Explore SOLAS requirements for ship steering gear systems, including main and auxiliary gear, performance standards, testing, and compliance for safe navigation.

Steering gear systems are the backbone of a ship’s navigational control, enabling precise direction changes and ensuring safe operation in diverse maritime conditions. The International Convention for the Safety of Life at Sea (SOLAS), governed by the International Maritime Organization (IMO), establishes stringent regulations to ensure these systems are robust, reliable, and capable of performing under demanding scenarios. This article provides a comprehensive overview of SOLAS requirements for steering gear systems, covering their design, performance standards, redundancy, testing protocols, and compliance challenges. By adhering to these standards, ship operators can mitigate risks, ensure crew safety, and maintain operational efficiency.

Importance of Steering Gear Systems

The steering gear is a critical component of a vessel’s safety and navigational framework. A failure in this system can lead to catastrophic consequences, especially in congested waterways, adverse weather, or emergency situations. SOLAS Chapter II-1 (Construction – Structure, Subdivision, Stability, Machinery, and Electrical Installations) and Chapter V (Safety of Navigation) outline detailed requirements to ensure steering gear reliability. These regulations apply to all seagoing vessels, with specific provisions for tankers, chemical carriers, gas carriers, and passenger ships.

The primary objectives of SOLAS steering gear requirements are:

- Ensuring rapid and precise rudder control at maximum service speeds.

- Providing redundancy to maintain steering capability during system failures.

- Mandating regular testing and crew training to ensure operational readiness.

- Incorporating alarms and indicators for early detection of faults.

Types of Steering Gear Systems

Steering gear systems vary based on vessel size, type, and operational needs. Understanding these systems is essential for appreciating SOLAS requirements:

- Ram-Type Steering Gear

This system uses hydraulic rams connected to a tiller or quadrant to turn the rudder. It is robust and widely used in large commercial vessels due to its reliability and ability to handle high torque. - Rotary Vane Steering Gear

A compact system where hydraulic pressure acts on vanes within a housing to rotate the rudder stock. It is quieter, space-efficient, and common in modern vessels. - Electro-Hydraulic Steering Gear

Combines electric motors with hydraulic pumps for precise control. It is prevalent in vessels requiring responsive steering, such as passenger ships and offshore vessels. - Mechanical Steering Gear

Found in smaller vessels, this system uses cables or rods for direct mechanical linkage between the steering wheel and rudder. It is less common in SOLAS-regulated ships due to its limited scalability.

Each system must comply with SOLAS performance and redundancy standards, which we’ll explore in detail.

SOLAS Steering Gear Requirements

SOLAS Chapter II-1, Regulations 29 and 30, and Chapter V, Regulation 26, provide the statutory framework for steering gear systems. These regulations ensure that ships are equipped with reliable main and auxiliary steering gears, robust power systems, and effective control mechanisms.

1. Main and Auxiliary Steering Gear

Requirement: Every ship of 100 gross tons and above, and all passenger ships, must have a main steering gear and an auxiliary steering gear, unless otherwise specified. The systems must be arranged so that the failure of one does not render the other inoperative.

- Main Steering Gear:

- Must be capable of turning the rudder from 35° on one side to 30° on the other in no more than 28 seconds at the ship’s maximum ahead service speed and deepest seagoing draught.

- Must withstand maximum astern speed without damage.

- Requires sufficient strength to handle rudder torque under all operational conditions.

- Auxiliary Steering Gear:

- Must turn the rudder from 15° on one side to 15° on the other in no more than 60 seconds at half the maximum ahead service speed or 7 knots, whichever is greater.

- Must be deployable quickly in emergencies.

- Can be omitted in ships with two or more identical main steering gear power units, provided they meet redundancy criteria.

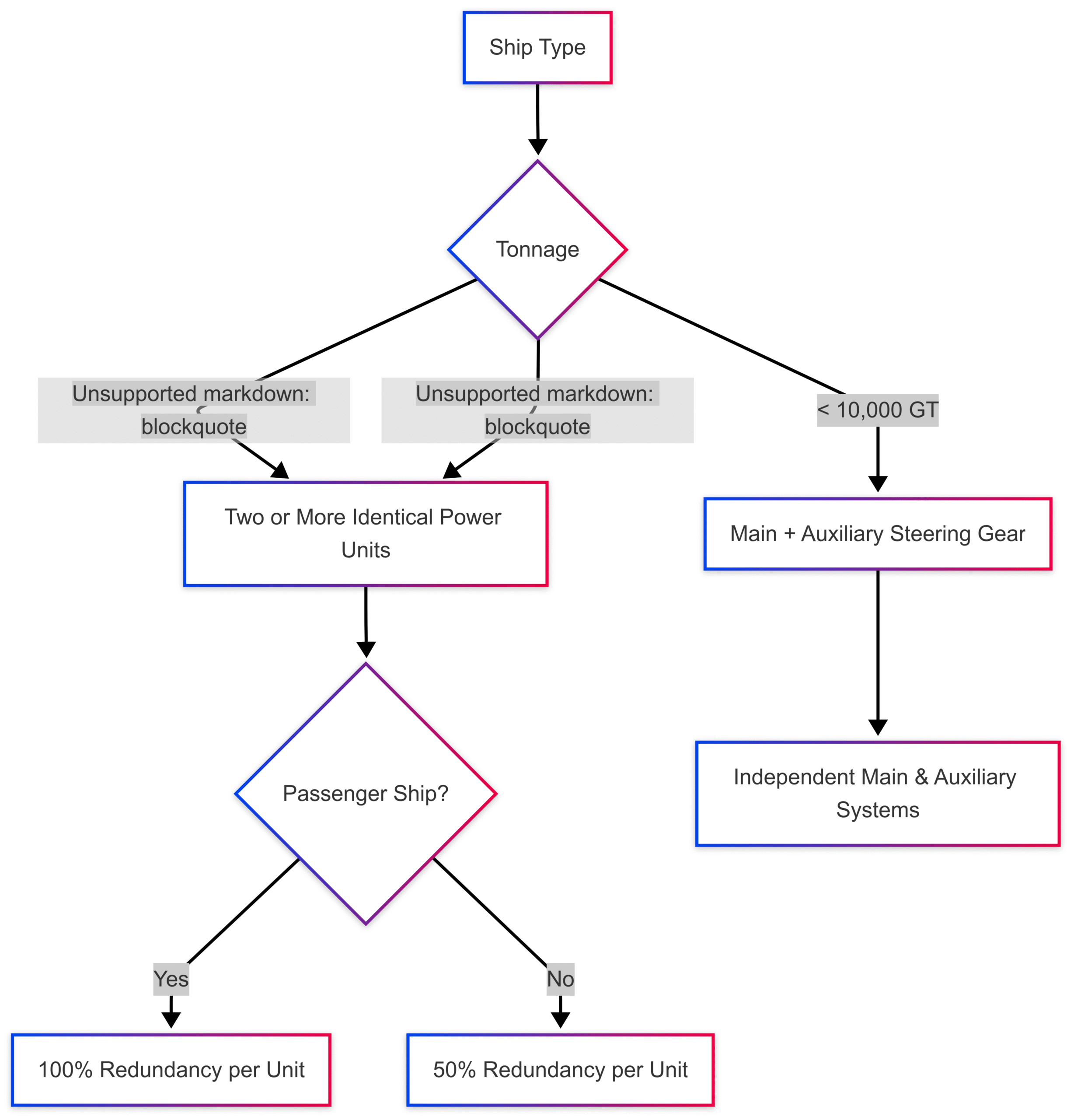

Special Provisions for Tankers and Large Vessels:

- For tankers, chemical tankers, or gas carriers of 10,000 gross tonnage and above, and other ships of 70,000 gross tonnage and above, the main steering gear must comprise two or more identical power units.

- In passenger ships, each power unit must provide 100% redundancy, ensuring steering capability even if one unit fails.

- In cargo ships, each unit must provide 50% redundancy, allowing operation with all units active.

- For tankers between 10,000 and 100,000 deadweight tons, steering capability must be regained within 45 seconds after a single failure in the piping or power unit.

Chart: Steering Gear Redundancy Requirements

2. Power and Hydraulic Systems

Power Units:

- The main and auxiliary steering gears must have independent power sources.

- For ships with a rudder stock diameter exceeding 230 mm (excluding ice-strengthening), an alternative power supply (e.g., emergency generator) must be available, capable of powering the auxiliary steering gear or one main steering gear unit, along with its control system and rudder angle indicator, within 45 seconds.

- For ships of 10,000 gross tonnage and above, the alternative power supply must support at least 30 minutes of continuous operation; for smaller ships, at least 10 minutes.

Hydraulic Systems:

- Hydraulic power-operated steering gears must include:

- Two independent pumps, each capable of operating the system.

- A fixed storage tank with sufficient capacity to recharge at least one power actuating system, including the reservoir.

- Low-level alarms for hydraulic fluid reservoirs, with audible and visual alerts on the bridge and engine control room (ECR).

- Isolation valves to separate defective systems without draining fluid.

- The design pressure for hydraulic components must be at least 1.25 times the maximum working pressure under operational conditions.

3. Control Systems

Bridge and Local Control:

- The main steering gear must be controllable from both the navigation bridge and the steering gear compartment.

- The auxiliary steering gear must be controllable from the steering gear compartment, with bridge control if power-operated.

- Bridge control systems must:

- Be powered by a separate circuit from the steering gear compartment or main switchboard.

- Include a mechanism to disconnect bridge control from the steering gear compartment.

- Trigger audible and visual alarms on the bridge in case of power or control system failure.

- Communication systems must be provided between the bridge and steering gear compartment.

Rudder Angle Indication:

- The rudder’s position must be displayed on the bridge and in the steering gear compartment, independent of the control system.

- Rudder angle limiters (e.g., limit switches) must prevent the gear from exceeding mechanical stops.

4. Alarms and Protection

- Power Failure Alarms: Audible and visual alarms must activate on the bridge and ECR upon failure of the electrical power supply or control system.

- Short Circuit and Overload Protection: Required for steering gear motors, with protection set at not less than twice the full load current to accommodate starting currents.

- Phase Failure Alarms: For three-phase systems, alarms must indicate failure of any supply phase.

- Hydraulic Fluid Monitoring: Low-level alarms must detect fluid leakage early.

Table: Key SOLAS Steering Gear Specifications

| Component | Requirement |

|---|---|

| Main Steering Gear | Rudder movement: 35° to 30° in ≤ 28 seconds at max service speed |

| Auxiliary Steering Gear | Rudder movement: 15° to 15° in ≤ 60 seconds at half max speed or 7 knots |

| Power Supply | At least two independent sources; emergency supply for rudder stock > 230 mm |

| Hydraulic System | Two pumps, low-level alarms, fixed storage tank, isolation valves |

| Control System | Bridge and local control, independent circuits, alarms for power/control failure |

| Rudder Angle Indicator | Independent display on bridge and steering gear compartment |

Testing and Drills

SOLAS mandates rigorous testing and drills to ensure steering gear reliability and crew preparedness. These requirements are outlined in Chapter V, Regulation 26.

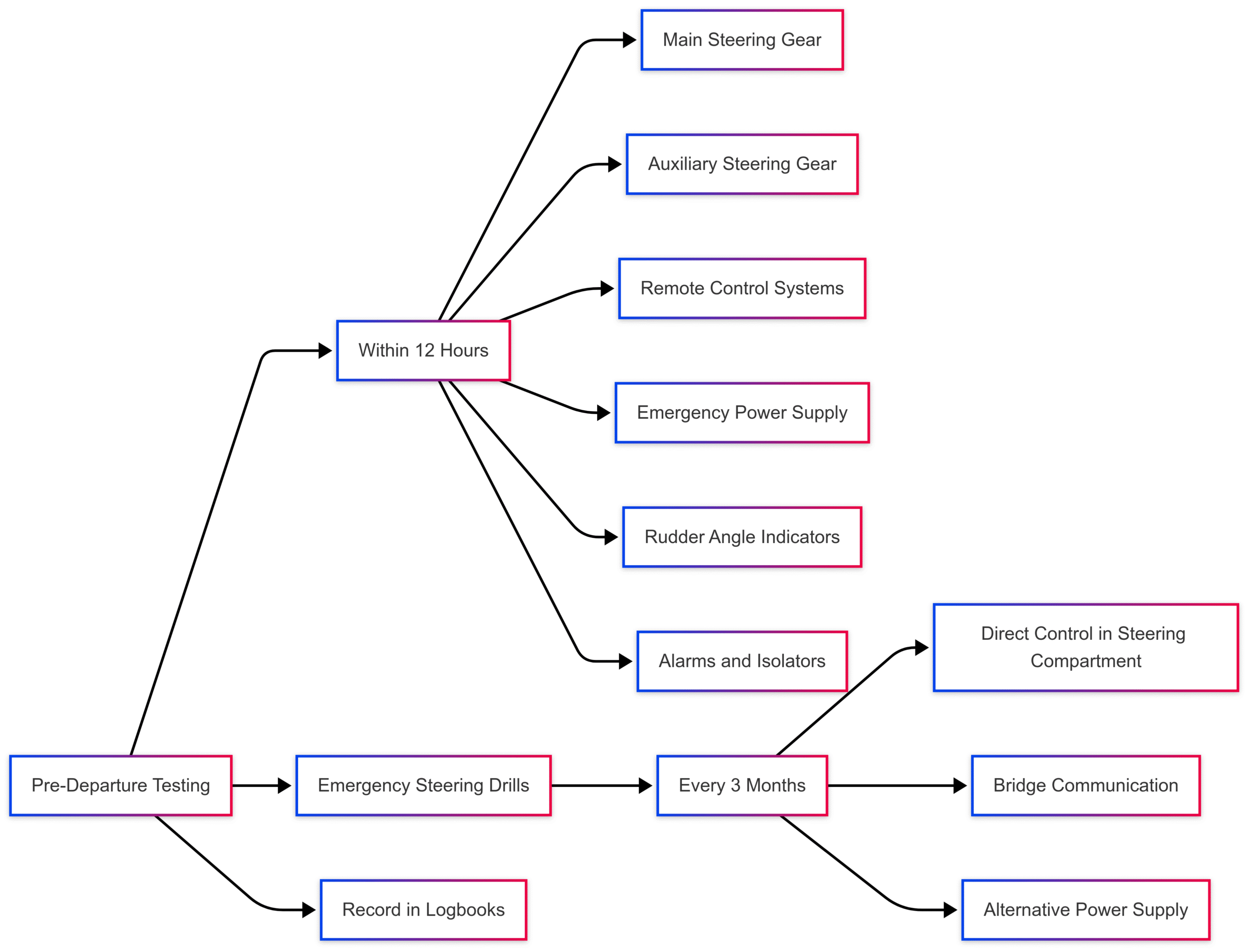

Pre-Departure Testing

Within 12 hours before departure, the following must be tested:

- Main and auxiliary steering gears.

- Remote steering gear control systems.

- Bridge steering positions.

- Emergency power supply.

- Rudder angle indicators.

- Power unit and control system failure alarms.

- Automatic isolating arrangements.

Note: For ships on short voyages, flag states may waive pre-departure testing, provided checks are conducted weekly.

Emergency Steering Drills

- Conducted at least once every three months.

- Include direct control from the steering gear compartment, communication with the bridge, and operation of alternative power supplies.

- Dates and details must be recorded in logbooks.

Visual Inspections and Communications

- Verify full rudder movement per SOLAS performance standards.

- Inspect steering gear linkages for wear or damage.

- Test communication systems between the bridge and steering gear compartment.

Chart: Steering Gear Testing Workflow

Amendments and Updates to SOLAS

SOLAS steering gear regulations have evolved to address technological advancements and operational needs:

- IMO Resolution MSC.137(76): Introduced stricter testing and documentation protocols.

- SOLAS 2000 and 2004 Amendments: Emphasized automatic isolation of failed components and mandatory rudder order indicators.

- SOLAS 2020 Updates: Added requirements for electrically-propelled steering systems and enhanced sensor diagnostics.

These updates ensure that steering gear systems remain reliable as ships adopt advanced technologies.

Classification Society Integration

Classification societies like DNV, Lloyd’s Register, and ABS supplement SOLAS with stricter standards, including:

- Detailed load calculations for rudder torque.

- Failure mode and effects analysis (FMEA).

- Endurance and shock testing for naval vessels.

- Integration with dynamic positioning (DP) systems for offshore vessels.

Compliance with both SOLAS and class rules is necessary for vessel certification and insurance.

Compliance Challenges and PSC Deficiencies

Non-compliance with SOLAS steering gear requirements is a common reason for Port State Control (PSC) detentions. Frequent deficiencies include:

- Inoperative alarms or rudder angle indicators.

- Leaking hydraulic lines or low fluid levels.

- Incomplete testing records or logbooks.

- Crew unfamiliarity with emergency steering procedures.

- Delayed switching to auxiliary power.

Table: Common PSC Deficiencies and Solutions

| Deficiency | Solution |

|---|---|

| Inoperative Alarms | Regular testing and maintenance of alarm systems |

| Hydraulic Leaks | Routine inspection of hydraulic lines and seals |

| Incomplete Logbooks | Implement structured logging and crew training |

| Crew Unfamiliarity | Conduct regular emergency steering drills and training |

| Delayed Auxiliary Power Switch | Test automatic changeover systems and ensure crew proficiency |

Best Practices for Compliance

To ensure SOLAS compliance and enhance safety:

- Log all tests and drills in engine and bridge logbooks.

- Train deck and engine officers on emergency procedures.

- Conduct joint drills between bridge and steering gear teams.

- Regularly inspect and replace hydraulic oil filters.

- Use condition-monitoring sensors for early fault detection.

- Follow class-approved maintenance schedules.

- Display manual override instructions in the steering gear compartment.

Future Trends in Steering Gear Technology

Advancements in maritime technology are transforming steering gear systems:

- Condition-Based Maintenance (CBM): IoT sensors monitor system health in real-time.

- AI-Driven Diagnostics: Predictive alerts for potential failures.

- Digital Twins: Simulate steering gear performance for fault modeling.

- Autonomous Navigation: Integration with self-steering systems.

- Eco-Friendly Hydraulic Fluids: Reduce environmental impact.

These innovations enhance reliability, reduce downtime, and align with global sustainability goals.

Conclusion

Steering gear systems are vital for safe maritime navigation, and SOLAS provides a robust framework to ensure their reliability. By mandating main and auxiliary systems, redundancy, rigorous testing, and crew preparedness, SOLAS minimizes the risk of steering failures. Ship operators must prioritize compliance through regular maintenance, crew training, and adoption of modern technologies. As the maritime industry evolves, staying abreast of SOLAS amendments and emerging trends will ensure vessels remain safe, efficient, and compliant in an increasingly complex navigational environment.

Happy Boating!

Share SOLAS Requirement on steering gear system with your friends and leave a comment below with your thoughts.

Read What is IMO’s Global Integrated Shipping Information System (GISIS)? until we meet in the next article.