Comprehensive guide to the Raritan PHII Rebuild Kit for marine toilet maintenance. Learn features, benefits, and step-by-step rebuild instructions.

Marine sanitation systems are a critical component of any vessel, ensuring hygiene and comfort during your time on the water. For boat owners, maintaining these systems is not just a matter of convenience but a necessity to avoid costly repairs and ensure a pleasant onboard experience. The Raritan PHII Rebuild Kit stands out as a reliable, cost-effective solution for maintaining the Raritan PHII and PHEII marine toilets. This comprehensive guide explores the features, benefits, and detailed steps for using the Raritan PHII Rebuild Kit, empowering boat owners to keep their marine sanitation systems in peak condition.

Understanding the Raritan PHII Rebuild Kit

Who is Raritan?

Raritan Engineering, a trusted name in marine sanitation since 1960, is renowned for producing high-quality, durable marine toilets and accessories. Their PHII and PHEII models are among the most popular manual and electric marine toilets, valued for their reliability and ease of maintenance. The company’s commitment to quality ensures that their products, including the PHII Rebuild Kit, meet the rigorous demands of marine environments.

What is the PHII Rebuild Kit?

The Raritan PHII Rebuild Kit (part number PHRKIIU) is a universal repair kit designed to service all PHII and PHEII marine toilets manufactured since 1960. It replaces older kits like PHRK, PHRKII, and PHRKIIC, offering a comprehensive set of components to restore the toilet’s functionality. Priced at approximately $50, the kit is an economical alternative to replacing the entire toilet ($550) or pump assembly ($230).

Compatibility

The kit is compatible with both manual PHII and electric PHEII models, including variants like the PH Superflush and PH PowerFlush. Its universal design ensures that boat owners with older or newer units can use it to address common wear and tear issues, such as leaks, backflow, or reduced pumping efficiency.

Why Regular Maintenance Matters

Marine toilets operate in harsh conditions, exposed to saltwater, humidity, and constant use. Neglecting maintenance can lead to:

- Clogs and Backflow: Worn components like joker valves or flapper valves can cause waste to flow back into the bowl, creating odors and hygiene issues.

- Leaks: Cracked pump housings or degraded seals can result in water or waste leakage, damaging the boat’s interior.

- Reduced Efficiency: A worn joker valve or piston seal can require excessive pumping to clear the bowl, frustrating users.

- Costly Replacements: Ignoring maintenance can necessitate replacing the entire toilet, which is significantly more expensive than using a rebuild kit.

Regular maintenance with the PHII Rebuild Kit extends the toilet’s lifespan, improves performance, and prevents unexpected failures during voyages. It also minimizes environmental impact by reducing waste from discarded units.

Key Components of the Raritan PHII Rebuild Kit

The PHII Rebuild Kit includes high-quality components made from durable materials like acetal, neoprene, plastic, and nylon. Below is a detailed list of the kit’s contents and their functions:

| Part Number | Description | Quantity | Function |

|---|---|---|---|

| 1201 | Inlet & Outlet Valve Ball | 2 | Controls water and waste flow into and out of the pump. |

| 1202 | Inlet & Outlet Valve Cap Gasket | 2 | Seals the valve caps to prevent leaks. |

| 1203B1 | Inlet Valve Stem O-Ring | 1 | Ensures a tight seal around the valve stem. |

| 1203B2 | Inlet Valve Body O-Ring | 2 | Prevents leaks around the valve body. |

| 1203B3 | Inlet Valve Bottom O-Ring | 1 | Seals the bottom of the inlet valve. |

| 1213A | U-Cup Seal | 1 | Seals the piston rod (pre-1992 models). |

| 1213B | Delrin Washer | 1 | Provides structural support for the piston seal (pre-1992). |

| 1213C | Snap Ring | 1 | Secures the piston seal assembly (pre-1992). |

| 1213D | White Rubber Washer | 1 | Enhances sealing for the piston (pre-1992). |

| 1214 | Piston Shaft Seal Cartridge Assy | 1 | Modern seal for post-1992 pumps, preventing leaks around the piston shaft. |

| 1214A | Piston Shaft Seal Cartridge Assy | 1 | Additional cartridge component for post-1992 models. |

| 1214B | Piston Shaft Seal Cartridge Assy | 1 | Additional cartridge component for post-1992 models. |

| 1226C | PH Plastic Spacer Washer | 4 | Ensures proper spacing and alignment of pump components. |

| 1226CA | Spacer Washer | 1 | Additional washer for alignment. |

| 1228CW | Flapper Valve Assembly | 1 | Prevents backflow from the discharge line into the pump. |

| 1232MS | Piston Multi-Seal O-Ring | 1 | Seals the piston to maintain vacuum and pressure during pumping. |

| 1234 | Bowl Gasket | 1 | Seals the connection between the bowl and pump to prevent leaks. |

| 25103 | Base O-Ring | 1 | Seals the toilet base to prevent leaks. |

| 25105 | Bowl Gasket | 1 | Additional gasket for securing the bowl. |

| C253 | Joker Valve | 1 | Critical component that prevents backflow and maintains pump efficiency. |

| RNI | Nylon Shoulder Washer | 4 | Provides structural support and reduces wear on bolts. |

| SL1CC | Super Lube 1cc Tube | 3 | Lubricates O-rings and seals for smooth operation and longevity. |

Material Quality

The kit’s components are crafted from durable materials:

- Acetal: Used for valve balls and washers, offering high strength and corrosion resistance.

- Neoprene: Used for gaskets and O-rings, providing flexibility and excellent sealing properties.

- Nylon: Used for washers, ensuring durability and resistance to wear.

- Plastic: Used in the pump housing and other components, designed to withstand marine conditions.

These materials ensure the rebuilt toilet can handle the rigors of saltwater and frequent use, with proper maintenance.

Step-by-Step Rebuild Process

Rebuilding a Raritan PHII or PHEII toilet with the rebuild kit is a straightforward but meticulous process. Below is a detailed guide, based on Raritan’s instructions and user experiences:

Tools Required

- Flathead screwdriver (stubby for tight spaces)

- Phillips screwdriver

- Wrench

- Rags and cleaning supplies

- Bucket for waste containment

- Gloves and protective eyewear

Step-by-Step Instructions

1. Preparation:

- Pump out the holding tank completely to avoid spills.

- Close all seacocks to prevent water ingress.

- Disconnect hoses from the toilet, using rags to catch residual water or waste.

- Remove the pump assembly by unscrewing the four 1/4″-20 housing screws (1226).

2. Disassembly:

- Remove the pump handle (1206W) and cotter pins (1210A).

- Unscrew the intake valve cap (1204B) and discharge valve cap (1217).

- Extract the piston rod assembly (1212W) and piston seal components (1213W or 1214W, depending on the model year).

- Remove the flapper valve (1228CW) and joker valve (C253) from the discharge line.

- Inspect all components for wear, cracks, or mineral buildup.

3. Component Replacement:

- Replace the inlet and outlet valve balls (1201) and gaskets (1202).

- Install new O-rings (1203B1, 1203B2, 1203B3) on the inlet valve body.

- For pre-1992 models, replace the U-cup seal (1213A), Delrin washer (1213B), snap ring (1213C), and white rubber washer (1213D). For post-1992 models, install the piston shaft seal cartridge assembly (1214, 1214A, 1214B).

- Replace the piston multi-seal O-ring (1232MS) and bowl gasket (1234).

- Install a new joker valve (C253) with the correct orientation (lips facing the discharge line).

- Replace the flapper valve assembly (1228CW), ensuring the hinge is vertical to prevent backflow.

- Apply Super Lube (SL1CC) to all O-rings and seals to ensure smooth operation.

4. Reassembly:

- Reattach the piston rod assembly and secure it with the handle socket (1210) and cotter pins.

- Reinstall the valve caps and tighten the housing screws with plastic spacer washers (1226C).

- Reconnect hoses and ensure all fittings are secure.

- Test the pump in both wet and dry flush modes to confirm proper operation.

5. Testing and Troubleshooting:

- Check for leaks around the piston shaft and valve caps.

- Ensure the joker valve prevents backflow by observing the discharge line.

- If the pump requires excessive strokes, recheck the joker valve and piston seals for proper installation.

- If leaks persist, verify that all gaskets and O-rings are correctly seated.

Troubleshooting Tips

- Leak at Piston Shaft: Ensure the piston seal cartridge (post-1992) or U-cup seal (pre-1992) is properly installed and lubricated.

- Backflow Issues: Confirm the joker valve is oriented correctly and free of debris.

- Hard Pumping: Lubricate the piston O-ring with Super Lube and check for mineral buildup in the pump housing.

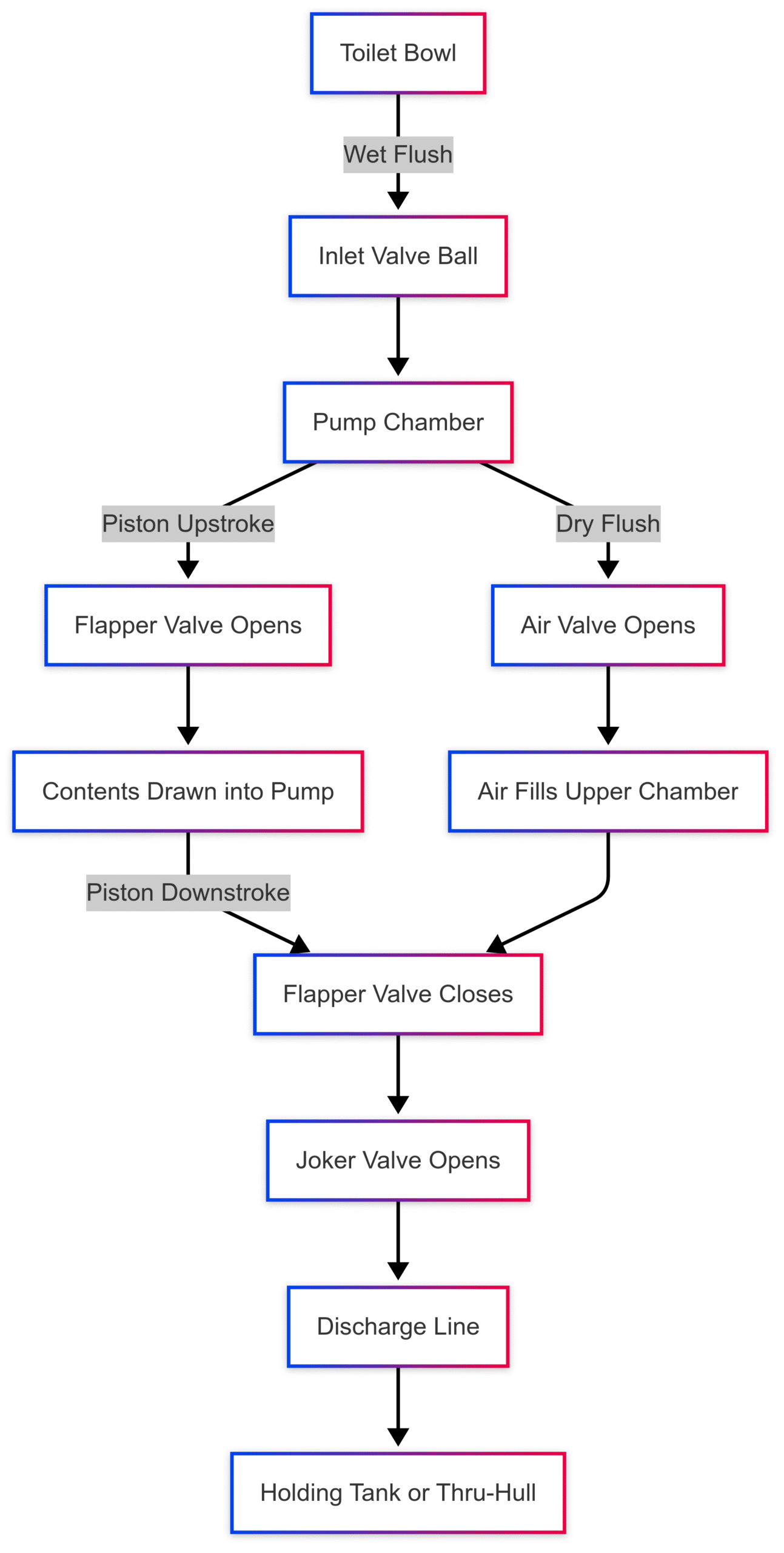

Diagram: Raritan PHII Pump Flow

This diagram illustrates the flow of water and waste through the pump, highlighting the roles of the flapper and joker valves.

Benefits of the Raritan PHII Rebuild Kit

Cost-Effectiveness

At $50, the rebuild kit is significantly cheaper than replacing the entire PHII toilet ($550) or pump assembly ($230). For example, user S. Thompson reported successfully rebuilding a toilet that failed after a lightning strike, saving hundreds of dollars. Even in cases where additional parts were needed, as noted by James Madden, the total cost remained lower than a new unit.

Time-Saving

The rebuild process takes approximately 1-2 hours for a moderately skilled boat owner, compared to the time and effort required to source and install a new toilet. The included Super Lube and detailed instructions streamline the process.

Environmental Benefits

By rebuilding rather than replacing, you reduce waste and the environmental impact of manufacturing and shipping a new toilet. The kit’s durable components ensure long-term reliability, minimizing the need for frequent replacements.

Improved Performance

A rebuilt toilet with new seals, gaskets, and valves operates as efficiently as a new unit. User John K Kudera noted that the kit restored his toilet’s performance with no issues, while captn bob fixed backflow problems in a 25-year-old unit.

Customer Reviews and Testimonials

The Raritan PHII Rebuild Kit has a 4.2 out of 5-star rating based on 23 reviews on Amazon. Below are key insights from user feedback:

- S. Thompson (5 stars): “This kit provided all the parts needed to rebuild the head with confidence. The diagrams resolved any questions I had.”

- John K Kudera (5 stars): “A very good value, fit my unit with no problems. Will buy again.”

- captn bob (5 stars): “Perfect for fixing a 25-year-old head that had some backflow.”

- Brian D. (5 stars): “As advertised, perfect.”

- James Madden (3 stars): “Not all parts were included, requiring additional purchases costing $14.”

- tommy (1 star): “Missing the joker valve and two tubes of grease.”

While most users praise the kit’s comprehensive components and ease of use, some reported missing parts, suggesting variability in kit packaging. Raritan’s customer service is noted for addressing such issues promptly.

Addressing Common Concerns

- Missing Parts: Users like James Madden and tommy reported missing components. Always verify the kit’s contents against the included list and contact Raritan or the retailer for replacements.

- Longevity: Skipper’s review highlighted cracking in the pump housing and base after 10 years of heavy use. Experts like Peggie Hall suggest that proper lubrication and annual joker valve replacement can prevent such issues.

- Pumping Force: Hayden Watson and Ralph Johnstone emphasized gentle pumping to avoid stressing components, which may explain Skipper’s experience with cracks.

Maintenance Tips for Longevity

To maximize the lifespan of your Raritan PHII or PHEII toilet:

- Lubricate Regularly: Apply Super Lube or mineral oil to the piston O-ring every few weeks, ideally via the freshwater flush line.

- Replace Joker Valve Annually: As Peggie Hall explains in her “Joker Valve 101,” a worn joker valve reduces pump efficiency, requiring more strokes.

- Use Freshwater Flushing: Flushing with freshwater from the sink, as described by Ralph Johnstone, minimizes mineral buildup.

- Pump Gently: Avoid aggressive pumping to prevent stress on the pump housing and piston.

- Clean with Mild Agents: Use citric-based cleaners or bio-enzymatic products like Raritan’s 1PCP22 to maintain the porcelain bowl without damaging components.

Conclusion

The Raritan PHII Rebuild Kit is an essential tool for boat owners seeking to maintain their marine sanitation systems efficiently and economically. With its comprehensive set of high-quality components, including gaskets, O-rings, valves, and Super Lube, the kit restores the PHII and PHEII toilets to like-new performance. The step-by-step rebuild process, supported by Raritan’s instructions and user feedback, makes it accessible even for those with moderate DIY skills. By investing in the $50 kit, you save hundreds compared to replacing the toilet or pump, reduce environmental waste, and ensure a hygienic onboard experience.

Boat owners should prioritize regular maintenance, including annual joker valve replacements and consistent lubrication, to extend the toilet’s lifespan beyond the 25 years Raritan claims. Despite occasional reports of missing parts, the kit’s 4.2-star rating reflects its reliability and value. Whether you’re preparing for a weekend cruise or a long-term voyage, the Raritan PHII Rebuild Kit offers peace of mind and dependable performance. Always follow Raritan’s guidelines for installation and maintenance to achieve the best results.

Happy Boating!

Share Raritan PHEII Electric Marine Toilet PHII and PHEII Repair Kit with your friends and leave a comment below with your thoughts.

Read Anyone familiar with the ProMariner ProNautic 1240P? until we meet in the next article.