Discover if aluminum or fiberglass boats are better for your needs. Compare durability, performance, maintenance, and costs to choose wisely.

Choosing between an aluminum or fiberglass boat is a pivotal decision for any boater, whether you’re an angler chasing bass in shallow rivers, a family seeking weekend adventures, or a coastal cruiser targeting snook and tarpon. Both materials offer distinct advantages and trade-offs, and the “better” choice hinges on your boating needs, budget, and preferences. This comprehensive guide dives into the pros and cons of aluminum and fiberglass boats, evaluates their performance across various conditions, and explores their suitability for saltwater use. With insights from real-world boaters and detailed comparisons, we’ll help you navigate this decision to find the perfect vessel.

Understanding Aluminum Boats

Aluminum boats have long been a staple for anglers and recreational boaters due to their durability, affordability, and lightweight construction. Brands like Lund, Tracker, and Xpress dominate this market, offering models ranging from compact skiffs to tournament-ready bass boats.

Advantages of Aluminum Boats

- Durability and Impact Resistance

Aluminum boats are renowned for their ability to withstand rough conditions. Unlike fiberglass, which can crack under impact, aluminum typically dents or bends, making repairs simpler and less costly. This resilience is ideal for navigating boulder-strewn rivers or rocky lakes, as highlighted by Lund’s claim that their aluminum boats, some over 40 years old, are still in use. - Lightweight Construction

Aluminum boats are significantly lighter than their fiberglass counterparts. For example, a Ranger RT188 (18’8”) weighs approximately 1,200 lbs, compared to a fiberglass Nitro Z18 (18’6”) at around 1,700 lbs. This reduced weight translates to easier towing with smaller vehicles, better fuel efficiency, and enhanced maneuverability in shallow waters. - Affordability

Aluminum boats are generally more budget-friendly. A fully rigged aluminum bass boat like the Ranger RT188 with a 115 HP outboard might cost around $25,000-$30,000, while a comparable fiberglass model like the Phoenix 618 with a 150 HP engine could approach $40,000. Lower purchase prices, combined with reduced fuel and maintenance costs, make aluminum appealing for cost-conscious buyers. - Low Maintenance

Aluminum’s natural corrosion resistance eliminates the need for regular painting or gel coat waxing. Routine cleaning with soap and water, plus periodic inspections for loose fittings, keeps maintenance minimal. This is a significant advantage for busy boaters, like a single parent with limited time for upkeep. - Shallow Water Performance

The lightweight nature of aluminum boats allows them to float in skinny waters, making them ideal for rivers, ponds, or backwaters. Boaters targeting shallow-water species like bass or redfish often prefer aluminum for its ability to access tight spots.

Disadvantages of Aluminum Boats

- Rougher Ride

Aluminum boats can deliver a less smooth ride in choppy conditions compared to fiberglass. Their lighter weight and simpler hull designs contribute to a jarring experience in rough waters, as noted by Reddit user Evodius, who contrasts aluminum’s ride with the smoother feel of fiberglass. - Wind Sensitivity

The lighter weight makes aluminum boats more susceptible to being blown around in strong winds, which can be a challenge for anglers who rely on precise drifting. A robust trolling motor (e.g., Minn Kota Ultrex with 70+ lbs thrust) can mitigate this issue, but it adds to the cost. - Noise

Aluminum boats tend to be noisier, with hulls transmitting more wave slap and vibration. This can spook fish in calm waters, as mentioned by forum user wcffish, who recommends fiberglass for stealthier fishing. - Limited Design Complexity

Aluminum is harder to mold into complex hull shapes, limiting design options compared to fiberglass. Features like integrated livewells, tackle stations, or sleek bow flares are less common in aluminum boats. - Aesthetics

While subjective, many boaters, including Evodius, find fiberglass boats more visually appealing due to their glossy gel coats and customizable designs. Aluminum boats often have a utilitarian look, though brands like Vexus offer more stylish options.

Aluminum Boats in Saltwater

Aluminum boats are viable for saltwater use, particularly in bays, estuaries, and coastal waters, as evidenced by their popularity in areas like Sabine Lake and Western Australia. However, specific considerations are crucial:

- Corrosion Resistance: Aluminum’s natural oxide layer provides corrosion resistance, but prolonged exposure to saltwater, especially when stored in water, requires protective measures. Special bottom paints and sacrificial anodes (zinc or magnesium) are essential to prevent galvanic corrosion, as noted by forum user thataway.

- Trailer Storage: Trailering the boat after each use, as planned by user minimav777 with his Excel Bay Pro 230, minimizes corrosion risks. Regular rinsing with freshwater further protects the hull and hardware.

- Saltwater-Specific Designs: Boats like the Excel Bay Pro 230 or Klamath models are built for saltwater, featuring sealed wiring, tinned electrical components, and robust hulls. However, accessories like cleats or anchor winches must also be saltwater-rated to avoid corrosion, as learned by user scallen2112 after hardware issues on his Tracker.

- Electrolysis Risks: In marinas with faulty electrical systems, aluminum boats are vulnerable to electrolysis, which can cause severe hull damage. Isolation transformers and proper grounding, as suggested by Toudmon, help mitigate this.

With proper care, aluminum boats perform well in saltwater for trailered applications, offering durability and affordability for coastal anglers.

Understanding Fiberglass Boats

Fiberglass boats, favored for their sleek designs and performance, dominate markets for bass boats, center consoles, and family-oriented vessels. Brands like Ranger, Phoenix, and Nitro offer fiberglass models tailored for diverse boating activities.

Advantages of Fiberglass Boats

- Smooth Ride and Stability

Fiberglass boats, due to their heavier construction, provide a smoother ride in choppy waters. The added weight enhances stability, making them ideal for open bays or large lakes. For instance, a Phoenix 721 cuts through wakes effectively, as noted by a Reddit user, offering a stable platform for tournament fishing. - Complex Hull Designs

Fiberglass’s moldability allows for intricate hull shapes, such as variable-degree deadrise, bow flare, or stepped hulls, which improve performance and aesthetics. These designs enable features like integrated fishboxes, livewells, and seating modules, enhancing functionality. - Speed and Power

Fiberglass boats often support larger outboards, delivering higher speeds. A fiberglass Ranger Z185 with a 150 HP engine can reach 60-70 MPH, outpacing a similar-sized aluminum boat with the same power. High-performance models like the Xpress X21 with a 250 HP engine are exceptions, but fiberglass generally leads in speed. - Aesthetic Appeal

The glossy gel coat finish of fiberglass boats, often customizable with vibrant colors, appeals to boaters who value style. This “shiny glitter boat” look, as Evodius describes, is a draw for many. - Low Maintenance (With Caveats)

Fiberglass requires less frequent painting or varnishing than wood but needs periodic waxing to maintain its shine. Its resistance to rot and corrosion simplifies upkeep compared to wooden boats.

Disadvantages of Fiberglass Boats

- Higher Cost

Fiberglass boats are pricier due to complex manufacturing and heavier materials. A Nitro Z18 might cost $35,000-$45,000, significantly more than an aluminum Ranger RT188. Operating costs are also higher due to larger engines and increased fuel consumption. - Complex Repairs

Fiberglass repairs, especially for cracks or stress fractures, are costly and often require professional expertise. Unlike aluminum’s simple dent fixes, fiberglass restoration can involve sanding, patching, and gel coat matching, as noted by Lund. - Heavier Weight

The added weight (e.g., Phoenix 721 at ~1,900 lbs) makes fiberglass boats harder to tow and launch, requiring larger tow vehicles and more effort at ramps. This can be a drawback for solo boaters or those with smaller SUVs. - Impact Vulnerability

Fiberglass is prone to cracking under impact, unlike aluminum’s dent-resistant nature. This makes fiberglass less ideal for rocky or shallow environments. - Maintenance Needs

While generally low-maintenance, fiberglass requires regular waxing to prevent gel coat fading and occasional refinishing for scratches or cracks, adding to long-term costs.

Comparing Aluminum and Fiberglass Boats

To help you decide, let’s compare aluminum and fiberglass across key factors, incorporating real-world insights and specifications.

Durability and Longevity

- Aluminum: Excels in rugged environments due to impact resistance and corrosion-resistant properties. Lund’s aluminum boats withstand decades of use, even in saltwater with proper care.

- Fiberglass: Highly durable with proper maintenance, but vulnerable to impact damage. Gel coat protects against scratches, but cracks require costly repairs.

Winner: Aluminum for rugged use; fiberglass for longevity with meticulous care.

Performance and Handling

- Aluminum: Lightweight and maneuverable, ideal for shallow waters and tight spaces. Rougher ride in choppy conditions.

- Fiberglass: Superior speed, smoother ride, and better handling in rough waters due to weight and hull design. Less agile in skinny waters.

Winner: Fiberglass for open water; aluminum for shallow or calm conditions.

Maintenance

- Aluminum: Minimal upkeep with routine cleaning and corrosion checks. No waxing or gel coat maintenance.

- Fiberglass: Requires waxing, gel coat repairs, and professional fixes for structural damage, increasing long-term costs.

Winner: Aluminum for ease of maintenance.

Cost

| Boat Model | Material | Length | Engine (HP) | Approx. Price (USD) |

|---|---|---|---|---|

| Ranger RT188 | Aluminum | 18’8” | 115 | $25,000-$30,000 |

| Tracker Pro Team 190 | Aluminum | 18’7” | 115 | $22,000-$28,000 |

| Nitro Z18 | Fiberglass | 18’6” | 150 | $35,000-$45,000 |

| Phoenix 618 Pro | Fiberglass | 18’6” | 150 | $38,000-$50,000 |

- Aluminum: Lower purchase price, fuel costs, and maintenance expenses.

- Fiberglass: Higher upfront and operating costs due to larger engines and repair needs.

Winner: Aluminum for budget-conscious buyers.

Saltwater Suitability

- Aluminum: Performs well in saltwater when trailered and maintained with anodes and bottom paint. Vulnerable to electrolysis in marinas.

- Fiberglass: Less prone to electrolysis but requires bottom paint for prolonged saltwater exposure. Heavier weight suits coastal conditions better.

Winner: Tie, depending on storage and maintenance practices.

Aesthetics and Features

- Aluminum: Utilitarian look with fewer integrated features. Modern designs like Vexus improve aesthetics.

- Fiberglass: Sleek, customizable designs with integrated amenities like livewells and tackle storage.

Winner: Fiberglass for style and functionality.

Real-World Boater Insights

Reddit and forum discussions reveal diverse perspectives:

- Tournament Anglers: Users like Evodius and the OP debating Ranger RT188 vs. fiberglass models prioritize speed and ride quality for tournaments, often leaning toward fiberglass for its performance edge. However, aluminum’s affordability and durability appeal to first-time buyers.

- Saltwater Boaters: Forum users like Fishman39 and andosan confirm aluminum’s viability in saltwater, citing its use in Sabine Lake and Australia. Proper maintenance is critical, as scallen2112’s corrosion issues with non-saltwater-rated hardware illustrate.

- Recreational Users: Aluminum’s ease of use and low maintenance resonate with casual boaters, while fiberglass’s stability and family-friendly features attract those planning watersports or overnight trips.

Decision-Making Framework

To choose between aluminum and fiberglass, consider these factors:

- Boating Environment

- Shallow rivers or rocky lakes: Aluminum (e.g., Lund Adventure series).

- Open bays or large lakes: Fiberglass (e.g., Ranger Z-series).

- Budget

- Limited budget: Aluminum for lower purchase and operating costs.

- Higher budget: Fiberglass for premium performance and aesthetics.

- Usage

- Solo fishing or shallow-water access: Aluminum.

- Family outings or watersports: Fiberglass.

- Maintenance Tolerance

- Minimal upkeep: Aluminum.

- Willing to wax and repair: Fiberglass.

- Saltwater Plans

- Trailered coastal use: Either, with proper maintenance.

- Marina storage: Fiberglass to reduce electrolysis risks.

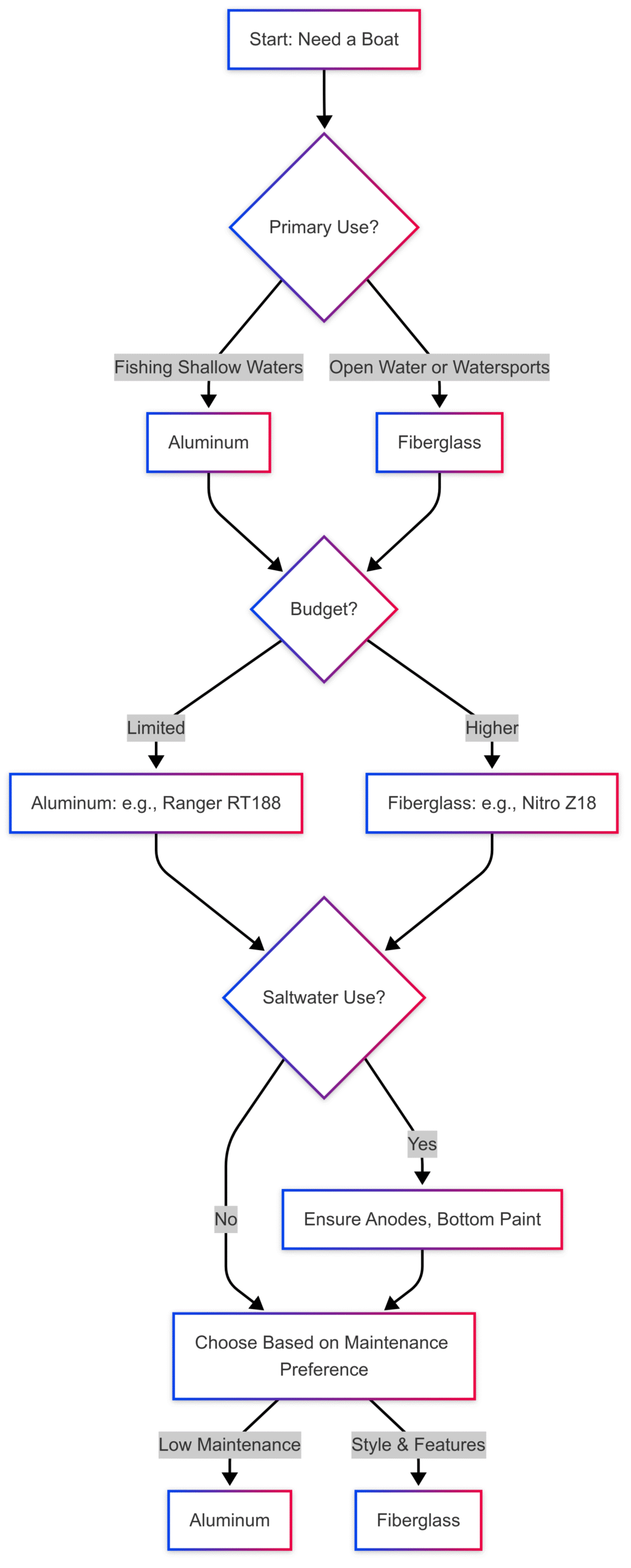

Chart: Decision Flow

Conclusion

Neither aluminum nor fiberglass boats are universally “better”—the right choice depends on your priorities. Aluminum boats shine for budget-conscious anglers, shallow-water adventurers, and those seeking low maintenance and durability. Fiberglass boats excel for speed, stability, and style, catering to tournament anglers, family boaters, and open-water enthusiasts. In saltwater, both materials perform well with proper care, though aluminum requires vigilance against electrolysis.

By assessing your boating environment, budget, and usage, you can confidently select a boat that enhances your time on the water. Whether it’s the rugged reliability of a Lund aluminum skiff or the sleek performance of a Phoenix fiberglass bass boat, your perfect vessel awaits.

Happy Boating!

Share are aluminum boats better than fiberglass with your friends and leave a comment below with your thoughts.

Read Are boat ignition keys unique until we meet in the next article.