Learn how to winterize a 2-stroke, oil-injected outboard motor like a Mercury 50hp with this step-by-step guide. Protect your engine effectively.

Winterizing a 2-stroke, oil-injected outboard motor, such as a Mercury 50hp from 1998, is a critical maintenance task to ensure your engine remains in top condition during the off-season. Proper winterization prevents corrosion, fuel degradation, and mechanical issues, saving you costly repairs when spring arrives. This guide provides a detailed, step-by-step process tailored for 2-stroke, oil-injected outboards, addressing common concerns and incorporating expert advice for optimal results.

Why Winterize Your 2-Stroke Outboard?

Winterizing protects your outboard motor from damage caused by cold temperatures, moisture, and prolonged inactivity. For a 2-stroke, oil-injected engine, the oil reservoir and fuel system require special attention to prevent corrosion and ensure smooth operation in the next season. Skipping this process, even for garage-stored boats, risks issues like seized pistons, clogged carburetors, or damaged lower unit seals, especially in older models like the 1998 Mercury 50hp.

Step-by-Step Winterization Process

Step 1: Preparation and Cleaning

Before winterizing, prepare your boat and gather necessary supplies. Cleaning the engine removes salt, dirt, and debris that could cause corrosion.

- Rinse the Boat and Engine: Remove the boat from the water and rinse the outboard thoroughly with fresh water to eliminate salt and grime.

- Secure the Engine: If possible, remove the outboard and secure it to a stable stand or leave it lowered on the boat to drain water.

- Gather Supplies:

- Fuel stabilizer (e.g., STA-BIL Marine, ~$10 for 16 oz)

- Fogging oil (e.g., Mercury Precision Parts Fogging Oil, ~$12 for 12 oz)

- Gear oil (e.g., Mercury High-Performance Gear Lube, ~$15 per quart)

- Water pump repair kit (if needed, ~$50-$100 depending on model)

- Antifreeze (marine-grade, non-toxic, ~$20 per gallon)

- Basic tools (screwdrivers, wrenches, bilge pump, etc.)

Step 2: Fuel System Stabilization

The fuel system is the heart of a 2-stroke outboard, and unstabilized fuel can degrade, clogging carburetors or causing corrosion.

- Fill the Fuel Tank: Top off the inboard fuel tank to minimize air space and prevent condensation, which can introduce water into the fuel.

- Add Fuel Stabilizer: Add a marine-grade fuel stabilizer per the manufacturer’s instructions (typically 1 oz per gallon of fuel). For a Mercury 50hp, a 10-gallon tank requires about 10 oz of stabilizer.

- Run the Engine: Start the engine and run it for 5-10 minutes to circulate stabilized fuel through the fuel lines and carburetors. If your boat has a fuel/water separator, consider adding a small amount of 2-stroke oil to it for extra lubrication, as suggested by some experts.

For oil-injected 2-strokes, the oil reservoir does not need annual draining unless contaminated. Check the oil for water or milky appearance, indicating a seal issue. If clean, top off with manufacturer-recommended 2-stroke oil (e.g., Mercury Premium Plus TC-W3, ~$30 per gallon).

Step 3: Engine Lubrication with Fogging Oil

Fogging oil coats internal engine components to prevent corrosion during storage.

- Access the Carburetors: For a Mercury 50hp with three carburetors, locate the air intake (often under a black cover). You don’t need to remove the cover; spray fogging oil directly into the intake.

- Spray Fogging Oil: With the engine running, spray fogging oil into each carburetor intake one at a time until the engine sputters and stalls, producing white smoke from the exhaust. This indicates the oil has coated the cylinders.

- Alternative Method: If you prefer, remove the spark plugs and spray fogging oil directly into each cylinder while cranking the engine briefly (with fuel disconnected). Reinstall the plugs afterward.

Step 4: Cooling System Maintenance

The cooling system must be free of water to prevent freezing damage.

- Drain the System: Lower the outboard fully to drain water from the cooling system. If possible, remove the lower unit to ensure complete drainage.

- Flush with Antifreeze: Using a bilge pump and muffs, run 3-4 gallons of marine-grade, non-toxic antifreeze through the cooling system. Disconnect the fuel line near the end to run the carburetors dry, preventing fuel residue from clogging jets.

- Reassemble: Reattach the lower unit and tighten bolts to the manufacturer’s torque specifications (consult the owner’s manual, available at Mercury Marine’s website).

Step 5: Gearcase Maintenance

The lower unit gearcase requires fresh oil to prevent corrosion and ensure smooth operation.

- Drain Old Gear Oil: Remove the lower unit drain plug and drain the oil into a container. Inspect for milky or gray oil, indicating water contamination and potential seal damage. If contaminated, schedule a seal replacement.

- Refill with Gear Oil: Use a pump to fill the gearcase with high-quality gear oil (e.g., Mercury High-Performance Gear Lube) from the bottom plug until it flows from the top plug. Replace both plugs and tighten to specifications.

- Check Annually: Even if stored in a garage, always replace gear oil annually to prevent water-related damage.

Step 6: Water Pump Inspection

The water pump ensures proper cooling and must be inspected for winter storage.

- Remove the Cover: Access the water pump cover and inspect the impeller and gaskets for wear or cracks.

- Replace if Needed: If damaged, use a water pump repair kit specific to your Mercury 50hp (check serial number 8M0110565 for compatibility).

- Reassemble: Replace the cover and tighten bolts to the manufacturer’s specifications.

Step 7: Battery and Final Checks

- Battery Storage: Disconnect the battery’s negative terminal or remove it entirely. Store it indoors on a wooden surface and charge monthly with a maintenance charger (~$30-$50) to prevent freezing or discharge.

- Protect the Engine: Spray the engine exterior with a light corrosion-resistant oil (e.g., CRC 6-66, ~$10) and replace the cowling.

- Lower the Engine: Store the outboard in the fully lowered position to prevent water accumulation.

Should You Skip Winterization?

Some boaters in milder climates or with garage storage consider skipping winterization to save costs (professional winterization: $100-$200). However, even in a garage, temperature fluctuations can cause condensation in the fuel tank or gearcase, leading to corrosion. For a 1998 Mercury 50hp, skipping winterization risks carburetor clogs, seized pistons, or lower unit damage, costing $500-$2,000 in repairs. Running marine stabilizer and storing the battery indoors can reduce risks, but full winterization is recommended for long-term reliability.

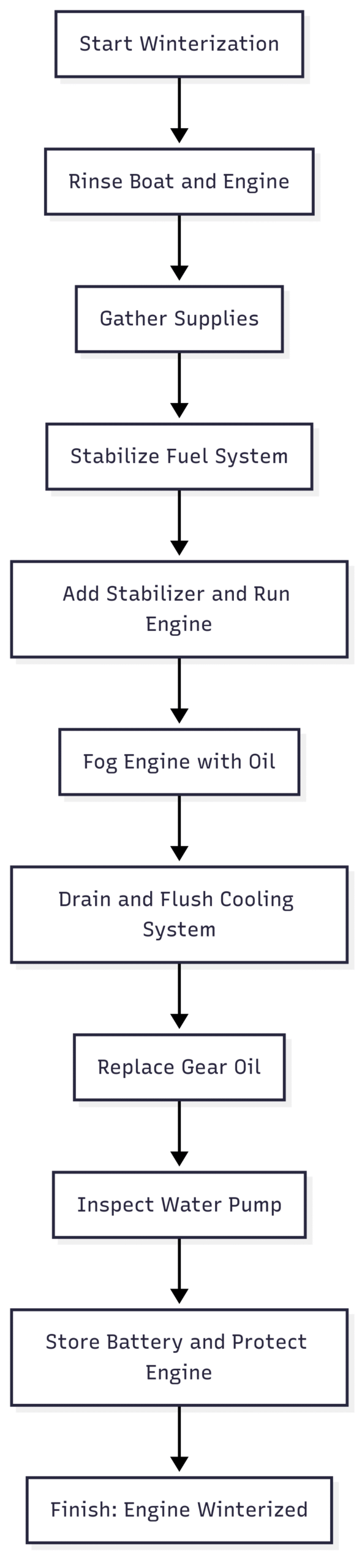

Maintenance Workflow (Chart)

Recommended Products and Prices

| Item | Brand/Product | Approx. Price | Where to Buy |

|---|---|---|---|

| Fuel Stabilizer | STA-BIL Marine | $10 (16 oz) | Amazon, West Marine |

| Fogging Oil | Mercury Precision Fogging Oil | $12 (12 oz) | Mercury Marine Dealers |

| Gear Oil | Mercury High-Performance Gear Lube | $15 (quart) | West Marine, eBay |

| 2-Stroke Oil | Mercury Premium Plus TC-W3 | $30 (gallon) | Mercury Marine Dealers |

| Antifreeze | Star brite Non-Toxic Antifreeze | $20 (gallon) | Amazon, Walmart |

| Water Pump Kit | Sierra Water Pump Kit for Mercury 50hp | $50-$100 | iBoats, Amazon |

Tips for Success

- Consult the Manual: For a 1998 Mercury 50hp (serial 8M0110565), download the owner’s manual from Mercury Marine’s website for exact specifications.

- Work Safely: Disconnect the fuel line and spark plugs before spraying fogging oil to avoid accidental starts.

- Check Regularly: Even during storage, inspect the oil reservoir and gearcase monthly for leaks or contamination.

- Spring Prep: In spring, run Seafoam or similar fuel additive through the first tank to clean residual deposits.

Conclusion

Winterizing a 2-stroke, oil-injected outboard like the Mercury 50hp is straightforward with the right steps and materials. By stabilizing the fuel, fogging the engine, maintaining the cooling system and gearcase, and storing the battery properly, you ensure your motor’s longevity and reliability. Investing $50-$100 in supplies and a few hours of work can save thousands in repairs, making winterization a worthwhile task for any boat owner.

Happy Boating!

Share Winterizing a 2 stroke, oil injected outboard? with your friends and leave a comment below with your thoughts.

Read Tugboat Pictures Clip Art 4K HD Wallpapers until we meet in the next article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.