Optimize your marine diesel generator with our expert guide on turbocharger cleaning and maintenance. Learn essential procedures, safety tips, and global best practices.

Marine diesel generators are the backbone of a vessel’s power supply, and their turbochargers play a critical role in ensuring efficiency and performance. A turbocharger increases engine power by forcing more air into the combustion chamber, but without regular cleaning and maintenance, soot, carbon deposits, and operational inefficiencies can lead to reduced performance, higher fuel consumption, and costly breakdowns. This comprehensive guide provides marine engineers, officers of the watch (OOW), and vessel operators with detailed procedures, best practices, and technical insights for maintaining turbochargers on marine diesel generators. From daily blower washing to periodic turbine cleaning and overhauls, we cover everything you need to keep your turbocharger—and your vessel—running smoothly.

Why Turbocharger Maintenance Matters

A turbocharger is a forced-induction device that enhances engine efficiency by compressing intake air, allowing more fuel to be burned and increasing power output. In marine diesel generators, turbochargers operate under harsh conditions, handling high temperatures, pressures, and exhaust gases laden with soot and carbon. Neglecting maintenance can result in:

- Reduced Efficiency: Soot and carbon buildup on the compressor or turbine sides restrict airflow, lowering boost pressure and engine power.

- Increased Fuel Consumption: A dirty turbocharger forces the engine to work harder, burning more fuel.

- Mechanical Failure: Accumulated deposits can cause imbalance, vibration, or bearing damage, leading to costly repairs.

- Operational Downtime: Turbocharger failure at sea can halt power generation, jeopardizing vessel schedules and safety.

A real-world example underscores the importance of maintenance: a reefer vessel suffered turbocharger over-speeding and engine derating due to soot accumulation from skipped turbine cleanings. The repairs cost over $25,000 and delayed operations. Regular maintenance could have prevented this.

This guide outlines daily, weekly, and periodic maintenance procedures, operational best practices, and overhaul protocols to ensure your turbocharger remains in peak condition.

Daily and Weekly Turbocharger Maintenance

Daily Blower Washing

Daily blower washing removes light soot, dust, and oil residue from the compressor side of the turbocharger, ensuring optimal airflow. This procedure is typically performed while the engine is running at a steady load, as the high airflow helps dislodge contaminants.

Procedure:

- Prepare a cleaning solution as recommended by the turbocharger manufacturer (e.g., MAN, ABB, Mitsubishi). Common solutions include water with a mild detergent, such as Yanmar’s YF-2 cleaner or a 1:32 ratio of dish soap to water.

- Open the blower washing valve, typically located near the air intake.

- Use a hand pump or garden sprayer to inject the cleaning solution into the compressor side for 5–10 seconds.

- Allow the solution to flow through the system, cleaning the compressor blades.

- Close the valve and monitor engine parameters, ensuring no fluctuations in boost pressure or turbocharger RPM.

- Avoid starting or stopping the engine during cleaning to prevent thermal shock or residue buildup.

Key Checks:

- Boost Air Temperature: Ensure it remains below 200°C or within manufacturer-specified limits.

- Boost Air Pressure: Compare against baseline engine parameters to confirm effective cleaning.

Weekly Blower Washing

Weekly washing targets heavier deposits that daily cleaning may miss. The process is similar to daily washing but may involve a stronger cleaning solution or a larger volume.

Procedure:

- Follow the same steps as daily washing, but consult the manufacturer for specific solution strength or duration.

- Inject the solution for a slightly longer period (10–15 seconds) to tackle stubborn buildup.

- Monitor exhaust smoke after cleaning. White or black smoke may indicate incomplete cleaning or other issues.

- Log the cleaning session in the engine room logbook for compliance and tracking.

Best Practices:

- Use only manufacturer-approved cleaning agents to avoid damaging compressor blades.

- Wear personal protective equipment (PPE), including gloves, goggles, and masks, to comply with STCW/IMO safety protocols.

- Maintain a steady engine load during cleaning to ensure consistent airflow.

Periodic Maintenance: Turbine Side Cleaning

The turbine side of the turbocharger, exposed to hot exhaust gases, is prone to heavy carbon and soot accumulation. Cleaning every 200–250 operating hours prevents backpressure, surging, and potential blade damage.

Turbine Side Cleaning Procedure

- Preparation:

- Allow the engine to cool down to avoid thermal shock.

- Isolate and secure the turbocharger to prevent accidental operation.

- Verify oil pressure and turbocharger RPM before starting.

- Cleaning:

- Open the turbine washing valve, typically located near the exhaust manifold.

- Inject hot fresh water (around 60–70°C) or a manufacturer-approved cleaning agent using a hand pump.

- Allow the turbine to spin freely, distributing the solution across the blades.

- Continue washing until clean water drains from the system, indicating the removal of deposits.

- Drain residual fluid and close the valve.

- Post-Cleaning Checks:

- Monitor boost air temperature and pressure to ensure normal operation.

- Check turbocharger RPM for stability.

- Inspect the exhaust for smoke or unusual odors, which may indicate incomplete cleaning or other issues.

Safety Notes:

- Always use approved cleaning agents to prevent corrosion or blade damage.

- Follow manufacturer guidelines for water temperature and pressure (typically around 1 bar).

- Ensure the drain valve remains open during cleaning to prevent water accumulation.

Alternative: Grit Washing (Dry Cleaning)

Grit washing, or dry cleaning, uses solid granules (e.g., walnut shells, 12–34 mesh) to clean the turbine side without reducing engine speed. This method is ideal for vessels that cannot afford downtime.

Procedure:

- Inject granules into the exhaust system using compressed air (3–5 bar) at the same point as water washing.

- Keep the turbine casing drain open during the 2-minute cleaning process.

- Monitor turbocharger performance post-cleaning, checking for vibration or abnormal noise.

Advantages:

- No need to reduce engine RPM, minimizing impact on voyage schedules.

- No water use, eliminating corrosion or thermal stress risks.

- Effectively removes hard deposits and combustion residues.

Disadvantages:

- Requires specialized equipment and granules, which may not be available on all vessels.

- Improper execution can damage turbine blades if granules are too abrasive.

Turbocharger Overhaul: Step-by-Step Guide

Turbocharger overhauls are performed as part of planned maintenance, typically every 8,000–12,000 operating hours or as specified by the manufacturer. Overhauls restore the turbocharger to near-new condition, addressing wear and tear on bearings, seals, and rotating components.

Overhaul Procedure

- Preparation:

- Lock off the engine starting mechanism to ensure safety.

- Drain oil from both drain plugs and remove the turbocharger air filter.

- Remove bearing covers and locking wires from both sides.

- Disassembly:

- Unscrew hexagon screws and remove oil suction pipes.

- Tighten bearing box screws to secure the assembly.

- Use a pick tester and magnet stand to measure the deflection of the divergent nozzle.

- Remove the divergent nozzle using a screwdriver.

- Measure the K value (axial clearance) at the blower side using a depth micrometer or caliper.

- Lock the rotor with a special tool and extract the lubricating disc and bearings using a bearing extractor.

- Wrap disassembled parts in waxed paper to protect against dirt and moisture.

- Inspection and Cleaning:

- Check the divergent nozzle deflection and K value.

- Clean the blower and turbine sides with chemical cleaners and inspect for wear or damage.

- Verify the labyrinth seal and clear its air line.

- Inspect the casing for cracks or wear and check blade condition.

- Measure impeller and casing clearances.

- Reassembly:

- Replace bearings with new ones, as their service life typically aligns with overhaul intervals.

- Reassemble components, ensuring proper alignment and torque settings.

- Perform static balance checks and verify impeller and casing clearances.

Key Measurements During Overhaul

| Measurement | Method | Typical Range |

|---|---|---|

| Axial Clearance (K Value) | Depth gauge or caliper | 0.2–0.3 mm |

| Radial Clearance | Dial gauge, lifting shaft radially | 0.15–0.2 mm |

| Rotor and Casing Clearance | Caliper or micrometer | Manufacturer-specified |

When to Replace Bearings:

- As per running hours (aligned with overhaul schedule).

- If clearance exceeds manufacturer limits.

- When bearings are damaged or cause heavy vibration.

Operational Best Practices

Beyond cleaning and overhauls, operational practices significantly impact turbocharger longevity.

- Warm-Up and Cool-Down:

- Warm up the engine gradually before applying high loads to prevent thermal stress.

- Idle the engine for 2–5 minutes before shutdown to allow the turbocharger to cool, reducing oil coking.

- Lubrication Management:

- Follow recommended oil change intervals and use the correct oil grade.

- Ensure oil is clean and free of contaminants to prevent bearing wear.

- Verify adequate oil pressure and flow to avoid oil starvation.

- Address oil leaks promptly to prevent fires or turbocharger failure.

- System Monitoring:

- Regularly check intake filters and replace or clean them to prevent debris ingress.

- Monitor boost pressure, exhaust temperatures, and turbocharger RPM for anomalies.

- Address excessive vibration immediately to prevent damage.

- Fuel and Coolant Systems:

- Maintain clean fuel and proper fuel pressure to avoid injector clogs, which can cause uneven combustion.

- Keep coolant levels topped up and the system clean to prevent overheating.

Common Turbocharger Issues and Solutions

| Issue | Symptoms | Solution |

|---|---|---|

| Soot Buildup | Reduced boost, high fuel consumption | Perform regular blower and turbine washing |

| Oil Leaks | Oil in air or exhaust system, high exhaust temp | Inspect seals, repair leaks, clean system |

| Vibration | Abnormal noise, reduced performance | Check bearings, balance rotor, inspect blades |

| Surging | Howling noise, fluctuating RPM | Clean turbine, check air intake for blockages |

| Over-Speeding | High RPM, engine derating | Clean turbine, ensure proper fuel distribution |

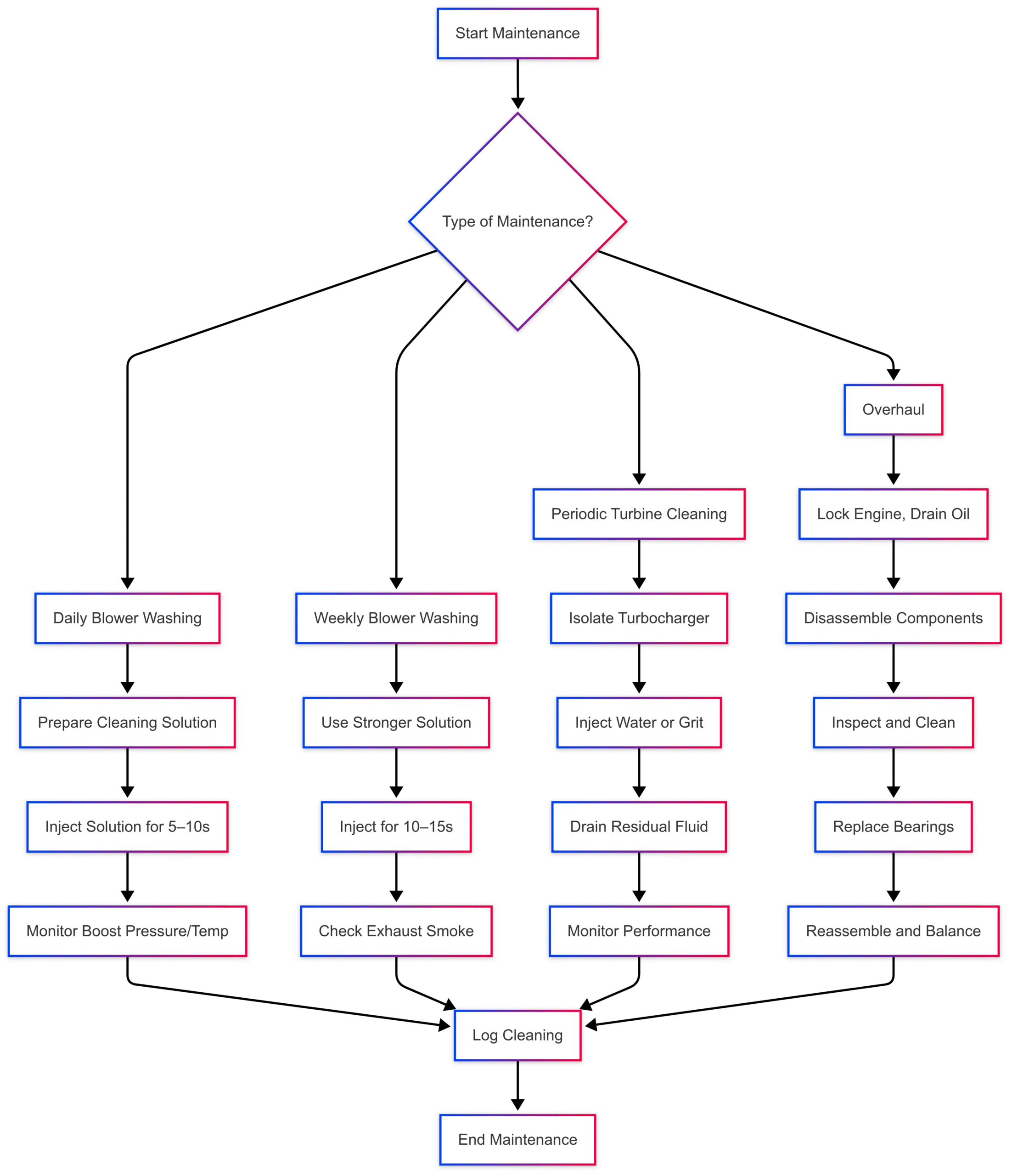

Chart: Turbocharger Maintenance Workflow

Below is a visual representation of the turbocharger maintenance process using a flowchart.

Turbocharger Specifications and Costs

Turbochargers vary by manufacturer and engine type. Below is a table of common marine turbocharger brands and their approximate costs for new and refurbished units (based on industry standards, as specific pricing requires consultation with suppliers).

| Brand | Model Example | Power Range | New Price (USD) | Refurbished Price (USD) |

|---|---|---|---|---|

| MAN | TCR Series | 500–5,000 kW | $15,000–$50,000 | $8,000–$25,000 |

| ABB | A100 Series | 300–6,000 kW | $12,000–$45,000 | $6,000–$20,000 |

| Mitsubishi | MET Series | 400–7,000 kW | $18,000–$60,000 | $10,000–$30,000 |

| BorgWarner | EFR Series | 200–2,000 kW | $10,000–$30,000 | $5,000–$15,000 |

Note: For exact pricing, contact suppliers like Ababil Marine.

FAQs: Turbocharger Maintenance

Can I clean the turbocharger while the engine is running?

Yes, blower side cleaning is designed for running conditions. Turbine side cleaning typically requires engine shutdown or reduced RPM.

What cleaning solution should I use?

Use manufacturer-approved solutions (e.g., Yanmar YF-2, MAN-recommended cleaners). Avoid unapproved chemicals to prevent damage.

How do I know if my turbocharger is dirty?

Signs include increased fuel consumption, reduced power, high exhaust temperatures, or black/white smoke.

Can I skip weekly cleaning if daily washing is done?

No. Daily washing removes light particles, while weekly cleaning addresses heavier buildup.

Is high-pressure air enough for cleaning?

No. High-pressure air can damage turbo components. Use approved liquids or grit washing.

Conclusion: A Clean Turbocharger for Reliable Operation

Regular turbocharger maintenance is essential for the efficiency, reliability, and safety of marine diesel generators. By implementing daily blower washing, weekly cleaning, periodic turbine washing, and scheduled overhauls, you can prevent performance losses, reduce fuel consumption, and avoid costly repairs. Adhering to manufacturer guidelines, monitoring key parameters, and following operational best practices will extend the life of your turbocharger and keep your vessel compliant with international standards.

Whether you’re a seasoned marine engineer or a new engine cadet, this guide equips you with the knowledge and procedures to maintain your turbocharger effectively. A clean turbocharger ensures your marine diesel generator delivers the power your vessel needs to stay on course.

Happy Boating!

Share Turbocharger Cleaning & Maintenance for Marine Diesel Generators with your friends and leave a comment below with your thoughts.

Read Marine Diesel Engine Maintenance And Cooling Systems until we meet in the next article.