type cooler, designed for marine and industrial applications.

Types of Lubrication Systems

Marine diesel engines employ various lubrication types, each suited to specific components:

- Hydrodynamic Lubrication: A continuous oil film forms due to the motion of moving parts, as seen in main bearings and thrust bearings.

- Hydrostatic Lubrication: External pressure from a pump creates the oil film, used in slow-moving parts like crosshead bearings.

- Boundary Lubrication: A thin film persists under high pressure or low speed, common during engine start/stop cycles.

- Elastohydrodynamic Lubrication: Occurs in rolling or sliding contacts, such as gears, where elastic deformation affects the oil film.

The main engine typically has three separate systems: the main lubricating oil system, the cylinder oil system, and the turbocharger lubricating oil system, each requiring specific maintenance protocols.

Daily Maintenance Procedures

Daily checks are the first line of defense in maintaining the lubricating oil system. These tasks ensure the system operates within safe parameters and catch issues early.

Oil Level Check

- Procedure: Use the dipstick or level gauge on the sump tank to verify the oil level is within the manufacturer’s specified range. For Cummins QSC 8.3 and QSL 9 engines, the sump capacity is approximately 18.9–22.7 liters.

- Frequency: Daily, before starting the engine.

- Tip: Top off with the recommended oil (e.g., 15W-40 API CJ-4) if levels are low, but avoid overfilling, which can cause pressure buildup and leaks.

Oil Quality Inspection

- Procedure: Visually inspect oil samples for water, metal particles, or discoloration. Send samples for laboratory analysis every 500 hours to assess viscosity, Total Base Number (TBN), and contamination levels.

- Key Metrics:

- Viscosity: Should remain within manufacturer-specified limits (e.g., 12.5–16.3 cSt at 100°C for 15W-40 oil).

- TBN: Must neutralize acidic combustion byproducts, typically 10–20 mg KOH/g for high-sulfur fuels.

- Flash Point: Should stay above 200°C to avoid fuel contamination.

- Tip: Use a test kit for onboard analysis if lab facilities are unavailable.

Oil Leak Detection

- Procedure: Inspect the sump, oil pan, valve covers, and piping for wet spots or puddles. Use UV dye or pressure testing for hard-to-detect leaks.

- Common Leak Points: Valve cover gaskets, oil pan seals, and oil cooler connections.

- Tip: Address leaks immediately to prevent oil loss and environmental hazards.

Oil Pressure and Temperature Monitoring

- Procedure: Use gauges to verify oil pressure (30–40 psi at operating temperature for Cummins engines) and temperature (90–95°C for purifier operation, 45°C at engine inlet).

- Indicators of Issues:

- Low pressure: Blocked filters or failing pump.

- High temperature: Malfunctioning cooler or thermostatic valve.

- Tip: Log readings daily to identify trends or deviations.

Scheduled Maintenance Tasks

Scheduled maintenance ensures long-term reliability and prevents gradual degradation of the lubricating oil system.

Oil and Filter Changes

- Frequency:

- Standard Oil (15W-40): Every 250 hours or 6,000–10,000 miles.

- Synthetic Oil (5W-40): Every 500 hours.

- Severe Duty: Every 200 hours.

- Procedure:

- Drain old oil from the sump.

- Remove the oil filter using a wrench.

- Apply fresh oil to the new filter’s gasket and install it.

- Refill with the correct oil type and quantity (e.g., 18.9 liters for QSC 8.3).

- Run the engine and check for leaks.

- Cost: Approximately $50–$100 for oil and filter, depending on brand and region.

Oil Cooler Maintenance

- Procedure: Clean or replace the oil cooler every 1,000 hours to ensure efficient heat transfer. Inspect for corrosion or blockages.

- Tip: Use a low-temperature freshwater system to cool the plate-type cooler, maintaining 45°C at the engine inlet.

Oil Purifier Maintenance

- Procedure:

- Set the purifier’s gravity disc per the manufacturer’s manual.

- Operate at 90–95°C for optimal separation of water and sludge.

- Adjust sludge discharge intervals based on oil contamination levels.

- Inspect the bowl regularly to prevent overflow.

- Frequency: Clean every 500–1,000 hours or as indicated by oil analysis.

- Tip: Circulate the oil 4–5 times every 24 hours through the purifier.

Centrifugal Bypass Strainer Cleaning

Automatic Backwashing Filter Maintenance

- Procedure:

- Check the revolution indicator and differential pressure gauge daily.

- If the gauge shows red, drain the filter and soak the strainer in cleaning fluid for 24 hours.

- Clean with high-pressure hot water or compressed air.

- Inspect for damage and replace worn elements.

- Frequency: Clean every 500 hours or when indicated by the gauge.

- Tip: Ensure gears re-engage properly during reassembly.

Advanced Maintenance Techniques

Oil Analysis

Regular oil analysis provides insights into engine health:

- Viscosity: Indicates oil degradation or fuel contamination.

- TBN: Measures the oil’s ability to neutralize acids.

- Metal Particles: Suggests internal wear (e.g., iron from bearings, aluminum from pistons).

- Water Content: Indicates leaks or condensation.

- Frequency: Every 500 hours or after significant operational changes.

- Cost: $20–$50 per sample, depending on the lab.

Adjusting Oil Pressure and Temperature

- Pressure Adjustment:

- Remove the cap nut and loosen the lock nut.

- Turn the regulating screw to adjust pressure.

- Tighten the lock nut and replace the cap nut.

- Temperature Adjustment:

- Remove the cap nut.

- Adjust the thermostatic valve bolt to set the desired temperature.

- Secure all components.

- Tip: Always refer to the engine manual for specific settings (e.g., 30–40 psi for Cummins engines).

Oil Pump Servicing

- Procedure:

- Drain the oil and remove the oil pan.

- Inspect the pickup tube for blockages.

- Check gear clearance and relief valve function.

- Replace worn components and reassemble.

- Frequency: Every 2,000 hours or during major overhauls.

- Cost: $200–$500 for parts and labor.

Troubleshooting Common Issues

Low Oil Pressure

- Causes: Clogged filters, failing pump, or leaks.

- Solution: Inspect filters and pump, replace if necessary, and fix leaks.

High Oil Temperature

- Causes: Blocked cooler, thermostatic valve failure, or low coolant flow.

- Solution: Clean or replace the cooler, adjust the valve, and check the freshwater system.

Oil Leaks

- Common Sources:

- Worn gaskets (valve cover, oil pan).

- Damaged oil cooler or lines.

- Loose drain plug.

- Solution:

- Replace gaskets or seals ($10–$50 per gasket).

- Tighten or replace the drain plug with a new crush washer.

- Repair or replace the oil cooler ($100–$300).

Sludge Buildup

- Causes: Infrequent oil changes or purifier neglect.

- Solution: Increase oil change frequency and clean the purifier regularly.

Real-World Example: The Cost of Neglect

A bulk carrier in the Indian Ocean faced a critical engine failure due to low oil pressure caused by a clogged bypass strainer. The crew had skipped weekly cleaning to meet tight schedules, leading to a forced shutdown and a two-day delay for repairs. The financial impact was over USD 60,000, highlighting the importance of adhering to maintenance schedules, even under pressure.

Specifications and Costs

| Component | Specification | Maintenance Frequency | Approx. Cost |

|---|---|---|---|

| Engine Oil | 15W-40 API CJ-4 or 5W-40 synthetic | 250–500 hours | $50–$100 |

| Oil Filter | Cummins-specified, 10–20 µm filtration | 250–500 hours | $10–$30 |

| Oil Pump | Gear-driven, 30–40 psi | 2,000 hours | $200–$500 |

| Oil Cooler | Plate-type, 45°C outlet | 1,000 hours | $100–$300 |

| Purifier | 90–95°C operation | 500–1,000 hours | $50–$150 (service) |

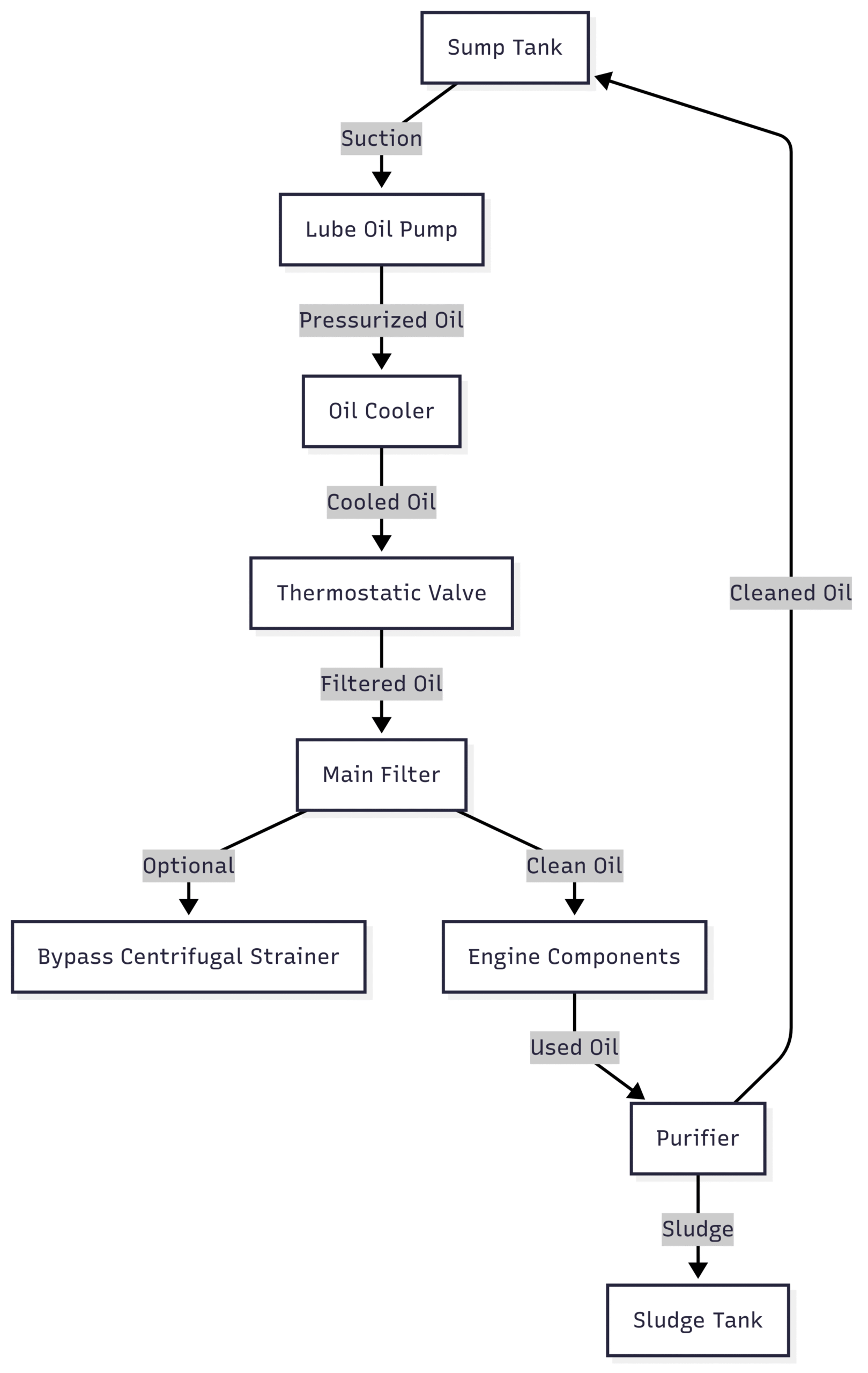

Chart: Lubricating Oil System Flow

This chart illustrates the flow of oil through the lubricating system, highlighting the roles of the pump, cooler, filters, and purifier.

FAQ: Common Questions

How often should lube oil be changed?

Follow manufacturer guidelines, typically every 250–500 hours, based on oil type and operating conditions.

Can cleaned lube oil be reused?

Yes, if purified and tested to ensure no contaminants remain.

What’s the difference between a bypass strainer and a main filter?

The main filter handles all oil flow, while the bypass strainer filters a portion to remove fine particles.

Why is the purifier set at 90–95°C?

This temperature optimizes viscosity for effective separation of water and sludge.

How do I detect system issues early?

Monitor pressure drops, unusual noises, high temperatures, or red indicators on filters.

Best Practices for Optimal Performance

- Use Manufacturer-Recommended Oil: Stick to 15W-40 or 5W-40 for Cummins engines to ensure compatibility.

- Maintain a Maintenance Log: Track oil changes, filter replacements, and analysis results to identify trends.

- Train Crew: Ensure all personnel understand maintenance procedures and safety protocols.

- Comply with Regulations: Regular maintenance ensures compliance with environmental and safety standards, such as MARPOL.

- Invest in Quality Components: Use OEM filters and parts to avoid premature wear.

Conclusion

Maintaining the lubricating oil system in marine diesel engine generators, such as the Cummins QSC 8.3 and QSL 9, is critical for ensuring reliability, efficiency, and compliance in maritime operations. By adhering to daily checks, scheduled maintenance, and advanced troubleshooting, operators can prevent costly failures and extend engine life. From monitoring oil pressure to cleaning purifiers and replacing filters, every step plays a vital role in keeping the engine running smoothly. With proper care, the lubricating oil system becomes a safeguard against downtime, protecting both the vessel and its crew.

Happy Boating!

Share Maintenance of Lubricating Oil Systems in Marine Diesel Engine Generators with your friends and leave a comment below with your thoughts.

Read Turbocharger Cleaning & Maintenance for Marine Diesel Generators until we meet in the next article.